4. Doorhanginghrackets

The door hanging brackets are made of iron and are connected to the door with bolts. Each

pulley has a greased, sealed ball bearing and a plastic tire. The rail is extruded

aluminum.

For installation on fire doors, the pulley tires and rail are made of iron (EDM-30Z)

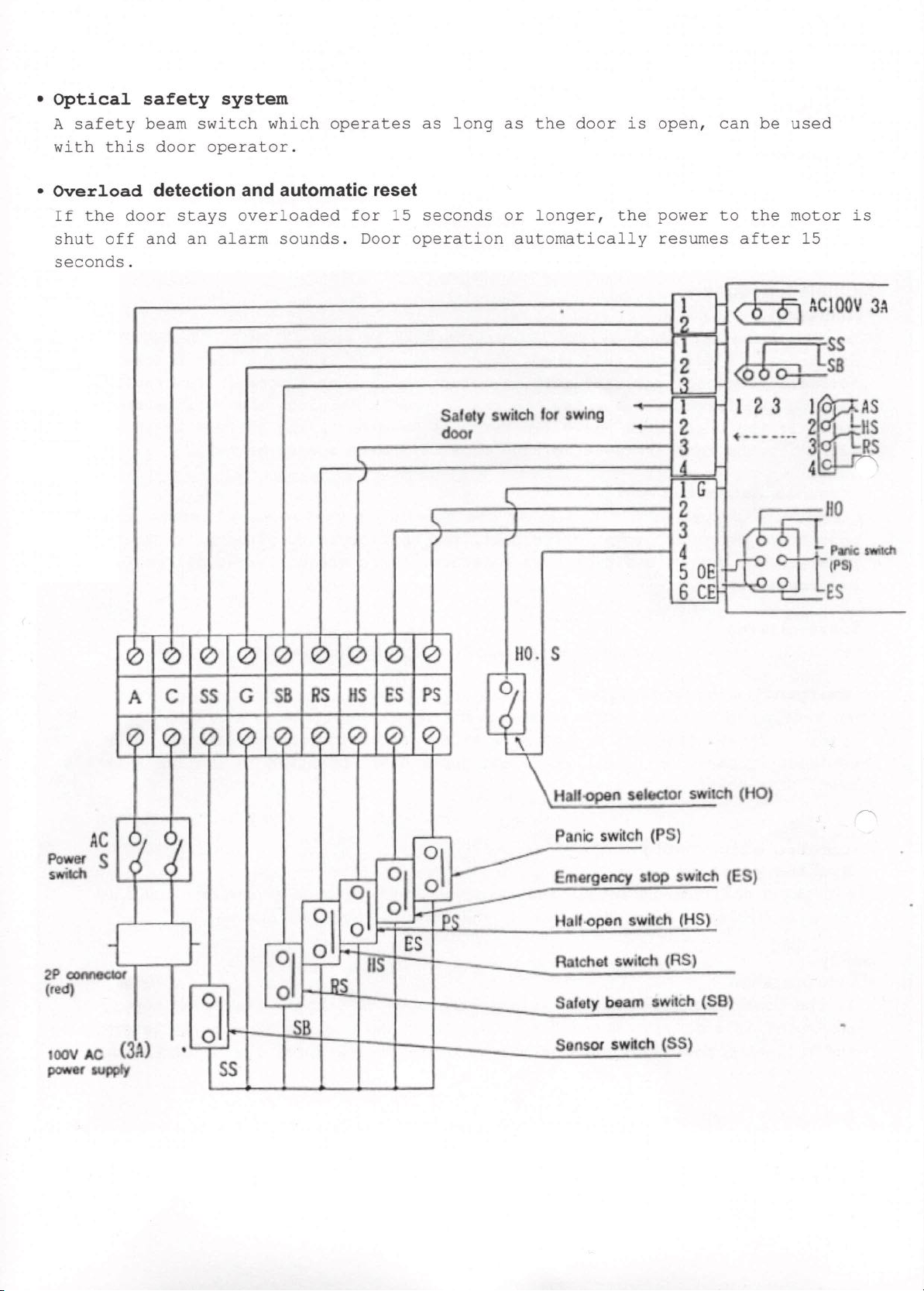

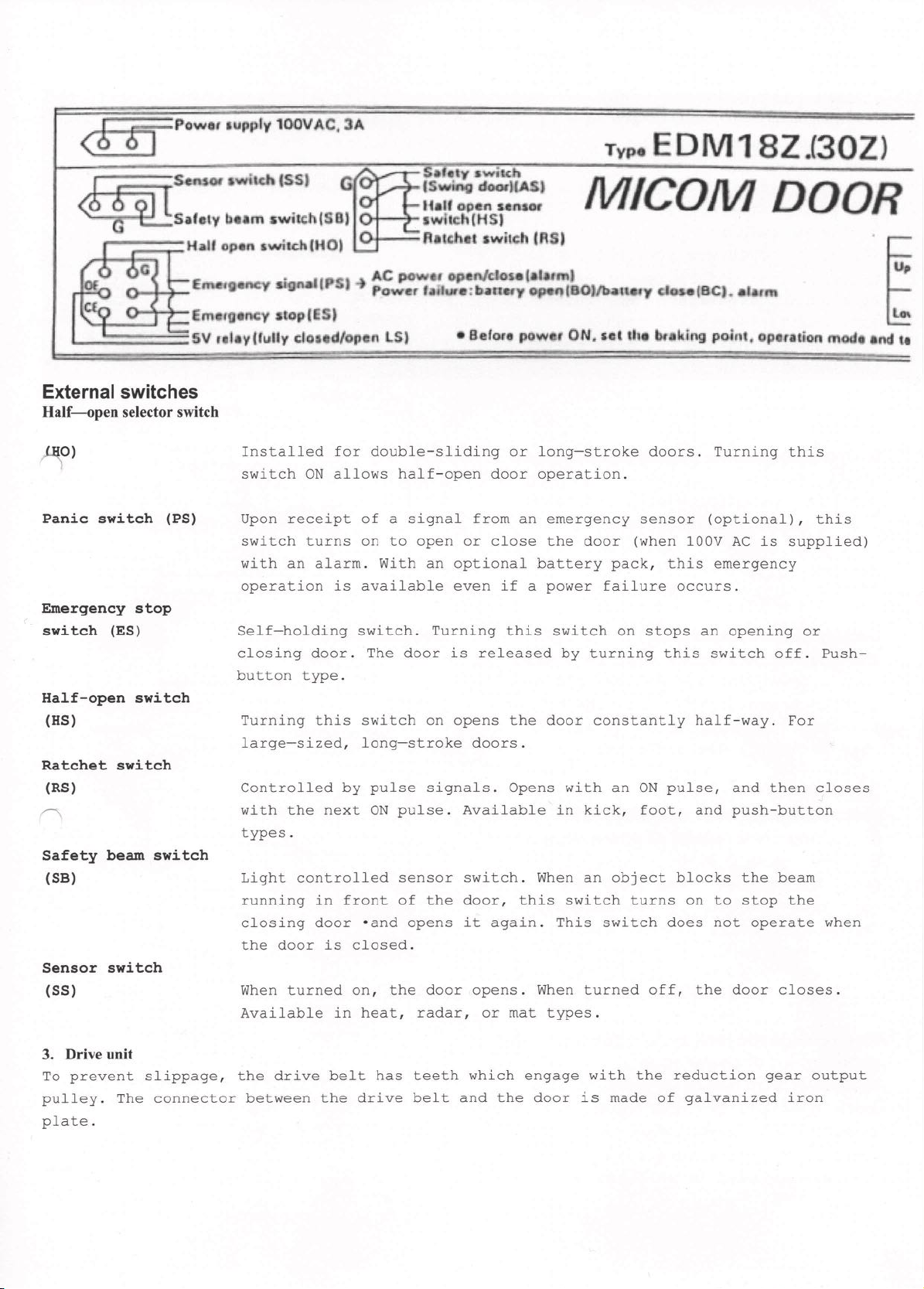

BOilary opon

.~I

Panic switch

5. Sensor switch

Sensor switches are available in

various types: heat, radar, infrared,

ultrasonic, electronic mat, rubber

mat, touch, loop coil, push-button,

etc. Choose the one the most suited to

the installation site.

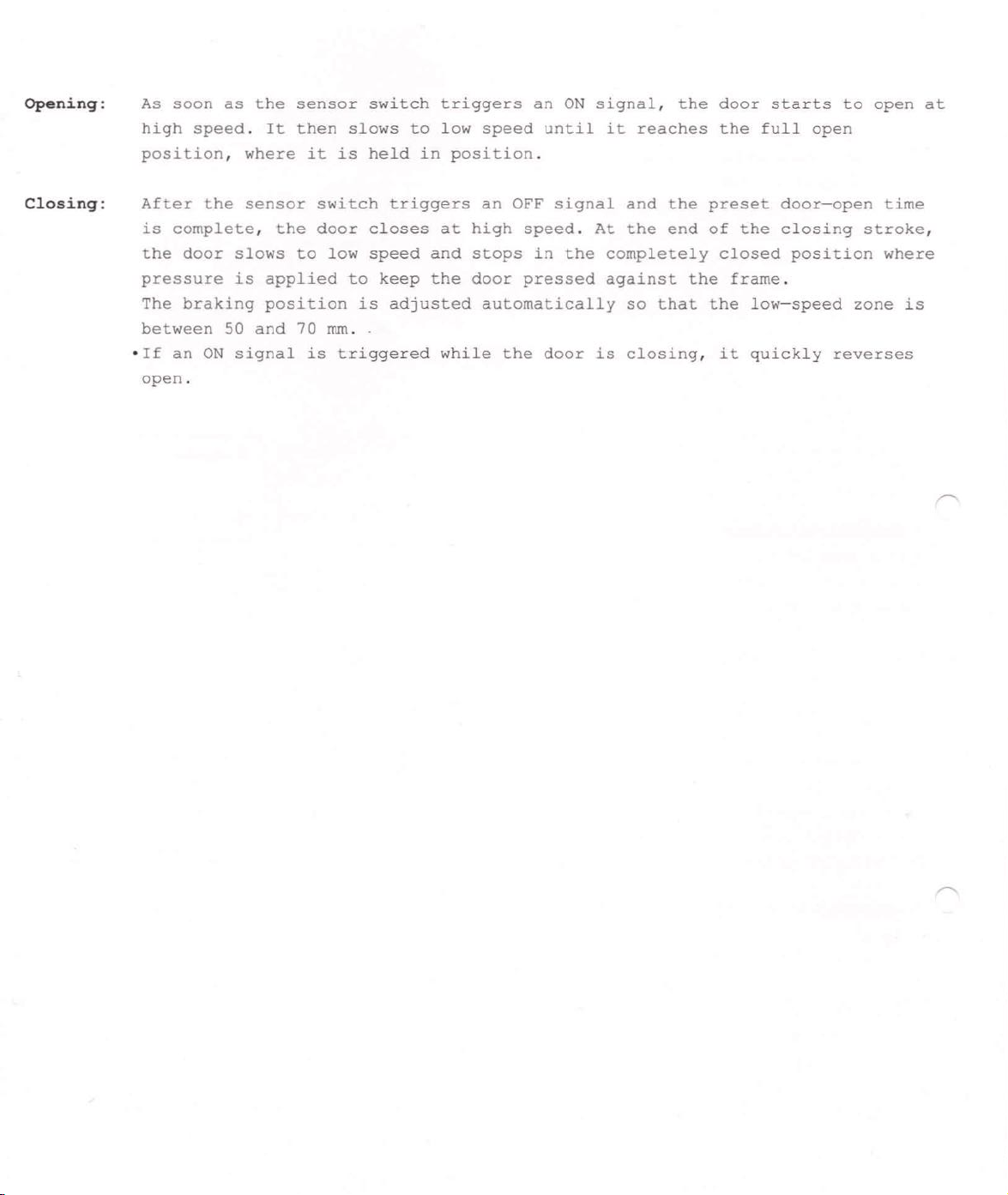

6. Optional systems Battery-open system

(BOZ)

The door opens fully with an alarm

when a power failure occurs. (Power

supply to the motor continues for 25

seconds.

l00V IIC

Con1rOl box

,

DC_

M

BatIOry pad<

(0Cz4V )

I

-----7'-->

I

Open

r

Battery-close system (BCZ)

The door closes fully with an alarm

when a power failure OCCUrS. The door

is then press-closed until the battery

is exhausted (approx. 30 minutes) .

This system is useful for fire doors.

Ba,." -..

<--~._._.-

Close

loc~

control bo.•

lOOV IIC

DC molar

Electromagnetic lock system (Li Z)

(unlocking upon receipt of power supply)

When the sensor switch turns on and

power is supplied, the door is

unlocked. The door is automatically

locked when fully closed. When there

is no power supply or when a power

failure occurs, the door is locked.

Electromagnetic lock system (L2Z) (locking

upon receipt of power supply)

When sensorswitchturnson andpower iscutoffthe

doorisunlocked. The door is automatically

lockedwhen fullyclosed. When there is no

power supply or when a power failure

occurs, the door is unlocked.

,.-

• (L1)

I

lO<ll convol boo

~ed ••hen

Of.oII