2

Chapter-2

Introduction

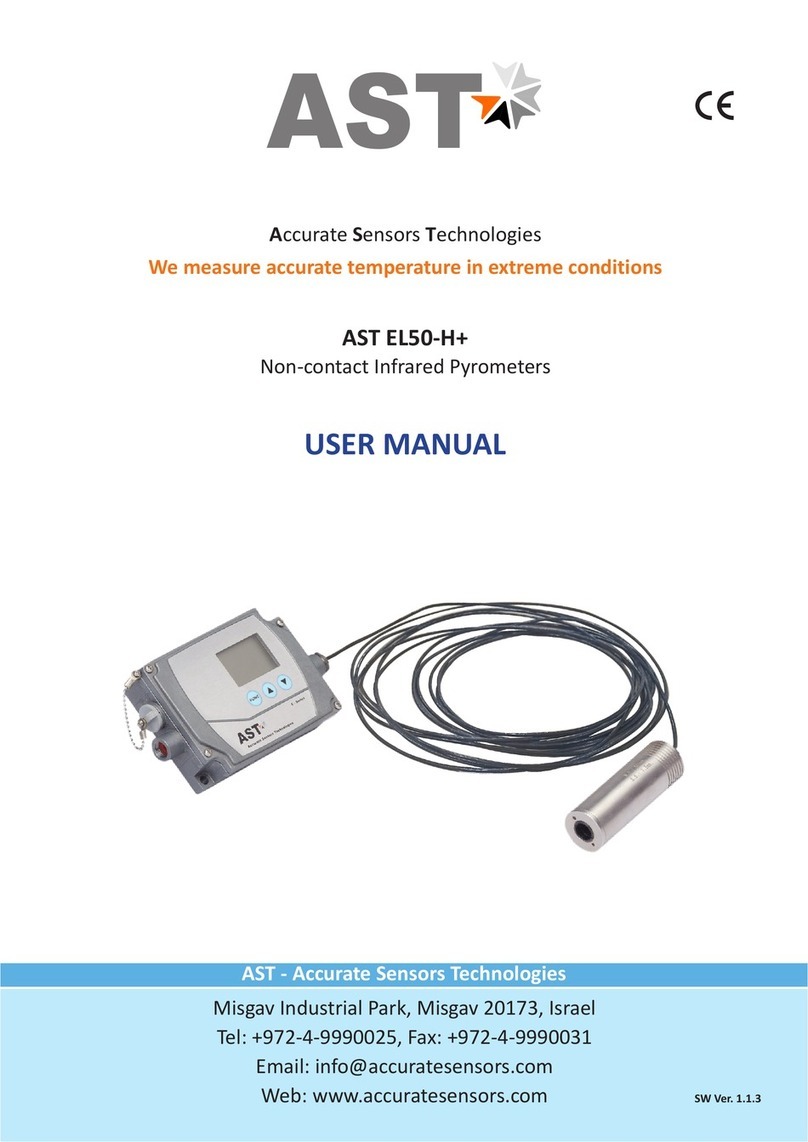

AST A250C PL/TL are specially designed highly accurate digital two-color pyrometers to provide high

performance and low maintenance of non contact temperature measurement in demanding industrial environment.

2.1 Application, Range and Working Principle

The digital AST A250C PL/TL pyrometer use ratio method in which 2 adjacent wave lengths are used for

measurement of temperature. They are suitable for high temperature measurement ranging from 350°C to 1350°C.

AST A250C PL/TL pyrometers are suitable for industrial purpose due to following advantages:

ŸMeasurement of temperature is not affected by emissivity of object.

ŸMeasurement of object temperature is possible where dust, moisture & other contaminants are present in

surrounding environment.

ŸThe measuring object can be smaller than spot size.

ŸThe pyrometer can be switched between 1-colour & 2-colour mode.

These pyrometers have solid body in stainless steel housing which provides high operation safety even in rough

industrial environment, and large variety of optics with fixed focus which can be easily used in all industrial areas.

AST A250C PL/TL has a fast response time of 100msec. Pyrometer have RS-232, RS-485 & Bluetooth outputs.

Response time, emissivity, sub range and peak picker selection can be preset ex works or adjusted through available

software.

The pyrometer temperature measurement method utilizes the fact that objects emit thermal radiation in an

amount that directly corresponds to their own temperature and surface emissivity. Two color pyrometer involves

measuring thermal radiance at two different wavelengths and inferring the temperature from the ratio of these

spectral radiances. Radiance ratio thermometers can be significantly more accurate than single band thermometers

in many applications.

Temperature measurement can be taken in any of the following modes:

1. Single colour mode.

2. Two colour mode.

Single Colour Mode: Single colour mode is best for measuring the temperature of target object in areas where no

sighting obstacle is present between the target object and the pyrometer. Sighting obstacle can be any solid item,

gaseous particles, smoke and dust etc. This mode is very useful where target object completely fills the spot size.

Two colour Mode: The basic concept of two colour mode is temperature measurement of the target object is done by

the ratio of two separate and overlapping of infrared bands. Two sensors are used in this type of pyrometer.

2.2 Operational Theory for 2-colour sensors

Accurate and repeatable temperature measurement is possible with the two colour ratio technology that does not

depend on emissivity of object. Basically a 2 colour sensor determines temperature from the ratio of radiated

energies in two separate wavelength bands (2 different colours).

Advantages of two colour pyrometer over single colour pyrometer which makes it suitable for industrial usage are as

follows:

ŸMeasurement of temperature is not affected by emissivity of object.

ŸMeasurement of object temperature is possible where dust, moisture and other contaminants are present in

surrounding environment.

ŸThe measuring object can be smaller than the spot size.

ŸThe pyrometer can be switched between 1-colour and 2-colour mode.

ŸThe spot is partially blocked or obscured.