2

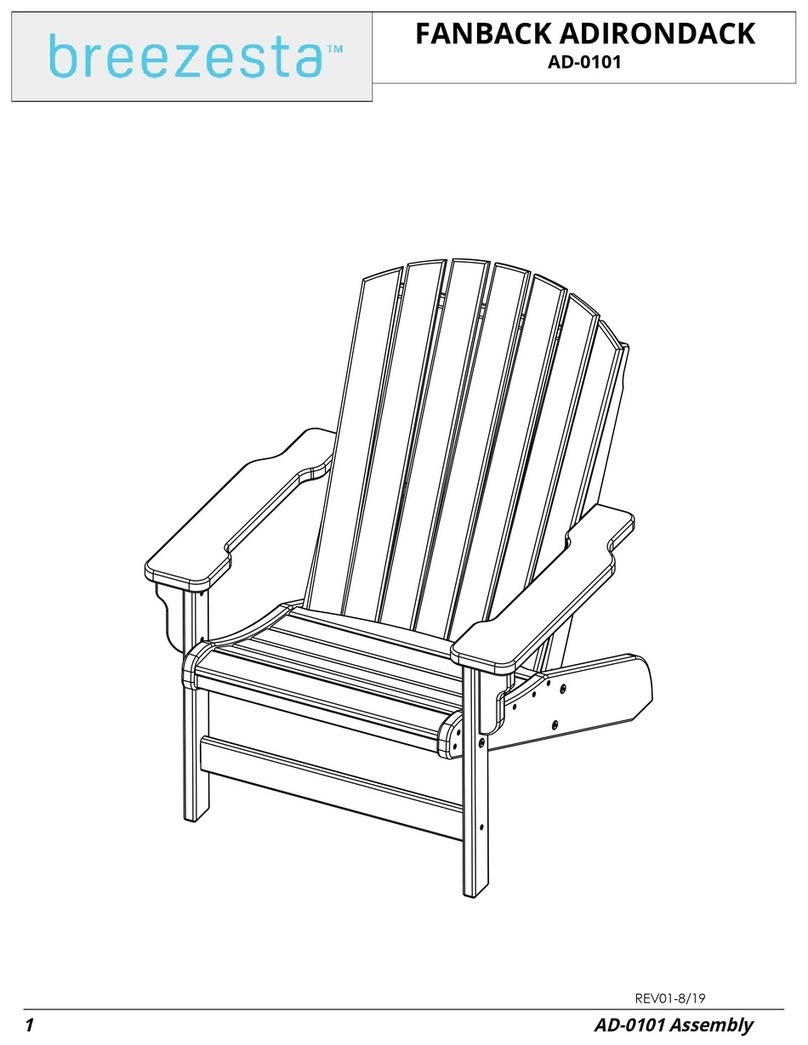

Part List

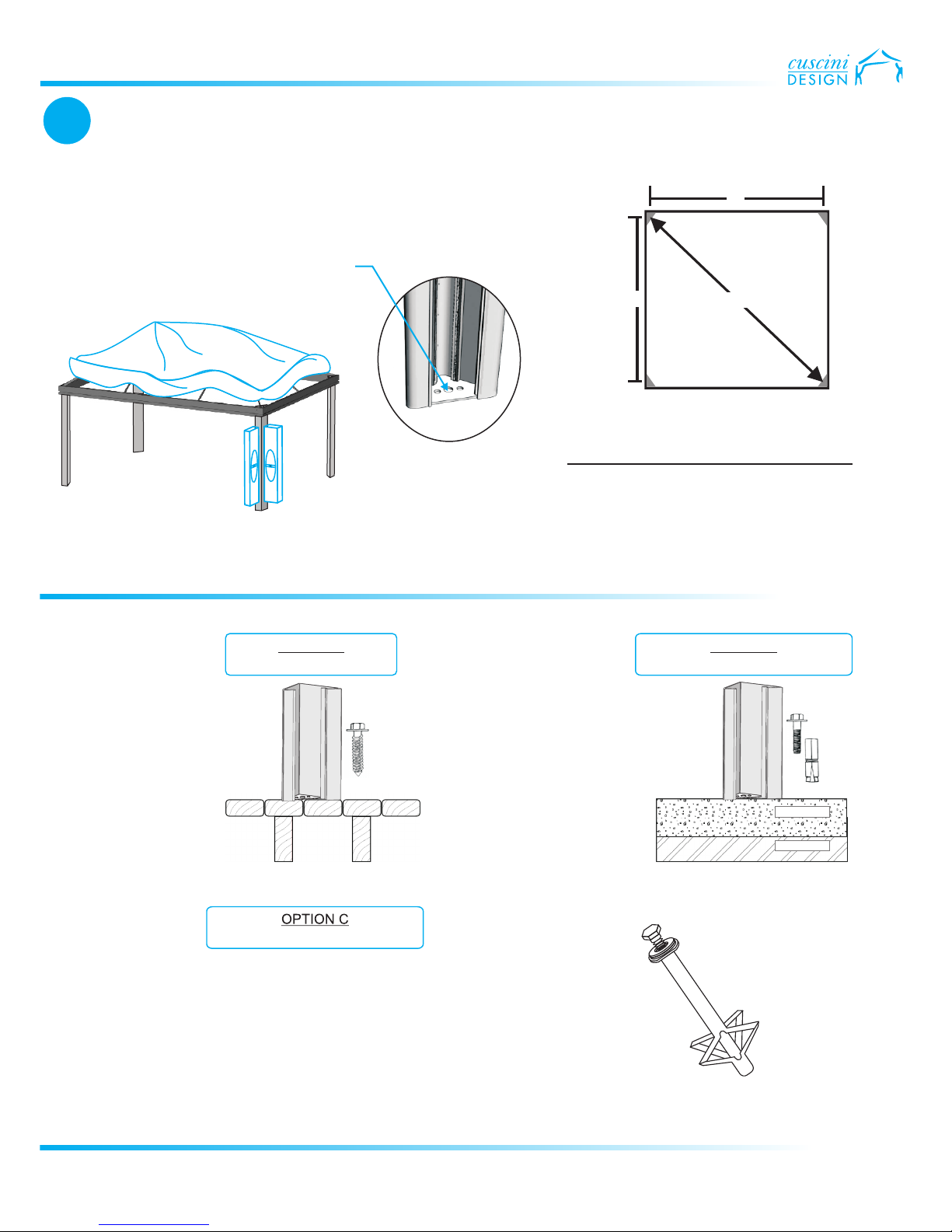

Metal Screw #8-3/4”

Metal Screw #8-1”

Plastic Corner Beam Inserts

Cover Screw - 1/4” x 1-3/4”

Corner Post Top Cover

KC01

Post End Plate

Plate Screw 1/4” x 1-3/4”

16x 002

KC09

KC06

Carriage Bolt - 5/16” x 2”

5/16” x 1-1/2" Flat Washer

16x 003

16x 007

16x 012

4x PL014

8x 002

5/16” Nylon Lock Nut

KC04

4x PL102

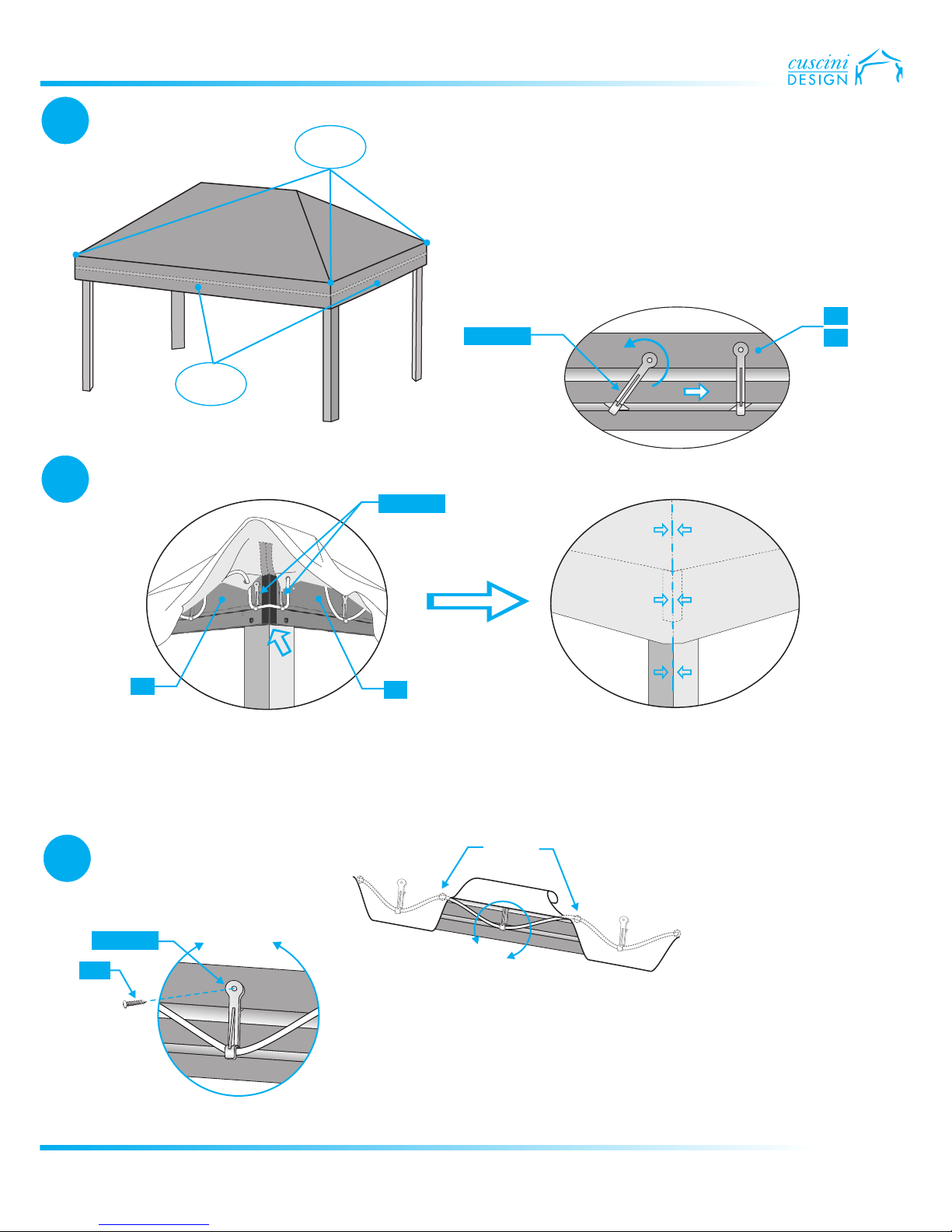

Roof Cover

Hook

#8 Square Head Screwdriver Bit*

#10 Square Head Screwdriver Bit*

* Provided for European countries only

Pulleys included

with curtains

Velcro Strips (shipped with decorative curtains)

8x 025

8x 013

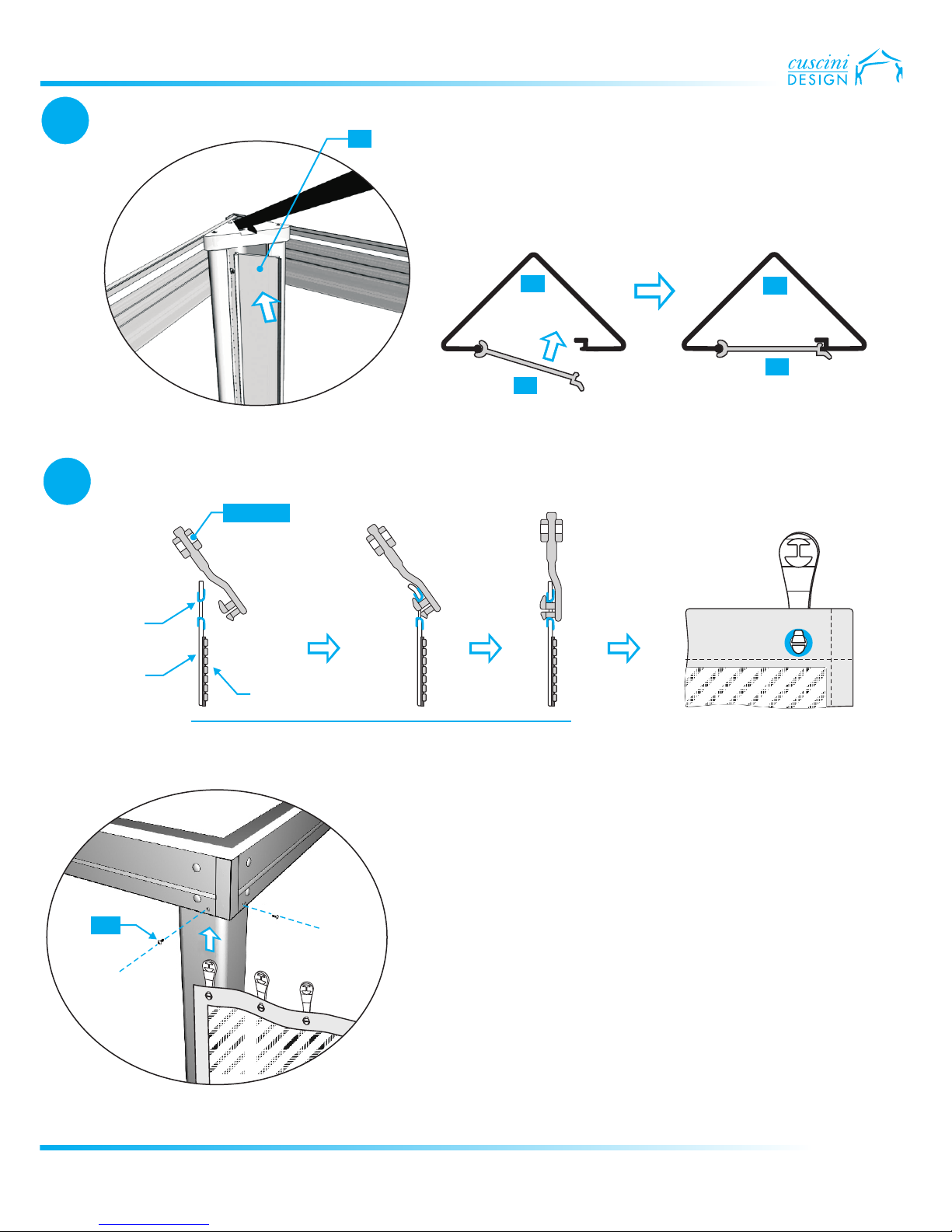

Joint Cover Screw #7-3/4”

Joint Cover Screw #7-3/4”

Roof Joint

Box (2 pieces)

Roof Joint

Box (2 pieces)

Bottom

Bottom

Top

Top

Self-tapping Screw #8-3/4”

Self-tapping Screw #8-3/4”

6x 040

4x 040

KC10

16x 062

8x 062

2x PL104

1x PL105

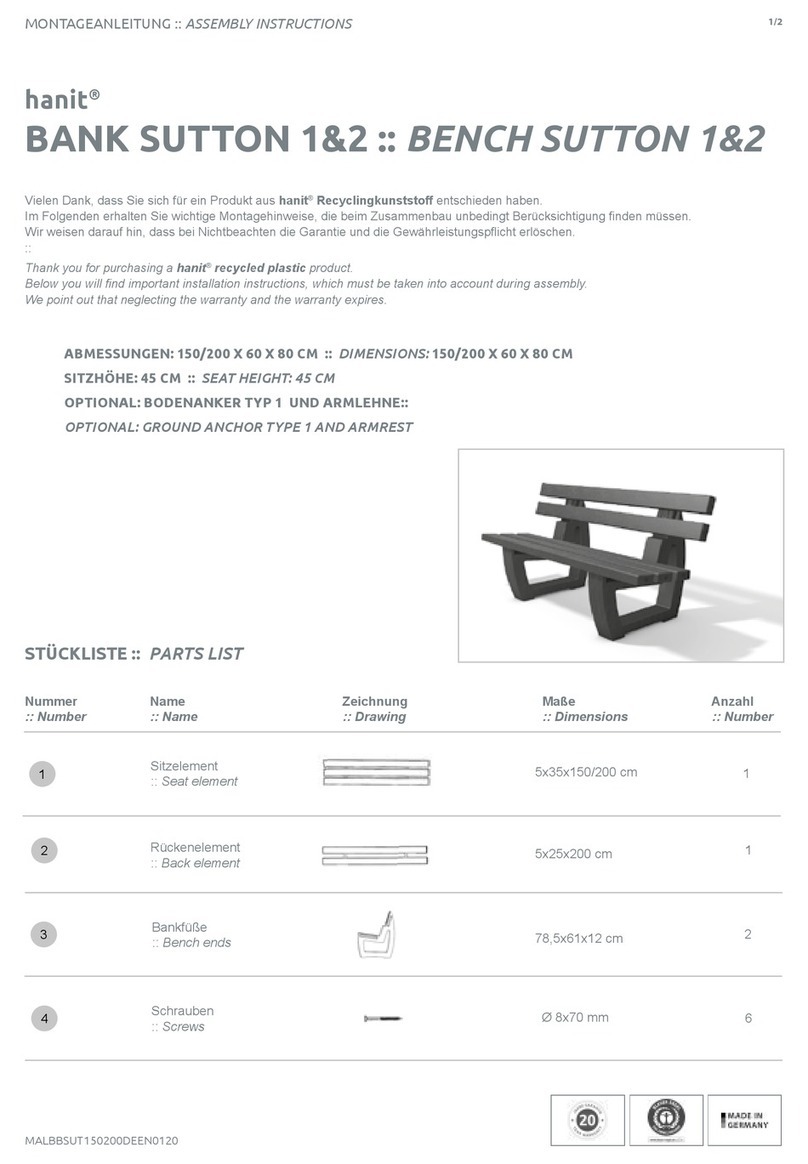

Supplied with rectangular models

KC21 Supplied with square models

12’ or 14’ Side Beam

10’ Side Beam

10’ Side Beam

Triangular Corner Post

Corner Post Cover

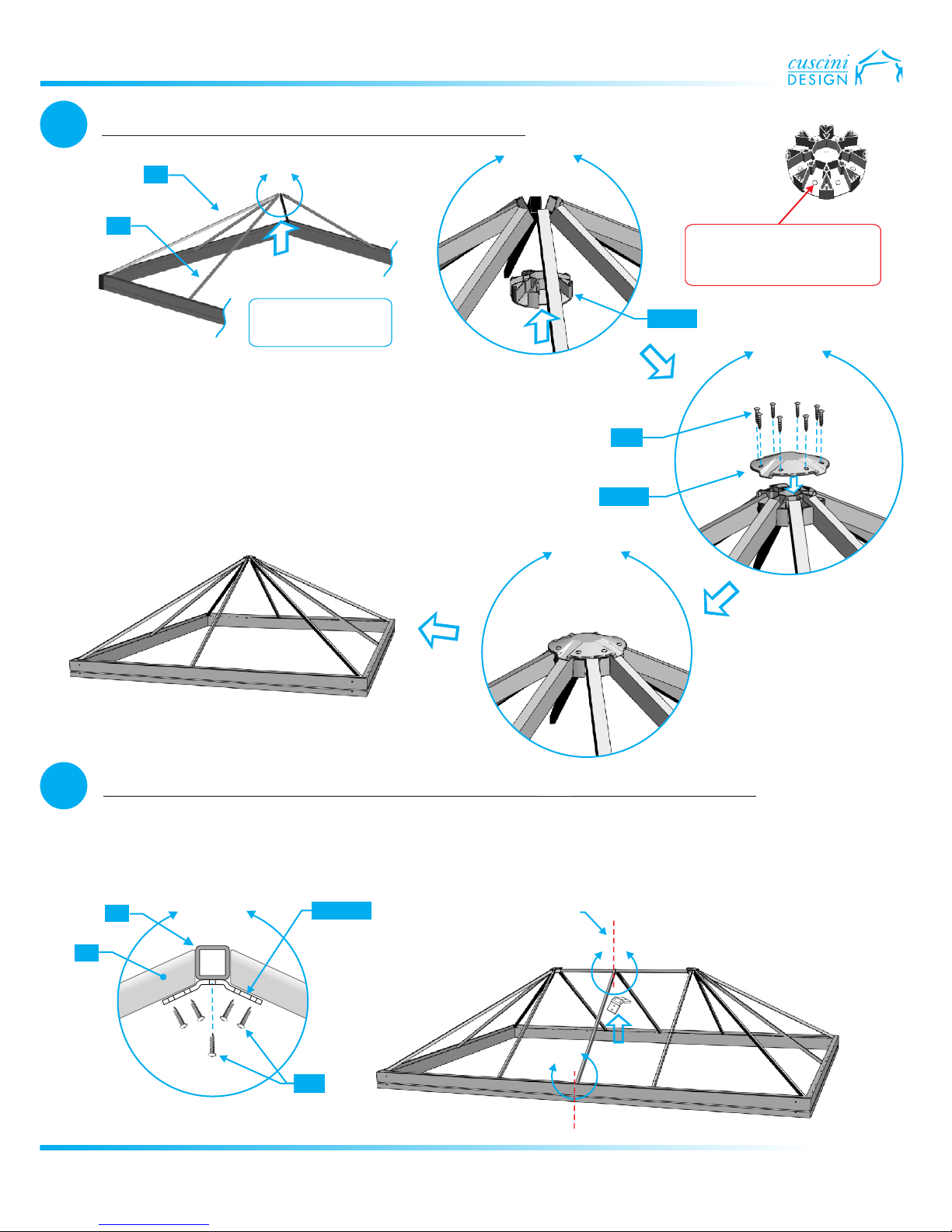

2x B1

2x B2

4x B2

4x P1

4x P2

6x S1

4x S1

4x S2

4x S2

1x S3

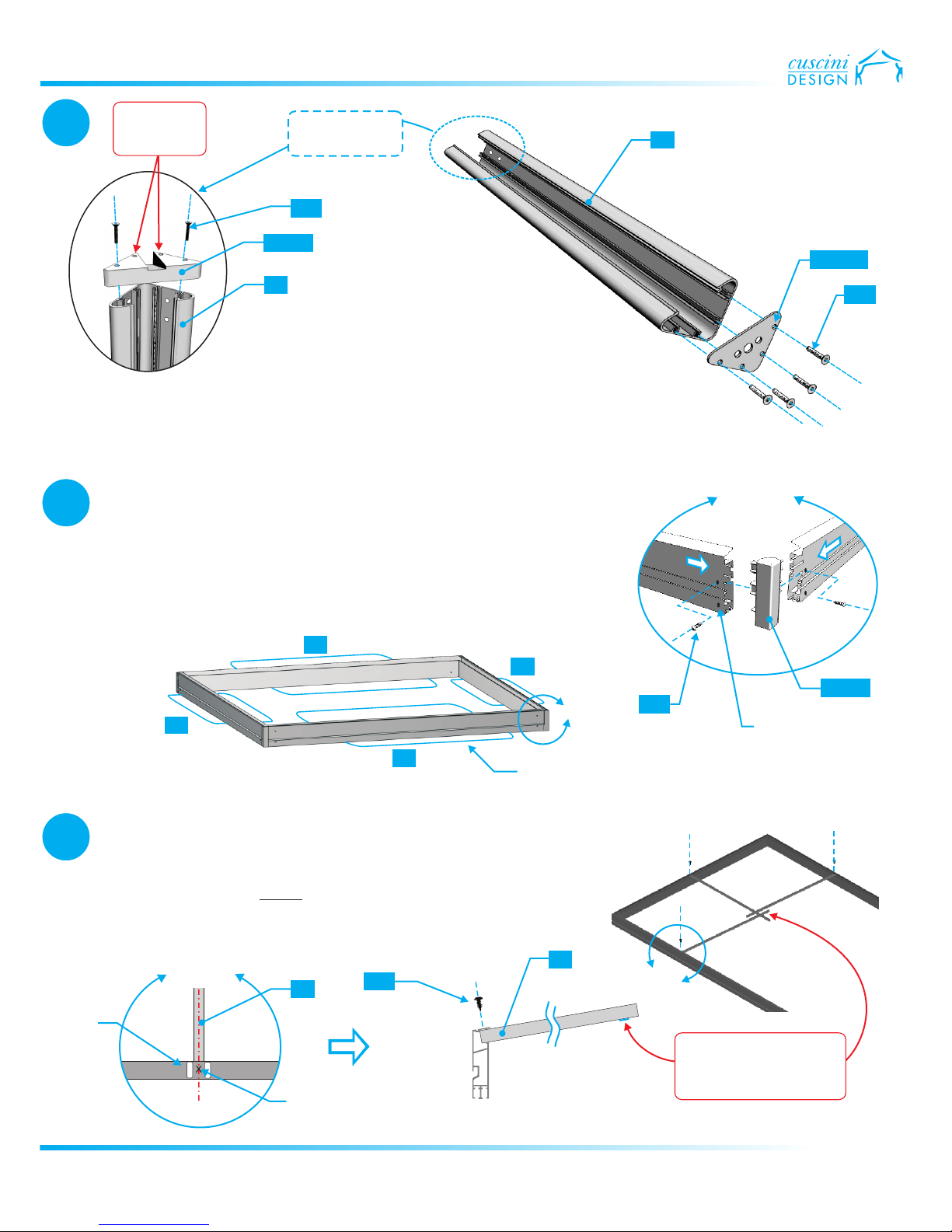

Roof Corner Spoke (punched hole at one end)

Roof Corner Spoke (punched hole at one end)

Roof Side Spoke (punched hole at one end)

Roof Side Spoke (punched hole at one end)

Roof Middle Support Spoke (both ends with punched holes)

Supplied with rectangular models

Supplied with square models

Mid Roof Support

2x S4

Mid Roof

Support Bracket

Self-tapping Screw #8-3/4”

Self-tapping Screw #8-1”

KCLA3003

Supplied with extended models

6x 040

4x 072

LA3003

1x

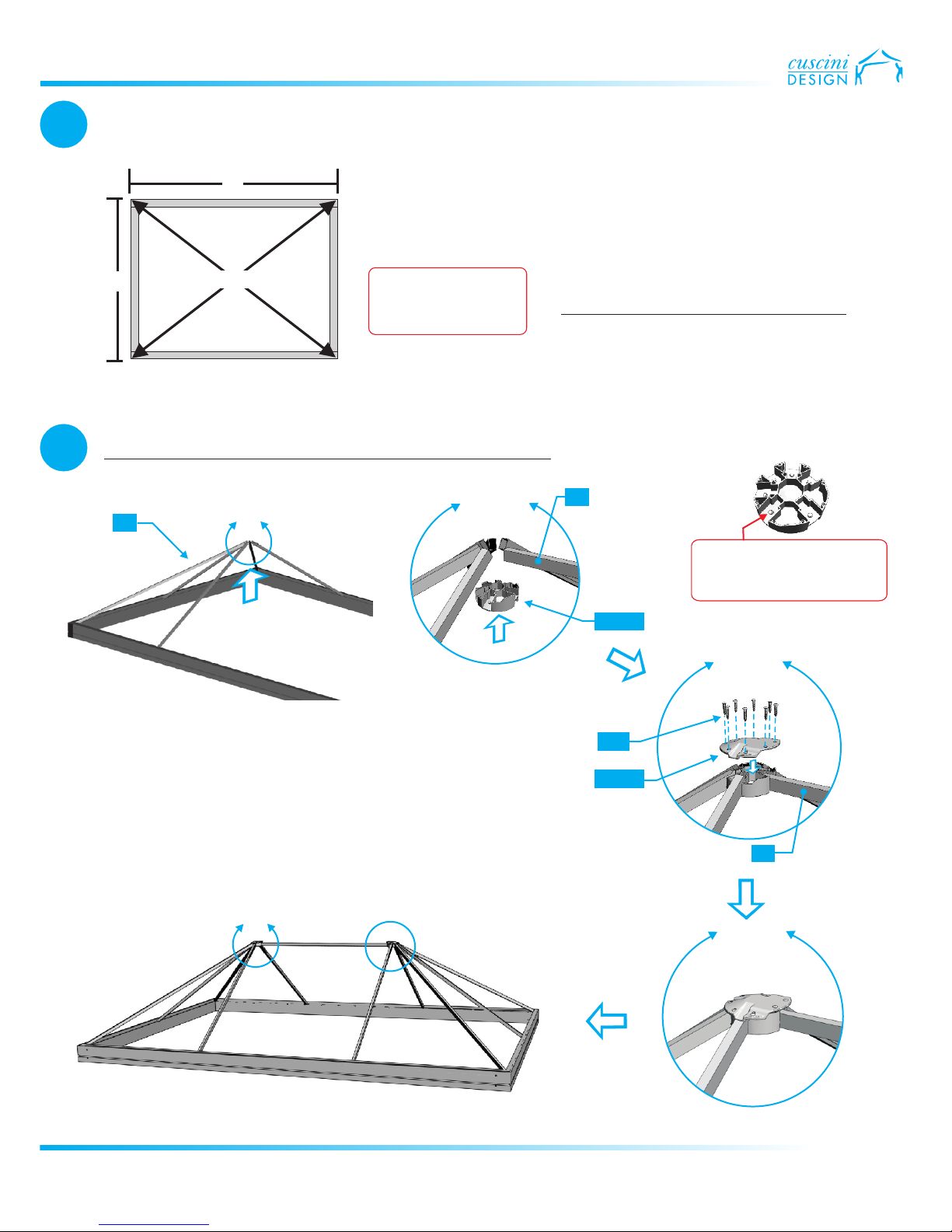

DIVERS

4x 005 9/32” x 5 Flat Washer/8”

K.PL101

K.APL001

K.PL106

4x LA3002

Self-taping Screw #8-3/4”

040

of 10

www.cuscini-design.com