Daewoo DWC-UD121DC User manual

Other Daewoo Washer manuals

Daewoo

Daewoo DWF-1095 E Series User manual

Daewoo

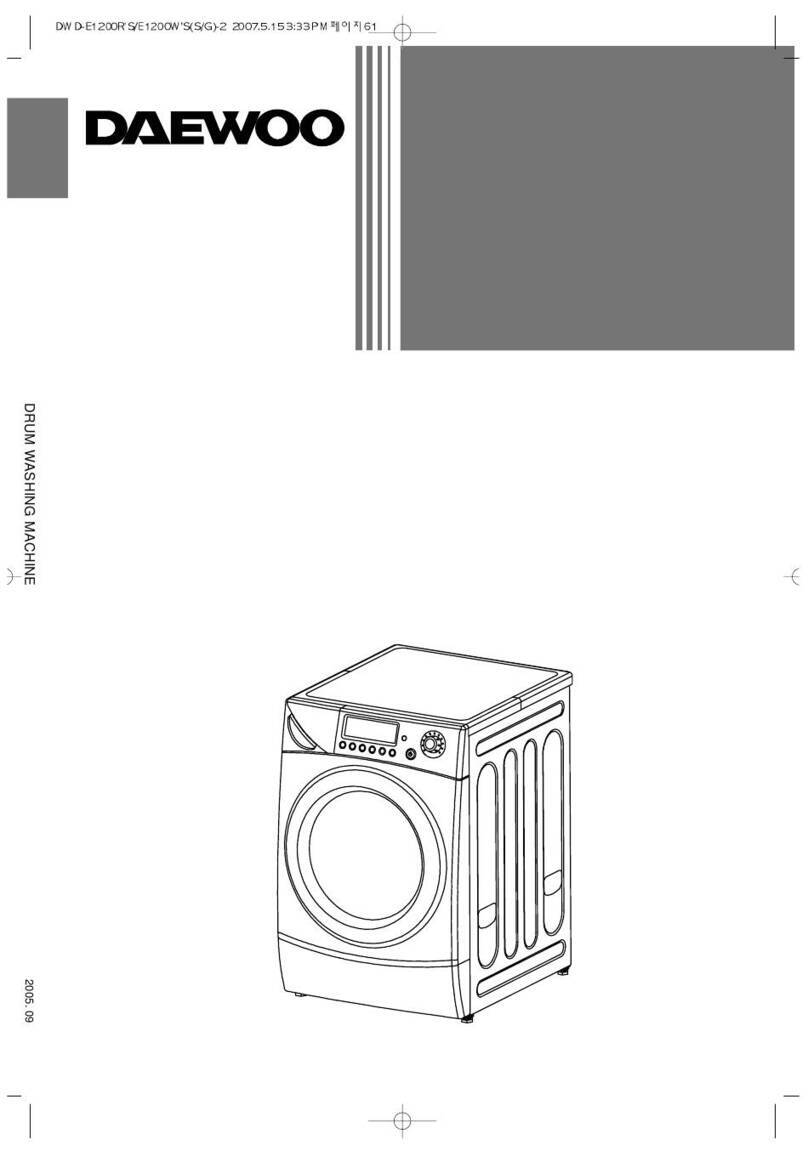

Daewoo DWD-E1200R S User manual

Daewoo

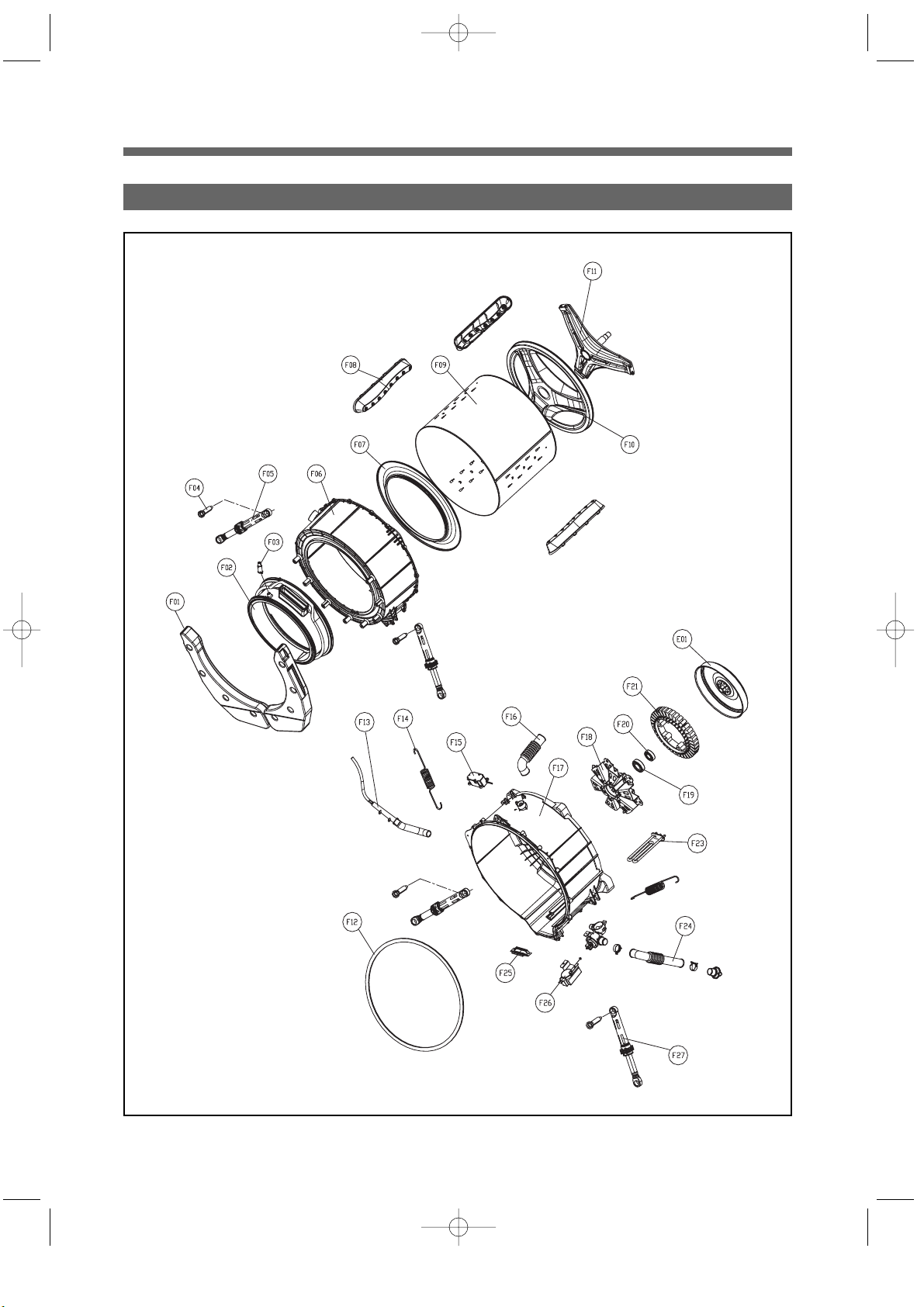

Daewoo DWF-170M User manual

Daewoo

Daewoo DWD-FD2442 User manual

Daewoo

Daewoo DWC-ED1213 User manual

Daewoo

Daewoo DWF-270TAP User manual

Daewoo

Daewoo DWF-600M User manual

Daewoo

Daewoo DWD-M1041 User manual

Daewoo

Daewoo DWF-753 User manual

Daewoo

Daewoo DWM30-999PG User manual

Daewoo

Daewoo DWF-178L User manual

Daewoo

Daewoo DWF-111W User manual

Daewoo

Daewoo DWC-LD141X User manual

Daewoo

Daewoo HURRICANE CAT 3 User manual

Daewoo

Daewoo DWD-FD1411 User manual

Daewoo

Daewoo DWF-5510P User manual

Daewoo

Daewoo DWD-G1081S User manual

Daewoo

Daewoo DWF-4230 Series User manual

Daewoo

Daewoo DWF-201M User manual

Daewoo

Daewoo DWD-M10E6 User manual