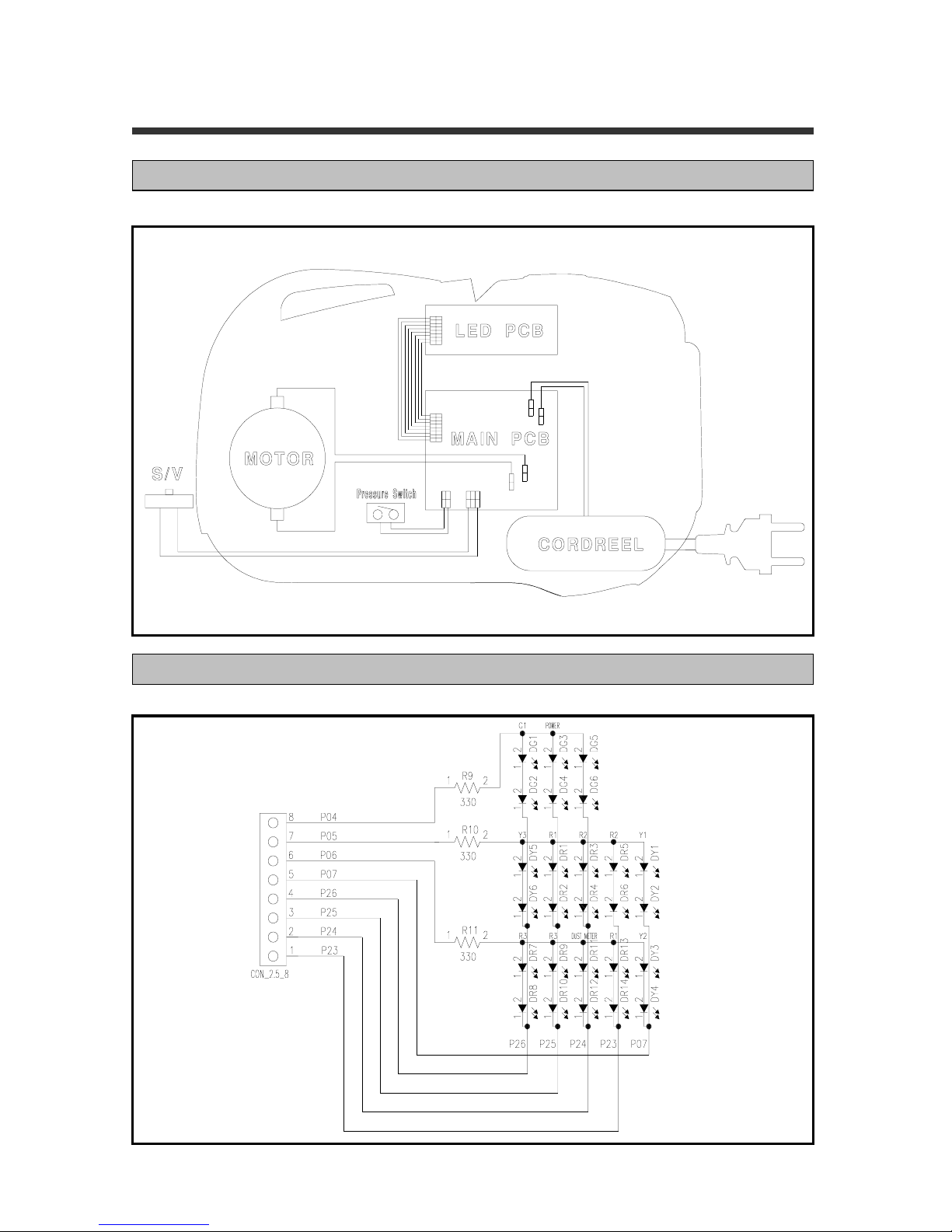

4. Trouble Shooting Guide

☞

CAUTION ! Please surely unpluged power plug before repairing.

TROUBLE CAUSE CHECKING COUNTERMEASURE

Dust box is full with dust Dust Box (See 5-8) Remove the dust

Dust box is installed incorrectly Dust Box (See 5-8) Reinstall dust box

Filter in dust box is clogged with dust Dust Box (See 5-8) Cleaning→drying→using

Exhaust filter is clogged with dust Exhaust Filter (See 5-6) Cleaning→drying→using

Defective motor Motor (See 5-5) Replace the motor

Filter in motor assembly is clogged with dust Motor (See 5-5) Clean the filter

Pressure switch is defective Body (See 5-2) Replace pressure switch

Clogging or tear in hose Hose (See 5-7 ) Remove obstacle or replace the hose

Telescopic/elbow pipe is clogged with large dust Elbow Pipe (See 5-9) Remove obstacle

Brush nozzle or hose is clogged with large dust Brush (See 5-7,10~12) Remove obstacle

Dust Box (See 5-8) Remove dust

PCB (See 5-1) Replace PCB

Hose (See 5-7 ) Remove obstacle

Elbow Pipe (See 5-9) Remove obstacle

Breaking in power cord Replace power cord

Bad contacts in cord reel assembly Repair bad contact

Breaking of connections in cord reel assembly Repair Disconnection

Defective terminal connection of PCB in body PCB (See 5-1) Check terminal connection state

Wire disconnection in body Body (See 5-2) Repair Disconnection

Pressure switch disconnection in body Body (See 5-2) Repair Disconnection

Defective terminal contact between body and hose Body, Hose (See 5-2, 5-7) Repair bad contact

Breaking of connections in hose Replace hose

Defective terminal contact in hose handle Repair bad contact

Defective slide volume in hose handle Replace slide volume

Defective PCB PCB (See 5-1) Replace PCB

Defective contact between PCB and motor/cord reel PCB (See 5-1) Repair bad contact

Motor out Motor (See 5-5) Replace Motor

Fuse disconnection Cord reel (See 5-4) Replace fuse

Broken reel sping of cord reel Cord reel (See 5-4) Replace Cord reel

Power cord is interwined Cord reel (See 5-4) Repair interwinement

Power cord is not

wound up

Suction power

is weak

(Red light blink)

Vacuum cleaner

does not work

Motor does not stop

even if switch off

Red light on the body

blink and suction

power is low and high

repeatedly

Motor protect system will be executed when dust

box is filled up with dust or hose is clogged

with obstacle over 15 seconds.

Cord reel (See 5-4)

Hose (See 5-7 )

Defective PCB PCB (See 5-1) Replace PCB

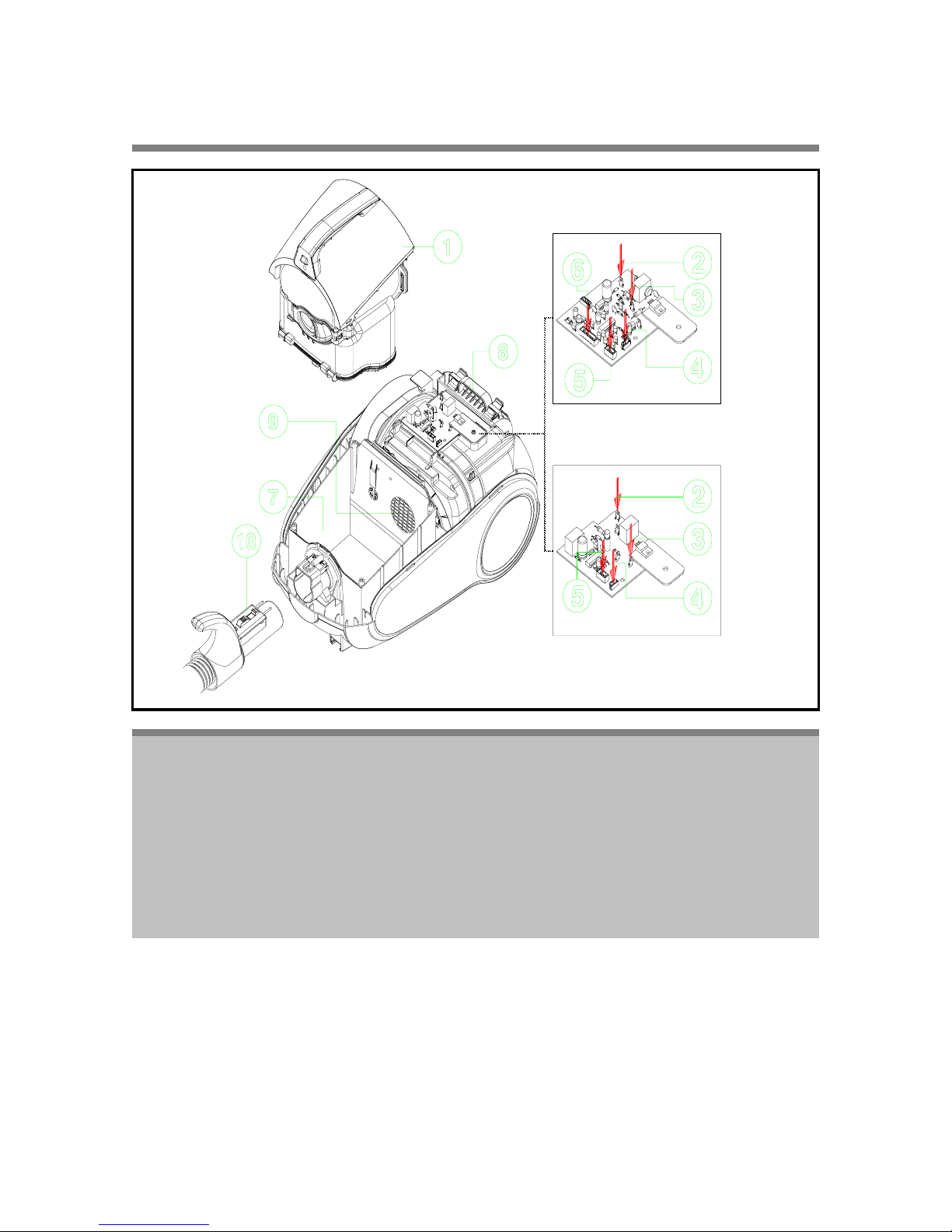

Be careful when breaking up the cord reel, the reelspring may spring out of the spring cover.

CAUTION

- 11 -