July 31, 2019 4 Part#: 212-0042

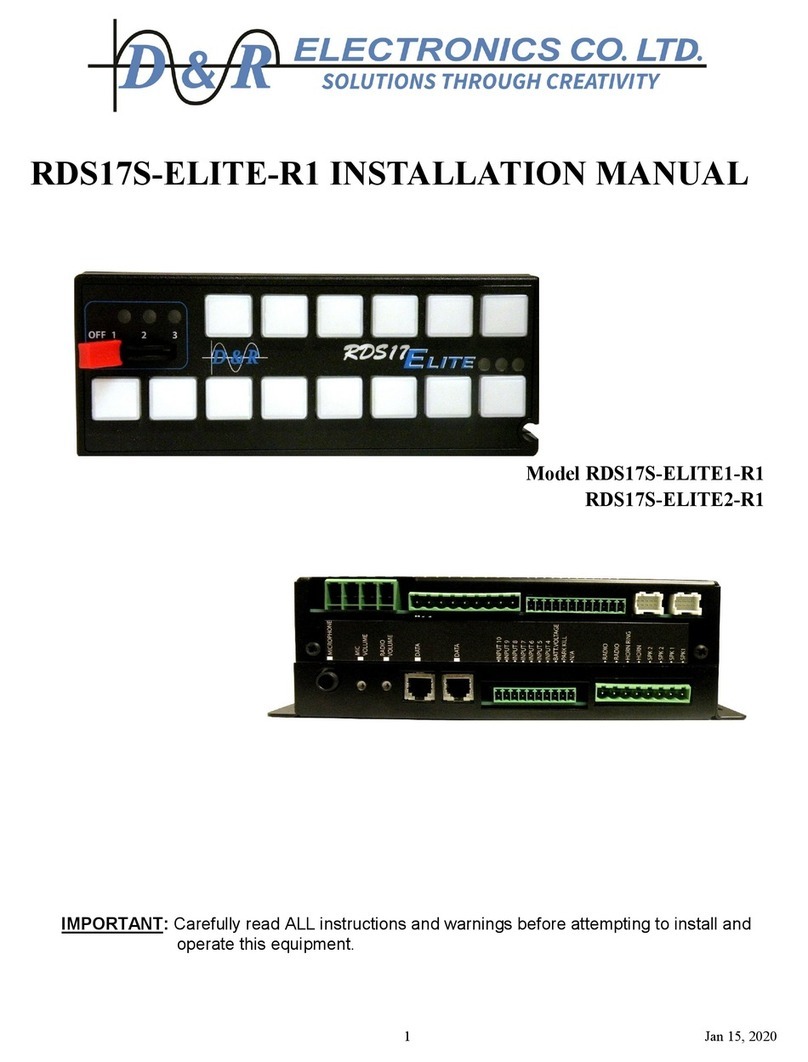

RDS17S - Siren Rear Panel wiring connection points

GND – The ground terminal should be connected to the negative terminal of the battery or vehicle chassis

using a black 8 gauge wire. When connecting the ground wire, ensure that it is physically secured to

the chassis or battery terminal. Ensure the electrical connection is not obstructed by paint on the

chassis. Never run two ground cables for one ground connection, thus creating a ground loop.

12V – This is the main power connection and should be connected to the positive terminal of the battery

using an 8 gauge wire. A fuse or circuit breaker should be installed on this wire in a location as close

to the battery as possible.

Outputs 1 to 3 (+12V outputs) – These 3 outputs can be used to control light modules or other devices.

These outputs are controlled by the SS1, SS 2, and SS 3. High power loads can be connected to

these outputs as they have a higher output current rating than the remaining outputs (see specifica-

tions).

Outputs 4 to 8 (+12V outputs) – These outputs are used for triggering and for loads that draw less

than 8A. These outputs are controlled by SW3, SW6, SW7 and SW8.

Output 9 (Relay Contact output)

Output 9 can be set to provide either +12VDC or GND depending on the jumper setting of J5. The

maximum current load for this pin is 5A and it is controlled by SW8.

Output 9 can also be configured to behave as path interrupt in this mode input 9 and Out 9 are nor-

mally connected through. When the relay is activated (called by the touch pad), then the path be-

tween the input and output will be interrupted.

NOTE: in this mode the jumper on J5 must be removed.

P. KILL – Park Kill input is +12VDC or GROUND activated, and used to immediately disable all siren

tones when a vehicle is shifted into park. Connect the P. KILL pin to the vehicle transmission neutral

safety switch signal wire. This wire should output a signal when the vehicle is shifted into park.

Output 10 & 11 ( HLF +12V outputs) – the outputs from these terminals can be used to alternate

flash the headlights on a vehicle. The maximum load for these outputs is 8A each. The output is

programmed according to table 1-11 and controlled by SW4.

Output 13 & 14 (+12V outputs) – Activated by SW16, when the arrowstick is enabled in “911 mode”

are used to activate the “LEFT ARROW”, “RIGHT ARROW” and “CENTER OUT” functions.

IGN – Ignition input should be connected to the vehicle ignition signal that outputs 12V only when the igni-

tion is “ON”.

HORN RING – This is an input, it uses the horn activation signal to trigger the siren while the unit is in

standby.

HORN – This is an output used to activate the regular vehicle horn during normal vehicle operation (no

siren or air horn).

MICR –Microphone input., for the P.A.

1.

RADIO – Connect the two (2) RADIO pins to either side of the two-way radio speaker in the vehicle. This

is for the Radio Rebroadcast feature, any incoming radio signal is sent to the PA system, by press-

ing SW10., this must be programmed see figure 6 interclear/Radio programming.

SPEAKER – Speaker output pins to be connected to a DRSC100 or compatible speaker.

Touch pad

The RDS17S is a remote keypad model, this allows for the installation of the siren “main box” in an remote

location. This is useful when the space in a vehicle’s console does not permit the mounting of the whole

siren and touch pad combination. The keypad layout is configured when the order is placed by the cus-

tomer.