MG.03.F5.02-VLT is a registeredDanfosstrademark

02/00

The control cables must be screened cables.

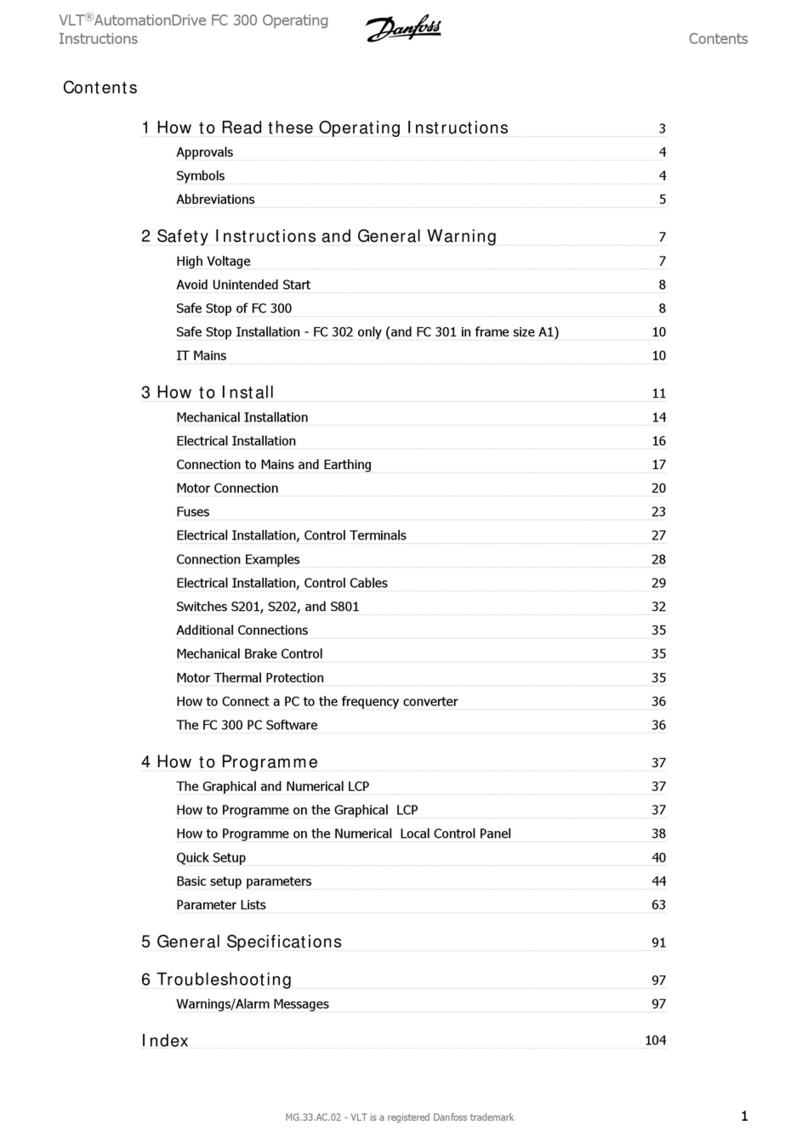

X101: Terminal block for analog/digital control signals

Terminal Function Example

No.

1 Analog input (0-20 mA) Feedback

signal

2 Analog (0-10 V)/digital input 2 Speed

reference

3 Digital input (or pulse) 3 Reset

4 Digital input (or precise stop) 4 Start

5 Digital input (other) 5 Jog (fixed

speed)

6 24 V DC supply for digital inputs (max. 50 mA)

7 10 V DC supply for potentiometer (max. 15 mA)

8 0 V for terminals 1-7 and 9

9 Analog (0-20 mA)/digital output Fault

indication

X100: Terminal block for data communication

Terminal Function

No.

1 P RS 485 for connection to

2 N RS 485 bus or PC

3 5 V DC Supply for RS 485 bus

4 0 V DC

TT

TT

Table Bable B

able Bable B

able B

Reset (pushbutton)

Start

Jog

Speed reference

Terminals

1: Analogue input

2: Analogue input

3: Digital input

4: Digital input

5: Digital input

6: 24 V DC supply

7: 10 V DC supply

8: 0 V

9: Output

-Reset to be closed short time for

resetting fault trips

-Start to be closed for changing

to run mode

- Jog will run at fixed speed

while closed (10 Hz)

-Speed reference (0-10 V)

determines speed while in run mode

Fig. 1Fig. 1

Fig. 1Fig. 1

Fig. 1

Factory setting

TT

TT

Table Aable A

able Aable A

able A

Fig. 2Fig. 2

Fig. 2Fig. 2

Fig. 2

175R0129

➊Mechanical installationMechanical installation

Mechanical installationMechanical installation

Mechanical installation

Install the FC motor with adequate access for routine

maintenance. Adequate space, particularly at the fan

inlet (50 mm), is necessary to facilitate airflow.

Where several FC motors are installed in close

proximity, care must be taken to ensure that there is

no recirculation of exhausted warm air.

NB!NB!

NB!NB!

NB!

Ambient temperature

To avoid the FC part getting overheated, the

ambient temperature is not to exceed 40 °C

and the 24-hour average temperature is not to exceed

35 °C. If the ambient temperature is in the range of

40 °C - 55 °C, a reduction of the service life of the FC

part is to be expected. For further information, please

see the section on derating in the Design Guide.

NB!NB!

NB!NB!

NB!

Bearings

Ball and roller bearings are despatched from

the works fully charged with grease. Shielded

bearings have sufficient grease for an operating life of

at least two years in normal ambient temperatures,

providing there is little or no leakage.

Tapping of fitments onto the motor shaft,

with a hammer or mallet, causes bearing

damage. This results in increased bearing

noise and a significant reduction in bearing life.

VLVL

VLVL

VLTT

TT

T®®

®®

®DriveMotor FCM 300 Quick SetupDriveMotor FCM 300 Quick Setup

DriveMotor FCM 300 Quick SetupDriveMotor FCM 300 Quick Setup

DriveMotor FCM 300 Quick Setup

➋Electrical connectionsElectrical connections

Electrical connectionsElectrical connections

Electrical connections

Remove the inverter box cover, which is held by four

screws, to obtain access to the terminals.

Remove the detachable terminal plugs from the

terminal blocks X100 and X101 to obtain access to

the mains terminals.

Lift only the corner of the black plastic cover by the

cable entries to expose the mains terminals L1, L2and

L3(see fig. 2).

NB!NB!

NB!NB!

NB!

Do not lift or remove the entire plastic

cover. The voltage on the FC motor is

dangerous and may lead to material

damage, serious injury or it may be fatal.

NB!NB!

NB!NB!

NB!

Mains terminals L1, L2and L3:

Make sure that your mains supply

corresponds to the voltage required by the FC

motor (see inverter label), TT and NT mains .

Connect the three mains phases to terminals L1, L2and

L3and the earth to the separate terminal provided.

TT

TT

Tightening Tightening T

ightening Tightening T

ightening Toror

oror

orquesques

quesques

ques

L1, L2, L3 FCM 305-340 0,5-0,6 Nm

L1, L2, L3 FCM 355-375 1,2-1,5 Nm

Earth ground FCM 305-375 3,4 Nm

Fixed wires:

Rated temperature for fixed wires min. 60° C or

140° F. Use copper conduction only.

NN

NN

NB!B!

B!B!

B!

You cannot change the rotation direction of the

motor by shifting around the phases. The

direction of rotation is clockwise by default.

Another direction of rotation can be programmed, see

the Design Guide.

Prefuses Max.Prefuses Max.

Prefuses Max.Prefuses Max.

Prefuses Max.

UL1)

FCM 305-322 10A

FCM 330-340 15A

FCM 355-375 25A

IEC1)

FCM 305-375 25A

1) Type gG prefuses must be used. If you want to maintain

UL/cUL you must use prefuses of the type Bussmann

KTS-R 500 V or Ferraz Shawmut, type ATMR (max. 30A). The

fuses must be placed for protection in a circuit that is capable of

supplying a maximum of 100,000 amps RMS (symmetrical), 500

V maximum.

ContrContr

ContrContr

Control terminalsol terminals

ol terminalsol terminals

ol terminals

For information on terminal blocks X100 and X101, please

see table A and B.

RS 485 switchRS 485 switch

RS 485 switchRS 485 switch

RS 485 switch

For terminating an RS 485 interface serial communication,

the bus must be terminated by a resistor network at both

ends. This is provided by setting both switches to ON.

LEDsLEDs

LEDsLEDs

LEDs

The FC motor has five LEDs which indicate the status of

the FC motor:

LED 300 (red): Fault trip

LED 301 (yellow): Warning

LED 302 (green): Power on

LED 303-304 (green): Communication

EMC-corrEMC-corr

EMC-corrEMC-corr

EMC-correct installationect installation

ect installationect installation

ect installation

The control cables must be screened cables to ensure

EMC-correct electrical installation.

Connect the screen to earth at both ends.

Avoid installation with twisted screen ends (pigtails), since

this ruins the screening effect at high frequencies. Use

cable clamps instead.

➌Start the FC motorStart the FC motor

Start the FC motorStart the FC motor

Start the FC motor

Connect mains. LED 302 (green) lights up to indicate

that the power is on. In Profibus versions, LED 303

will flash. For further information on Profibus, please

see the Profibus manual.

Connect terminal 4 and 6 to the start button (see fig.

1).

Connect terminal 2, 7 and 8 to the potentiometer

(see fig. 1).

The voltage on the FC motor is

dangerous when the motor is connected

to mains. Incorrect installation of the FC

motor may lead to material damage or

serious injury or it may be fatal.

➍Mount the inverter box cover.

Fastening torque: 2.2 - 2.4 Nm

Use the start button to start the FC motor and adjust the

speed by means of the potentiometer.

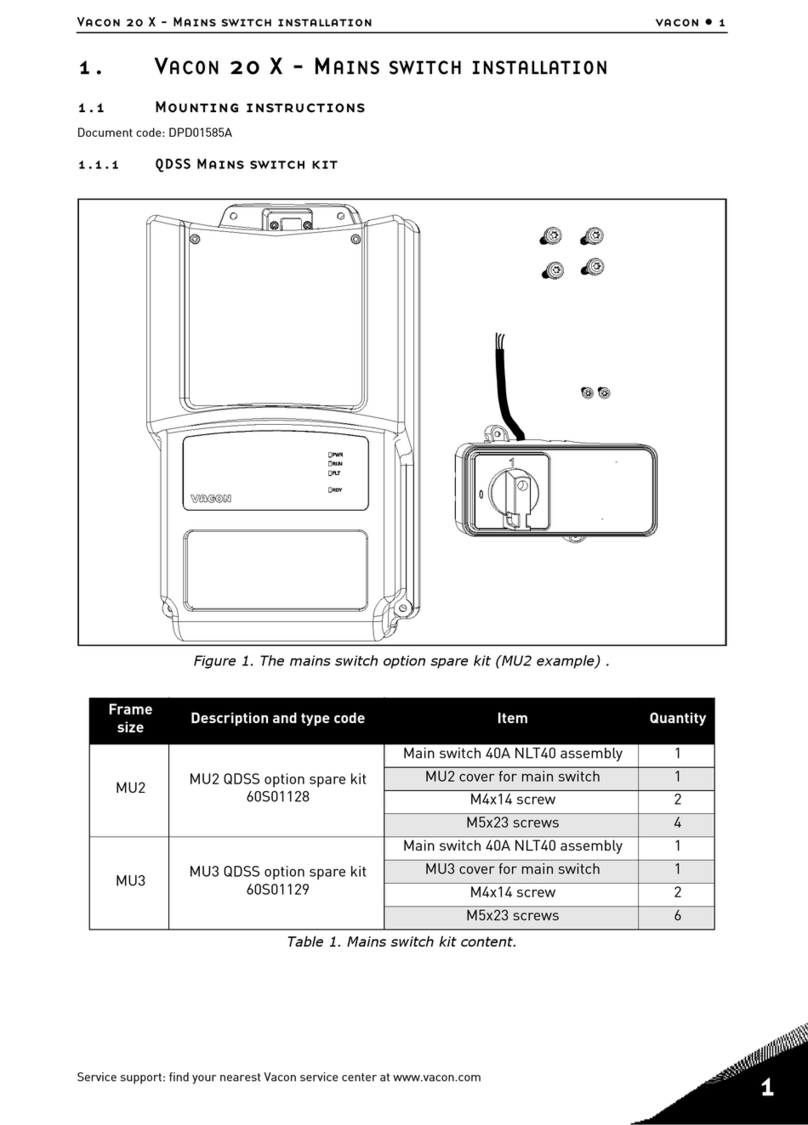

Motors type B14 & B34 mounting

1) Max length of the fixing bolts / screws

penetrating the B14 flange:

FCM 305-307 (frame 80) = 11.0 mm

FCM 311-315 (frame 90) = 11.5 mm

FCM 322-330 (frame 100) = 15.0 mm

FCM 340 (frame 112) = 15.5 mm

FCM 355-375 (frame 132) = 17.0 mm

2) The following precautions must be taken:

a) A non-setting jointing and sealing

compound must be used to seal the bolt /

screw threads in the motor flange.

b) A soft copper washer must be inserted

underneath the bolt / screw head.

c) The joint face between the motor flange

and the mounting must be sealed using

non-setting jointing and sealing compound.

For B34 types where it is only foot mounted, the flange

is not used. Then the bolts should be fitted in

accordance with parts a) & b) of item 2 to maintain the

IP55.