PAGE 2 05774-0598 <90-00122>

NOTE: This section lists the different options available for this product. To order any of the avail-

able options, contact Dantel Inside Sales through our toll-free number, 1-800-432-6835.

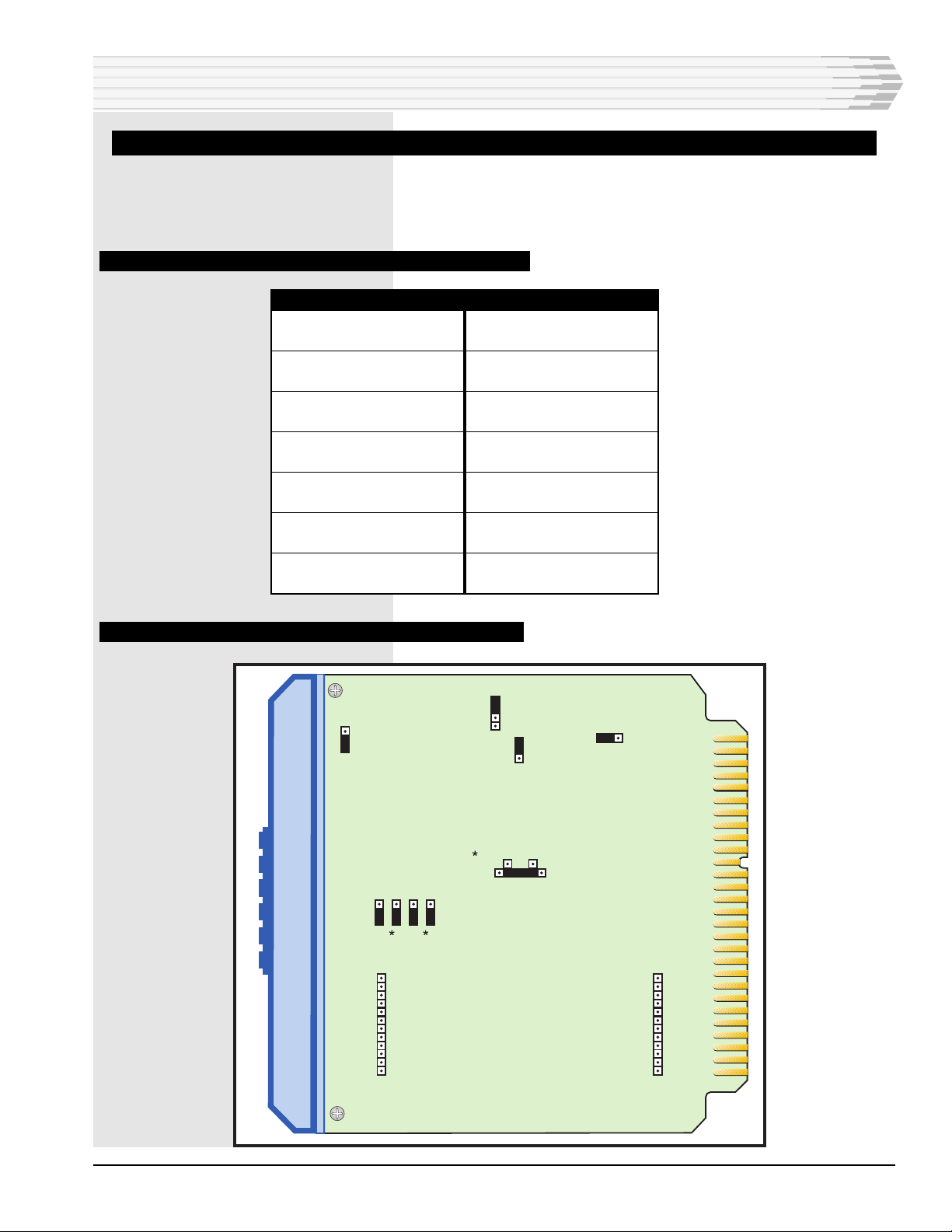

OPTION NUMBER FEATURES

A18-05774-00 Wired only. No modules.

A18-05774-01 Equipped VNET Interface Shelf

ORDERING INFORMATION

GENERAL DESCRIPTION

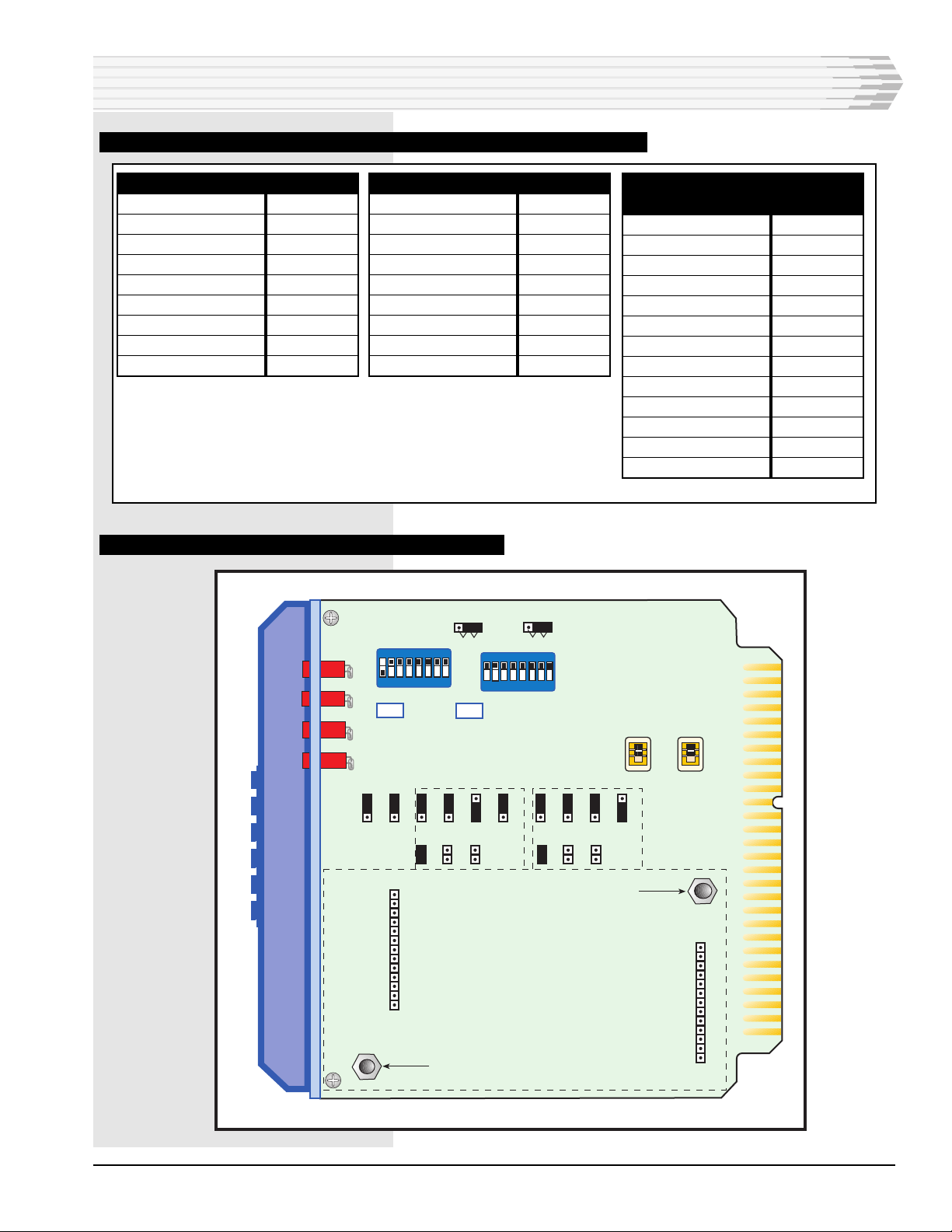

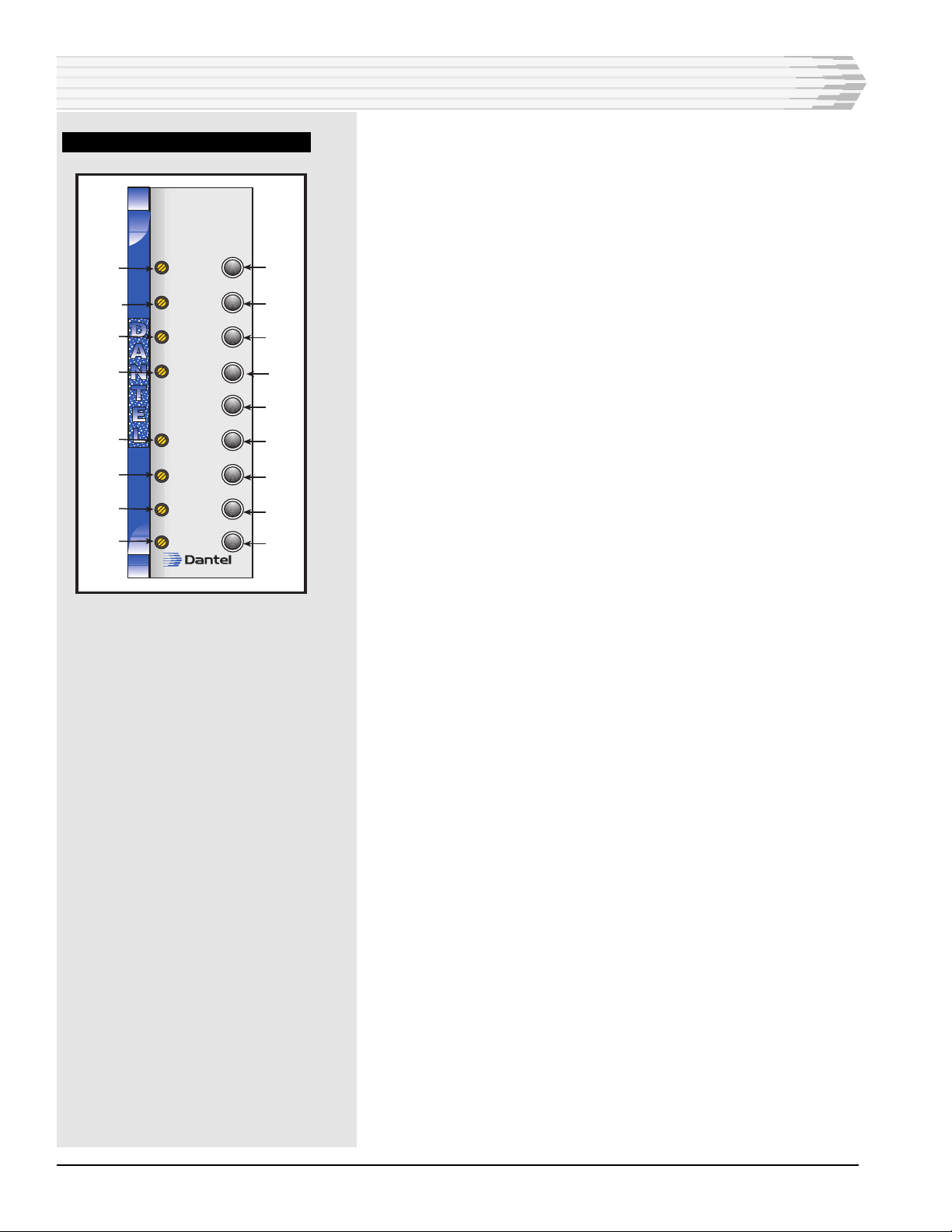

This unit is designed to be a 4 wire, DTMF controlled PBX

interface that will output battery or ground on its M lead and

it will accept battery or ground on its E lead depending upon the

user’s requirements.

The unit is designed so that the caller, from the PBX side, will

shout down to the desired remote after the VNET interface has

been accessed. No DTMF signaling to the remote Order Wire

stations will be used. The DTMF signaling is only used to get

access for the order wire to the PBX.

The user calling from the order wire side of the system will dial

3 digits plus “*” to gain access to the order wire. The same 3

digits plus “#” will release the system. Either party hanging up

will release the system. The unit will operate from -21 to -56

volts with levels of +7 to -16 dBm on any port, using the Dantel

44118 VF bridge. In this application, port 4 (which is used for

PBX acces) will be set for -6dBm on the RX input and 0dBm on

the TX output. All other ports will be used for the order wire and

will be +7 dBm on the RX and -16 dBm on the TX.

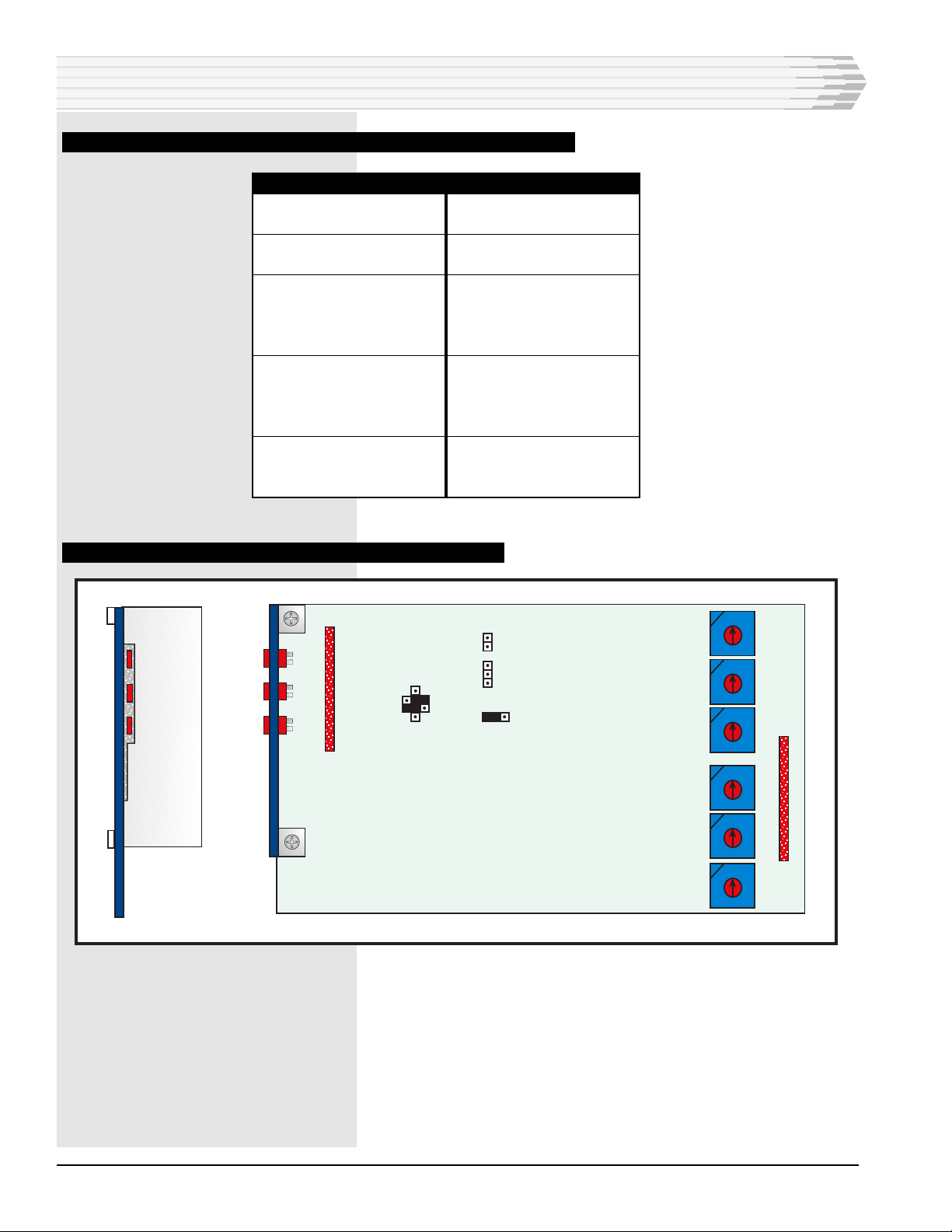

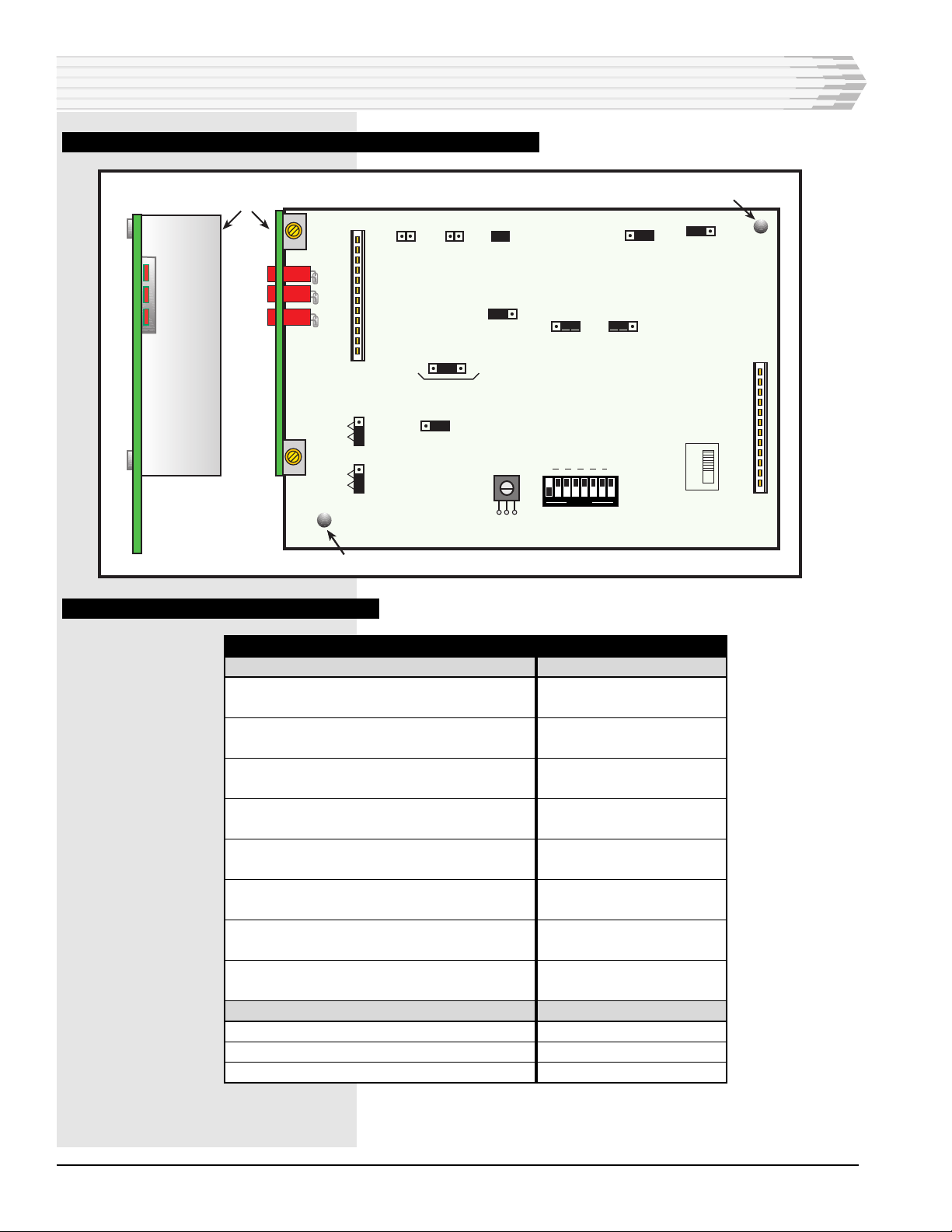

The OW interface will be made up of:

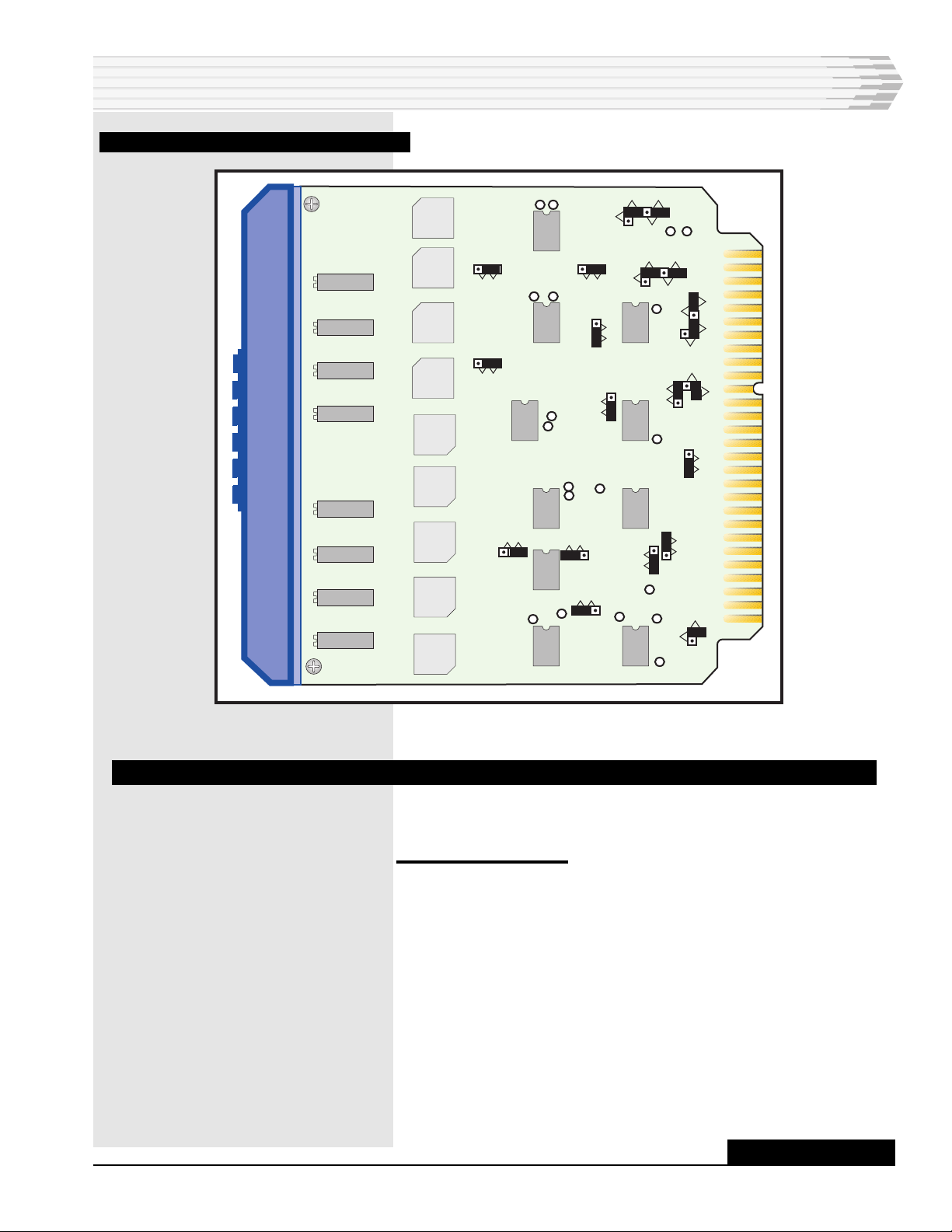

♦An A17-44020-01, comprised of the A12-49018-00 Station

Selector combined with the A11-44020-00 DTMF decoder in

slot 1 (J1).

♦An A17-44931-01, comprised of the A11-44931-00 timer com-

bined with the B12-49031-00 sub assembly timer in slot 2

(J2).

♦The A17-44118-00 4W/4W VF bridge in slot 3 (J3).

With this application, there is no signal tone sent to the PBX

telling the user that he has access to the OW system after he

has dialed the access number for the OW interface. The user will

shout down for the desired station required.