Data Aire dap4 touch User manual

2

Notice: The screens displayed in this manual are for illustration purposes

only. Most settings are shown at their default value or a setting that allows

another screen or setting to appear. These settings are not necessarily the

best for your specific application.

Data Aire, Inc. reserves the right to make design changes for the purpose of

continuous product improvement or to withdraw any design without notice.

This manual was written when dap4 controllers were shipped with:

Software Version 2.16

Earlier versions may not have some of the features indicated, while later

software versions may have additional features that are not listed.

The graphic touch screen contains its own software version which must be

equal to or higher than the controller’s software version.

3

Table of Contents

(If viewing as a pdf, press Ctrl and click section you want to access).

Introduction........................................................................................................................ 4

Optional Equipment &

Features

......................................................................................... 5

Getting Started.................................................................................................................... 6

Status Loop.......................................................................................................................... 7

MENU A –ON / OFF.......................................................................................................... 16

MENU B –SETPOINTS ....................................................................................................... 17

MENU C –CLOCK/SCHEDULER.......................................................................................... 23

MENU D –INPUT/OUTPUT ............................................................................................... 28

MENU E –HISTORICAL DATA............................................................................................ 29

MENU F –INFORMATION................................................................................................. 31

MENU G –NETWORK CONFIGURATION (Service Level) ............................................... 32

MENU H - CALIBRATE SENSORS (Service Level)............................................................. 34

MENU I –MANUAL CONTROL (Service Level)............................................................... 35

MENU J –FACTORY SETTINGS (Factory Level)............................................................... 36

MENU K –ALARMS & LIMITS (Service Level).................................................................... 62

MENU L –CONFIGURE I/O (Factory Level) .................................................................... 79

MENU M –SET ZONE CONTROL ....................................................................................... 81

Operation of Fan............................................................................................................... 89

Operation of Chilled Water Cooling.................................................................................. 91

Operation of DX Cooling ................................................................................................... 93

Operation of Reheat ......................................................................................................... 98

Operation of

De

humidifi

c

ation....................................................................................... 101

Operation of Humidifier.................................................................................................. 105

Operation of Zone Con

tr

ol.............................................................................................. 107

Operation of Airside Economizer.................................................................................... 112

Alarms............................................................................................................................. 116

Wiring Connections......................................................................................................... 129

Glossary........................................................................................................................... 132

4

Introduction

The dap4 continues the tradition of advanced electronic devices from Data Aire for

monitoring and control of computer room air conditioning units which began in 1977.

Each generation has provided more accurate monitoring and application flexibility.

Control - The dap4 offers the definite answer for precision environmental

control. The dap4 control system not only controls temperature, humidity, airflow

and cleanliness; it provides component run times, hourly duty cycles and 24-hour

temperature and humidity deviations.

Efficiency - Airside and waterside economizers are available to help conserve

power usage. Features like “Humidity Anticipation” offsets the humidity set point

to reduce excess humidification and dehumidification. Options such as variable

compressors and electronic expansion valves also contribute to energy savings.

Alarm Management -The dap4 offers extensive alarm management. An

array of alarms conditions may be enabled, and some can be set to stop

operations or completely shut down the unit. Up to 200 of the most recent alarms

are stored in an alarm log. Each alarm has temperature and humidity readings

and the date time it occurred to assist in diagnosing what caused the alarm. There

are four alarm relay contacts that can be programed to energize for any multiple

of alarm conditions.

NOTICE… Please don’t let the size of this manual overwhelm

you, as it covers many options and features of the dap4 that

may not apply to your specific application.

5

Optional Equipment & Features

Electronic Expansion Valve: The module communicates to the dap4 to drive a

stepper motor inside the expansion valve. The module controls refrigerant

superheat and optimizes the efficiency of the refrigerant circuit. It features low

superheat, high evaporation pressure (MOP), and low evaporation pressure (LOP)

protection.

Power Meter Module: The module communicates to the dap4 to allow monitoring

of voltage, amperage, wattage, VA and power consumption (kWh). It also records

daily power use trends for the last 30-day span and offers phase loss alarm

protection. The ultra-compact module measures only 3.11”tall by 4.25” long and

uses only 1.4” of DIN rail space.

Zone Control: A feature that offers multiple dap4 controls a teamwork solution.

Up to sixteen dap4 units may be arranged in the Zone Control network. Unit 1 has

menus with selectable features of:

•Minimum number of units that must always be on

•Automatic lead/lag and standby unit rotation

•Activate a standby unit due to selected alarm conditions

•Activate standby units to assist with controlling temperature or airflow

•Inhibit control functions to prevent units from conflicting operations

•Primary and secondary schedules for economical control

•Unified zone airflow control

Idap Communication Card: A network card with web-based application software

installed. It allows a standard PC to communicate with the dap4 controller. It has

an intuitive menu system that includes: System Status, Configuration, Data and

Graphs, Events and Emails and a Points Table. It can be setup to send trending

data for the previous 24-hour period allowing for review and analysis. The idap

card can be used on a stand-alone basis, in place of a BMS system. It can also

operate in conjunction with a BMS system, using BACnet, Modbus TCP/IP or

SNMP protocols.

Rack Sensor Modules: Allows up to 20 rack temperature sensors to be

connected to the dap4 to control fan speed. Sensors can be set to work

independently or arranged in groups. The rack temperature calculation can be set

to use the highest of the sensors or an average of the sensors.

Power Cap: Allows the dap4 to continue operation during short term power

interruptions. This feature is valuable where power sources are not reliable or

when power may switch to a stand-by generator.

6

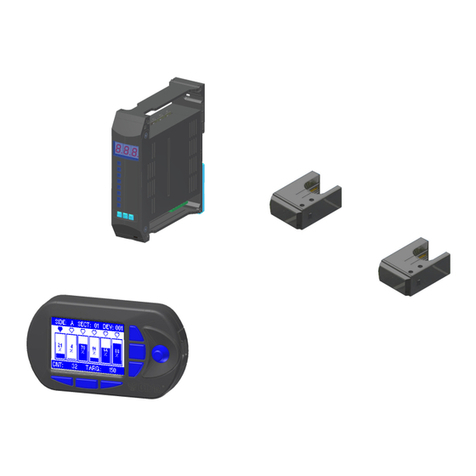

Getting Started

The dap4 consists of two main components: the controller and the display panel. The

controller is located inside the electrical panel. The display panel is mounted on the

front door of the cabinet and/or mounted in a remote location. They are connected by

a special telephone type cable. (Note: If you need a longer cable, please contact the

factory, as special cables are used for long

dap4 Controller (standard size shown)

7

dap4 Color Touch Display

There are several touch sensitive areas on home screen of the display. Listed below

is how each area works when it is touched.

Access service menus shown later in this manual (requires holding 1 sec.)

Displays the next screen.

Displays the Alarm Log screen.

Touch Temp/Hum

readings to display the

Set Points screen.

LED Unit Status

White = On Blue

= Cooling Green

= E. Saver

Red = Alarm

“Power Key” turns Unit on or off.

Color red = unit is off, Green = unit is on.

Displays the system

Information Screen.

Status Loop

The first screen in this loop is the Home screen, which displays the basic status of

the unit. It contains icons that appear when a specific operation is running as

described below:

Fan On - If variable type, speed modulation is also shown.

8

Compressor On - A number will also appear next to the icon to

indicate multiple compressors are running. If variable type, speed

modulation is also shown.

Humidifier On - If variable type, humidity demand modulation is

also shown.

Dehumidification Mode Running.

Heaters On - A number will also appear next to the icon to indicate

multiple heaters are on. If SCR or Hot Water heat type, heat

modulation is also shown.

Chilled Water Cooling On –A number will also appear next to the

icon to indicate valve modulation.

Energy Saver Available –Indicates that chilled water is cold enough

to provide cooling. Also indicates if Airside economizer can provide

cooling with damper modulation shown to the right.. Both are optional

features.

CO2 Valve On –This option only available on gPOD model.

9

Status Loop (continued):

The next screen in the status loop is the Optional screen, which displays the status

of optional inputs of the unit. (Note: this screen does not appear if no optional

inputs are used).

The next screen in the status loop is the Rack Temperature Status screen, which

displays the status of all optional rack sensor. (Note: this screen does not appear if

a rack sensor module is not used). The highest or average (depending on

selection) is shown on the top line, followed by individual sensor readings.

Sensors that are in a Low Temperature alarm have a blue colored bell next to it

(like T04). Sensors that are in a High Temperature alarm have a red colored bell

next to it (like T09). Sensors T16 to T20 (if used) appear on the next Rack

Temperature screen.

10

Status Loop (continued):

The next screen in the status loop is the Zone Status screen, which displays the

status of the zone. (Note: this screen only appears on Unit 1 when the Zone

Control feature is enabled).

The next screen the Zone Units screen, which displays the status of each units in

the zone. Note: this screen only appears on Unit 1 when the Zone Control feature

is enabled.

Touch the unit icon to see specific information such as Temperature, Humidity and

Airflow. General unit status is indicated by color:

Green = Unit On Blue = Unit in Standby

Red = Unit in Alarm Gray = Unit set not to participate

11

Status Loop (continued):

The next screen in the status loop is the Power Meter Status screen. (Note: this

screen only appears when an optional power meter is installed.

The next screen in the status loop is the Variable Compressor Status screen. Note:

this screen only appears when a variable compressor is installed. The operating

envelope is indicated by the green colored polygon. The compressor’s current

status is indicated by a red dot within the envelope.

12

Status Loop (continued):

The next screen in the status loop is the Airside Economizer Status screen. Note:

this screen only appears when the Airside Economizer is enabled is installed.

Sensor readings are displayed based on the Mode setting of the airside

economizer. Any condition that disables the economizer from running is shown in

red text at the bottom of this screen.

The next screen in the status loop is the Trending screen. It displays the historical

trends of the return air temperature and humidity. Additional trends of discharge air

temperature and chilled water temperature will also appear if installed. To display

the legend information, touch the information icon located at the top right corner.

The historical time frame screen can be scrolled forward or backwards by pressing

and dragging the screen.

13

Alarm Log Screen: (Accesses by touching the Alarm icon on the main

status screen). The time and date of past alarms along with readings at the time of

the alarm can be viewed. Touch the Up or Down icon to see past alarm logs.

There will be a short delay as each log is loaded.

14

Turning the Unit On

Turn the disconnect switch to the ON position. The controller will boot up and

conduct a self-test. After approximately 20 seconds the display will become

active.

NOTE: Unless otherwise specified, the unit is shipped with the unit to start-up in

the OFF mode. This setting can be changed to start-up in the ON mode using the

“On/Off” Menu A.

The unit may be turned on (or off) by pressing the Power icon at the bottom

left corner of the main screen. The icon is green when unit is on and red

when unit is off.

Once turned on there will be a 5 to 600 second start delay indicated by “Time

before start: XXs”. If the unit does not turn on, the Unit Status line will indicate the

reason, such as an alarm condition, scheduler setting or command from a BMS.

Service Menus

Press the “Tools” key for one second to change mode of

display to access the service menus.

15

Menus

Press the middle key on left side to access the Main Menu. The first screen will

ask for a numerical password which determines the three levels of menus that will

be displayed: User, Service and Factory.

Note: The User level password is always 0000. The Service level password by

default is also 0000 and may be changed by the installer. The Factory level

password is usually set by the maintenance supervisor to protect from

unauthorized use.

After a password is entered, the Main Menu will appear with “Service” or “Factory”

level indicated at the top right of the screen. Note: These levels will expire if no key

is pressed after 10 minutes. Use the Up or Down key to move the menu of choice

to appear in the center black line. Then press Enter key to access that menu.

The USER level displays the following main menu choices:

A. On/Off

B. Setpoint

C. Clock / Scheduler

E. Historical Data

F. Information

The SERVICE level adds the following menu choices to the user level:

D. Input / Output

G. Network Configuration

H. Calibrate Sensors

I. Manual Control

K. Alarms & Limits

M. Zone Control (only shown if feature is enabled)

The FACTORY level adds the following menu choices to the service level:

J. Factory Settings

L. Configure I/O

16

Changing the Passwords

Important Notice –Service and Factory level passwords should only

be given to qualified technicians. Under normal circumstances the

Factory menus should not be changed. Please consult with Data Aire

engineering or service personnel for help using these menus.

Change the Service level and Factory level passwords following these steps:

1. Press the Menu key.

2. Enter the current Service Level or Factory Level password.

3. The Main Menu will appear. Press the Menu key

4. The password screen will appear. Press the DOWN key.

5. A Service Security screen will appear. Choose a new service level

password. Note: if the Factory level password was entered on step 2; press

the DOWN key again to be able to change the Factory level password.

Note: Be sure you write down any changes to these passwords and store in a safe

and secure location.

MENU A –ON / OFF

On

/

O

ff

U

n

i

t

S

t

a

r

t

-

up

D

e

l

a

y

:

5

s

S

t

a

r

t

-

up

M

od

e

:

O

ff

S

t

a

t

u

s

:

O

FF

by

K

E

Y

H

o

l

d

ESC

for

5

s

ec

ond

s

t

o

t

u

r

n

un

i

t

ON

or

O

FF

Start-up Delay: This is the amount of time that the control will wait before starting.

It is often used to prevent multiple units from starting at the same time, which may

cause a surge in power. Selection is from 5 to 600 seconds with a default setting of

5 seconds. A count down timer for this delay is shown on the main status screen.

Startup- Mode: This is the mode that the unit will be in when power is applied.

Selection is either On or Off with a default setting of Off. Note: When startup mode

is set to Off, the Esc key must be used in order to turn the unit on.

Status: Shows the current unit status as displayed on the main status screen.

17

MENU B –SETPOINTS

S

e

t

po

i

n

t

s

T

e

m

p

S

e

t

po

i

n

t:

72

.

0

•

T

e

m

p

D

ea

db

a

nd

:

2

.

0

•

H

ea

t

D

ea

db

a

nd

:

2

.

0

•

S

t

age

-

T

o

-

S

t

age

:

0

.

3

•

Sync Zone

T

SP

:

No

Temp Setpoint: This set point is used to control the return or discharge air

temperature (whichever is chosen for control mode in the factory settings menu).

The range of adjustment is 45 to 105°F with a default value of 72.0°F.

Cool Deadband: This is the amount temperature must rise above set point before

the first stage of cooling turns on. Range of adjustment is 1.0 to 10.0 °F with a

default value of 2.0°F.

Heat Deadband: This is the amount temperature must drop below set point

before the first stage of heating turns on. Range of adjustment is 1.0 to 10.0 °F

with a default value of 2.0°F.

Stage-To-Stage: (Only shown on multiple compressor units). This is the amount of

temperature that separates each stage of DX cooling. The range of adjustment is

0.3 to 3.0 °F with a default of 0.3 °F.

Latent Setpoint: (IRDX model only when set for discharge latent control mode in

factory settings menu). This setpoint is calculated from the temperature setpoint

and offset by the discharge air humidity. It is not adjustable.

Latent Deadband: (IRDX model only when set for discharge latent control mode

in factory settings menu). For each increase in humidity of 0.2% above this dead

band (range of adjustment is 60 to 80% with a default of 64%) will cause the latent

set point to increase by 0.1°F.

Fan Delta Temp: (IRDX model only when fan mode is set to delta in the factory

settings menu). This is the set point for fan modulation based on the difference

between the Return and discharge air temperatures. The range of adjustment is

10.0 to 40.0 °F with a default of 20.0 °F.

Sync Zone TSP: (Only shown on Unit 1 of Zone Control network). When set to

Yes (default is No), all units in the zone will use the temperature setpoint and

deadband of Unit 1.

18

MENU B –SETPOINTS continued

E

c

ono

m

i

ze

r

S

e

t

po

i

n

t

s

H

i

E

n

t

a

l

py

:

28

.

0

BT

U

E

n

t

h

a

l

py

D

B

:

0

.

5

BT

U

M

i

n

OA

T

e

m

p

SP

:

32

.

0

•

M

a

x

OA

T

e

m

p

SP

:

78

.

0

•

OAT

D

ea

db

a

nd

:

1

.

0

•

Note: This screen is only shown when the airside economizer feature is enabled in

the factory settings menu.

Hi Enthalpy: (Shown when Economizer is set to Fixed Enthalpy mode).

Setpoint for the highest outside air enthalpy can be to close the damper.

The range of adjustment is 26 –30.0 BTU with a default value of 28.0.

Enthalpy DB: (Shown when Economizer is set to an Enthalpy mode).

Fixed Enthalpy mode: This is the amount that the outside air enthalpy must

drop below the Hi Enthalpy setpoint before the damper can reopen.

Fixed Enthalpy mode: This is the amount that the outside air enthalpy must

drop below the inside air enthalpy before the damper can reopen.

The range of adjustment is 0.2 to 1.0 BTU with a default value of 0.5 BTU.

Min OA Temp SP: This is the lowest temperature that the outside air can

be before the damper is closed. The range of adjustment is 20.0 to 45.0°F,

with a default value of 32°F.

Max OA Temp SP: (Shown only in Fixed dry bulb mode) This setpoint is

based on the climate zone setting and is not user adjustable. It is the

highest temperature that the outside air can be before the damper is closed.

Range of adjustment is 65.0 to 85.0°F.

OA DB: This is how much the outside air temperature must rise above or

drop below the OA Temp SP before the damper may reopen. The range of

adjustment is 1.0 to 5.0° with a default value of 1.0°.

19

MENU B –SETPOINTS continued

R

ac

k

T

e

m

p

S

e

t

po

i

n

t

s

T

e

m

p

S

e

t

po

i

n

t:

72

.

0

•

T

e

m

p

D

ea

db

a

nd

:

2

.

0

•

Note: This screen is only shown when the fan is set to modulate to rack

temperature in factory settings menu.

Temp Setpoint: This fan temperature set point is used to control the fan speed

based on the Rack Air Temperature. The range of adjustment is 65 to 85 °F with a

default value of 72.0 °F.

Temp Deadband: This fan deadband is the amount that temperature must rise

above the fan speed setpoint before fan speed will begin to increase. The range of

adjustment is 1.0 to 5.0° with a default value of 2.0°.

D

e

w

po

i

n

t

S

e

t

po

i

n

t

s

Low

D

e

w

po

i

n

t

S

p

:

45

.

0

•

Low

D

e

w

po

i

n

t

D

b

:

1

.

0

•

H

i

D

e

w

po

i

n

t

S

p

:

59

.

0

•

H

i

D

e

w

po

i

n

t

D

b

:

1

.

0

•

Note: This screen is only shown when humidity control is set to “Dewpoint” in the

factory settings menu or if the Air-side Economizer feature is used.

Low Dewpoint Sp: This is the Low Dewpoint Setpoint. It sets the limit for when

humidification will begin. The range of adjustment is 30.0 to 55.0 °F with a default

value of 45.0 °F.

Low Dewpoint Db: This is the Low Dewpoint Deadband. It determines how much

above the setpoint that dewpoint must rise to end humidification. The range of

adjustment is 0.1 to 3.0 °F with a default value of 1.0 °F.

High Dewpoint Sp: This is the High Dewpoint Setpoint. It sets the limit for when

20

MENU B –SETPOINTS continued

dehumidification will begin. The range of adjustment is 50.0 to 65.0 °F with a

default value of 59.0 °F.

High Dewpoint Db: This is the High Dewpoint Deadband. It is the amount that the

dewpoint must drop below setpoint before dehumidification ends. The range of

adjustment is 1.0 to 3.0 °F with a default value of 1.0 °F.

Other manuals for dap4 touch

7

Table of contents

Other Data Aire Control System manuals