Checklist

The checklist below will assist you in preparing your location for the installation of your equipment. Please make

sure that everything is prepared to these requirements prior to scheduling your installation. See the ILLUSTRATED

PART S section for a list of available installation accessories.

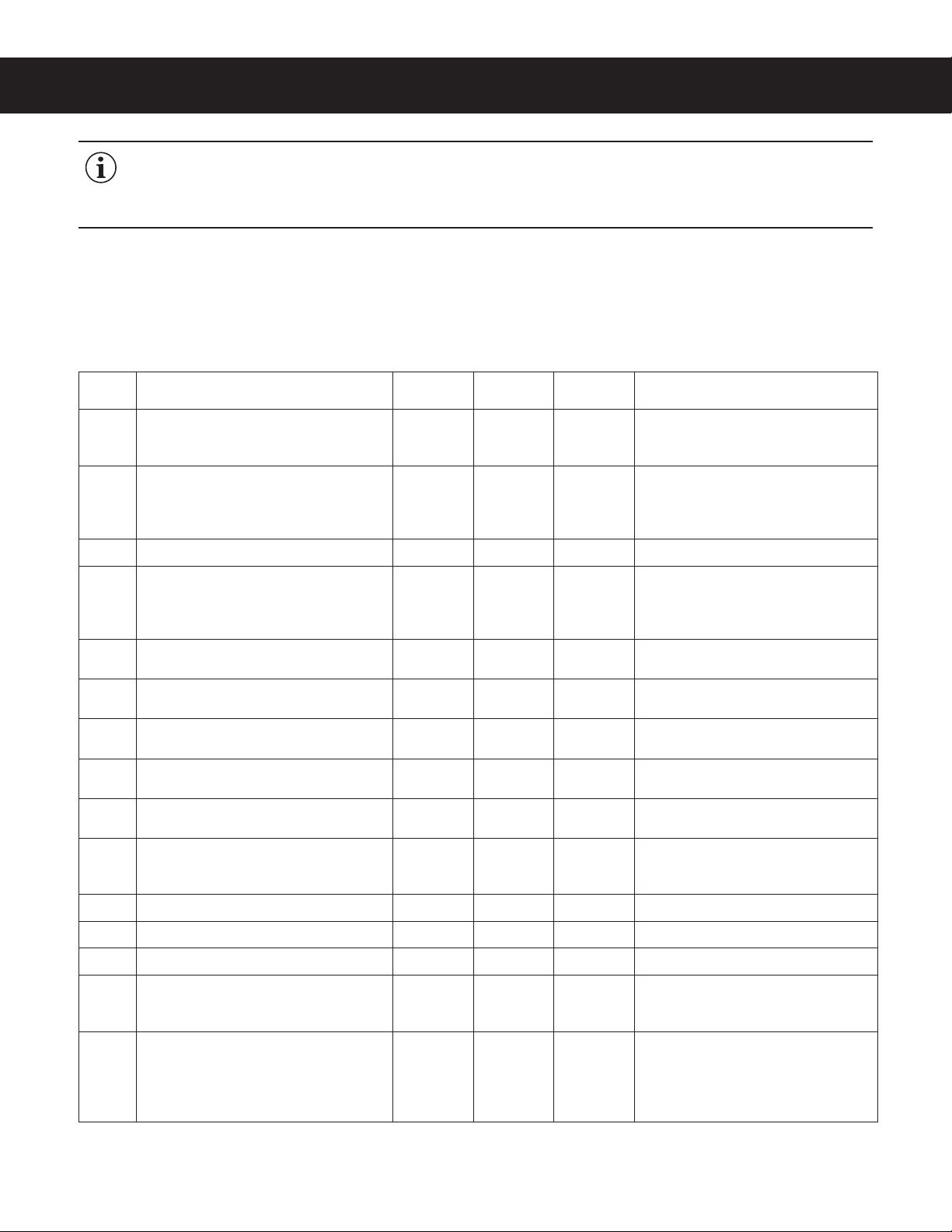

REQUIRED SYSTEM COMPONENTS

DESCRIPTION NIB1

QTY/TYPE

NIB2

QTY/TYPE

NIB3

QTY/TYPE COMMENTS

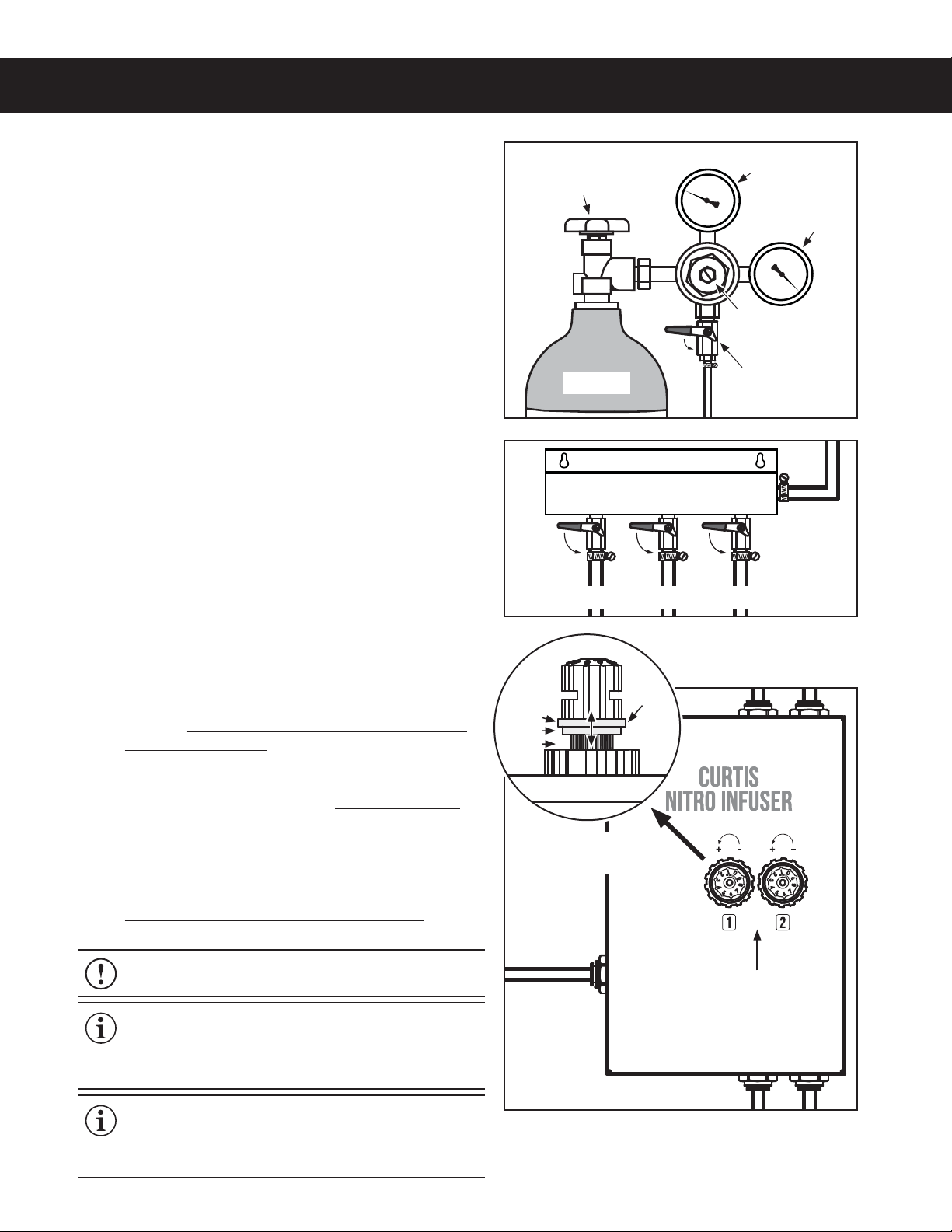

A food grade nitrogen (N2) supply with a

nitrogen regulator set to 30 - 50 psi

(207 - 345 kPa)

111

A kegerator or under counter refrigerator

with approximately 4.75”(H) x 6.42”(W) x

10.02”(D) of free space on one of the sides,

inside, for installation of the NIB

111

Allow room for plastic beverage and

N2 lines (allow for bend angles) and

mounting bracket (if used) around

mounting location.

Product keg(s)* 1 2 3 Sanke or Cornelius (Corny)

Keg connector(s) 1 Sanke or

2 Corny

2 Sanke or

4 Corny

3 Sanke or

6 Corny

Sanke kegs require 1 D style coupler per

keg. Corny kegs require 1 liquid ball lock

connector and 1 gas ball lock connector

per keg.

Dedicated tap(s) with a nitro stout faucet

installed 123

Tees or manifold for N2 supply lines. One

supply line required for NIB and each keg.**

1 tee or

1:2 manifold

2 tees or

1:3 manifold

3 tees or

1:4 manifold

A manifold allows for greater system

control (independent shut off of keg N2).

3/8” beverage line (food grade) - - From nitrogen regulator to gas

distribution tees or manifold

3/8” beverage line (food grade) 1 x 3 feet

minimum

1 x 3 feet

minimum

1 x 3 feet

minimum

From gas distribution tees or manifold

to NIB

3/8” beverage line (food grade) 1 x 3 feet

minimum

2 x 3 feet

minimum

3 x 3 feet

minimum

From gas distribution tees or manifold to

kegs

1/4” beverage line (food grade)* 1 x 3 feet

minimum

2 x 3 feet

minimum

3 x 3 feet

minimum

From taps to inside of kegerator with

a minimum of 3’ of line running from

kegerator ceiling

John Guest 3/8” barb(s) 1 2 3

John Guest 1/4” barbs 2 4 6

Hose Clamps 7 14 21 Oetiker type recommended

0HVKÀOWHUVWUDLQHUIRRGJUDGH 123

Optional, recommended. Installed on

each beverage supply line between keg

and NIB.

3/8” John Guest type plug - - -

Unused input(s) and output(s) on NIB

should be plugged when not in use. This

allows for the purchase of larger capacity

NIB than needed to allow for future

expansion.

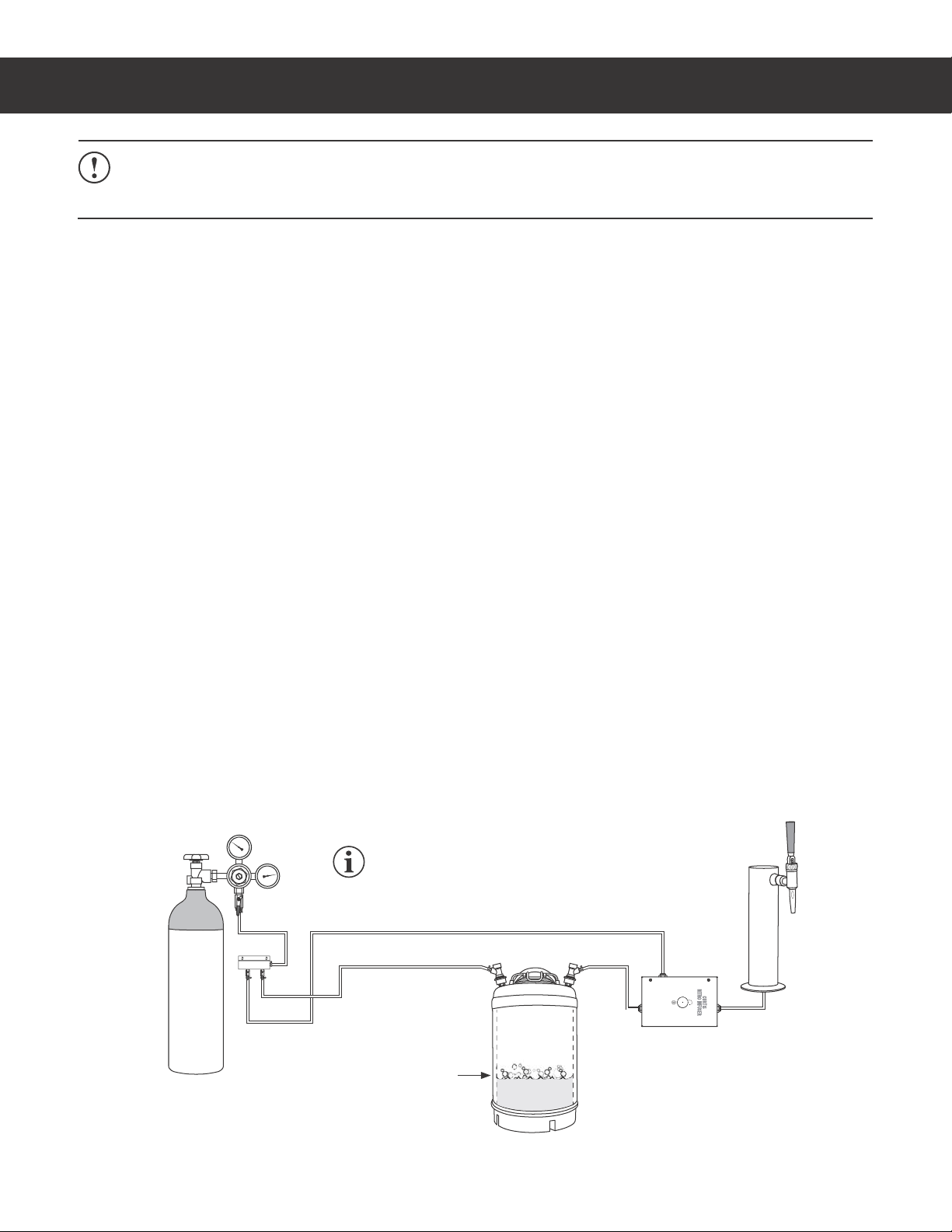

*7KH1,%WKHNHJVEHYHUDJHVXSSO\OLQHVDQGÀOWHUVLIDSSOLFDEOHPXVWEHLQVWDOOHGLQVLGHWKHNHJHUDWRUUHIULJHUDWRU

The kegerator/refrigerator must be set between 36°F/2°C to 40°F/4°C to avoid spoilage.

** Add additional tees/manifold ports for any standard cold brew kegs/faucets attached to the system that do not utilize ports on the NIB.

PRE-INSTALLATION CHECKLIST PC1

NIB, PRE-INSTALLATION CHECKLIST 041119A

IMPORTANT: The Curtis Nitrogen Infusion Box is designed for locations with an existing draft system. If

the NIB will be a component of a new draft system installation, please consult with your draft technician for

integration of the NIB into your new draft system. See the INSTALLATION INSTRUCTIONS section for a

typical system layout.