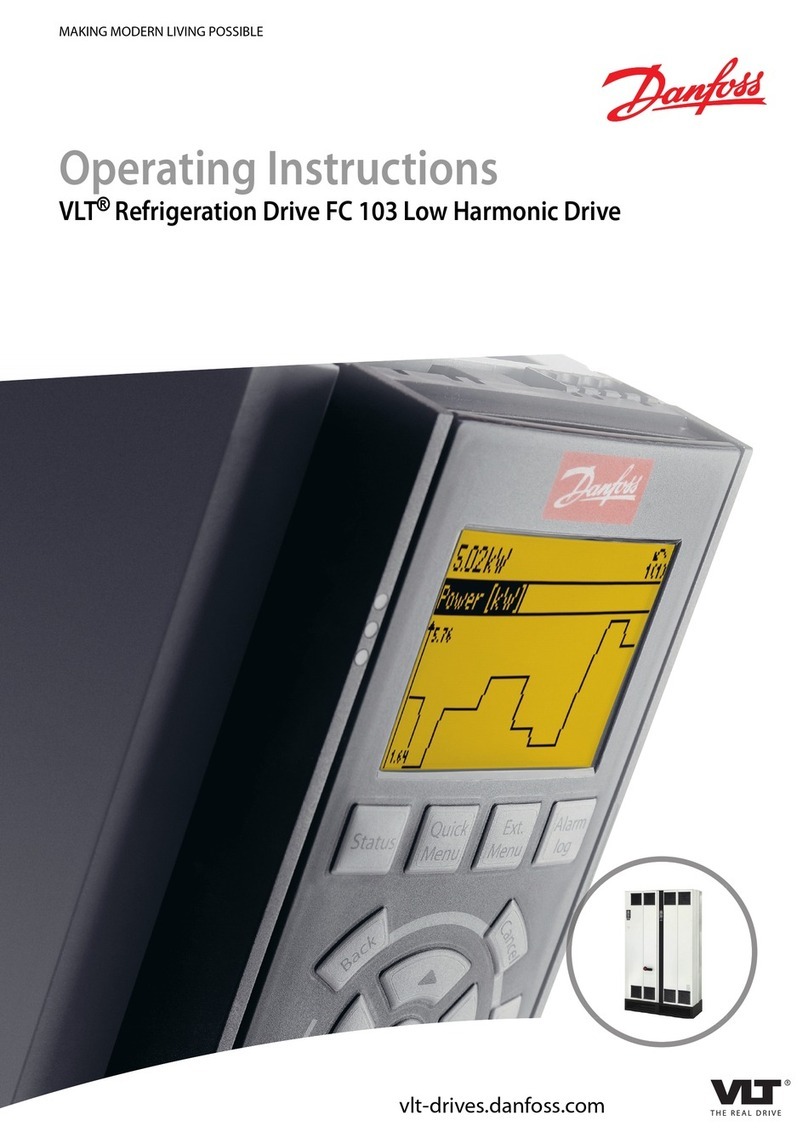

Description

The ground bar kit ts the following drives in E1h and E2h

enclosures:

•

VLT

®

HVAC Drive FC 102

•

VLT

®

Refrigeration Drive FC 103

•

VLT

®

AQUA Drive FC 202

•

VLT

®

AutomationDrive FC 302

The kit includes a pair of ground bars for installation inside

E1h/E2h enclosures.

Kit Part Numbers

Use these instructions with the following kits.

Kit number Kit description

176F6609 Ground bar kit for E1h/E2h drives

Table 1.1 Part Numbers for Kits

Items Supplied

The ground bar kit contains the following items.

Item Quantity

Ground bar 2

Angle bracket 2

M5x18 mm screw 4

M6 hex nut 4

Table 1.2 Items Supplied in Ground Bar Kit

Safety Information

WARNING

ELECTRICAL SHOCK HAZARD

VLT

®

FC series drives contain dangerous voltages when

connected to mains voltage. Improper installation, and

installing or servicing with power connected, can cause

death, serious injury, or equipment failure.

To avoid death, serious injury, or equipment failure:

•

Only use qualied electricians for the installation.

•

Disconnect the drive from all power sources before

installation or service.

•

Treat the drive as live whenever the mains voltage

is connected.

•

Follow the guidelines in these instructions and local

electrical safety codes.

WARNING

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain

charged even when the drive is not powered. High voltage

can be present even when the warning LED indicator lights

are o. Failure to wait 40 minutes after power has been

removed before performing service or repair work can result

in death or serious injury.

•

Stop the motor.

•

Disconnect AC mains and remote DC-link power

supplies, including battery back-ups, UPS, and DC-

link connections to other drives.

•

Disconnect or lock PM motor.

•

Wait 40 minutes for capacitors to discharge fully.

•

Before performing any service or repair work, use

an appropriate voltage measuring device to make

sure that the capacitors are fully discharged.

Installation Instructions

Ground Bar Kit for E1h/E2h Drives

VLT®FC Series FC 102, FC 103, FC 202, and FC 302

Danfoss A/S © 10/2017 All rights reserved. MI35K102