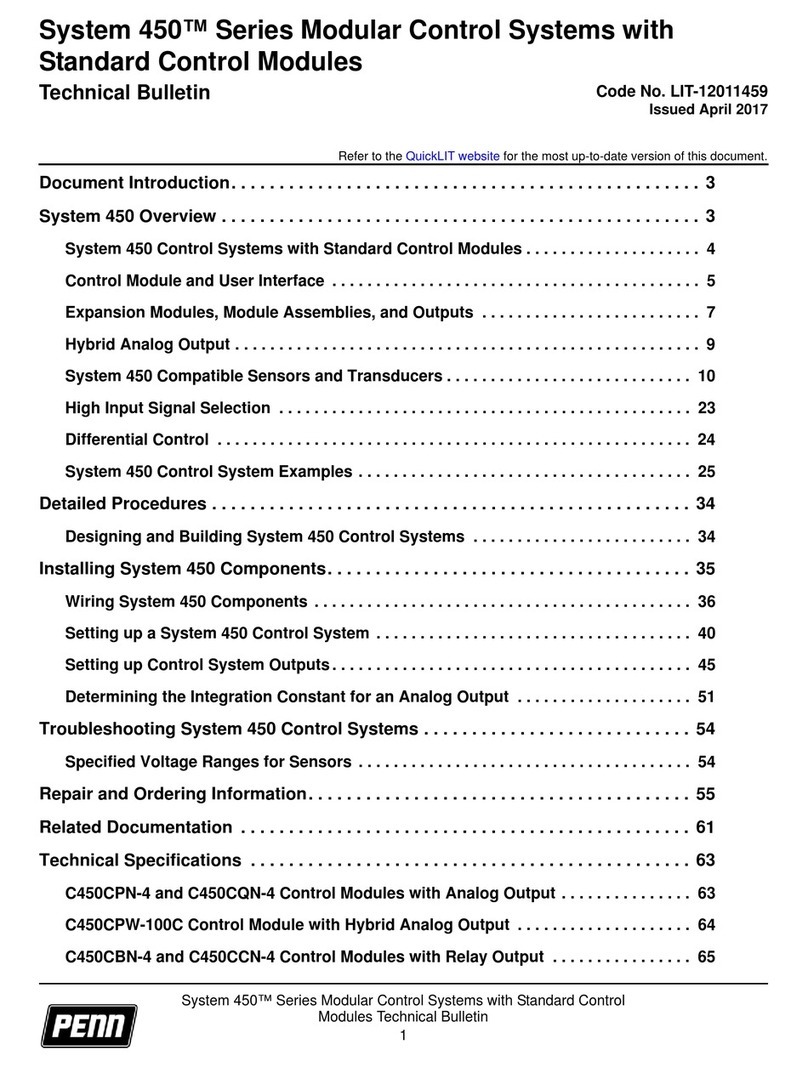

Table 3: C450CCU condensing unit control system

Callout Description

1 Sn3 low-pressure pump down transducer. To control a compressor or

compressor starter with low pressure, connect a P499 Series pressure

transducer to Sn3, 5V, and C.

2 Sn1 refrigerated space temperature sensor. To control the refrigeration

output, either a compressor or a liquid line solenoid valve, connect an A99

Series temperature sensor to Sn1 and C on the input terminal block.

3 Sn2 defrost termination temperature sensor or switch. To terminate defrost

using evaporator temperature, connect an A99 Series temperature sensor or

user-supplied temperature switch to Sn2 and C on the input terminal block.

4 C450CCU condensing unit control module

5 C450YNN power module

6 C450SCN relay expansion module with two relay outputs

7 C450SCN relay expansion module with two relay outputs

8 OUTR1: output relay 1 terminal block. Connects to and controls the liquid

line solenoid valve based on the temperature sensed at Sn1, the refrigerated

space temperature sensor.

9 OUTR2: output relay 2 terminal block. Connects to and controls either a 1-

speed evaporator fan or the high-speed on a 2-speed evaporator fan, based

on the evaporator fan control selections you configure in the UI.

10 Power module line-voltage supply power terminals. Connect 120VAC

or 240VAC power to the appropriate terminals to provide power to the

condensing unit control system.

11 OUTR3: optional output relay 3 terminal block. Connects to and controls the

low-speed on a 2-speed evaporator fan.

12 OUTR4: output relay 4 terminal block. Connects to and controls the defrost

heater based on the condensing unit’s daily defrost schedule that you

configure. The temperature sensed at the defrost termination sensor or

switch or the configured defrost duration time terminates the defrost cycles.

13 OUTR5: output relay 5 terminal block. Connects to and controls compressor

pump down based on the suction pressure sensed at Sn3, the low-pressure

pump down transducer.

14 OUTR6: output relay 6 terminal block. Connects to and controls an optional

alarm output that may be used to provide an onsite notification of any active

alarm condition within the CCU.

Note: To provide OUTR2, OUTR3, OUTR4, OUTR5, and

OUTR6, you need a C450 expansion module.

Ordering information

Table 4: System 450 modules

Product code Product description

C450CCU-4C Condensing unit control module with LCD, four-button touchpad, UI,

and two SPDT line-voltage relay outputs

Included in the box: quantity of two A99BB-500C temperature sensors

with 5.00 m (16 3/8 ft) cable length

Sensor temperature range: -40ºC to 120ºC (-40ºF to 250ºF)

Cable jacket temperature range: -40ºC to 100ºC (-40ºF to 212ºF)

C450SBN-4C Relay expansion module with one SPDT relay output

C450SCN-4C Relay expansion module with two SPDT relay outputs

C450YNN-1C Power module; provides 24 V to System 450 module assembly; 120 VAC

or 240 VAC supply power input terminals

Note: Refer to the System 450 Series C450CCU

Condensing Unit Control System Technical Bulletin

(LIT-12013266) and the System 450 Series C450CCU

Condensing Unit Control System Catalog Page

(LIT-1901123) for more information.

Table 5: Mounting accessories

Product code Product description

BKT287-1R DIN rail; 0.30 m (12 in.)

BKT287-4R DIN rail; 0.36 m (14 in.)

PLT344-1R DIN rail end clamps (2 clamps)

WHA-C450-100C System 450 module connection extension cable, 100 cm (3.3 ft) long

Table 6: A99 Series temperature sensors

Product code Description

A99BA-200C Positive temperature coefficient (PTC) silicon sensor with shielded

cable; cable length 2 m (6.50 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket temperature range: -40°C to 100°C (-40°F to 212°F)

A99BB-25C PTC silicon sensor with polyvinyl chloride (PVC cable); cable

length 0.25 m (0.82 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket temperature range: -40°C to 100°C (-40°F to 212°F)

A99BB-200C PTC silicon sensor with PVC cable; cable length 2 m (6.50 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket temperature range: -40°C to 100°C (-40°F to 212°F)

A99BB-300C PTC silicon sensor with PVC cable; cable length 3 m 9.75 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket temperature range: -40°C to 100°C (-40°F to 212°F)

A99BB-500C PTC silicon sensor with PVC cable; cable length 5 m (16.38 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket temperature range: -40°C to 100°C (-40°F to 212°F)

A99BB-600C PTC silicon sensor with PVC cable; cable length 6 m (19.50 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket temperature range: -40°C to 100°C (-40°F to 212°F)

A99BC-25C PTC silicon sensor with high temperature silicon cable; cable

length 0.25 m (0.82 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket rated for full sensor temperature range

A99BC-300C PTC silicon sensor with high temperature silicon cable; cable

length 3 m (9.84 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket rated for full sensor temperature range

A99BC-1500C PTC silicon sensor with high temperature silicon cable; cable

length 15 m (49 ft)

Sensor temperature range: -40°C to 120°C (-40°F to 250°F)

Cable jacket rated for full sensor temperature range

A99-CLP-1 Mounting clip for A99 temperature sensor

Note: Refer to the A99B Series Temperature Sensors

Product/Technical Bulletin (LIT-125186) for more

information.

Table 7: P499 Series transducers with 1/4 in. SAE 45

flare internal thread with depressor (Style 47)

Product code Description

P499RCPS100C -10 psis to 100 psis, sealed for wet and freeze and thaw

applications; order WHA-PKD3 type wire harness separately.

P499RCPS100K -10 psis to 100 psis, sealed for wet and freeze and thaw

applications; WHA-PKD3-200C wire harness included.

P499RCPS102C 0 psis to 200 psis, sealed for wet and freeze and thaw

applications; order a WHA-PKD3 type wire harness separately.

P499RCPS102K 0 psis to 200 psis, sealed for wet and freeze and thaw

applications; WHA-PKD3-200C wire harness included.

P499RCP-101C 0 psig to 100 psig; order a WHA-PKD3 type wire harness

separately.

P499RCP-101K 0 psig to 100 psig; WHA-PKD3-200C wire harness included.

Table 8: P499 Series transducers with 1/8 in. 27 NPT

external thread (Style 49)

Product code Description

P499RAPS100C -10 psis to 100 psis, sealed for wet and freeze and thaw

applications; order a WHA-PKD3 type wire harness separately.

P499RAPS100K -10 psis to 100 psis, sealed for wet and freeze and thaw

applications; WHA-PKD3-200C wire harness included.

P499RAPS102C 0 psis to 200 psis, sealed for wet and freeze and thaw

applications; order a WHA-PKD3 type wire harness separately.

System 450 Series C450CCU Condensing Unit Control Module Installation Guide4