5

SYSTEM OPERATION

The refrigerant used in the system is R-410A. It is a clear,

colorless, non-toxic and non-irritang liquid. R-410A is a

50:50 blend of R-32 and R-125. The boiling point at atmo-

spheric pressure is -62.9°F.

A few of the important principles that make the

refrigeraon cycle possible are: heat always ows from

a warmer to a cooler body. Under lower pressure,

a refrigerant will absorb heat and vaporize at a low

temperature. The vapors may be drawn o and condensed

at a higher pressure and temperature to be used again.

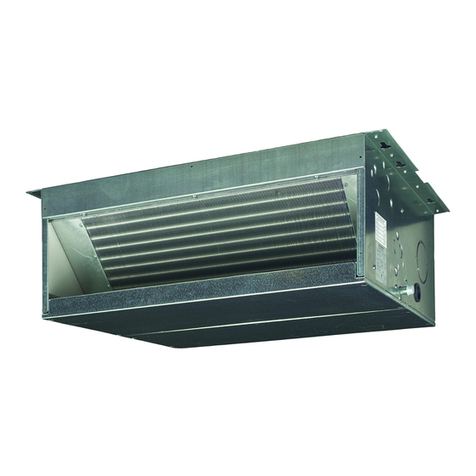

The indoor evaporator coil funcons to cool and

dehumidify the air condioned spaces through the

evaporave process taking place within the coil tubes.

Liquid refrigerant at condensing pressure and

temperatures, (270 psig and 122°F), leaves the outdoor

condensing coil through the drier and is metered into the

indoor coil through the metering device. As the cool, low

pressure, saturated refrigerant enters the tubes of the

indoor coil, a poron of the liquid immediately vaporizes.

It connues to soak up heat and vaporizes as it proceeds

through the coil, cooling the indoor coil down to about

48°F.

Heat is connually being transferred to the cool ns and

tubes of the indoor evaporator coil by the warm system air.

This warming process causes the refrigerant to boil. The

heat removed from the air is carried o by the vapor.

As the vapor passes through the last tubes of the coil, it

becomes superheated. That is, it absorbs more heat than is

necessary to vaporize it. This is assurance that only dry gas

will reach the compressor. Liquid reaching the compressor

can weaken or break compressor valves.

The compressor increases the pressure of the gas, thus

adding more heat, and discharges hot, high pressure

super-heated gas into the outdoor condenser coil.

In the condenser coil, the hot refrigerant gas, being

warmer than the outdoor air, rst loses its superheat by

heat transferred from the gas through the tubes and ns

of the coil. The refrigerant now becomes saturated, part

liquid, part vapor and then connues to give up heat unl

it condenses to a liquid alone. Once the vapor is fully

liqueed, it connues to give up heat which subcools the

liquid, and it is ready to repeat the cycle.

The heang cycle is accomplished by using a unique

tubular design heat exchanger which provides ecient gas

heang on natural gas fuel. The heat exchanger’s compact

tubular construcon provides excellent heat transfer for

maximum operang eciency.

The induced dra blower draws fuel and combuson air

into the burner and through the heat exchanger for proper

combuson.

Blower operaon is controlled by the integrated control

module. The module allows for eld adjustment of the

blower delay at the end of the heang cycle. The range

of adjustment is 90, 120, 150 or 180 seconds. The factory

delay sengs are 30 seconds delay on, 150 seconds delay

o.

DP14UM/DP16UM units are equipped with a direct spark

ignion system. Ignion is provided by a 25,000 volt

electronic spark. A ame sensor then monitors for the

presence of ame and closes the gas valve if ame is lost.

1. When the thermostat calls for connuous fan (G) with

out a call for heat or cooling, the indoor the fan has

a 7 second delay on make and energizes the “HEAT”

speed. The fan remains energized as long as the call

for fan remains without a call for heat or cooling. The

fan call “G” has a 60 second delay on break. Note:

When the Conguraon tab is broken, the connuous

fan mode “G” will have a 7 second delay on make and

a 60 second delay on break and the “COOL” speed tap

will be energized.

2. If a call for cool (Y) occurs during connuous fan, the

blower will switch over to “COOL” speed.

3. If a call for heat (W) occurs during connuous fan, the

blower will remain energized through the heat cycle

or unl “G” is de-energized.