5

4. FUNCTION OF MAIN COMPONENTS

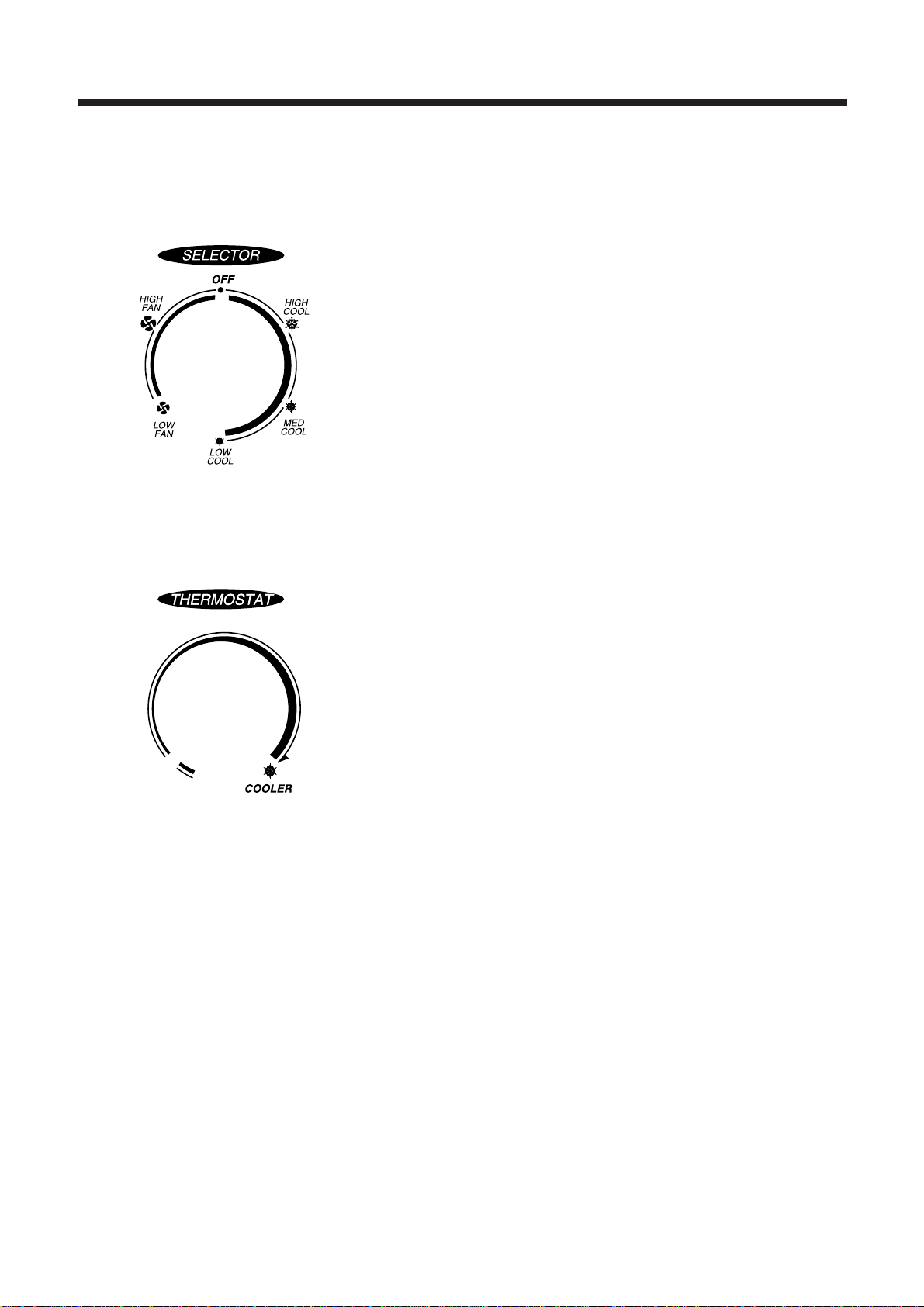

1. ROTARY SWITCH (SELECTOR)

Please refer to the part of selector in the chapter 9 (Wiring Diagram).

The rotary switch (selector) controls the fan motor’s rotation speed, and has six positions.

The function of the six position is as follow.

¡

OFF: This position stops all operations of the air conditioner.

¡

HIGH COOL: This position provides the maximum air flow for rapid

cooling, dehumidifying and dust removing operations.

(Use this position on sultry summer days.)

¡

MED COOL: This position provide the medium air flow for cooling

dehumidifying and dust removing operations

¡

LOW COOL: This position provides the minimum air flow for quiet

cooling, dehumidifying operations.

(Use this position on suitable for night-time.)

¡

HIGH FAN: This position provides the maximum air fiow alone fan

operation without cooling operation.

¡

LOW FAN: This position provides the minimum air flow air flow alone

fan operation without cooling operation.

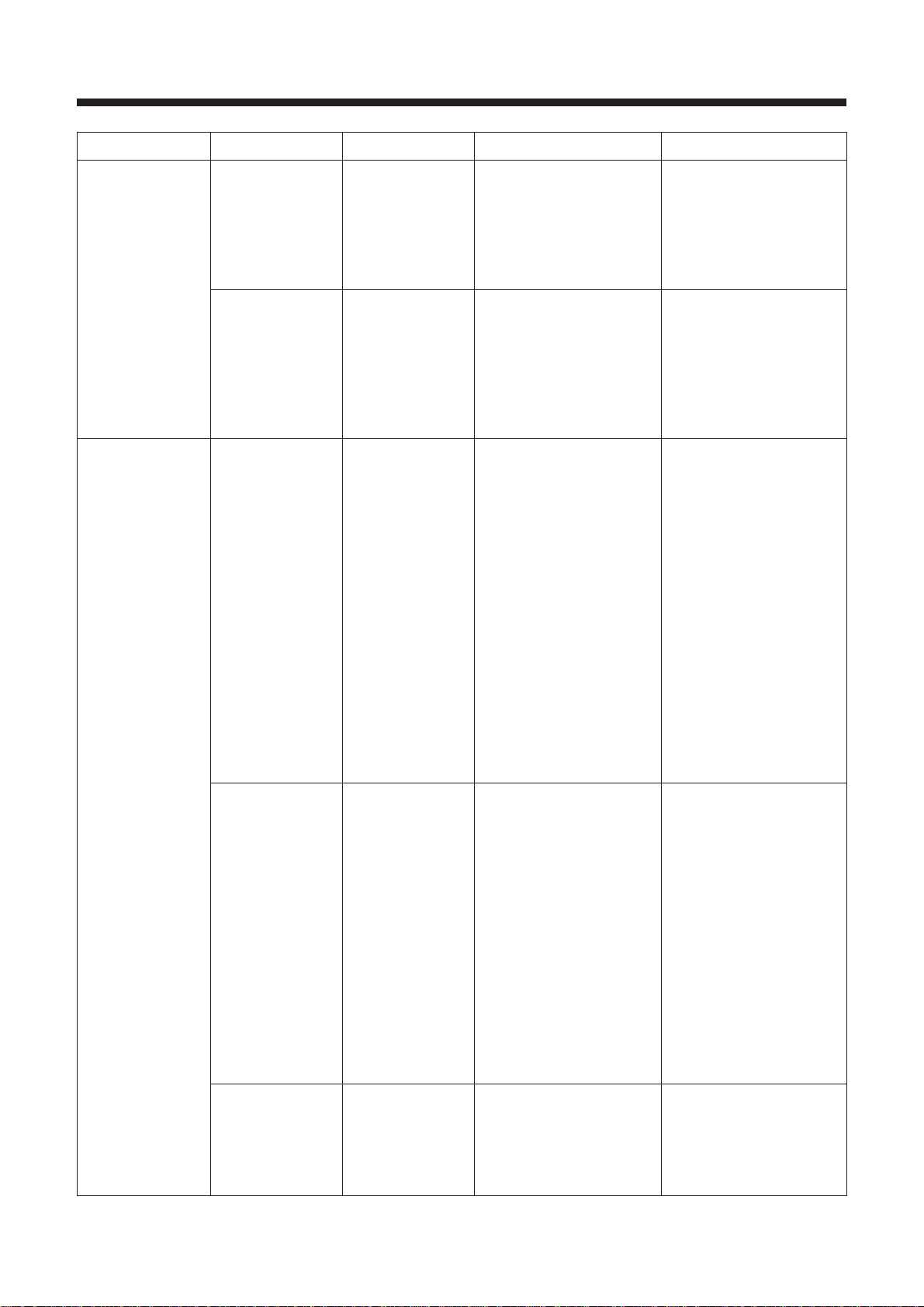

2. THERMOSTAT (TEMPERATURE CONTROL)

¡

The Thermostat automatically starts and stops operation in order to keep

the room temperature at a proper level, and this results in efficient use of

power and economical cooling.

¡

Turn clockwise for a cooler room temperature.

¡

Turn counter-clockwise for a warmer room temperature.

3. MOTOR

The motor is used to rotate the indoor and outdoor fan so that the room air can be recirculated.

4. FAN

¡

BLOWER FAN: The Blower draws hot air from the room through the Evaporator and then discharges it back into the

cool air. It circulates the room air.

¡

PROPELLER FAN: The propeller draws outdoor air through louvering and cools Condenser, and then blows the hot

air out.

5. CAPACITOR

The Capacitor enlarges the difference of phase between main coil and sub coil so that the Compressor and Fan Motor

starts well.

6. ACCUMULATOR

The Accumulator blocks the unflow of liquid refrigerant and impurities into the Compressor.