INDEX

1. INSTRUCTIONS FOR CORRECT UNIT INSTALLATION

..................................................................... 2

2. STARTING AND WORKING

................................................................................................................... 2

3. WIRING DIAGRAMS FOR CONNECTING THE UNIT TO DIFFERENT KINDS

OF PUMP’S MOTORS

................................................................................................................................ 3

4

. DEFECT DETECTING ............................................................................................................................. 5

5

. AFTER SALES SERVICE ......................................................................................................................... 5

6. TECHNICAL DATA

.................................................................................................................................. 5

WARRANTY ................................................................................................................................................. 6

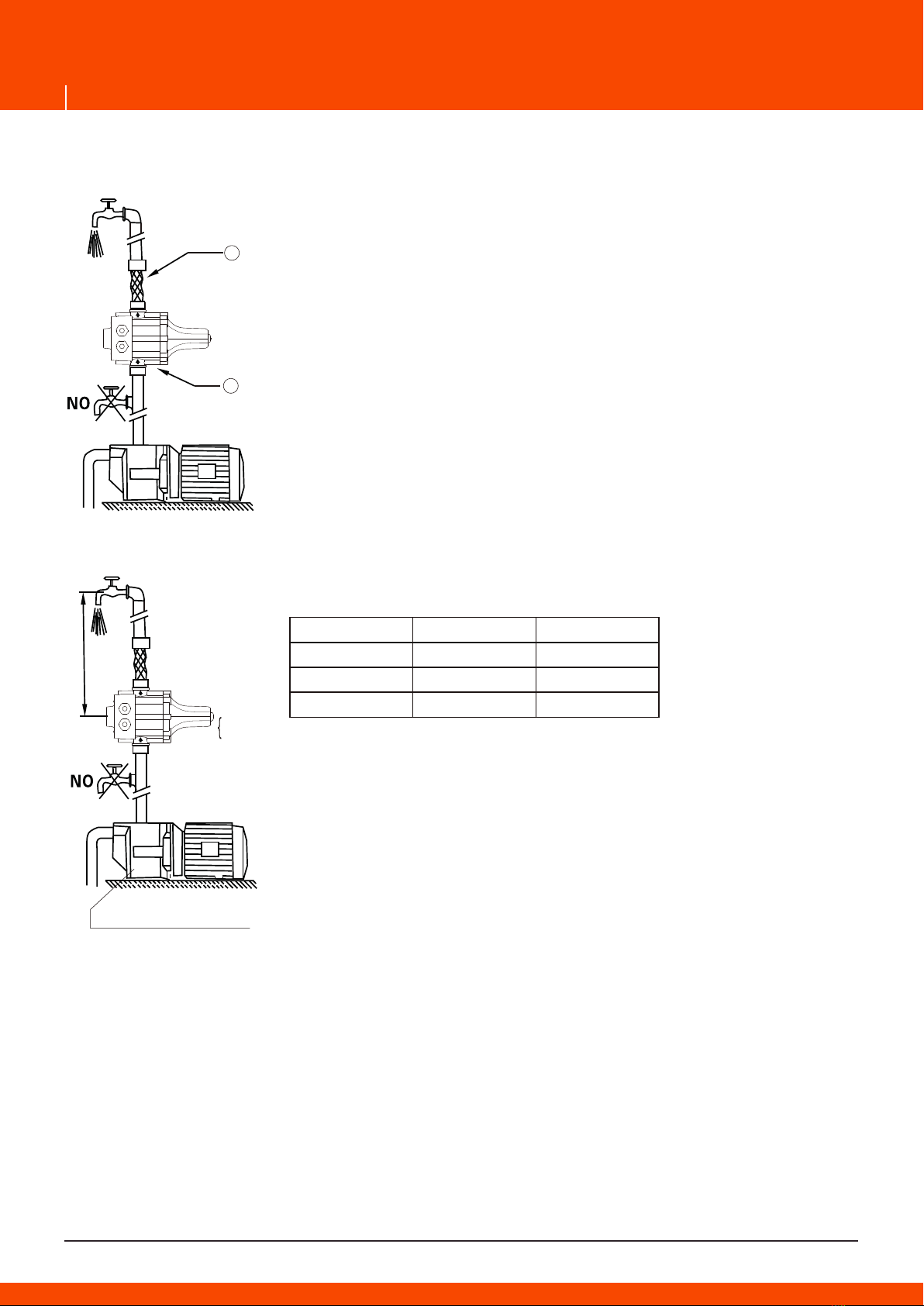

1. INSTRUCTIONS FOR CORRECT UNIT INSTALLATION

The control can be installed directly onthe pump or installed between

pump and the first tap. A pressure reducing valve must be installed on

the inlet of the control if pump's pressure exceeds 10 bar.

No taps can be installed between the pump and the control.

It is imperative to install the control with the arrows in the

upward position. (Fig 1/A)

It is advisable to connect the control outlet to the system by means

of a flexible pipe. (Fig 1/B)

Check suction and ensure that the pump is primed before starting the

control.

Normally pressure produced by the pump must be 1bar (0.1 MPa)

higher than the control's pre-set pressure, that is, checking on the

effective pressure of pump and system water column height

must be carried out according to the pre-set pressure.

The control's is set at its standard starting pressure

as 1.5bar (0.15 MPa) and starting pressure at 1.2 bar

or 2.2 bar are also available upon requests.

The pump can be blocked or continues to operate without stop if its

pressure is lower than stated minimum pressure. On the other hand,

the pump will not work if the height of water column exceeds above

standards. It is advisable to install the unit on a higher level to restore

a good installation condition as mentioned in the above or to change

for a unit with larger starting pressure.

2. STARTING AND WORKING

CAUTION: Never take the electronic board out of the control box. The wiring diagram inside the

terminal block will show you a correct connection. Wrong or loose connection will destroy the whole

electronic circuit.

Cable used for connection must be H05 or H07 type with 3×1.5 mm section .It shall have the outer

diameter at 8.9mm min. and 9.2 mm max. One of the leading end of the cable must be lower than

the position of the fixing screws while the cable being connected to the power as shown in the fig.

The six screws on the panel board and the two nuts for fixing cable must be well fastened to avoid

water entering into the control box and damaging the electronic circuit.

FUNCTION

The control is programmed to start and stop the pump operations automatically.

Its feature of water-shortage protection can protect the pump from being damaged during dry

running.

Except all ordinary function, It with timer can reset the pump automatically without water. When the

pump stop without water failed in the water supply system, the indicator light will be twinkled regu-

larly. In definite time, the controller reset pump every 15mins 1 time to test whether the water source

get right. If water source get right, the controller will exite this state. If in those time, no water suc-

tion, the control will keep without-water state, and after start the pump 4times every 15mins, the

control will reset pump in every 1h.Rectification of the failures that have caused the blockage allows

the system to be restarted by pressing the “restart” button for more than 2seconds. Keep button

“restart” pressed can stop the pump duringits operation and resume its work after stopping.

STARTING

When the control is connected to the electrical network, the green led “power on” lights up and the

yellow led “on”(pump in operation) lights 2-4 seconds later indicating that the pump has been

started. The pump continues to operate for 8 seconds enabling the system to fill in the pipes and to

reach the required pressure. If this lapse is insufficient, the red led “failure” lights up. In this event,

keep the “restart” button pressed and wait with a tap opened until the red led is off. Once the

button is released and the tap is closed, the control stops the pump at its max. Pressure.

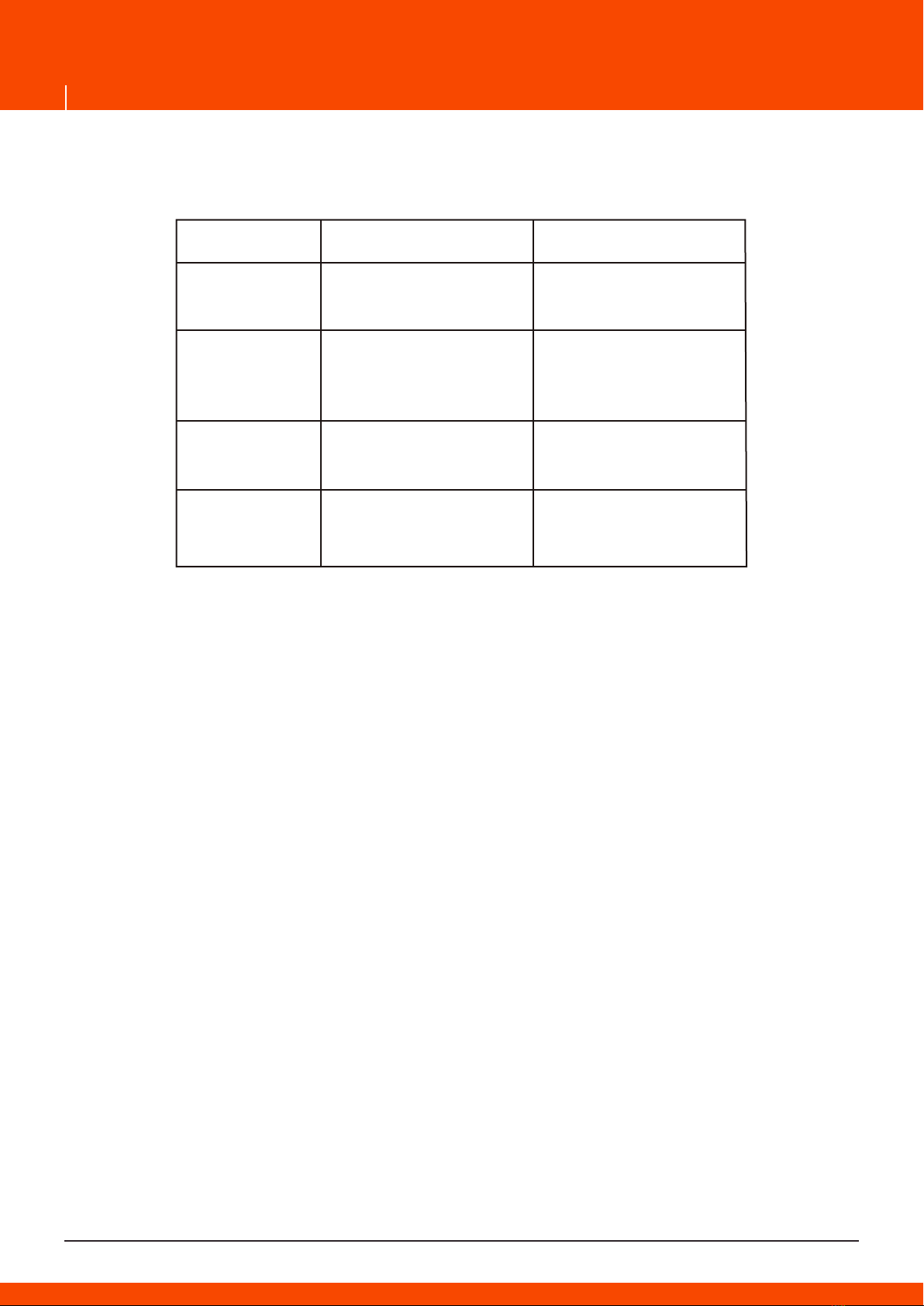

3. WIRING DIAGRAMS FOR CONNECTING THE UNIT TO DIFFERENT KINDS OF PUMP’S

MOTORS

4. DEFECT DETECTING

5. AFTER SALES SERVICE

This control is guaranteed for a period of twelve months from the date of purchase and shall not be

subject to any claims caused by subjective misusing and disassemblies or any installations not in

accordance with the instruction.

6. TECHNICAL DATA

Power: 2.2 kW

Current: 30 A

Maximum working pressure: 10 bar

Max working temperature: 55ºC

Connection: 1"male - 1 1/4"male

Protection rating: IP65

1