Pinout connections examples

Analog grip pinout connections example CAN and CAN+ minimum pinout

connections example

Pin

number Signal number Description Pin

number Signal number

7 Digital1 Faceplate push-button 1 1 Battery Ground

12 Digital6 Back side push-button 6 2 Battery Power

14 Digital8 Trigger switch 3 CAN Hi

3 Proportional1 Face plate proportional

1

PN, S2, S3 4 CAN Lo

5 Proportional3 Back side proportional 3 PN, S2, S3 5 CAN Shield

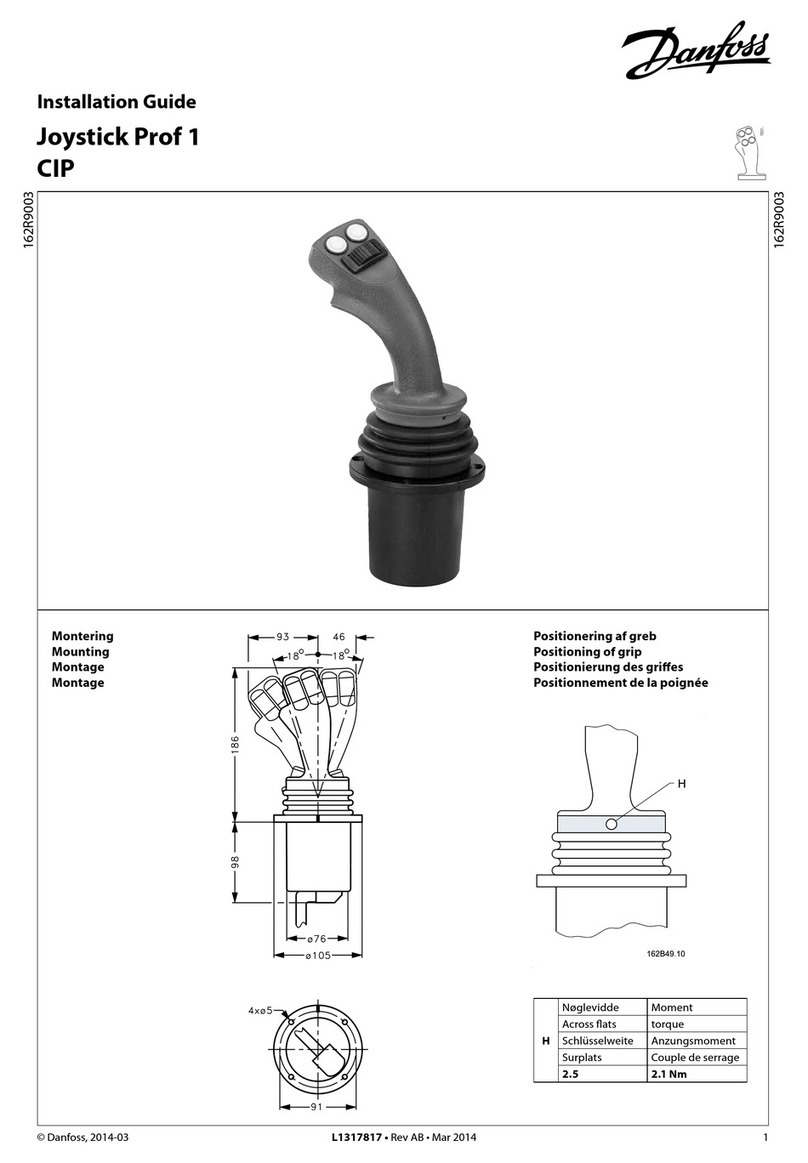

One 18 pin connector

18 pin DEUTSCH connector (DT16-18SB-K004)

Pinouts

Analog CAN CAN+

Pin

number Signal name Pin

number Signal name Pin

number Signal name

1 Battery Ground 1 Battery Ground 1 Battery Ground

2 +5V 2 Battery Power 2 Battery Power

3 Proportional1*3 CAN Hi 3 CAN Hi

4 Proportional2*4 CAN Lo 4 CAN Lo

5 Proportional3*5 CAN Shield 5 CAN Shield

6 Proportional4*6 Not Connected 6 Digital Input 7

7 Digital1 7 Reference Ground 7 Sensor Ground

8 Digital2 8 Reference +5V 8 Sensor Power +5V

9 Digital3 9 Not Connected 9 Analog/Digital Input 1

10 Digital4 10 Not Connected 10 Analog/Digital Input 2

11 Digital5 11 Not Connected 11 Analog/Digital Input 3

12 Digital6 12 Not Connected 12 Analog/Digital Input 4

13 Digital7 13 Not Connected 13 Digital Input 1

14 Digital8 14 Not Connected 14 Digital Input 2

15 Proportional Y Axis 1 15 Proportional Y Axis 1 15 Digital Input 3

16 Proportional X Axis 1 16 Proportional X Axis 1 16 Digital Input 4

17 Proportional Y Axis 2 17 Proportional Y Axis 2 17 Digital Input 5

18 Proportional X Axis 2 18 Proportional X Axis 2 18 Digital Input 6

*Reference Proportional analog pinouts on page 7 for proportional roller with redundant output (HR option)

Electrical Installation

JS7000 Analog and CAN Output

Electrical installation

8 | ©Danfoss | May 2017 L1105361 | 0201