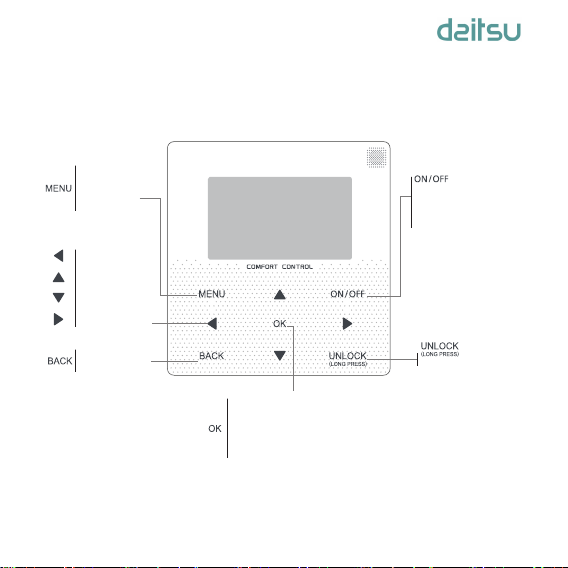

3.4 User Menu

6

When the current mode button is selected

(blinking), press "◄" and "►" to set a

mode or temperature, and then press "▼"

and "▲" to adjust the mode and set

temperature value. After setting, press the

"OK" button to save the setting and go

back to the home page; or press the

"BACK" button to go back to the previous

interface; if there is no subsequent

operation in 60s, the setting is saved

automatically, and the system returns to

the home page.

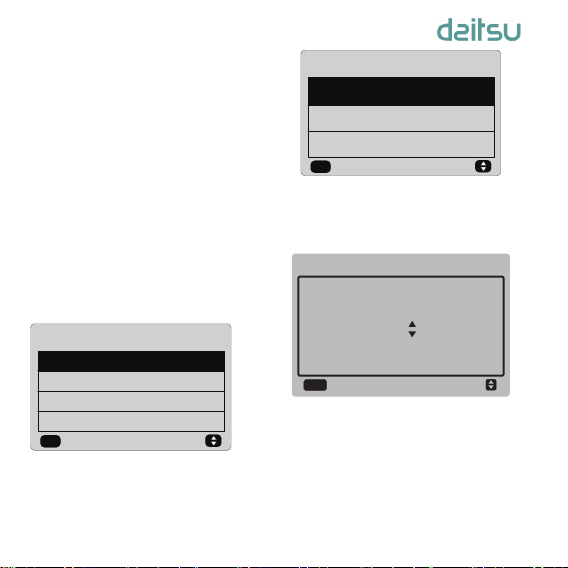

Select "USER MENU" to enter the user

menu. The interface display is as follows:

Select "QUERY" in the “USER MENU”

interface to access the query function. The

interface display and operation are as

follows:

The user first uses the "▼" and "▲"

buttons to select the address of module to

view (the offline address is skipped

automatically). Press the "OK" button to

access the next submenu or press "BACK"

to go back to the previous interface; during

operation on the menu page, press

"BACK" to go back to the previous

interface. After entry, the interface is

displayed as follows:

USER MENU

QUERY

TIMER

SILENT MODE

DOUBLE SETPOINT

1/2

ok

QUERY

USER MENU

TEMPERATURE COPENSATION

HEATER CONTROL(DISABLE)

HOT WATER SWITCH(DISABLE)

2/2

ok

TEMPERATURE COMPENSATION

SELECT THE QUERING ADDRESS

00

OK

QUERY

User Manual_________________________________________