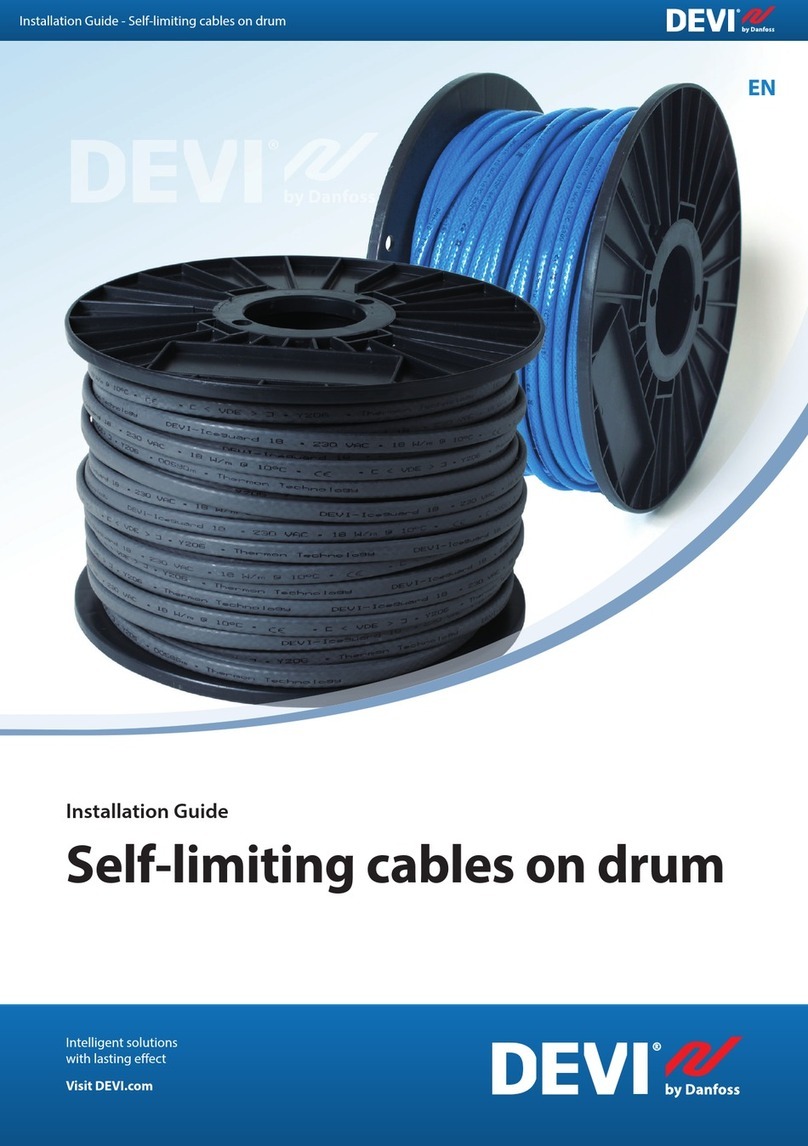

EN Ready-making of the cold tail

Drawing Designation Tools

- Outer sheath removed

Remove 50 mm of the outer sheath Knife and wire

cutter

Brown

Blue

- Primary insulation removed

Remove the outermost 50 mm of the

secondary insulation too.

Knife and wire

cutter

10

Brown

Blue

Yellow/Green

- Wire insulation removed

Strip off approx. 10 mm of each of

the three conductors. Provided two

conductor cold tail with screen is used,

the screen is released and twisted.

Wire cutter

Assembly process

Drawing Designation Tools

Brown

Blue

Yellow/Green

- Rivets added and squeezed

Now the two cables are ready for assembly.

On the cold lead 1,0 mm² rivets are squeezed

with an appropriate pliers onto the two

conductors and 1,0 mm² are squeezed onto

the ground wire (yellow/green).

Crimping pliers

Brown

Blue

Yellow/Green

- Heat shrink tube (Length =

150 mm) put over the cold lead

Now, put the 19/5 heat shrink tube

(length = 150) over the outer sheath of the

cold tail.

- Heat shrink tube (length =

45 mm) put over the conductors

Now, put the two 4/1 heat shrink tube

(length = 45 mm) over the two conductors

(L (Brown) + N (Blue)) of the cold tail with

the squeezed 1,0 mm² rivets.

- Heat shrink tube put over

the heating cable

Now, put the 9/3 heat shrink tube (Length

85 mm) over the outer sheath of the

heating cable. Be aware in this process that

the twisted and released aluminum foil

screen do not provide any damages to the

heat shrink tube.

Installation Guide Connection kit - cable to cold lead + end termination (Pipeheat)

DEVI10