Installation Guide Ready-made self-limiting cable ECpipeheat 10 V3

© Danfoss | 2022.01 | 508091499 / AN40004190359601-010101

EN

1 Introduction

In this installation guide, the phrase“heating cable”refers

to ready-made self-limiting cable ECpipeheat 10 V3.

To get the full installation guide, warranty registration,

product information, tips & tricks, addresses, etc.visit

www.danfoss.com

.

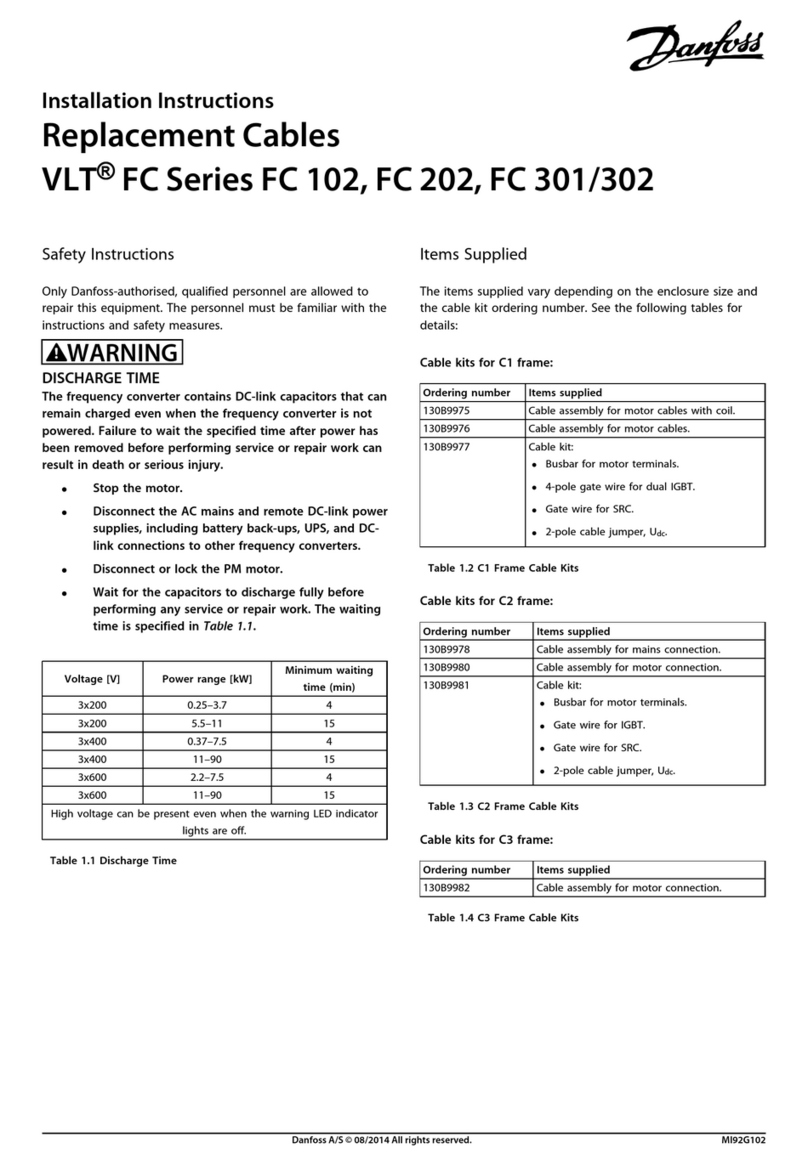

2 Safety instructions

Heating cables must always be installed according to

local building regulations and wiring rules as well as the

guidelines in this installation manual.

• De-energize all power circuits and do not connect the

plug to an outlet until installation is completed.

• Residual current device (RCD) protection is required.

RCD trip rating is max. 30 mA.

• Maximum fuse size is 10 A.

• In case of plug cutting the screen from each heating

cable must be connected to earthing terminal or

plug must be connected to outlet, securing a reliable

grounding of the screen in accordance with local

electricity regulations.

• In case of plug cutting heating cables must be

connected via a switch providing all pole disconnection.

• The heating cable must be equipped with a correctly sized

fuse or circuit breaker according to local regulations.

• Never exceed the maximum heat density (W/m or W/m²)

for the actual application. Refer to Application Guide.

• Heating cable must be used together with an

appropriate thermostat to secure against overheating

and reduce energy consumption.

• The cold lead is not allowed to be replaced by the user. If

cold lead is damaged, it must be replaced by service agent

or similarly qualified persons in order to avoid a hazard.

• This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge

if they have been given supervision or

instruction

concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play

with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

CAUTION: If the cable is installed inside a drinking water

pipe, it is a precondition for the certification for in drinking

water application, to secure that the water does not reach

a temperature of 23 °C or above.It is a must to secure the

installation by a thermostat with a set-point of +5 °C.

The presence of a heating cable must

• be made evident by affixing caution signs in the fuse

box and in the distribution board or markings at the

power connection fittings and/or frequently along the

circuit line where clearly visible (tracing).

• be stated in any electrical documentation following the

installation.

3 Installation guidelines

• It is not recommended to install heating cables at

temperatures below -5°C.

• Heating cable bending diameter must be minimum

50 mm (to the inside of the cable).

• Do not bend and pull connections.

• Ensure that the cable is sufficiently fixed and mounted

according to the installation guide.

• The heating cables must be temperature controlled.

See safety instructions.

• Ensure controllers and sensors are connected

according to the applicable installation guide and/or

application guide.

• Measure, verify and record insulation resistance during

installation.

• Persons involved in the installation and testing of electrical

trace heating systems shall be suitably trained in all special

techniques required. Installations are intended to be

carried out under the supervision of a qualified person.

4 Application/Product overview

Pipe frost protection Tank frost protection

ECpipeheat 10 V3

ECpipeheat 10 V3 is designed for preventing frozen water

pipes. ECpipeheat 10 V3 can be used on the outside of the

water pipe and will heat through the pipe and prevent it

from freezing. ECpipeheat 10 V3 can also be installed inside

water pipe, by using the dedicated fitting. It is certified

to be suitable for drinking and common water pipes and

is designed to be installed on pipe in all countries and

inside pipe in certified countries (DK, FI, SE, NO, RU), on the

condition that water temperature is always kept below 23 °C.

On water pipe installation In water pipe installation