DLR-6/6P Low-Rise Scissor Lifts 9P/N 5900254 — Rev. A — September 2020

Select a Site

Keep the following in mind when selecting a site for your Lift:

•Enough space. Make sure there is adequate space on all sides, plus enough space

above

for

the Vehicles you will be raising. Do not install the Lift under low-hanging obstructions. See Check

Clearancesfor more information.

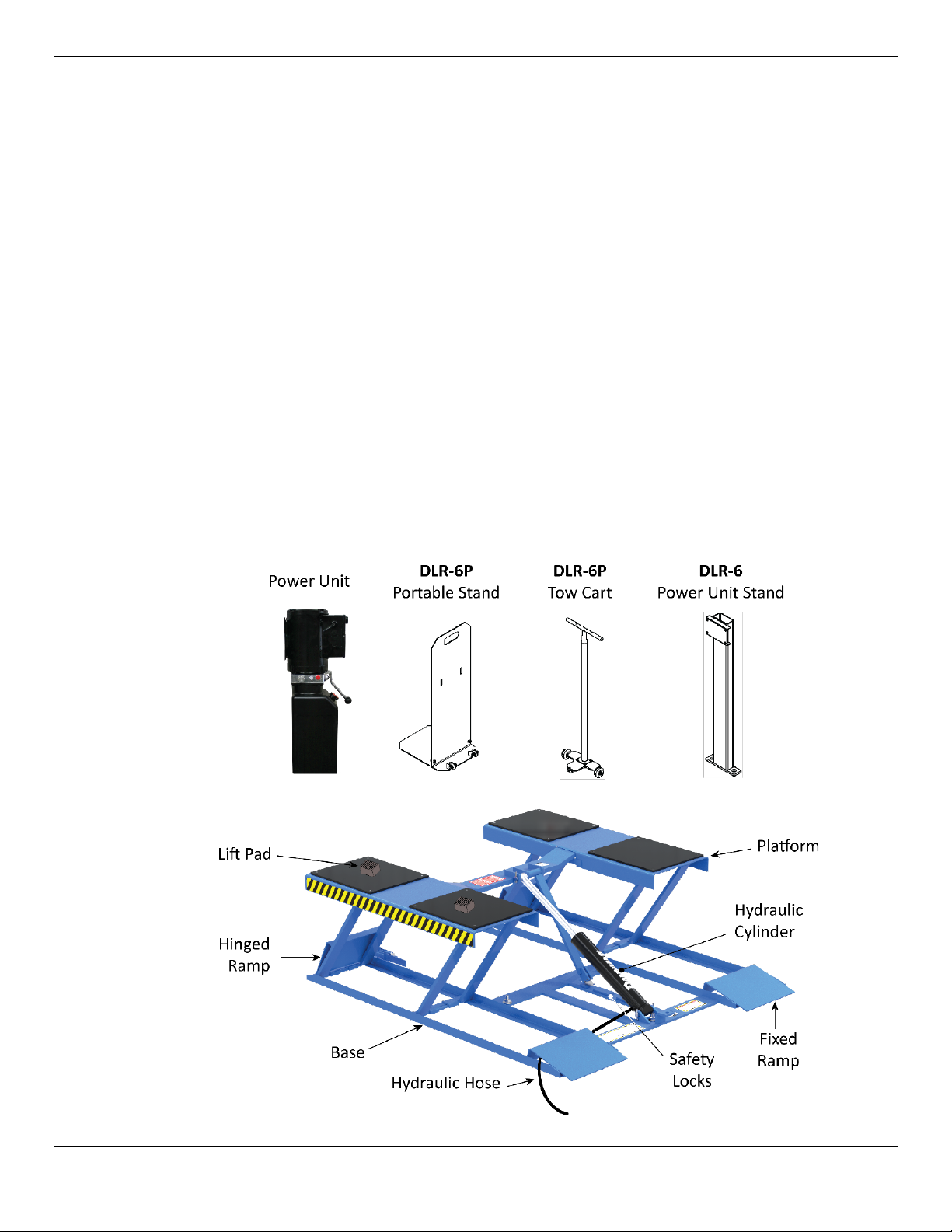

•Power Unit Location. The DLR-6 Power Unit Stand can be installed on either side of the Lift,

close enough for the Hydraulic Hose to reach. The DLR-6PPower Unit is installed on a Portable

Stand, which can be easily moved to the desired location on either side of the Lift within reach of

the Hydraulic Hose. Operators

must

always have a full, unobstructed view of the Lift.

•Hose Cover. The DLR-6 comes with a Hose Cover that you can anchor to the ground; it is

54 in / 1,372 mm long. If you plan to use the Hose Cover, make sure to leave enough room

between the Power Unit and the Lift.

•Operator. The operator

must

have a full, unobstructed view of the Lift and the Vehicle on it when

raising and lowering Vehicles.

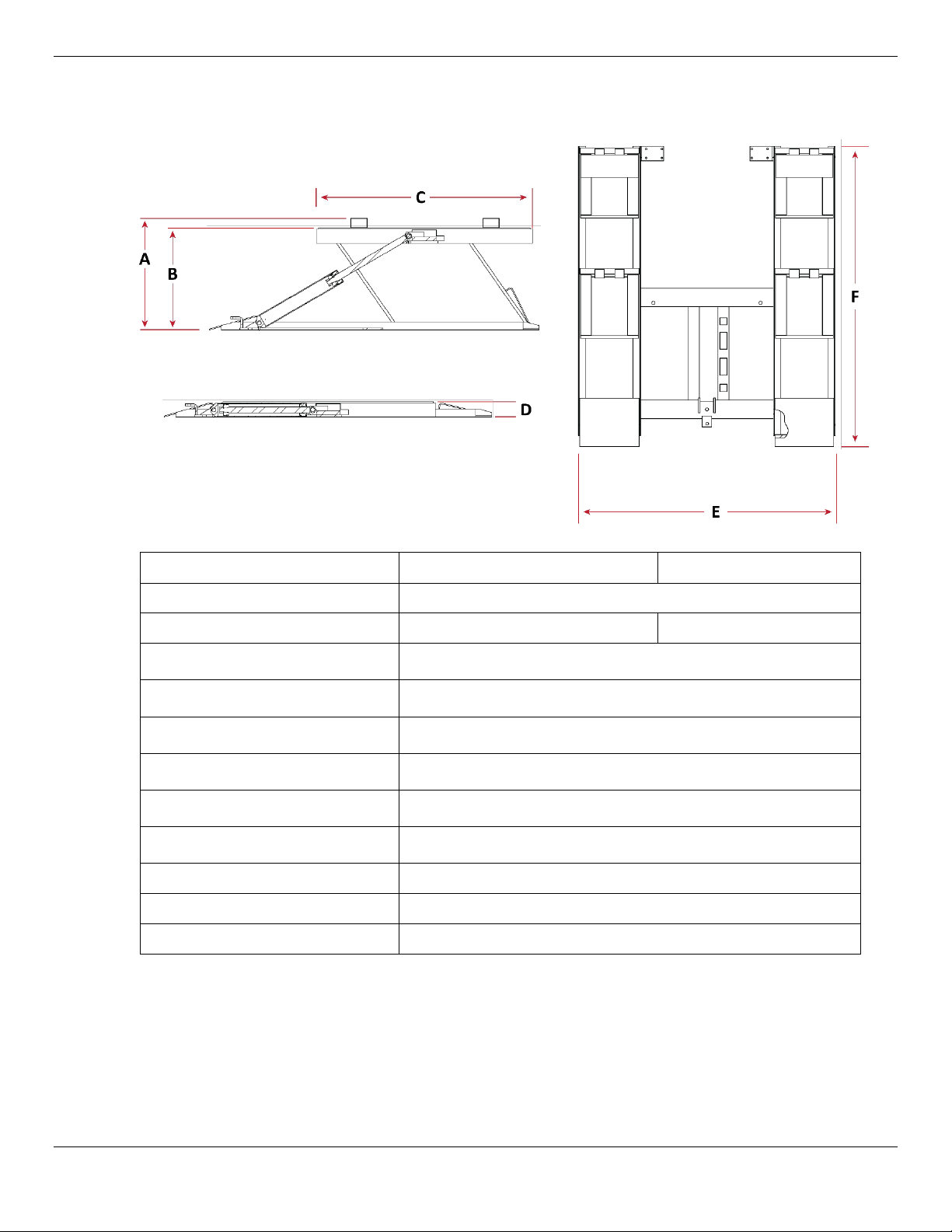

•Longitudinal Shift. When you raise the Lift, the geometry of the scissor arms moves the

Platforms up at an angle. The amount of longitudinal shift for the DLR-6/6P is approximately 14

inches. Refer to About Longitudinal Shift for more information.

•Check for overhead obstructions. The site must be free of overhead obstructions.

•Floor. Do not install or use this Lift on any asphalt surface or any surface other than concrete.

•Concrete specifications. Do not install the Lift on or within 6 in / 152 mm of expansion seams

or cracked or defective concrete. Make sure the concrete is at least 4.25 inches thick, 3,000 psi,

and cured for at least 28 days (if newly poured). Make sure the floor is defect-free, dry, and level.

⚠WARNING Do not install the Lift on a surface with 3° of slope or more. A 3° degree or greater

slope makes the Lift less secure, possibly causing Vehicles to fall, which could lead

to property damage, personal injury, or even death.

•Power. You will need a 115 VAC or a 230 VAC power source near the Power Unit. The Power

Unit ships configured for 115 VAC, but it can be reconfigured to operate on 230 VAC Power. See

Reconfigure the Power Unit to 230 VAC for more information.

•Operating temperature. The Lift is designed to be used between temperatures of 41º to 104ºF

(5º to 40ºC).

•Outdoor installation. The Lift

cannot

be installed outside. It is for indoor use only. If you have

the DLR-6P, you can move it outside and use it outside temporarily; make sure to keep it

completely moisture free while it is outside.

•Second floor installs. Do not install the Lift on a second floor or elevated floor without first

consulting the building architect and getting their permission.

•Dress properly. Always wear protective gear when installing the Lift. Leather gloves, steel-toed

work boots, eye protection, back belts, and hearing protection

are mandatory

. Do

not

wear

loose clothing or jewelry; contain long hair; keep hair, clothing, and gloves away from moving parts.

⚠WARNING You

must

wear OSHA-approved (publication 3151) Personal Protective Equipment

at all times when installing

the Lift.