SDLC-207-104

9

2.6 Performance

Item Specification

Setting accuracy (4) ±0.1% (% for input span)

Display accuracy (5)(6) ±0.1% (% for input span) ±1digit

Reproducibility of the

operating point (4) ±0.1% (% for input span)

Operating time accuracy ±0.25 seconds of contact delay time set value

(However, in case of set value = 0 second. 0.5±0.25 seconds)

Reset time Less than 0.5 seconds

Starting delay time

accuracy ±0.25 seconds of starting delay time set value

Influence of temperature 0.2% (For input span) /23±10℃

Influence of auxiliary

supply voltage variation 0.1% (For input span) /Within variation range

Operation period About 0.1 second

Response time About 0.5 second

(In case 90 to 110% of step variation of operation value setting is given, in CD=0 second)

Overload

capacity

Voltage input 2 times 10 seconds and 1.5 times continuation of rated voltage.

Current input 10 times 5 seconds and 1.5 times continuation of rated current.

Aux. supply 1.5 times 10 seconds of rated voltage. And upper limit of the variation range is continued.

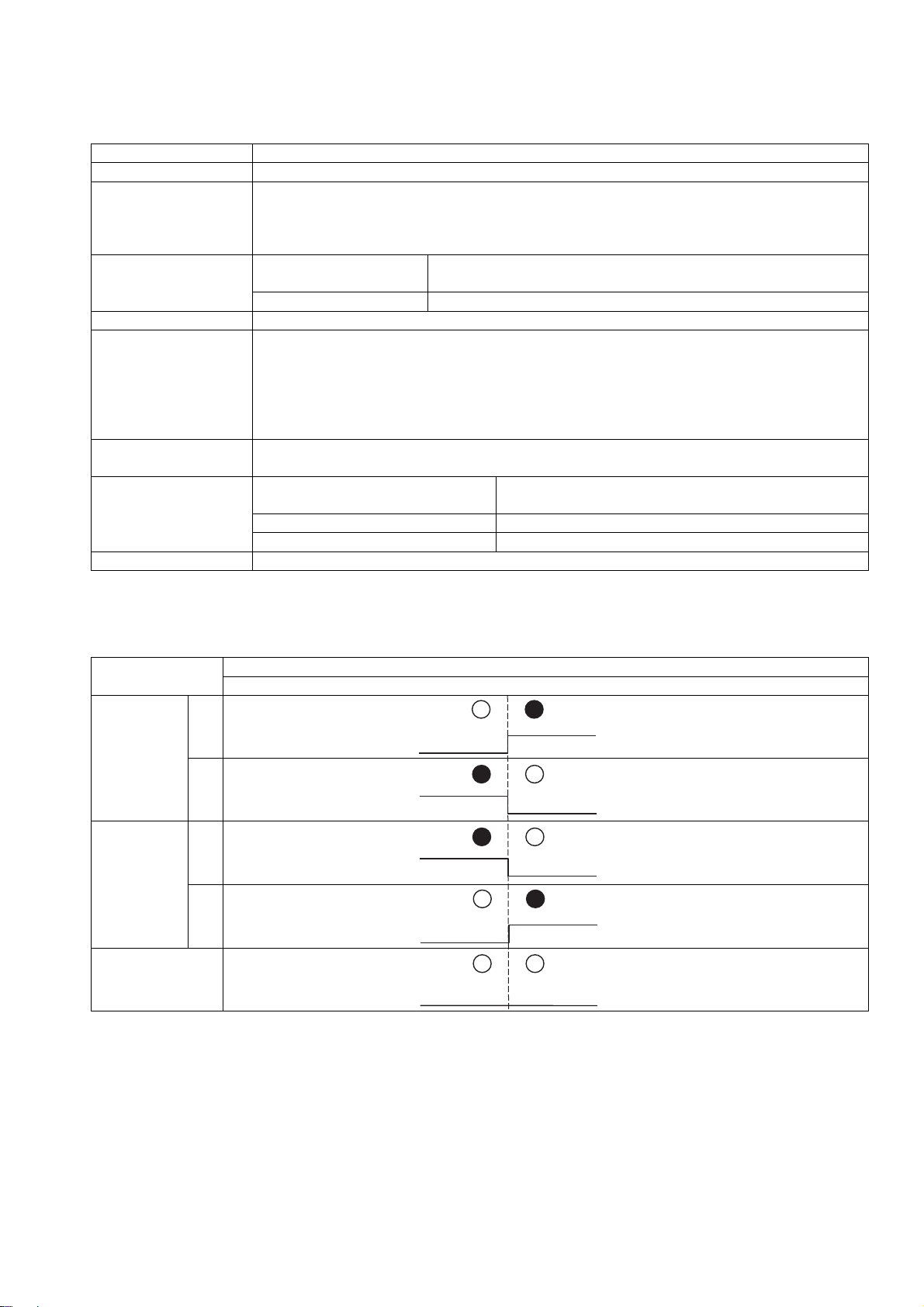

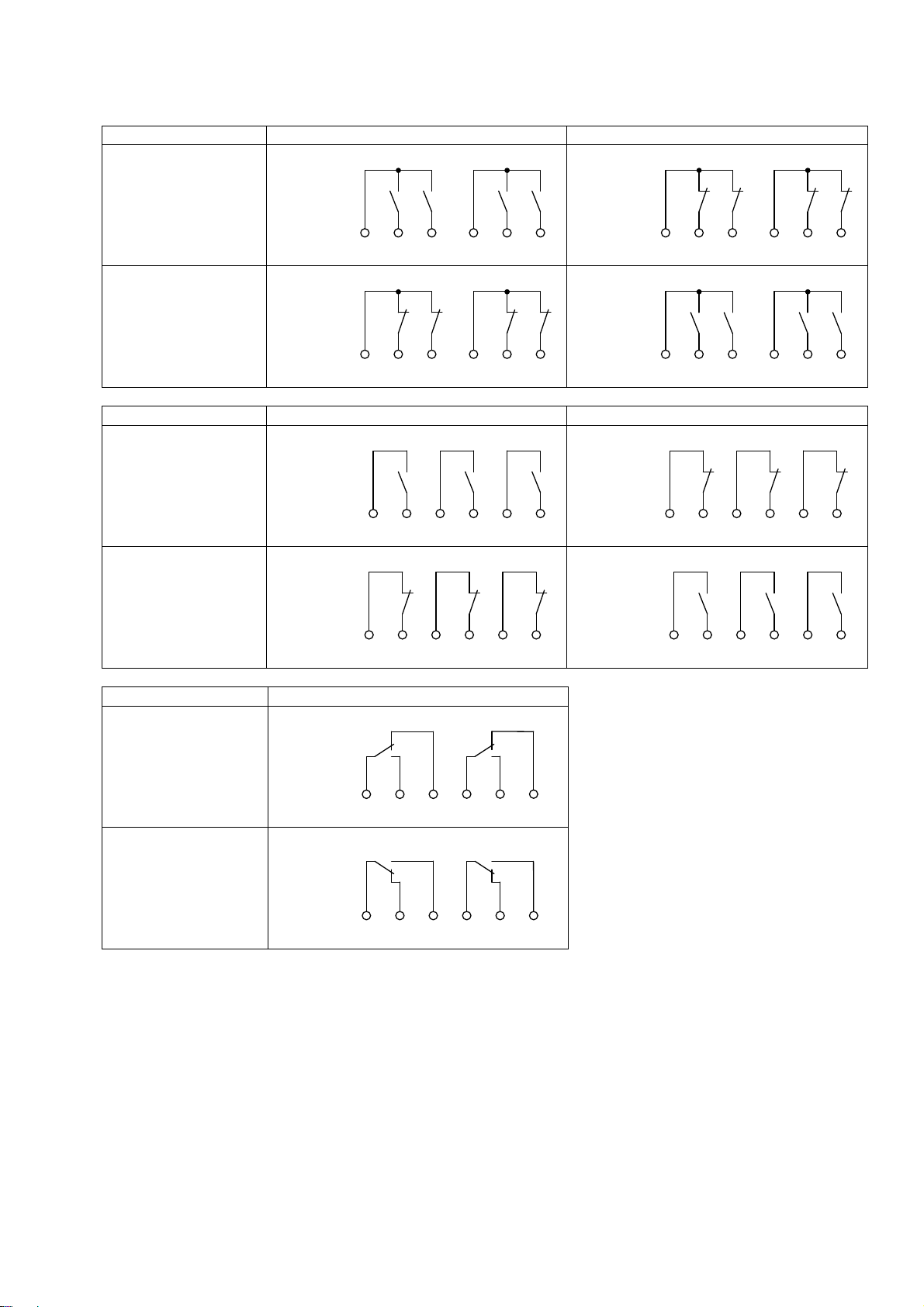

Insulation resistance

Between electric circuit and case.

Above 50MΩ at DC500V.

Between input, output terminals and auxiliary supply terminals.

Between input terminals and output terminals.

Between AL1 output terminals and AL2 output terminals.

(Only two alarm contact output specification)

Between AL1 output terminals and AL2 output terminals

and AL3 output terminals.

(Only three alarm contact output specification)

Between AL1・AL2 output terminals and AL3・AL4 output terminals.

(Only four alarm contact output specification)

Power frequency

withstand voltage

Between electric circuit and case.

AC2000V (50/60Hz) 1 minute.

There must not be malfunction.

Between input, output terminals and auxiliary supply terminals.

Between input terminals and output terminals.

Between AL1 output terminals and AL2 output terminals.

(Only two alarm contact output specification)

Between AL1 output terminals and AL2 output terminals

and AL3 output terminals.

(Only three alarm contact output specification)

Between AL1・AL2 output terminals and AL3・AL4 output terminals.

(Only four alarm contact output specification)

Impulse withstand

voltage Between electric circuit and case.

5kV 1.2/50

μ

s.

Positive and negative

polarity for each 3 times.

There must not be malfunction.

Vibration Vibration of vibration frequency 16.7Hz,Double amplitude 1mm. In the direction of X Y Z for

each 10 minutes. There must not be malfunction.

Shock Error:98m/s

2

, X, Y, Z direction for each 3 times.

Duration:294m/s

2

, X, Y, Z direction for each 3 times.

Power failure guarantee Each set value is data-saved by non-volatilized memory.

Material of case Case:Flame resisting ABS resin , Name plate:Polyester film , Socket:Glass filled PBT resin

Appearance color Case, Socket:Munsell N1.5 (Black) , Name-plate:Gray

Operating temperature

and humidity limits -10 to +55℃ , 5 to 90%RH (Non condensing)

Storage temperature

limits -25 to +70℃

Mass Approx. 350g

Accessories Socket,Unit symbol sheet,Instruction manual

Note(4) Input is DC60mV to less than 1V, DC±60mV to less than ±1V. ±0.2% (% for input span)

Note(5) Input is DC60mV to less than 1V, DC±60mV to less than ±1V. ±0.2% (% for input span) ±1digit.

note(6) In more than 10000 (5 digits except decimal point), a measurement display span constitutes ±0.1% (%

for input span)±2digit. And, if input is less than 1V and measurement display span is 10000 or more.

±0.2% (% for input span) ±2digit.