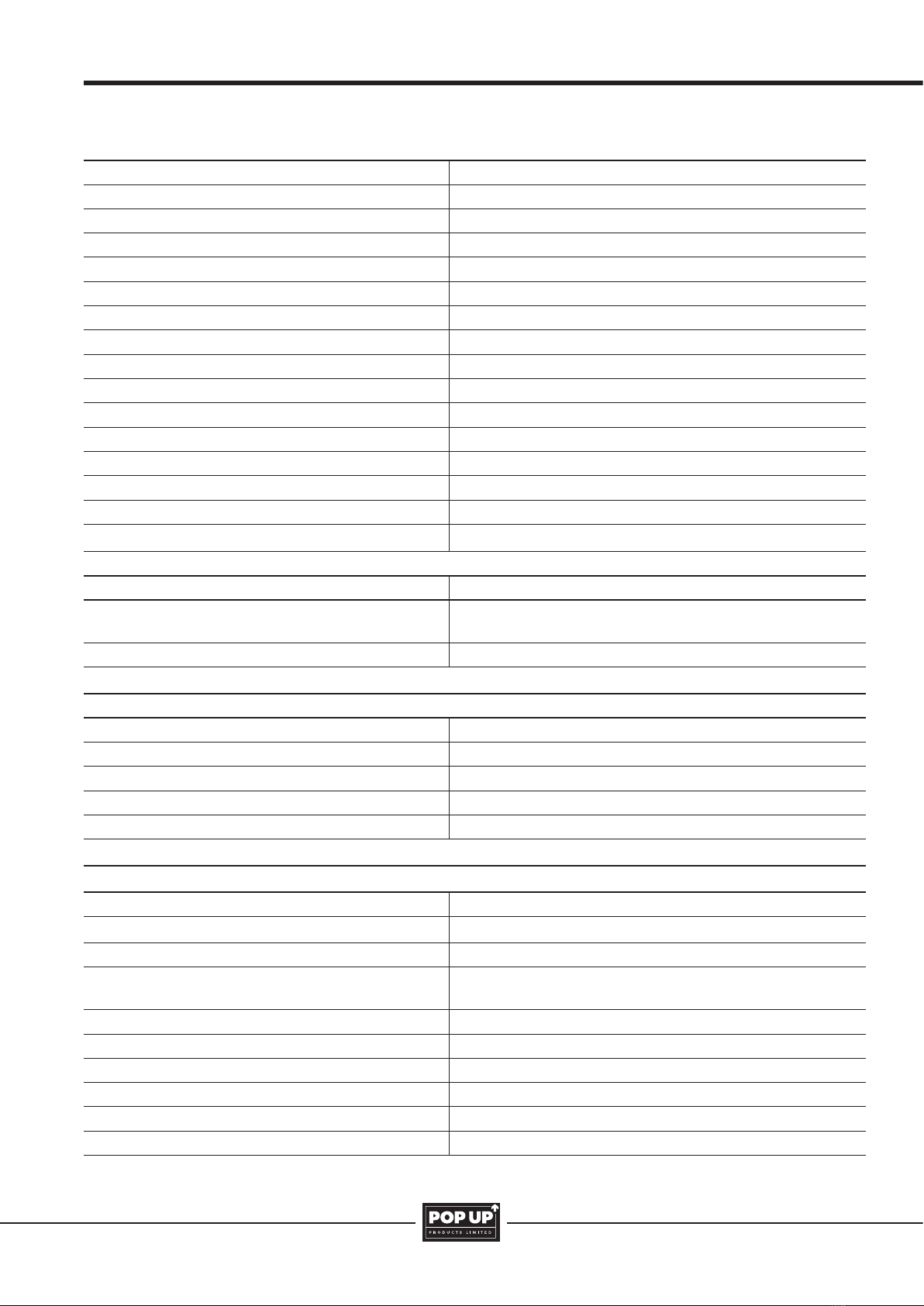

TABLE OF CONTENTS

NOTES............................................................................................................................................................................................. 2

FOREWORD.................................................................................................................................................................................. 4

FALL PROTECTION .....................................................................................................................................................................5

TABLE OF CONTENTS............................................................................................................................................................... 6

INDEX OF FIGURES ....................................................................................................................................................................7

SECTION 1 | PRODUCT DESCRIPTION................................................................................................................................ 8

1.1 | PRODUCT INFORMATION..............................................................................................................................................................................................8

1.2 | MACHINE SPECIFICATIONS........................................................................................................................................................................................9

SECTION 2 | SAFETY ............................................................................................................................................................... 10

2.1 | SAFETY SYMBOLS................................................................................................................................................................................................................10

2.2 | GENERAL RULES AND PRECAUTIONS.........................................................................................................................................................10

2.3 | SAFETY CONTROLS & INDICATORS..................................................................................................................................................................13

SECTION 3 | TRANSPORT, HANDLING, & STORAGE ...................................................................................................16

3.1 | PRELIMINARY UNPACKING INSTRUCTIONS AND DEALER INSPECTION .................................................................16

3.2 | STORAGE.....................................................................................................................................................................................................................................16

3.3 | PREPARATION FOR TRANSPORT.......................................................................................................................................................................16

3.4 | FORK LIFT POCKETS.......................................................................................................................................................................................................16

3.5 | LIFTING AND TIE-DOWN POINTS......................................................................................................................................................................17

SECTION 4 | DECALS................................................................................................................................................................18

4.1 | DECAL LOCATIONS ...........................................................................................................................................................................................................18

4.2 | DECAL SYMBOL MEANINGS ................................................................................................................................................................................ 20

SECTION 5 | OPERATION.......................................................................................................................................................24

5.1 | BEFORE YOU OPERATE...............................................................................................................................................................................................24

5.2 | WHEN WORK IS FINISHED .....................................................................................................................................................................................25

5.3 | OPERATING CONTROLS & INDICATORS ....................................................................................................................................................26

SECTION 6 | DAILY MAINTENANCE..................................................................................................................................28

6.1 | DAILY MAINTENANCE....................................................................................................................................................................................................28

6.2 | BATTERY CHARGING.....................................................................................................................................................................................................29

SECTION 7 | APPENDIX .........................................................................................................................................................30

7.1 | PRE-START INSPECTION CHECKLIST............................................................................................................................................................ 30

OPERATIONS & SAFETY

IQ LIFT

SUPO-758

REV C

6