192

GB

Contents

1. Introduction ...................................... 193

1.1 Description ................................... 193

1.2 Operator interface ........................ 194

1.3 Receiver-compatible products..... 195

2. Preparation ....................................... 196

2.1 Tooling required............................ 196

2.2 Opening the receiver.................... 196

2.3 Choosing the best place

to install the receiver..................... 196

2.4 Fixing the receiver in place........... 197

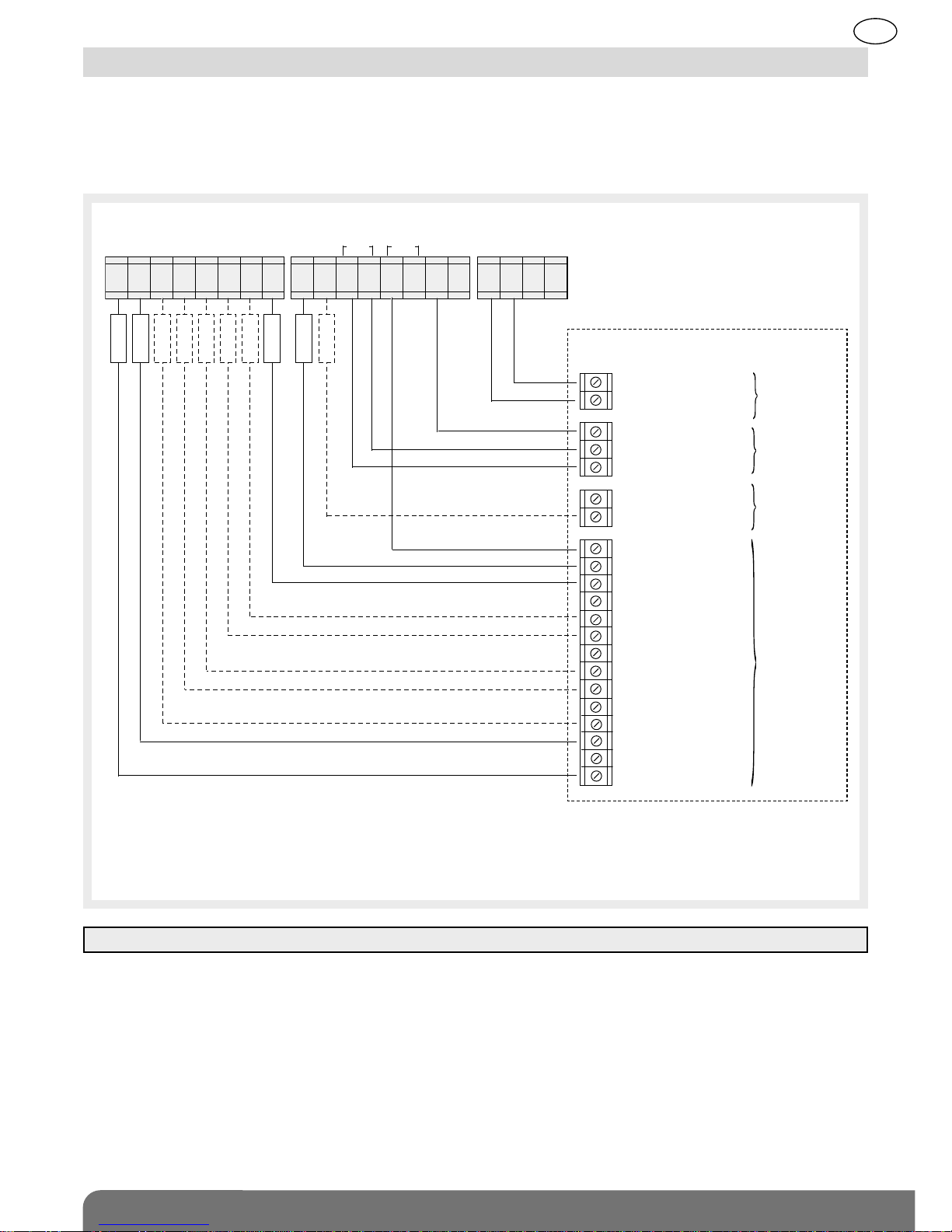

3. Installation ........................................ 198

3.1 Connections for hardwired

inputs/outputs .............................. 198

3.2 Connection example .................... 199

3.3 Dip switches for selecting

parameters.................................... 200

3.4 Accessing the installation menu .. 200

4. Product recognition programming 202

4.1 Programming the detectors ......... 202

4.2 Programming the control

devices.......................................... 205

4.3 Checking recognition

programming ................................ 206

5. Programming.................................... 207

5.1 Table of main factory-

programmed functions................. 207

5.2 Operating modes for intrusion

output relays (Z1 to Z8) ................ 207

5.3 Changing intrusion output relay

operation (Z1 to Z8)...................... 210

5.4 Operating modes for tamper

relays (TMP).................................. 211

5.5 Changing tamper relay

operation....................................... 211

5.6 Operating modes for fault

output relay (FLT).......................... 212

5.7 Changing fault output relay

operation....................................... 213

5.8 Operating modes for control

panel arm/disarm relay (RAC) ...... 214

5.9 Changing control panel arm/

disarm relay operation.................. 214

5.10 Operating modes for arm/

disarm input (ARS)...................... 215

5.11 Changing arm/disarm input

(ARS) operation .......................... 216

6. Erasing .............................................. 217

6.1 Erasing programmed detectors... 217

6.2 Erasing all programmed

detectors....................................... 217

6.3 Erasing programmed control

devices.......................................... 218

6.4 Erasing all programming

(return to factory configuration).... 219

7. Checking the installation:

test mode.......................................... 220

8. Use..................................................... 221

8.1 Consultation menu ....................... 221

8.2 Intrusion alarm display mode....... 222

8.3 Tamper alarm display mode......... 223

8.4 Fault display mode....................... 224

8.5 Consulting the list of events......... 225

9. Installation sheet (pullout) .............. 227

10. Technical data ................................ 229

Recommendations

The user must not attempt to access the siren’s internal parts, except areas described in this

manual. If the user does access these parts, the product guarantee will be considered null and

void and DAITEM shall not be held responsible for any problems. Touching the siren’s internal

parts and/or electronic components can damage the product. Furthermore, the siren is designed

in such a way that these parts and components do not need to be accessed for operation or

maintenance purposes.

IMPORTANT: installers should install the receiver according to the instructions provided in this

manual and in compliance with applicable standards. They are responsible for any problems

arising from lack of compliance with these instructions and applicable standards.