Si50-203 Periodic Inspection

Semi-Hermetic Single Screw Compressor Version III 7

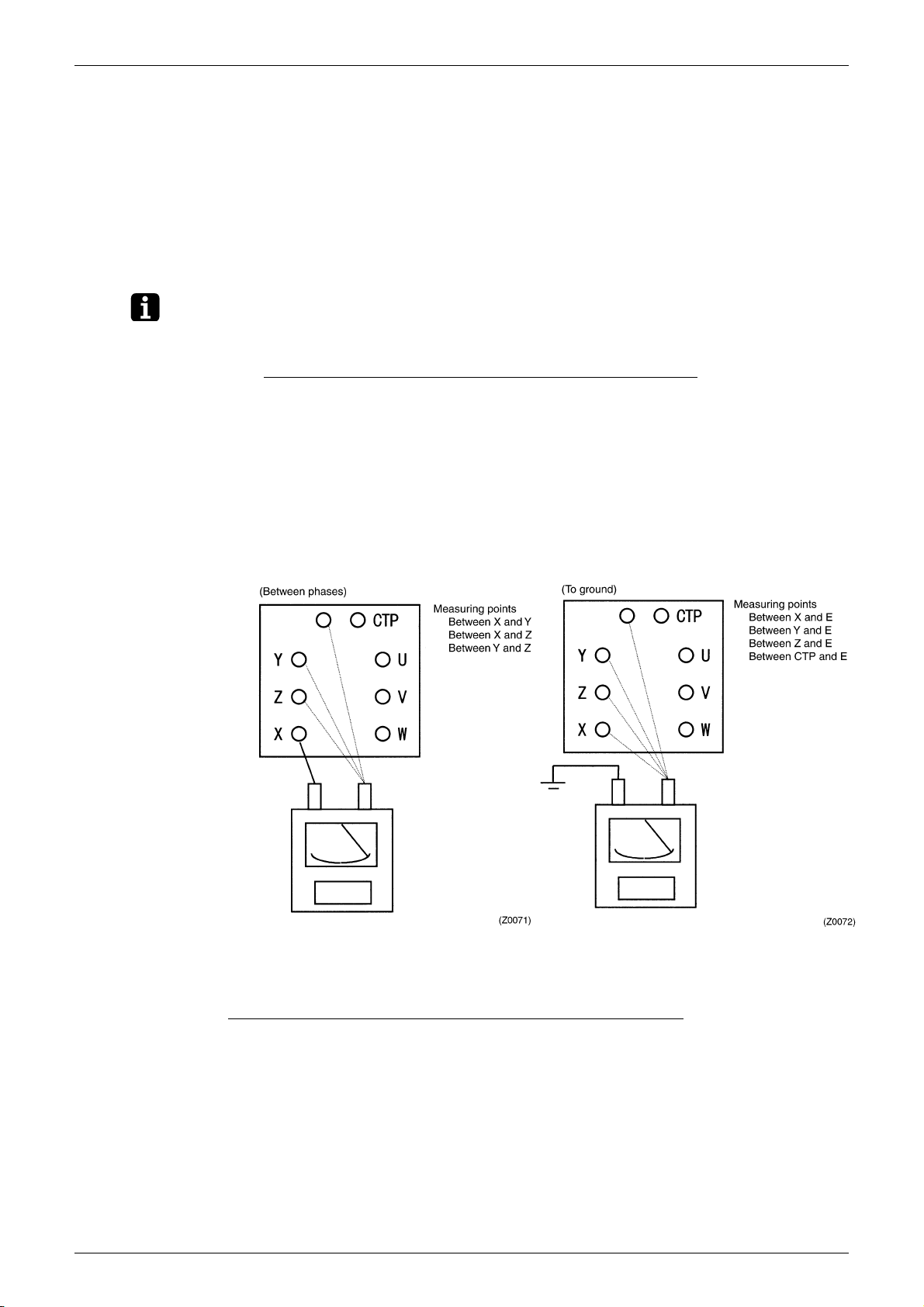

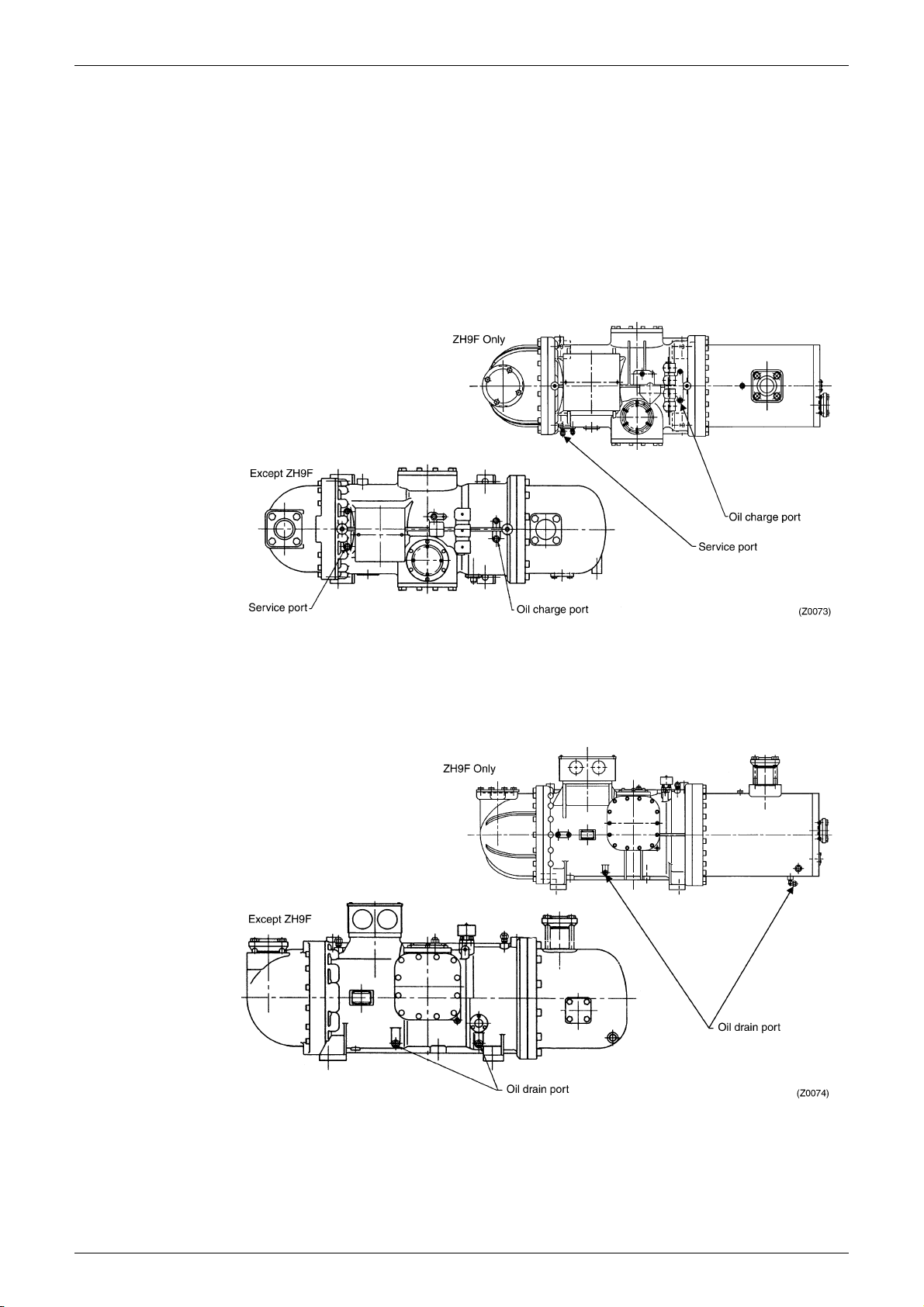

(4) Charging oil

Connect a vacuum pump to the suction service port (1/4" DCut) on the casing. While

evacuating the compressor, add oil from the discharge service port (3/8" DCut).

Use SUNISO 4GSD refrigeration oil (possible for use equal product) for refrigerant R22

and DAPHNE FVC68D refrigerant oil for refrigerant R407C and R134a.

Add the same amount of new oil as drained because some remains in the refrigerant and

on various parts inside. Drained oil contains refrigerant and appears to be more in

volume than actual oil amount. Stir the oil to evaporate the dissolved refrigerant before

measuring. Do not add more oil than necessary, since an excessive amount of oil

reduces oil separation efficiency and causes system problems. (Oil surface should be

visible on the level gauge during equipment operation.)

Take care not to let in air, or dust and other foreign particles remaining on the bottom of

the oil container.

When charging oil from a previously opened container, conduct vacuuming of the

compressor to remove moisture and air.

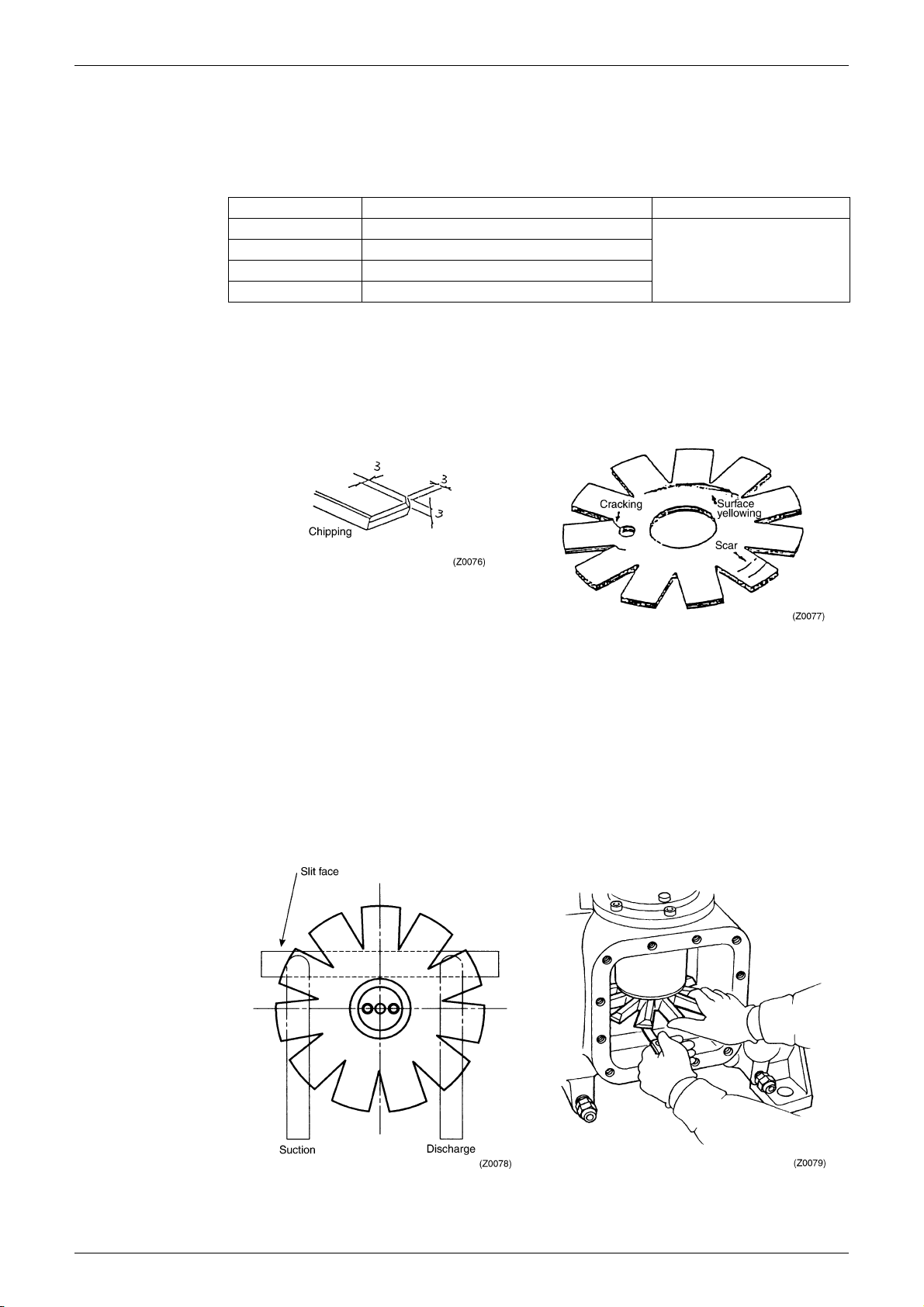

3. Inspecting The Gate Rotor

This inspection is done to check that no abnormal condition is present due to dust and other

foreign particles inside or harsh operating conditions of liquid compression, etc..

(1) Perform a pump down operation to reduce pressure inside the compressor.

(2) Release the internal pressure of the compressor.

Loosen the flare nut of the service port (with check valve) of the compressor (see Fig. 3-2).

Remove the partition lid, then tighten the flare nut to discharge refrigerant from the

compressor.

(3) Remove the side caps from both sides of the compressor. (Fig. 3-4)

Since a small amount of oil is still in the compressor, place drain pans under the side caps to

receive oil before opening the side caps.

Fig. 3-4 Side cap locations