ROBOT . HEAD to TOE

Product User’s Manual – MDDS10

1. INTRODUCTION

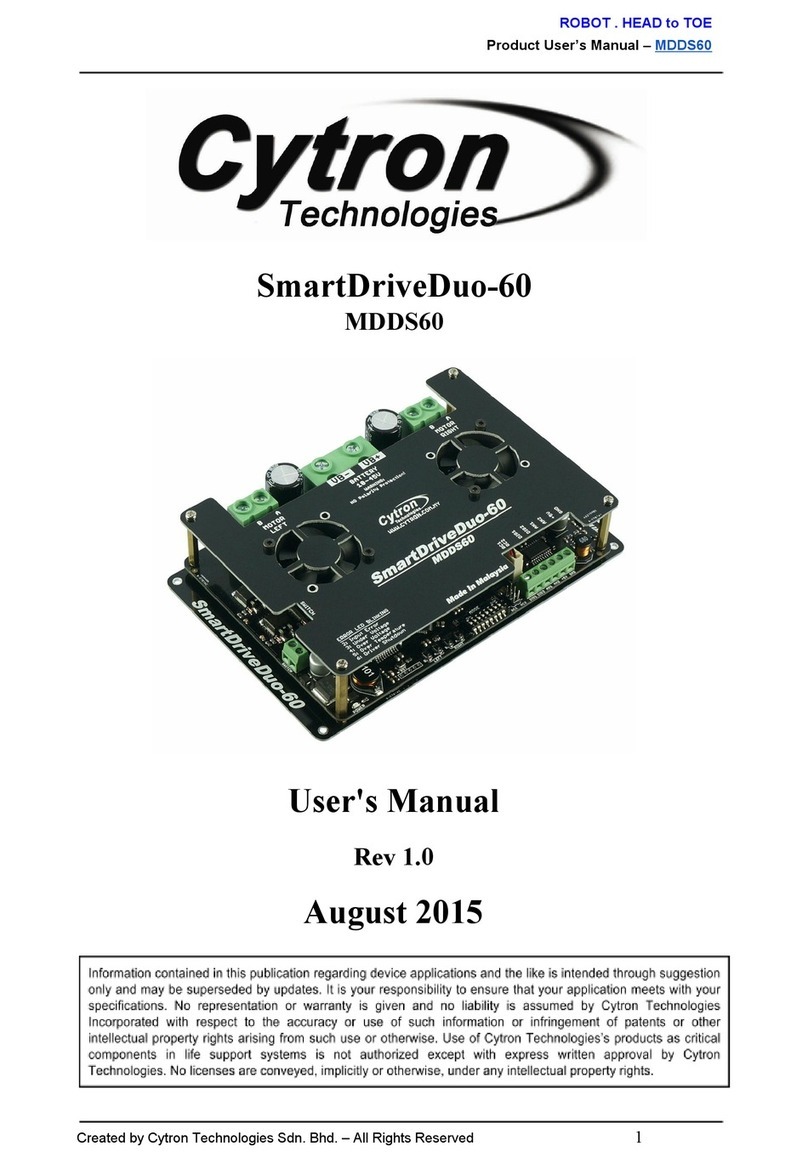

SmartDriveDuo-10 is one of the latest smart series motor drivers designed to drive medium

power brushed DC motor with current capacity up to 30A peak (few seconds) and 10A

continuously. This driver is designed specially for controlling differential drive mobile robot

using RC controller. Nevertheless, MDDS10 also can be controlled using analog joystick or

microcontroller (PWM, Serial). MOSFETs are switched at 16 KHz to ensure quiet operation

and no annoying whining sound. Besides, it also equipped with a microcontroller unit to

provide smart features such as multiple input mode and thermal protection.

SmartDriveDuo-10’s feature makes driving a robot with differential drive a truly plug and

play experience.

Some of the features for SmartDriveDuo-10 are summarized as below:

●Bi-directional control for dual brushed DC motor.

●Support motor voltage from 7V to 35V.

●Maximum current up to 30A peak (few seconds), 10A continuously.

●16 KHz switching frequency for quiet operation.

●Battery low voltage indicator.

●Battery over voltage indicator.

●Thermal protection.

●Multiple input modes: RC, Analog, PWM, Simplified Serial and Packetized Serial.

●On board push buttons for fast test and manual operation.

●No polarity protection for V motor.

Created by Cytron Technologies Sdn. Bhd. – All Rights Reserved 3