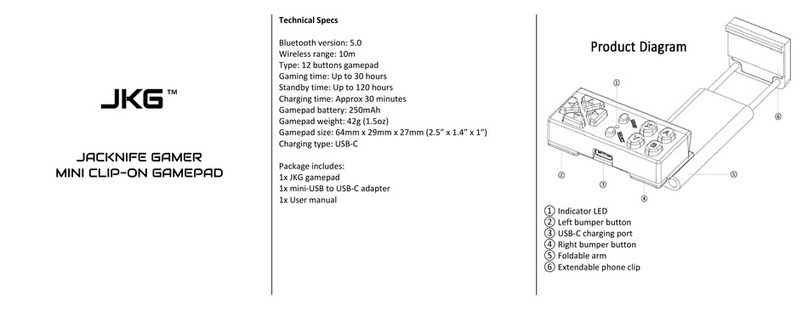

Output sense (direction)

The dual outputs from any JS2000 joystick can be configured in one of two possible ways. These are

designated within the joystick model code as same sense (P) or opposite sense (N). Refer to the following

Output sense (direction) diagram for clarification.

The slopes at the lower end start at 20% of supply voltage range (Vs) and at the upper end finish at 80%

of Vs.

In the same sense configuration, the outputs of an axis can be directly compared to determine the

serviceability of the joystick. In the opposite sense configuration, the sum of the outputs from any axis

should be equal to the applied voltage.

Output sense (direction) diagram

kwa1392485224960

1 2

3

4

5

6

8

7

1Oposite sense 5Sum of outputs 1 and 2

2Same sense 6Output 1

3Maximum difference sum to

supply voltage 7Maximum difference between output 1 and 2

4Supply voltage 8Output 2

Dual JS2000 output signals (X and XY options)

Each joystick axis is equipped with two outputs and it is recommended that both outputs are

continuously compared to ensure that the difference does not exceed the maximum specified difference

plus an appropriate safety margin. In addition, machine movement should not be enabled until both

outputs from any one axis exceed the center threshold voltage plus a suitable safety margin (for example

twice the joystick center deadband).

The outputs in normal use should be within the limits 0.35 to 4.65 V DC. Any output significantly outside

of this range must be regarded as erroneous and appropriate safe action taken. A high value pull-up or

pull-down resistance should be added to the X and Y outputs such that in the unlikely event of a wire or

connector failure, the output will be pulled out of range.

Single outputs (XYZ option)

Where a joystick incorporating only a single sensor per axis is used to control safety critical functions, an

independent momentary action system enable switch should be provided.

Center tap

A center tap is provided as a means of verifying the integrity of the Vs at the joystick. Clearly a high

resistance or open circuit in either the Vs or ground connections will affect the joystick outputs. The

normal output at the center tap connection is 49.16 to 50.84% of Vs. A center tap output outside this

range indicates a fault in the supply to the joystick Hall sensors.

Technical Information

JS2000 Joystick

Product configuration model code

8 | ©Danfoss | May 2017 520L0876 | BC00000073en-US0102