www.daewoopower.bg

5

EN

9. RECOMMENDED PUMP INSTALLATION DIAGRAM

1. Pump

2. Clamps for fastening the supply cable

3. Level control sensors (protection against dry running)

4. Fastening the cable

5. Manometer

6. Check valve

7. Shut-off valve

8. Power cable

9. Automatic control panel

10. Hydraulic accumulator

11. Pressure switch

8. TROUBLESHOOTING

Avoid unintentional power tool switching or startup.

Packaging

The product is placed in a package preventing damage during transport. This package is a raw

material therefire it can be handed over for recycling.

Instructions for use

Before beginning to work with the machine, read the following safety rules and instructions for use.

Familiarize with operating elements and the proper use of the device. Keep the manual in a safe

place for future reference. We recommend keeping the original package including the inner packa-

ging materials, cash voucher and guarantee card for a period of warranty at minimum.

Fir a case if transportation, pack the machine into the original box from the manufacturer, thus

ensuring a maximum protection of the product during a possible transport (e.g. moving or sending

into a service station).

NOTE: If you hand the machine over to next persons, hand it over together with the manual. Adhe-

rence to the attached instructions for use is a precondition for the proper use of the machine. The

operation manual includes also instructions for operation, maintenance and repairs.

The manufacturer does not take any responsibility for accidents or damages resulting from to

adhere to this manual.

2. SYMBOLS

The product complies with applicable standars and regulations.

Read the instruction manual attentively prior to use.

Double-insulated.

Use eyes protective equipment.

Use ears protective equipment.

Subjected to recycling.

markedly, and then you should exchange the stator and rotor in good time.

m. Always cut off the power before you should touch the motor pump, such as checking, moving or

dismantling to avoid contingency.

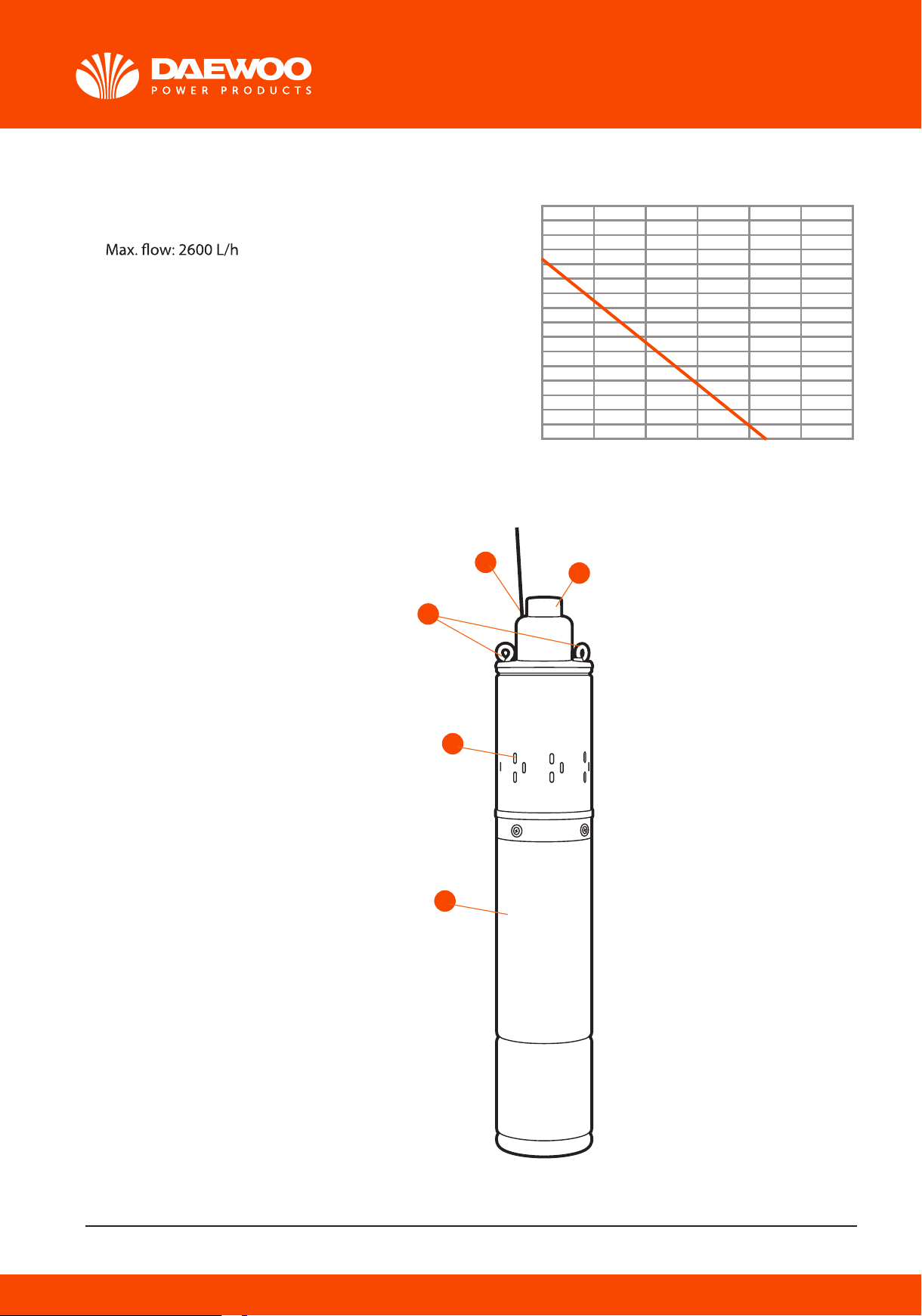

6. TECHNICAL SPECIFCATIONS

Power: 1200 W

Speed: 2850 rpm

Max. ow: 2600 L/h

Max. height: 135 m

Max. pressure: 13.5 bar

Depth of immersion: 5-30 m

Pump case diameter: 100 mm

Connection connector diameter: 1”

Cable section: 3x0.75 mm

Length of cable: 20 m

Acceptable liquid temperature: 40 °C

Installation method: Submersible vertical

N.W. / G.W.: 11.4 / 11.8 kg

7. DESCRIPTION OF PARTS

1. Pump housing

2. Outlet pipe

3. Power cable

4. Lugs for suspension

5. Water intake openings

1. IMPORTANT SAFETY INSTRUCTION

Read the instruction manual attentively before use.

Carefully remove the tool and any accessories from the box. Do not discard any of the packaging

materials until all parts are accounted for.

Keep the product in a dry place.

Read all warnings and instructions attentively. Failure to follow all warnings and instructions listed

below may result in electric shock, fire and/or serious personal injury.

Read operator`s manual carefulle. Learn its applications and limitations, as well as the specific

potential hazards related to this power tool. Following this rule will reduce the risk of electric shock,

fire, or serious injury.

Check whether the available power supply parameters correspond to the voltage parameters speci-

fied on the tool.

Check whether the power tool and connections are not damaged.

Connect the power cord to the outlet only when the tool is switched off.

Switch on the tool prior you place it on the workpiece.

Take all safety measures to reduce a risk of electric shock. Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators, ranges and refrigerators.

Sudden temperature changes may result in water condensation on live parts. Prior to use: Let the

power tool reach the workplace room temperature.

Do not use machines, tools and recommended accessories for any than intended purposes!

Clamp the workpiece safely. Secure the workpiece to be drilled in a vice or witch clamps to keep it

from turning as the drill bit rotates.

Dress properly. Do not wear loose clothing or jewellery. Loose clothes, jewellery or long hair can be

caught in moving parts. Wear safety shoes and gloves. Contain long hair.

Should dust, chips and sawdust result from activity or should you work above your head, always

wear safety goggles and dust mask, where appropriate.

While impact drilling, wear suitable ear protective equipment.

While working on ladders, scaffolding or upper floors, always stand on a film base.

Do not expose power tool to rain or wet conditions. Do not immerse the tool into water.

When operating a power tool outdoors, use an extension cord and other accessories suitable for

outdoor use.

Do not operated power tools in explosive atmospheres.

When the tool is handed over to the third person, the instruction manual shall always be included.

The power tool can be repaired only by a qualified specialist and with the original spare parts.

WARNING! Do not use a power tool while you ar tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools may result in serious personal

injury. Do not use the power tool in any of the following situations.

Keep the power tool out of reach of children.

Store idle power tools in the original package in a safe place and out of reach of children.

Disconnect the power cord from the power outlet before making any adjustments, changing acces-

sories, or storing power tools.

Do not abuse the cord. Never use the cord to carry the charger. Do not pull the cord to disconnect

the power tool from the power source.

When working: Do not let the motor stop if the power tool is loaded.

Keep the workplace clean and tidy. A messy workplace increases a risk of injury!

Do not assume unusual body positions while drilling.

3. PRODUCT INTRODUCTION

a. Submersible water pumps comply with standard DBP2500 the motor pump mainly consists of

three parts: pump, mechanical seal and motor, pump is as the upper part of motor pump, which

consists by stator and rotator. Motor is at the lower part of the motor pump and it is a single-phase

or three-phase asynchronous motor. Mechanical seal is between pump and motor and it is a king of

double end mechanical seal, “O” rings are applied in all static joints of the submersible pump,

inner-installed protector prevents the pump from damages due to abnormal power, clog and over-

load, etc.

b. Without limitation of lift, it can work smoothly within allowed highest. If it the screw submersible

pump is high lift, high efciency pump and widely used in at convey irrigation spray, high efciency

oxygen supply is agriculture adding pressure to running water in country aide and city drainage

inputs and mines, syrup and chemical liquid supply in food stuff lines.

4. OPERATING CONDITIONS

a. Medium temperature must not exceed +40 ºC.

b. PH range of medium between 6.5~8.5.

c. Quality ration of solid partial content shall be within 3%, size of solid particle shall be 3 not bigger

than 2 mm.

d. Power supply shall be 220V and 50 Hz for single phase and 380V, 50 Hz for three phases. Voltage

is allowed to uctuate between 0.9 to 1.1 times of its rated voltage.

e. The depth of the pump under water must be less than 15 m, more than 0.5 m.

5. INSTALLATION AND NOTICE POINTS

a. Thoroughly inspect the motor pump before installation, check the cable plug and appearance of

pump, conrm there is no problem with them and the insulation resistance is above 2m.

b. The motor pump must be equipped with over-heat or over-current and creepage protector, the

yellow-green core grounding mark must be reliably grounded.

c. Trial run the pump to see if the rotating is normal, but no more than 1 min, if the rotate direction

different with the red mark on pump; please displace two of the three phase.

d. Fit the hose to hose coupling and bind the m tightly with hoop, and then wrap a rope on the

handle to move the pump.

e. Never butt or press the cable, and never use cable as rope, or pull it lest break the cable and get

electric shock.

f. The depth of pump in water must be less than 5 m, and avoid the pump being het, into mud,

please put a bamboo or metal basketry around the pump to prevent the impeller from being blocked

by weeds notice decline of the water level and the pumpt must not be out of water while running.

g. Never washing, swimming and let domestic animals entering the water near the pump during

operating to prevent from getting electric shock.

h. If the pump is used far away from power source, please thicken the cable to insure acceptable

working voltage.

i. If the pumpt start and stop frequently, please cut off power supply, and check it, the problem must

be solved before using.

j. The head of the motor pump has no low limitation, but avoid the pump running under high head for

long time.

k. The motor is dry, and must not drain water or oil in it.

l. If rating of solid particle content went beyond the limit, ow of the motor pump should decline

9. RECOMMENDED PUMP INSTALLATION DIAGRAM

1. Pump

2. Clamps for fastening the supply cable

3. Level control sensors (protection against dry running)

4. Fastening the cable

5. Manometer

6. Check valve

7. Shut-off valve

8. Power cable

9. Automatic control panel

10. Hydraulic accumulator

11. Pressure switch

8. TROUBLESHOOTING

Avoid unintentional power tool switching or startup.

Packaging

The product is placed in a package preventing damage during transport. This package is a raw

material therefire it can be handed over for recycling.

Instructions for use

Before beginning to work with the machine, read the following safety rules and instructions for use.

Familiarize with operating elements and the proper use of the device. Keep the manual in a safe

place for future reference. We recommend keeping the original package including the inner packa-

ging materials, cash voucher and guarantee card for a period of warranty at minimum.

Fir a case if transportation, pack the machine into the original box from the manufacturer, thus

ensuring a maximum protection of the product during a possible transport (e.g. moving or sending

into a service station).

NOTE: If you hand the machine over to next persons, hand it over together with the manual. Adhe-

rence to the attached instructions for use is a precondition for the proper use of the machine. The

operation manual includes also instructions for operation, maintenance and repairs.

The manufacturer does not take any responsibility for accidents or damages resulting from to

adhere to this manual.

2. SYMBOLS

The product complies with applicable standars and regulations.

Read the instruction manual attentively prior to use.

Double-insulated.

Use eyes protective equipment.

Use ears protective equipment.

Subjected to recycling.

markedly, and then you should exchange the stator and rotor in good time.

m. Always cut off the power before you should touch the motor pump, such as checking, moving or

dismantling to avoid contingency.

6. TECHNICAL SPECIFCATIONS

Power: 1200 W

Speed: 2850 rpm

Max. ow: 2600 L/h

Max. height: 135 m

Max. pressure: 13.5 bar

Depth of immersion: 5-30 m

Pump case diameter: 100 mm

Connection connector diameter: 1”

Cable section: 3x0.75 mm

Length of cable: 20 m

Acceptable liquid temperature: 40 °C

Installation method: Submersible vertical

N.W. / G.W.: 11.4 / 11.8 kg

7. DESCRIPTION OF PARTS

1. Pump housing

2. Outlet pipe

3. Power cable

4. Lugs for suspension

5. Water intake openings

1. IMPORTANT SAFETY INSTRUCTION

Read the instruction manual attentively before use.

Carefully remove the tool and any accessories from the box. Do not discard any of the packaging

materials until all parts are accounted for.

Keep the product in a dry place.

Read all warnings and instructions attentively. Failure to follow all warnings and instructions listed

below may result in electric shock, fire and/or serious personal injury.

Read operator`s manual carefulle. Learn its applications and limitations, as well as the specific

potential hazards related to this power tool. Following this rule will reduce the risk of electric shock,

fire, or serious injury.

Check whether the available power supply parameters correspond to the voltage parameters speci-

fied on the tool.

Check whether the power tool and connections are not damaged.

Connect the power cord to the outlet only when the tool is switched off.

Switch on the tool prior you place it on the workpiece.

Take all safety measures to reduce a risk of electric shock. Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators, ranges and refrigerators.

Sudden temperature changes may result in water condensation on live parts. Prior to use: Let the

power tool reach the workplace room temperature.

Do not use machines, tools and recommended accessories for any than intended purposes!

Clamp the workpiece safely. Secure the workpiece to be drilled in a vice or witch clamps to keep it

from turning as the drill bit rotates.

Dress properly. Do not wear loose clothing or jewellery. Loose clothes, jewellery or long hair can be

caught in moving parts. Wear safety shoes and gloves. Contain long hair.

Should dust, chips and sawdust result from activity or should you work above your head, always

wear safety goggles and dust mask, where appropriate.

While impact drilling, wear suitable ear protective equipment.

While working on ladders, scaffolding or upper floors, always stand on a film base.

Do not expose power tool to rain or wet conditions. Do not immerse the tool into water.

When operating a power tool outdoors, use an extension cord and other accessories suitable for

outdoor use.

Do not operated power tools in explosive atmospheres.

When the tool is handed over to the third person, the instruction manual shall always be included.

The power tool can be repaired only by a qualified specialist and with the original spare parts.

WARNING! Do not use a power tool while you ar tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools may result in serious personal

injury. Do not use the power tool in any of the following situations.

Keep the power tool out of reach of children.

Store idle power tools in the original package in a safe place and out of reach of children.

Disconnect the power cord from the power outlet before making any adjustments, changing acces-

sories, or storing power tools.

Do not abuse the cord. Never use the cord to carry the charger. Do not pull the cord to disconnect

the power tool from the power source.

When working: Do not let the motor stop if the power tool is loaded.

Keep the workplace clean and tidy. A messy workplace increases a risk of injury!

Do not assume unusual body positions while drilling.

3. PRODUCT INTRODUCTION

a. Submersible water pumps comply with standard DBP2500 the motor pump mainly consists of

three parts: pump, mechanical seal and motor, pump is as the upper part of motor pump, which

consists by stator and rotator. Motor is at the lower part of the motor pump and it is a single-phase

or three-phase asynchronous motor. Mechanical seal is between pump and motor and it is a king of

double end mechanical seal, “O” rings are applied in all static joints of the submersible pump,

inner-installed protector prevents the pump from damages due to abnormal power, clog and over-

load, etc.

b. Without limitation of lift, it can work smoothly within allowed highest. If it the screw submersible

pump is high lift, high efciency pump and widely used in at convey irrigation spray, high efciency

oxygen supply is agriculture adding pressure to running water in country aide and city drainage

inputs and mines, syrup and chemical liquid supply in food stuff lines.

4. OPERATING CONDITIONS

a. Medium temperature must not exceed +40 ºC.

b. PH range of medium between 6.5~8.5.

c. Quality ration of solid partial content shall be within 3%, size of solid particle shall be 3 not bigger

than 2 mm.

d. Power supply shall be 220V and 50 Hz for single phase and 380V, 50 Hz for three phases. Voltage

is allowed to uctuate between 0.9 to 1.1 times of its rated voltage.

e. The depth of the pump under water must be less than 15 m, more than 0.5 m.

5. INSTALLATION AND NOTICE POINTS

a. Thoroughly inspect the motor pump before installation, check the cable plug and appearance of

pump, conrm there is no problem with them and the insulation resistance is above 2m.

b. The motor pump must be equipped with over-heat or over-current and creepage protector, the

yellow-green core grounding mark must be reliably grounded.

c. Trial run the pump to see if the rotating is normal, but no more than 1 min, if the rotate direction

different with the red mark on pump; please displace two of the three phase.

d. Fit the hose to hose coupling and bind the m tightly with hoop, and then wrap a rope on the

handle to move the pump.

e. Never butt or press the cable, and never use cable as rope, or pull it lest break the cable and get

electric shock.

f. The depth of pump in water must be less than 5 m, and avoid the pump being het, into mud,

please put a bamboo or metal basketry around the pump to prevent the impeller from being blocked

by weeds notice decline of the water level and the pumpt must not be out of water while running.

g. Never washing, swimming and let domestic animals entering the water near the pump during

operating to prevent from getting electric shock.

h. If the pump is used far away from power source, please thicken the cable to insure acceptable

working voltage.

i. If the pumpt start and stop frequently, please cut off power supply, and check it, the problem must

be solved before using.

j. The head of the motor pump has no low limitation, but avoid the pump running under high head for

long time.

k. The motor is dry, and must not drain water or oil in it.

l. If rating of solid particle content went beyond the limit, ow of the motor pump should decline

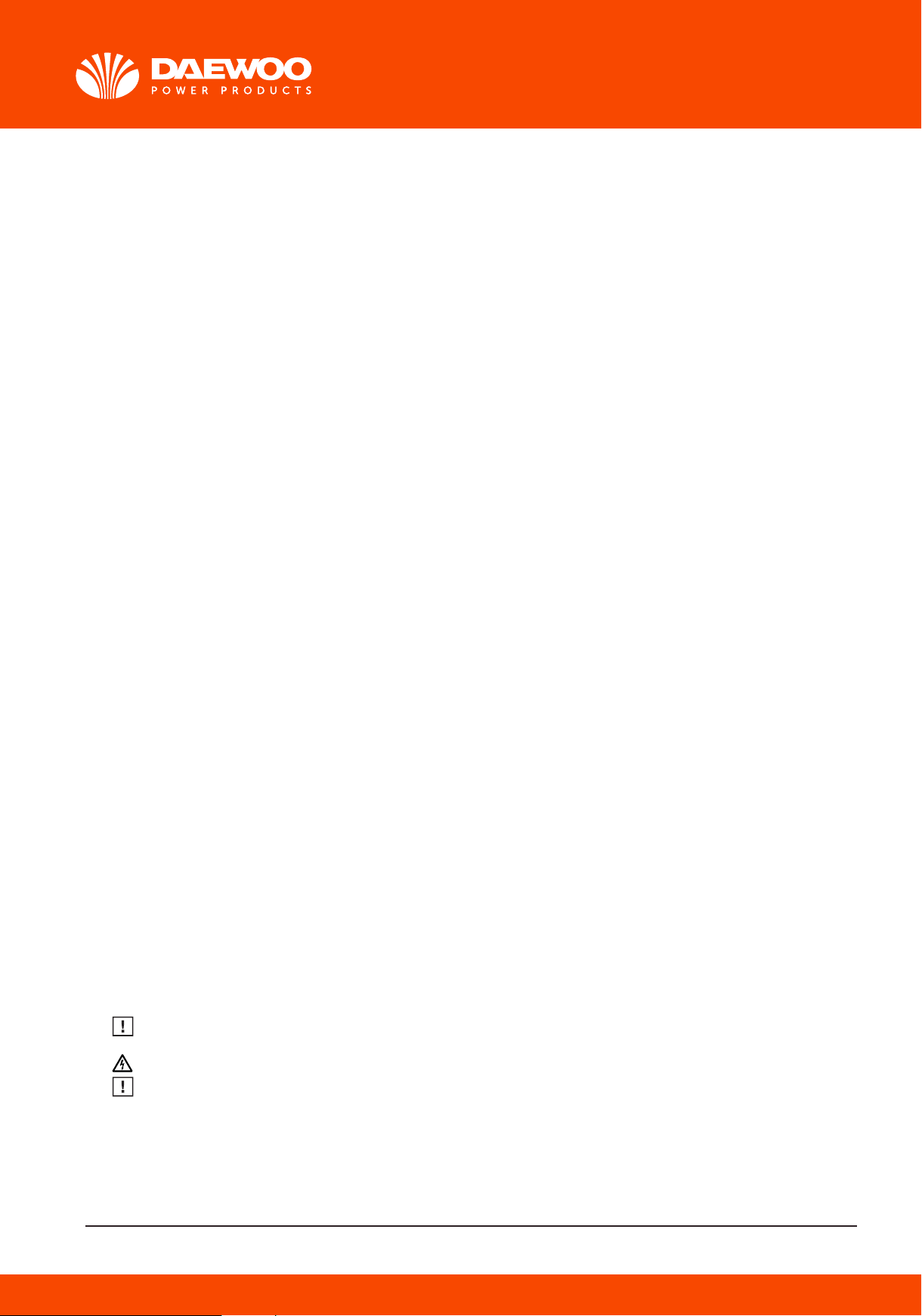

2

1

4

5

3

600 1200 1800 2400 3000 3600

20

40

60

80

100

120

140

DBP2500

Lifting height, m

Performance, L/h

6