DataApex Shimadzu GC2014C APC/AFC User manual

Clarity Controls

Shimadzu GC-2014C

GC ENG

Code/Rev.: M113/26C

Date: 13.5.2008

Phone: +420 251 013 400 DataApex Ltd. 2008

Fax: +420 251 013 401 Podohradska 1

www.dataapex.com The Czech Republic

Clarity®, DataApex®and ®are trademarks of DataApex Ltd. Microsoft®and WindowsTM are trademarks

of Microsoft Corporation.

DataApex reserves the right to make changes to manuals without prior notice. Updated manuals can be

downloaded from www.dataapex.com.

Author:

DM

Shimadzu GC-2014C Contents

i

Contents

1 Shimadzu GC-2014C Control module .....................................1

2 Requirements ........................................................................2

3 Installation Procedure............................................................3

3.1 Hardware - Wiring ................................................................. 3

3.2 Shimadzu GC-2014C setup - communication ........................ 3

3.3 Clarity Configuration ............................................................. 4

4 Using the control module .......................................................6

4.1 Hardware Configuration......................................................... 6

4.2 Method Setup - GC ................................................................ 7

4.2.1 Oven/Zones .................................................................... 7

4.2.2 INJ 1(2) ........................................................................... 8

4.2.3 DET 1 (..4)....................................................................... 9

4.2.4 Time Events .................................................................. 11

4.2.5 Pre Run......................................................................... 13

4.2.6 Other ............................................................................ 14

4.2.7 Gradients ...................................................................... 16

4.3 Method Setup - Acquisition.................................................. 17

4.4 Device Monitor..................................................................... 18

4.5 Shimadzu GC-2014C Setup ................................................. 19

5 Report Setup........................................................................24

Contents Shimadzu GC-2014C

ii

To facilitate the orientation in the Shimadzu GC-2014C manual and Clarity

chromatography

station, different fonts are used throughout the manual. Meanings of these fonts are:

Instrument (blue text) marks the name of the window, to which the text refers.

Open File (dark brown bold) describes the commands and names of fields in Clarity.

WORK1 (capitals) indicates the name of the file and/or directory.

ACTIVE (orange capital italics) marks the state of the station or its part.

Administrator (green italics) refers to a value or text inserted into a field.

The bold text is sometimes also used for important parts of the text and the name of the Clarity

station. Moreover, there are text sections written in format other than normal text. These

sections are closed in boxes with the appropriate pictogram:

- Note - notifies the reader of possibly interesting information.

- Caution - warns the user of possibly dangerous or very important information.

- Question - marks the problem statement or trouble question.

- Answer - marks the response to the question.

Shimadzu GC-2014C 1 Shimadzu GC-2014C Control module

1

1 Shimadzu GC-2014C Control

module

This manual describes the setting of the Shimadzu GC-

2014C chromatograph. The control module enables direct

control of the instrument over serial line.

Fig. 1 Shimadzu GC-2014C (with AOC-20i autosampler)

Shimadzu GC-2014C control module provides the means for

the direct control of the Shimadzu GC-2014C chromatograph.

It allows a limited control of the GC-2014 and GC-2010 - only

the digital data acquisition and temperature zone control is

supported at the moment, the APC (automatic pressure

control) and AFC (automatic flow control) parameters must be

set from the GC keyboard.

2 Requirements

Clarity Controls

2

2 Requirements

•Clarity Installation CD ROM with GC Control module (p/n

A23).

•Free serial COM port in the PC.

Modern computers usually have only 1 (if any) serial (COM)

port installed. To use more devices requiring the port, the

MultiCOM adapter (p/n MC01) is available.

•Serial cross DB9F-DB9F cable (p/n SK01).

Cables are not part of Clarity Control Module. It is strongly

recommended to order required cables together with the

Control Module.

Shimadzu GC-2014C

3 Installation Procedure

3

3 Installation Procedure

3.1 Hardware - Wiring

Start and Ready signals are communicated with Clarity

through the Serial cross DB9F-DB9F cable, so it is not

necessary to connect additional starting cables. The signal

cable has to be connected according to the following scheme.

In a set with the Autosampler synchronization cables might

be necessary.

Typical connections of a set with Autosampler can be found in

the Getting Started manual (chapter Device Setup and

Wiring).

Typical serial cable wiring is described in the picture.

Fig. 2 Serial cross cable DB9F – DB9F

3.2 Shimadzu GC-2014C setup - communication

The GC must be fully configured prior to connecting to

Clarity. No special settings have to be made on the

Shimadzu GC-2014C chromatograph, only the

communication protocol of the instrument (set on the FUNC

key screen by using 6. GC CONFIGURATION - 3.

TRANSMISSION PARAMETER) has to be set to LEVEL3.

Baud rate set in the instrument must correspond to the

Baud Rate set in the Shimadzu GC-2014C Setup dialog. For

locally connected instruments with short interconnecting

cable the Baud Rate set as default (115200) is

recommended. With the rising length of the cable or when

connected via the network the Baud Rate should be set

lower.

3 Installation Procedure

Clarity Controls

4

3.3 Clarity Configuration

Menu Path: Clarity -> System -> Configuration

•In the System Configuration dialog press the Add button to

invoke the Available Control Modules dialog.

Fig. 3 Available Control Modules

•Select the Shimadzu GC-2014C in the GC section and press

the Add button.

•The Shimadzu GC-2014C Setup dialog will appear.

Fig. 4 Shimadzu GC-2014C Setup

Shimadzu GC-2014C

3 Installation Procedure

5

•Fill in the Port, Baud Rate and Name according to the

settings and the connection of the GC (for more details see

chapter Shimadzu GC-2014C Setup on pg. 19).

•Press the Autodetect button to read all settings from the

instrument and apply them in the Shimadzu GC-2014C Setup

dialog.

It is strongly recommended not to change the settings gained

through the Autodetect function. When opening the

Instrument window, those settings are checked against the

settings of the GC and in case they are not the same the

warning message is issued and no control is possible.

•Switch to the Signals tab (for more details see the Shimadzu

GC-2014C Setup dialog section later in the manual), select the

correct number of signals you want to acquire, name them

and possibly check the Enable to start device(s) from

Clarity checkbox. Press the OK button.

•The Shimadzu GC-2014C item will appear in the Setup

Control Modules list of the System Configuration dialog.

•Drag the GC icon from the Setup Control Modules list on

the left side to the desired Instrument tab on the right

side , or use the button to do so.

Fig. 5 System Configuration

4 Using the control module

Clarity Controls

6

4 Using the control module

New GC tab appears in the Method Setup dialog, enabling the

setting of the GC control method.

4.1 Hardware Configuration

Menu Path: Instrument -> Method -> GC Control -> GC Status

Fig. 6 Hardware Configuration

This dialog is invoked by pressing the GC Status button in

the Method Setup - GC dialog. Hardware Configuration dialog

displays the type of the chromatograph and the COM port to

which it is connected.

Shimadzu GC-2014C

4 Using the control module

7

4.2 Method Setup - GC

4.2.1 Oven/Zones

Menu Path: Instrument -> Method -> GC Control

Fig. 7 Method Setup – GC – Oven/Zones

Oven Max

Sets the maximal allowed temperature for the column oven.

Possible values are: 0- 440.

Please note that the maximum value may differ for certain GC

models - listed values for it range between 400 and 470 °C.

Equilibry Time

Time that the GC needs to reach the temperature

equilibrium after the temperature program gets to the set

initial temperature. This time is used to distribute the heat

evenly in the oven.

Gradient Table

Sets the Heat Rate, desired temperature (Final Temp) and

time to hold this temperature (Hold Time). The Total Time

column will be calculated automatically. In other words, for

isothermal part of the temperature gradient, the temperature

set in Final Temp will be kept for the interval set in Hold

4 Using the control module

Clarity Controls

8

Time. To delete a row, simply delete the value in the Heat

Rate column on that row.

Temperature Zones

Sets the temperature and maximum temperature of the

zones that have been set in the Shimadzu GC-2014C Setup -

Heater Ports dialog (for more details see chapter Shimadzu

GC-2014C Setup on pg. 19).

Description

Description of the method (this description is not sent to or

read from GC, it serves for the information purposes only).

4.2.2 INJ 1(2)

Menu Path: Instrument -> Method -> GC Control

Fig. 8 Method Setup - GC - INJ 1

This tab governs the settings concerning the injection port of

the Shimadzu GC-2014C chromatograph. Up to two

injection ports may be configured and used at the same

time. The tab is only present when the SPL operation is

selected in the Shimadzu GC-2014 Setup - Piping dialog (for more

details see chapter Piping tab on pg. 20) for a given injector

port.

Split Mode

Defines the operation mode for the injector port. The

possible options are Split, Splitless and Direct (see Shimadzu

Shimadzu GC-2014C

4 Using the control module

9

GC-2014C hardware manual for more details on these

injection modes).

Sampling Time [min.]

Sets the sampling time in minutes for the Splitless Sampling

Mode.

4.2.3 DET 1 (..4)

Menu Path: Instrument -> Method -> GC Control

Fig. 9 Method Setup - GC - DET 1

This tab allows to set the parameters for a detector

configured in the Shimadzu GC-2014C Setup dialog. Particular

fields may vary, according to the type of the detector set.

On/Off

Switches the detector on and off. The detector switched off

gives 0as a resulting signal.

Filter Time Const.

The value set here influences the processing of the detector

signal. It works as a noise filter, the higher the constant, the

lower the noise. On the other hand, usage of the higher

values will flatten peaks and may cause lower or smaller

peaks to disappear.

4 Using the control module

Clarity Controls

10

Control Mode

Sets the mode of operation of the particular detector. Two

option sets are available in this field, depending on the type

of the detector used:

•Dual flame ionization detector (WDFID) may work in the

Dual mode or use the signal from one cell only. Dual

detector can also measure only on single cell - then select

Single L for the left cell or Single R for the right cell.

•Flame thermionic detector (FTD and WFTD) allows to use

two possible control modes - Current and Voltage.

Signal Polarity

This field is only present when using the dual detector in the

Dual mode or one of TCD detectors. Sets the polarity of the

dual data, or in other words, the method of data calculating

(either the signal of the right cell minus the signal of the left

cell (polarity -) or vice versa (polarity +)).

Range

Applies on the analog detector signal before its processing to

the digital data directly in the Shimadzu GC-2014C. This

value serves for the compensation of the overly high signals.

Current

Serves for entering the value of current set on the detector.

Possible range and units depend on the type of the detector -

FTD detector has the range of values 0.00-10.00 pA, ECD

detector 0.00-2.00 nA and TCD detector 0-200 mA. This field

is only present for Electron capture (ECD), Thermal

conductivity (TCD) and Flame thermoionic (FTD and WFTD)

detectors.

Signal Output Port

Specifies the signal output of the particular detector.

Shimadzu GC-2014C provides up to 4 signal outputs set in

the Shimadzu GC-2014C Setup - Signals dialog (for more details

see chapter Shimadzu GC-2014C Setup on pg. 19).

Power Controller

This field is only present on tabs of Flame thermoionic

detectors (FTD and WFTD).

Adjust Time

This field can only be edited when the Power Controller

checkbox is selected.

Shimadzu GC-2014C

4 Using the control module

11

Interference Filter

Possible values are P, Sand Sn. This field is only present

when using the Flame photometric detector (FPD or WFPD).

4.2.4 Time Events

Menu Path: Instrument -> Method -> GC Control

Fig. 10 Method Setup - GC - Time Events

This tab allows to set the events that should happen during

the run based on the analysis time. This includes events like

switching the detector polarity, range or current (where

applicable), setting temperatures to

detector/injector/auxiliary zones etc. To delete a row, simply

delete the value in the Time column on that row.

The table should be filled with the Time of the event in the

first column (in minutes, decimal format - 2 minutes 45

seconds should be set as 2.75), the event type in the Event

column, event value in the Value column and the Line

selected as set on the Shimadzu GC-2014C Setup - Line Config

tab. Possible events are:

Det 1(..4) Polarity

Sets the polarity of the detector (if the polarity for the given

detector has any sense). Polarity +corresponds to the value

1, polarity -corresponds to the value 2.

Det 1(..4) Range

4 Using the control module

Clarity Controls

12

Changes the detector range (as set before the analysis on the

DET X tab) during the course of the analysis. Range x1

corresponds to value 0, range x10-1 to value 1, x10-2 to value

2, x10-3 to value 3and x10-4 to value 4.

Det 1(..4) Current

Changes the current value of the detector (if the current for

the given detector has any sense). The new value should be

in range and units dependent on the type of the detector -

FTD detector has the range of values 0.00-10.00 pA, ECD

detector 0.00-2.00 nA and TCD detector 0-200 mA.

All 4 possible detectors are listed, even if they are not present

and configured in the Shimadzu GC-2014C Setup dialog. Those

not configured will have the text in the format Det #X Polarity

etc. with the # character - these shouldn't be used in the Time

Events table.

Event Operation

Performs an event operation defined by the event code.

These codes may be used as a positive number or negative

number, in which case the opposite of the operation is

performed. For example, event code 51 performs the

autozero operation on detector 1, while -51 event code

cancels the zero adjustment on detector 1. The basic event

codes and their functions are:

Event Code

Function

51 Autozeroes the Detector 1

52 Autozeroes the Detector 2

53 Autozeroes the Detector 3

54 Autozeroes the Detector 4

Tab 1: Event codes

For more event codes please see Shimadzu hardware

documentation.

Temperature of INJ1(2), DET1(2), AUX3(..5)

Changes the temperature of the particular temperature

zone. The initial temperature is set on the Oven/Zones tab,

but can be changed later during the analysis this way. The

Value column should hold the temperature in °C.

Program stop

Stops the GC control program. The value entered into the

Value column should be set to XY, where Xis the number of

Shimadzu GC-2014C

4 Using the control module

13

runs before the program stop command is sent and Yis the

number of file (in the GC) to be loaded after that. For

example value 16 corresponds to the program stop

command sent after one run of the method, after which the

FILE6 is loaded. The number of method runs doesn't have

any meaning for Clarity as the method is usually sent after

each injection, thus resetting the counter after each

injection. For more details, consult Shimadzu manual.

4.2.5 Pre Run

Menu Path: Instrument -> Method -> GC Control

Fig. 11 Method Setup - GC - Pre Run

This tab has the same functionality as the Time Events tab, so

the functions are described there together. The Pre Run tab

serves for setting of the program that takes place before the

analysis start.

4 Using the control module

Clarity Controls

14

4.2.6 Other

Menu Path: Instrument -> Method -> GC Control

Fig. 12 Method Setup - GC - Other

This tab allows to set the behavior of some parts of the

Shimadzu GC-2014C chromatograph.

Shutdown

Defines the behavior of the chromatograph after the analysis

end.

Keep State

The chromatograph will do nothing when the

analysis is completed.

Set Off after analysis

The chromatograph performs the System Off

function (check Shimadzu GC-2014C manual for

more details). This function is useful for switching

the chromatograph off after the last sample in the

sequence. When the Clarity Instrument is set to

send a method without prompting in the System

Configuration - Instrument Method Sending dialog and there

is another method opened in the Instrument window

at the analysis end, the chromatograph will be

Shimadzu GC-2014C

4 Using the control module

15

turned off by the current method and then turned

on by the sending of the instrument method.

Be careful when switching off instruments without automatic

pressure control (APC - GC-2014C) and automatic flow control

(AFC - all GC-2014 chromatographs) - the manually

controlled gasses flow is not switched off, which may end in

the leakage of possibly dangerous gasses (hydrogen) into the

laboratory environment.

Zero at ready

When checked, the chromatograph performs the autozero

action after it becomes READY.

Auto flame ON

When checked, the chromatograph will try to ignite the

flame in the detector after sufficient temperature and gasses

pressure was reached.

Re-ignite

While checked, the chromatograph will try to re-ignite the

flame in the detector when it is quenched. This may be

important during the start of the chromatograph as the auto

ignition may not be successful on the first try.

4 Using the control module

Clarity Controls

16

4.2.7 Gradients

Menu Path: Instrument -> Method -> GC Control

Fig. 13 Method Setup - GC - Gradients

This tab displays the temperature gradient as set on the

Method Setup - GC - Oven/Zones tab.

Table of contents

Other DataApex Control Unit manuals

Popular Control Unit manuals by other brands

Cooper Crouse-Hinds

Cooper Crouse-Hinds CEAG GHG 61 R Series operating instructions

Leviton

Leviton CP series Product data

Toradex

Toradex Apalis Series Design guide

Metso

Metso Jamesbury 4000 Series Safety manual

Honeywell

Honeywell Silent Knight SK-Monitor Installation and maintenance instructions

Allmatic

Allmatic SCOR.AS manual

Flowserve

Flowserve R6 Installation, operation and maintenance instructions

iRex

iRex IRM72S1-400 installation manual

McConnel

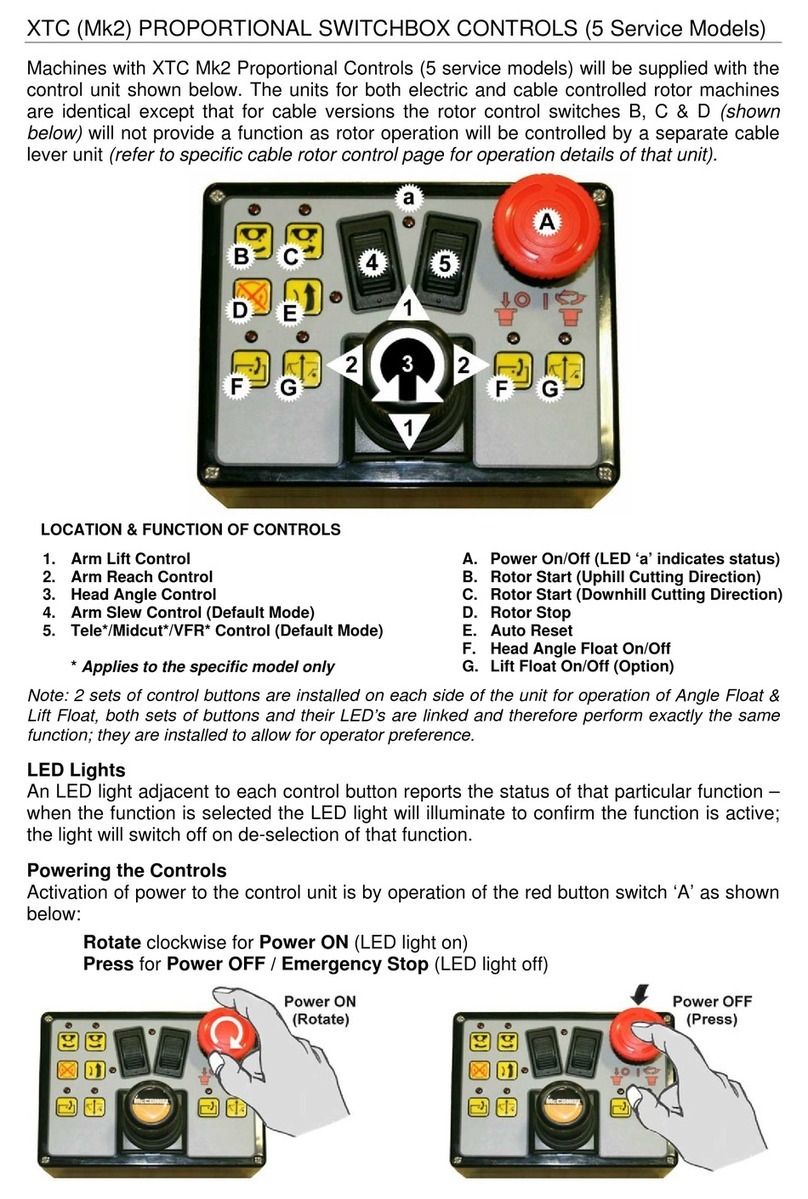

McConnel 5 Service XTC Mk2 PROPORTIONAL SWITCHBOX... quick start guide

M-system

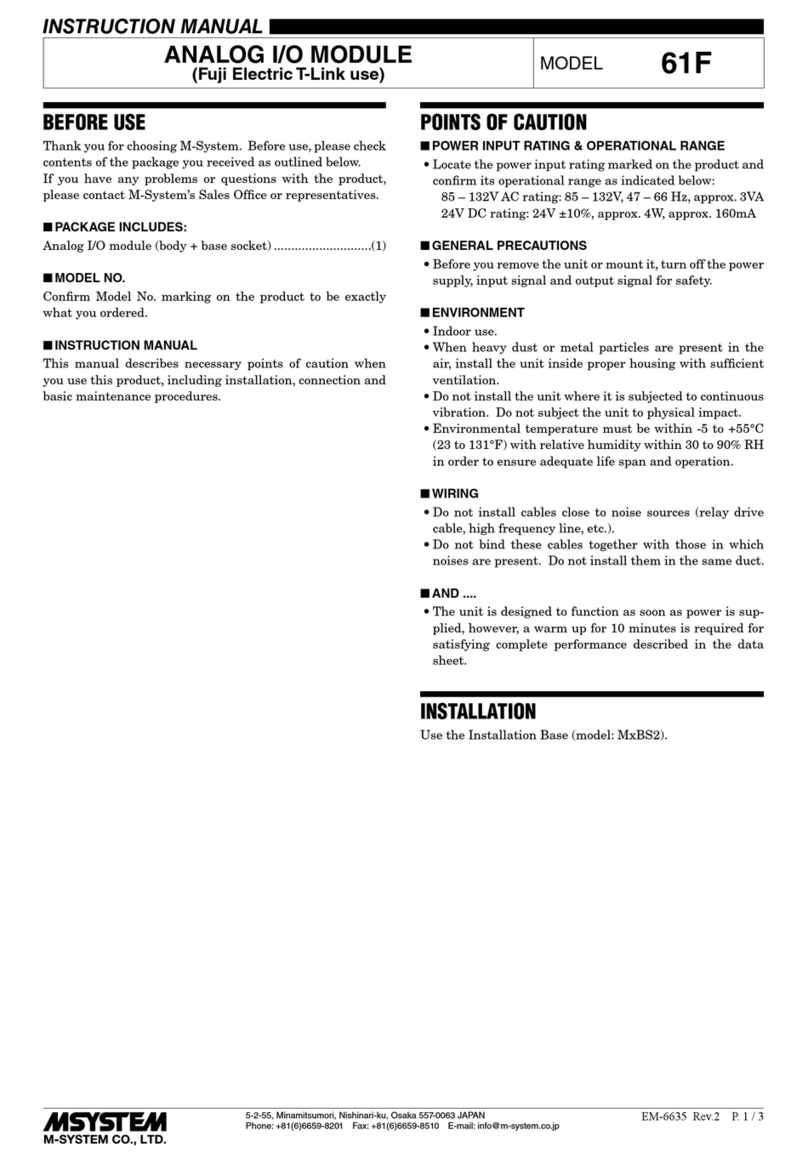

M-system 61F instruction manual

Rehau

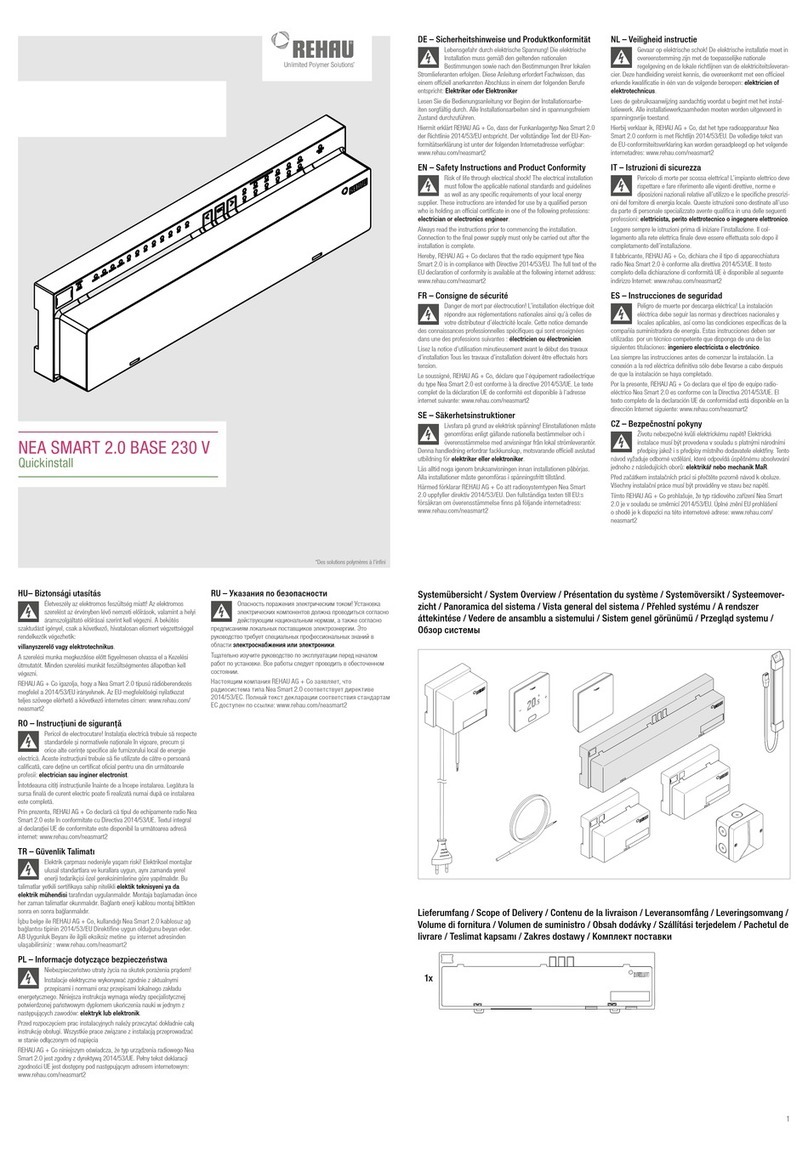

Rehau NEA SMART 2.0 BASE 230 V Quick install

Aircatglobal

Aircatglobal VirtualFly EFOS user manual