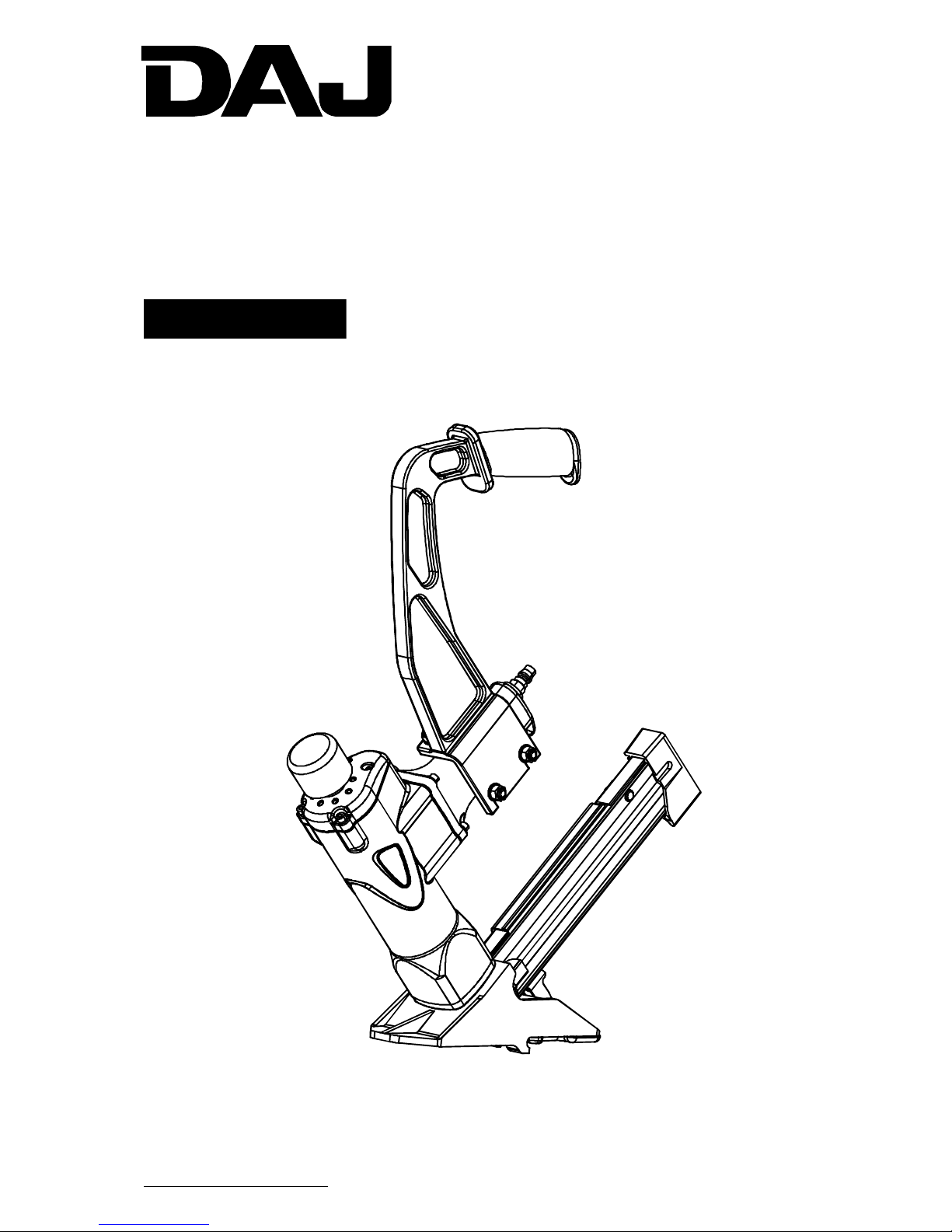

01

IMPORTANTINFORMATION

TOAVOIDSERIOUSPERSONALINJURY, ALL USERS

AND EMPLOYERS/OWNERSMUSTREADAND

UNDERSTANDALLINSTRUCTIONSINTHISMANUAL

BEFOREOPERATINGOR MAINTAINING THISTOOL.

GENERALSAFETYRULES

WORKAREA

KEEPTHEWORK AREACLEANANDWELLLIGHTED.

Cluttered benchesanddarkareasincrease therisksof

accidents.

suchas inthepresenceofflammable

liquids,gases,ordust.The toolcreatesasparkwhich

mayigniteflammableliquids,gasesordust.

Donotletvisitorshandlethe tool.

Allvisitorsshouldbe keptsafetyawayfromworkarea.

Respectthetoolasaworkingimplement.

DO NOTOPERATETHETOOLINEXPLOSIVE

ATMOSPHERES,

KEEPVISITORSAWAY.

NEVERENGAGEINHORSEPLAY WITHTHETOOL.

Keepthismanualforthe safetywarningsandprecautions,

operating, inspection,maintenance. Keepthismanual and

thereceiptinasafeanddryplaceforfuturereference.

WARNING

STAYALERT,WATCH WHATYOUAREDOINGANDUSE

COMMON SENSEWHENOPERATING APOWERTOOL.

AVOIDUNINTENTIONALFIRING.

DONOTOVERREACH.

MAKESUREAIRHOSEISFREEOFSNAGSAND

OBSTRUCTIONS.DONOTATTACHANAIRHOSEOR

TOOLTOYOUR BODY.

Donotuse toolwhiletired orundertheinfluenceof

drugs,alcohol,ormedication.Amomentofinattention

whileoperating thetoolmay causeseriousinjury.

Keep fingersawayfrom

triggerwhennotdrivingfasteners,especiallywhen

connecting thetooltothe airsupply.

keep properfootingandbalance

atall times.Properfootingand balanceenablebetter

controlofthetoolinunexpectedsituations.

Entangledorsnarledhoses can

causealoss ofbalance orfootinginadditionto

unintentionaltooloperation.Attachthehose tothe

structuretoreduce theriskofloss ofbalance ofthehose

shifts.

NEVERPOINTTOOLATYOURSELFOROTHERSIN

WORK AREA.

NEVERMODIFY ORALTERATOOL.

KNOWTHISTOOL.

Alwaysassumethe toolcontains

fasteners.Neverpointthetoolatyourselforothers,

whetheritcontainsfastenersornot.If fastenersare

mistakenlydriven,itcanlead tosevereinjuries.Never

engageinhorseplay withthetool. Respectthetool as a

working implement.

Doingso maycause

malfunctionandpersonalinjuries.

Readmanualcarefully,learnits

applications andlimitations,as wellas the specific

potentialhazardsrelatedtothistool.

USEONLYFASTENERSTHAT ARERECOMMENDEDFOR

YOUR MODELS.

CHECKFORMISALIGNMENTORBINDINGOFMOVING

PARTS,BREAKAGEOFPARTS,ANDANYOTHERS

CONDITION THATMAYAFFECTTHETOOL'SOPERATION.

NEVERUSETOOLWHICHISDEFECTIVEOROPERATING

ABNORMALLY.

MAINTAIN TOOLS WITHCARE.

NEVERCARRYTHETOOLBYAIRHOSE.

STORETOOLSOUTOFTHEREACHOFCHILDREN AND

OTHERUNTRAINEDPEOPLE.

Donotusethewrongfastenersorload

thefastenersincorrectly.

Ifdamaged, have thetool servicedbeforeusing.Many

accidentsarecausedbypoorlymaintainedtools.

Ifthe toolappearstobeoperating

unusually,making strange noises,orotherwiseappears

defective,stopusing itimmediatelyandarrangefor

repairsby anauthorized servicecenter.

Keepthetoolcleanand

lubricatedforbetterandsaferperformance.

Toolsaredangerousinthe

handsofuntrained users.

TOOLUSEANDCARE

PERSONALSAFETY

Safetyglassesmustconformtothe requirementsof

AmericanNationalStandards Institute,ANSIZ87.1and

provideprotection againstflying particles bothfromthe

frontandside.The employermustenforcetheuseof

safetyglassesbythetooloperatorand othersinwork

area.

ALWAYS WEAREARANDHEADPROTECTION.

USESAFETYEQUIPMENT.

DRESSPROPERLY.

Always

wearearprotection toprotectyourearsfromloudnoise,

Alwayswearheadprotectiontoprotectyourheadfrom

flyingobjects.

Adustmask, non-skidsafety

shoesandahardhatmustbeusedfortheapplicable

conditions. Wearafull faceshieldifyouareproducing

metalfilings orwood chips.

Donotwearlooseclothing or

jewelry.Containlong hair.Keepyourhair,clothing,and

glovesaway frommoving parts.Looseclothes, jewelry,

orlong haircanbecaughtinmovingpartsandincreases

theriskofinjury.

OPERATORSAND OTHERSINWORK AREA MUSTWEAR

SAFETY GLASSESWITHSIDESHIELDS. When operating

thetool, alwayswearsafetyglasseswithsideshields,

and makesureothersinworkareawearsafetyglasses.

www.chinaairtool.com

MODEL:06A-618BR