E-mail : cutex@chollian.net http://www.taewoocutex.com

- 9 -

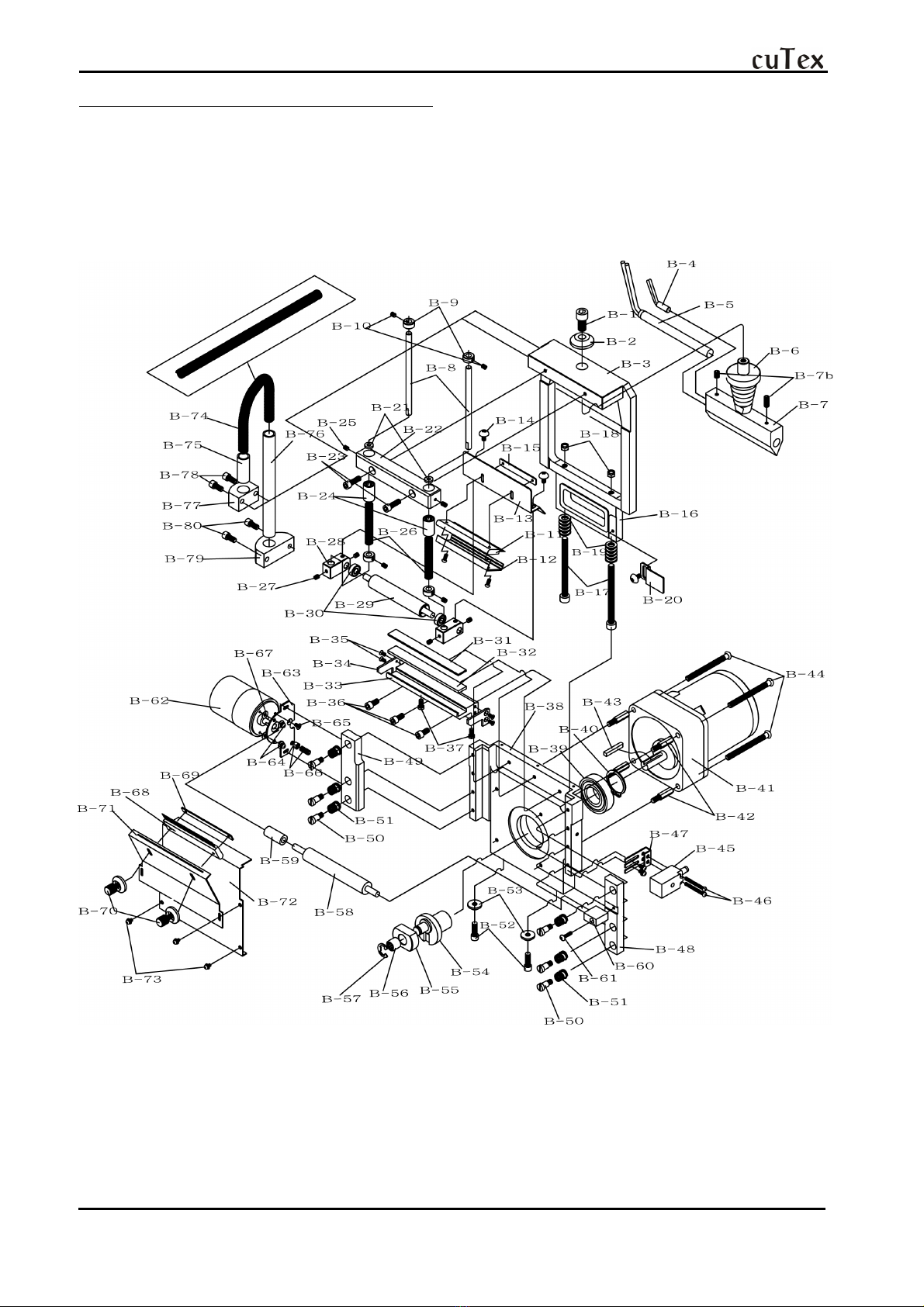

Part List B of TBC-50H (Cutting part)

Part No. Description Part No. Description

B-1 Clamping Bolt(M8×15L) B-38 Lower Knife Case

B-2

Neck Washer of Hot-knife Bracket

B-39 Ball Bearing(#6004)

B-3 Upper Knife Case B-40 Snap Ring

B-4 Heat Sensor B-41 Motor+Reduction Gear

B-5 Heater B-42 Motor Supporter

B-6 Hot-Knife Bracket B-43 Motor Key

B-7 Hot-Knife B-44 Clamping Bolt(M5×42L)

B-7b Detent Screw(M5×5L) B-45 Counting Sensor

B-8 Vertical Axle B-46 Clamping Bolt(M3×18L)

B-9 Shaft Ring B-47 Clamping Bracket

B-10 Detent Screw(M4×4L) B-48 Right Pressure Plate

B-11 Pressing Plate Cover B-49 Left Pressure Plate

B-12 Clamping Bolt(M4×6L) B-50 Clamping Bolt of Pressure Plate

B-13 Front Cover B-51 Pressure Spring

B-14 Clamping Bolt(M3×5L) B-52 Wrench Bolt(M5×15L)

B-15 Slide Ram B-53 Neck Washer

B-16 Clamping Bolt(M6×80L) B-54 Crank Bundle

B-17 Check Nut(M6) B-55 Cam

B-18 Flat-head Washer Spring B-56 Niddle Bearing

B-19 Counting-sensor Bracket B-57 E-Ring

B-20 Shaft Rubber-bushing B-58 Front Feeding Roller

B-21 LM Guide B-59 Front Feeding Sub-roller

B-22 Wrench Bolt(M5×20L) B-60 Roller Shaft Bracket

B-23 LM Bearing B-61 Clamping Bolt(M3×12L)

B-24 Detent Screw(M4×6L) B-62 DC Motor

B-25 Verical Axle Ring B-63 DC Motor Bracket

B-26 Detent Screw(M4×6L) B-64 Clamping Bolt(M3×4L)

B-27 Roller-clamping Bracket B-65 Flat-head Bolt(M3×4L)

B-28 Pressing Roller B-66 Vertical Control Nut

B-29 Roller Shaft B-67 Flat Washer

B-30 Ball Bearing(#686) B-68 Heater Wiring Spring

B-31 Heating Plate B-69 Heater Wiring Pipe(1)

B-32 Silicon Plate B-70 Heater Wiring Pipe(2)

B-33 Heating Plate Bracket B-71 Upper Pipe Bracket

B-34 Bracket Side Cover B-72 Wrench Bolt(M4×15L)

B-35 Flat-head Bolt(M3×8L) B-73 Lower Pipe Bracket

B-36 Wrench Bolt(M5×15L) B-74 Wrench Bolt(M4×15L)

B-37 Hexagon-head Bolt(M4×8L)