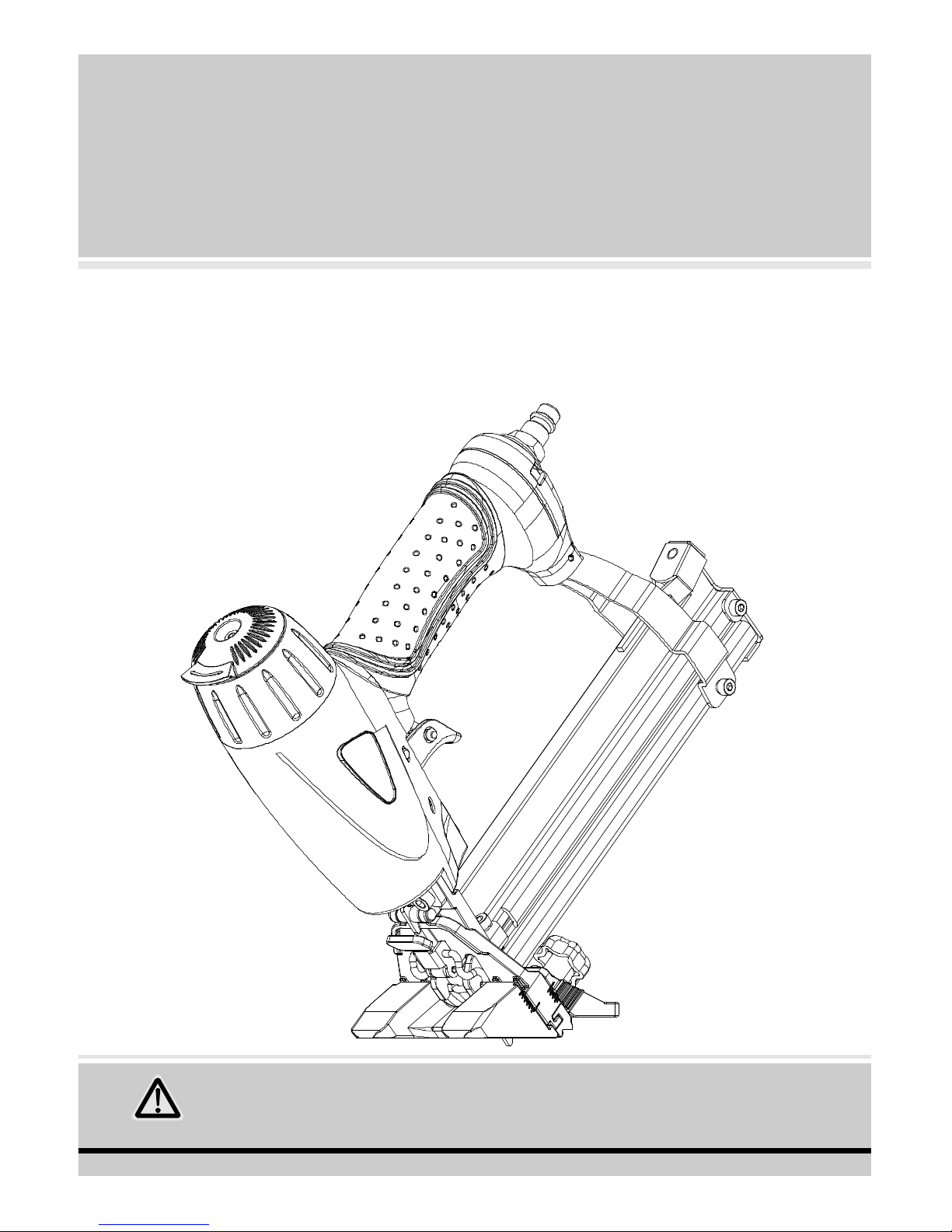

IMPORTANTINFORMATION

TO AVOIDSERIOUSPERSONALINJURY,ALL USERSAND

EMPLOYERS/OWNERSMUSTREADAND UNDERSTAND

ALLINSTRUCTIONSINTHISMANUAL BEFOREOPERATING

ORMAINTAININGTHISTOOL.

1

EXPLANATION OF

THENAILING ACTION

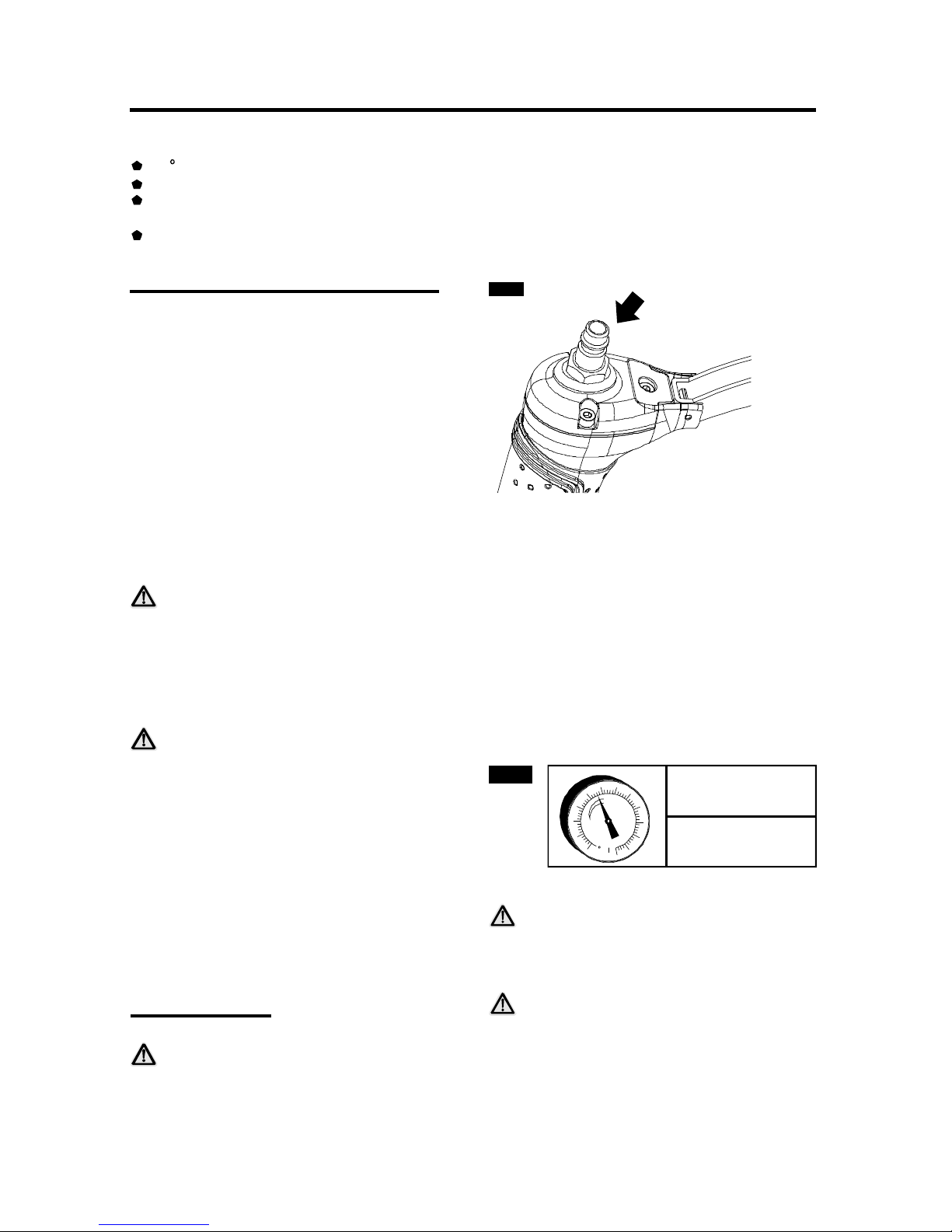

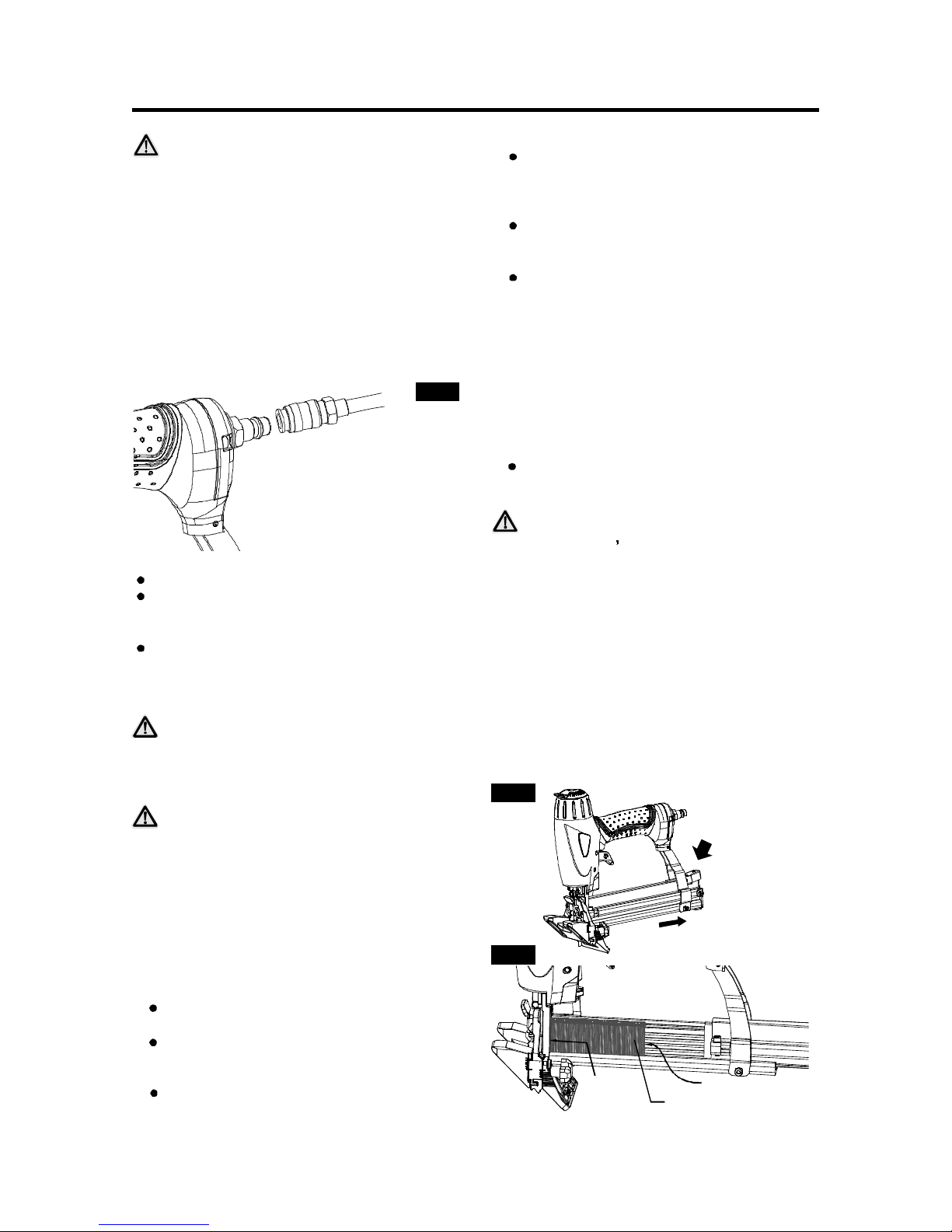

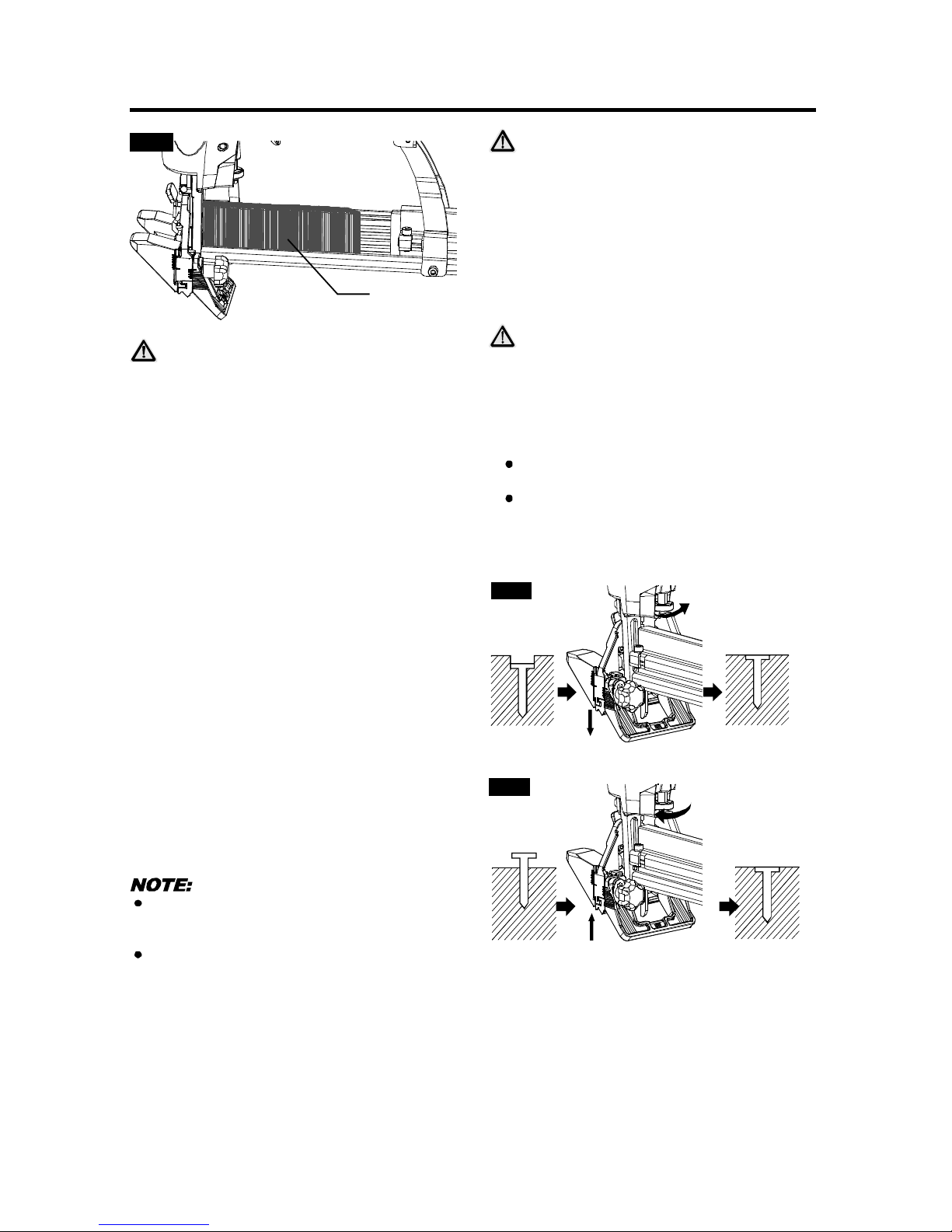

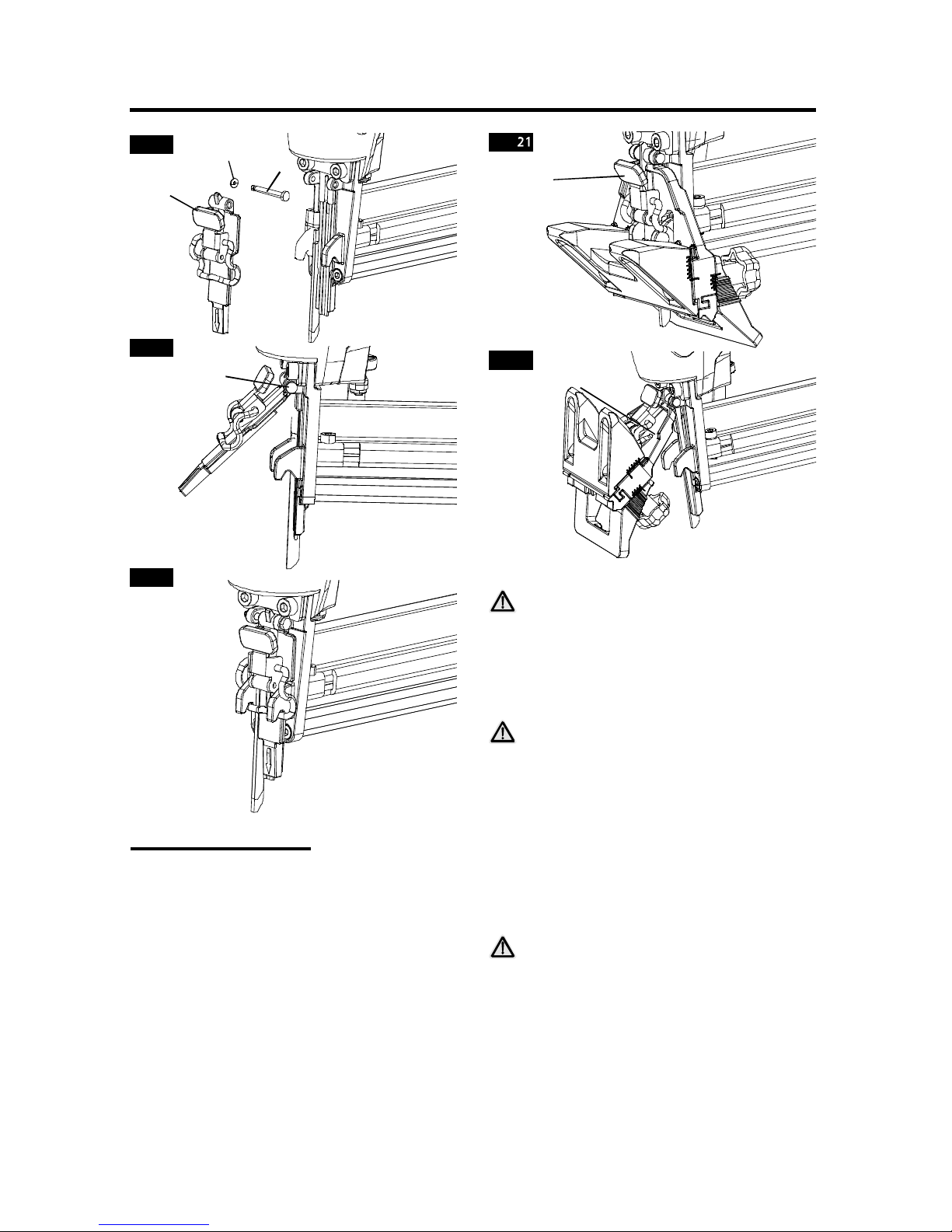

SINGLEACTUATION MECHANISM:

CONTACTACTUATIONMECHANISM:

FULLSEQUENTIALACTUATIONMECHANISM:

First,press thesafetyagainstthewood;next,pullthe

triggertodrivethefastener.Afterfasteningonce,

fasteningwillnotbepossibleagainuntilthetriggeris

releasedandpressedagain.

First,press thesafetyagainstthewood;next,pullthe

triggertodrivethefastener.First.Pullthetrigger;next,

pressthesafetyagainstthewoodtodrivethefastener.If

thetriggerisheldback,afastenerwillbedriveneach

time whenthesafety ispressedagainst thewood.

First,press thesafetyagainstthewood;next,pullthe

triggertodrive thefastener.Follow thesamesequence

tocontinuedrivingfasteners.

GENERAL SAFETYRULES

PERSONALSAFETY

Theemployermustenforcetheuseofsafety glasses by

thetooloperatorandothersinworkarea.

Always

wearearprotectiontoprotectyourearsfromloud noise,

Alwayswearheadprotectiontoprotectyourheadfrom

flying objects.

Adustmask, non-skidsafety

shoesandahardhatmustbeusedfortheapplicable

conditions.Wearafull faceshieldifyouareproducing

metalfilingsorwoodchips.

Donotwearlooseclothing or

jewelry.Containlonghair.Keepyourhair,clothing,and

glovesawayfrommoving parts.Loose clothes,jewelry,

or longhaircanbecaughtinmovingpartsandincreases

therisk ofinjury.

Donotusetoolwhiletiredor undertheinfluenceof

drugs,alcohol, or medication.Amomentofinattention

whileoperatingthetoolmay causeseriousinjury.

Keepfingersawayfrom

triggerwhennotdrivingfasteners,especiallywhen

connectingthetooltotheairsupply.

keepproperfooting and balance

at alltimes.Properfooting and balanceenablebetter

controlofthetoolinunexpectedsituations.

Entangledorsnarledhoses can

causealossofbalance or footinginadditionto

unintentionaltooloperation.Attachthehose tothe

structuretoreduce theriskoflossofbalance ofthehose

shifts.

ALWAYSWEAREARANDHEADPROTECTION.

USESAFETYEQUIPMENT.

DRESSPROPERLY.

STAYALERT, WATCH WHATYOUAREDOINGANDUSE

COMMONSENSE WHENOPERATING APOWERTOOL.

AVOIDUNINTENTIONALFIRING.

DONOTOVERREACH.

MAKESUREAIR HOSEISFREEOFSNAGSAND

OBSTRUCTIONS.DONOTATTACHANAIRHOSEOR

TOOLTO YOUR BODY.

WORKAREA

KEEPTHEWORK AREACLEANANDWELLLIGHTED.

Clutteredbenchesanddarkareas increasetherisksof

accidents.

suchas inthepresenceofflammable

liquids,gases,ordust.Thetool createsasparkwhich

may igniteflammableliquids,gasesordust.

Donotlet visitorshandlethe

tool. Allvisitorsshouldbekeptsafetyaway fromwork

area.

Respectthetoolas aworkingimplement.

DONOT OPERATETHETOOL INEXPLOSIVE

ATMOSPHERES,

KEEPVISITORSAWAY.

NEVERENGAGEINHORSEPLAYWITHTHETOOL.

WARNING

keepthismanualforthesafetywarningsandprecautions,

operating,inspection, maintenance. Keepthis manualand

thereceiptinasafeand dryplaceforfuturereference.

OPERATORSANDOTHERSINWORKAREAMUSTWEAR

SAFETYGLASSESWITH SIDESHIELDS. Whenoperating

thetool,alwayswearsafetyglasseswithsideshields,

andmake sureothersinworkareawearsafetyglasses.

Safety glassesmustconformtotherequirements of

AmericanNationalStandardsInstitute, ANSIZ87.1and

provideprotection againstflyingparticlesbothfromthe

frontand side.

TOOLUSEANDCARE

NEVERPOINT TOOLATYOURSELFOROTHERSIN

WORK AREA.

KEEPFINGERSAWAYFROMTRIGGERWHENNOT

DRIVING FASTENERSTO AVOIDACCIDENTALFIRING.

NEVERMODIFYORALTERATOOL.

KNOWTHISTOOL.

USEONLYFASTENERSTHATARERECOMMENDEDFOR

YOURMODELS.

CHECKFORMISALIGNMENT ORBINDINGOFMOVING

PARTS,BREAKAGEOF PARTS,ANDANYOTHERS

Alwaysassumethetoolcontains

fasteners.Neverpointthetoolat yourselfor others,

whetheritcontainsfastenersornot.If fastenersare

mistakenlydriven,itcanleadtosevereinjuries.Never

engageinhorseplaywiththetool. Respect thetool as a

working implement.

Nevercarrythetoolwithfingerontriggersince you

coulddriveafastenerunintentionallyandinjureyourself

or someoneelse.Alwayscarrythetoolbythehandle

only.

Doingsomaycause

malfunction andpersonalinjuries.

Readmanualcarefully,learnits

applicationsandlimitations,as well as thespecific

potentialhazardsrelatedtothistool.

Donotusethewrong fastenersorload

thefastenersincorrectly.