・Please read this instruction manual carefully.

・Please use product only as directed or severe damage to the product may occur.

・Not properly following these guidelines may result in extremely hazardous conditions that could cause electrical shock or fire.

Do not modify the product nor remove the protective enclosure. Under the protective enclosure are

contained high voltage and high temperature components during normal operation and after complete shutdown.

Avoid electric shock or burns by avoiding them.

・Under the protective enclosure are contained high voltage and high temperature components during normal operation and

after complete shutdown. Avoid electric shock or burns by avoiding them.

・Keep face and hands away at all times during operation to avoid unexpected injury.

・DANGER. Risk of fire, electric shock, and injury. DO NOT continually operate if there is smoke, odor, or irregular noise. Instead

immediately turn off the power and contact us. Do not attempt to repair it yourself because it is dangerous to do so.

・DANGER. Risk of fire, electric shock, and injury. DO NOT insert or drop any object in openings, this could cause unit failure or

severe hazardous conditions.

・DANGER. Risk of fire, electric shock, and injury. DO NOT use the product with condensation present, this could result in electric

shock or fire.

・This power supply is intended to be used as a component of a larger system of electrical equipment.

User is responsible for the safe design when this product is to be integrated in the equipment which requires

particularly high quality and reliability. There is a possibility to endanger persons or property by a failure or

malfunction of this product.

・Avoid sharp and sudden impacts to this unit such as dropping or damage will likely result.

・Ensure and maintain input voltage, output current, output power, ambient temperature, and humidity within specification or unit

may be damaged.

・Safety standards for this product are based on the condition that the product is to be used with forced air cooling. To prevent

the temperature of internal parts from exceeding the specification, ensure that the product is exposed to proper airflow when

installing

・Ensure that wires are properly secured to the input and output terminals as specified in this manual.

・Be sure to turn off the power before making the output connection.

・DO NOT use in a special environment (e.g. in the presence of strong electromagnetic field or erosive gas)

or environment where conductive foreign substance is present.

・DO NOT use or store product where condensation may occur due to moisture or humidity. For use in such conditions,

waterproof protection is necessary and must be installed.

・Do not operate under over current or short-circuit conditions for more than 10 seconds otherwise damage

and electrical insulation failure will likely result.

・No stress (e.g. twist, deflection) should be applied to the print board when the product is installed.

・Avoid impacts, such as dropping this product.

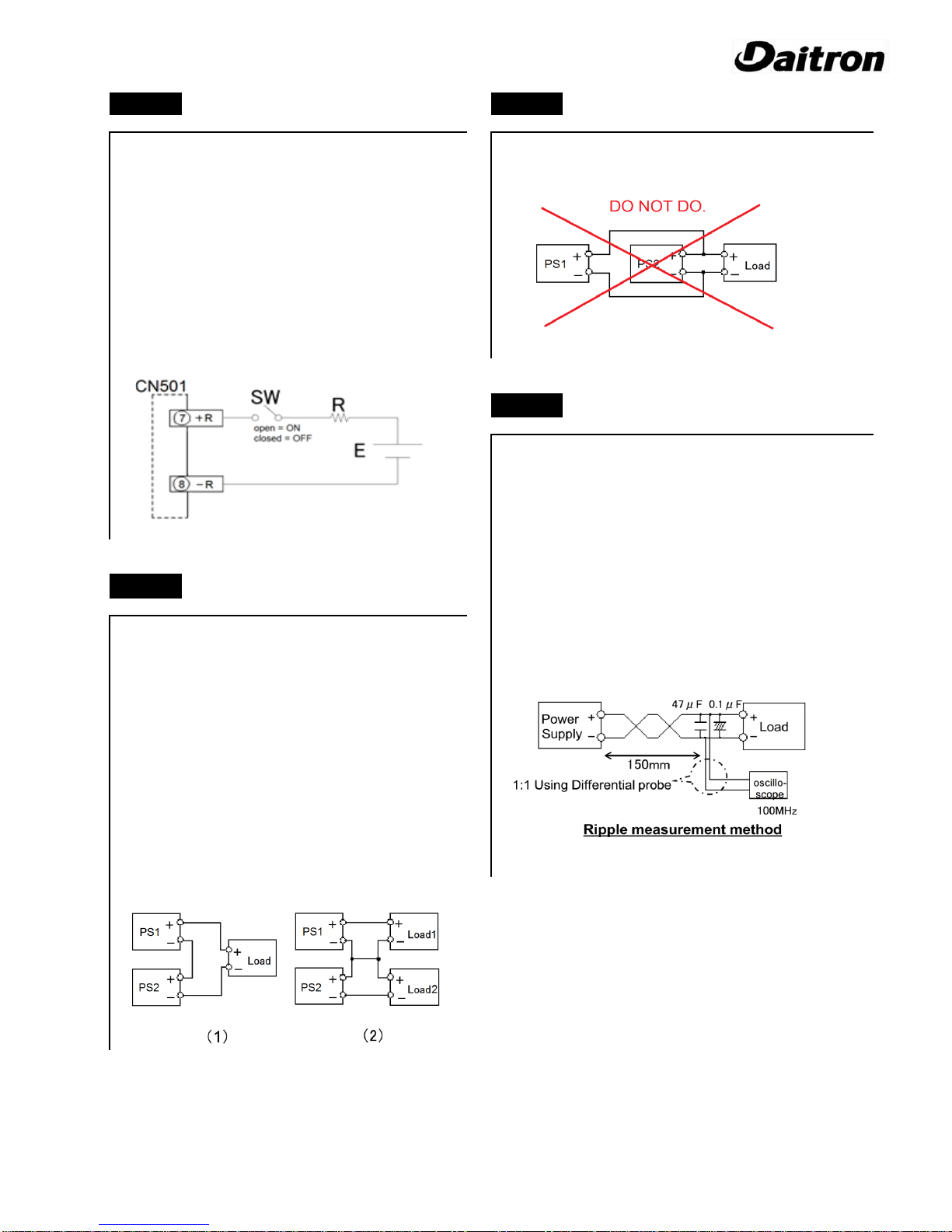

・Do not apply the load to signal connector CN501.

・DANGER. Output of this product is regarded as hazardous energy so this should not be accessible to end users.

・Use appropriate connecters for the terminal connection.

For the crimping of the contact, use the crimping tool recommended by the manufacturer.

・Prevent accidental contact with the output terminal of this product from dropped items such as tools by insuring proper

orientation and shielding/cover.

・Turn off the input power and ensure that the input and output terminal voltage drops to zero.

・This product uses fuses in the double pole/neutral line. When it is used for information processing equipment

(IEC/EN/UL60950-1), the following label must be provided for service engineers.

【CAUTION DOUBLE POLE / NEUTRAL FUSING 】

Special Instructions for IEC/EN/UL60601-1

CAUTION

・These products are not suitable for use in the presence of flammable anesthetic mixtures with oxygen or with nitrous oxide.

・These products have not been assessed to IEC/EN/UL60601-1-2(EMC), but EMC test data is available from us.