Dataprobe sBB-N15 Owner's manual

iBootBar V1.3x Page 1

Main: 201-934-9944 Website: dataprobe.com

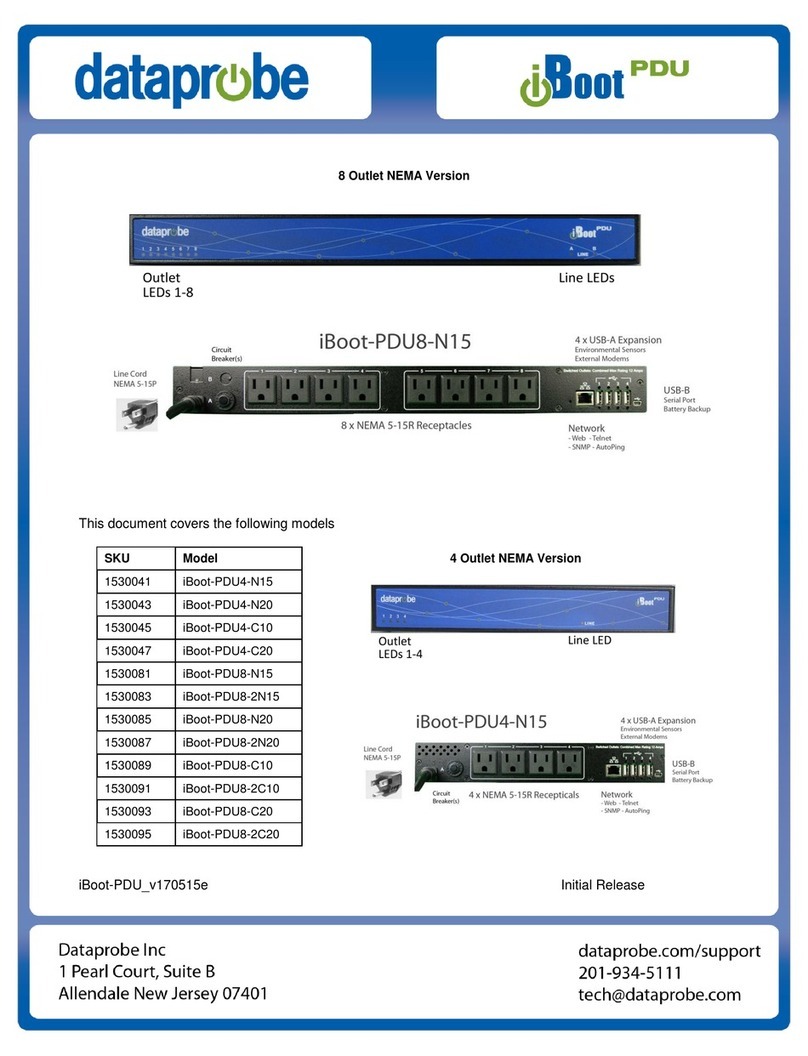

Scope of this Document:

This document covers the installation and operations of Dataprobe’s Serial iBootBar series of remote power control

units. These 1U rack mounted power strips are controlled via RS-232 serial communications and via contact closure

inputs. The following models are covered in this document:

Model Power Feed / Total Capacity Outlets

sBB-N15 NEMA 15 Amp 8 x NEMA 5-15

sBB-2N15 2 x NEMA 30 Amp 8 x NEMA 5-15

sBB-N20 NEMA 20 Amp 8 x NEMA 5-15

sBB-2N20 2 x NEMA 40 Amp 8 x NEMA 5-15

sBB-C10 IEC C14 10 Amp 8 x IEC C13

sBB-2C10 2 x IEC C14 20 Amp 8 x IEC C13

sBB-C20 IEC C20 20 Amp 8 x IEC C13

sBB-2C20 2 x IEC C20 40 Amp 8 x IEC C13

Serial BootBar

Installation and Operations

Ref: sBootBar_v090212d

SerialBootBar v.090212d Page 3

Table of Contents

Important Safety Instructions 4

Quick Start 5

General Overview 6

Installation 7

Rack Mounting

Serial Port

Contact Closure Inputs

Power Source

Serial Operation 9

Control Input Operation 14

Advanced Operation 15

Specifications 17

Compliance Statements 18

Technical Support, Warranty 19

Page

4

Serial

iBootBar

v090212d

Important Safety Information

When using this product, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and

injury to persons, including the following:

Disconnect all power cords before servicing!

1. Read and understand all instructions.

2. Follow all warnings in the manual and marked on the product.

3. Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

4. Do not use this product in an outdoor environment or near water, for example, near a bath tub, wash bowl, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool.

5. Do not place this product on an unstable cart, stand, or table. The product may fall, causing serious damage to the product.

6. Slots and openings in this product and the back or bottom are provided for ventilation to protect it from overheating, these openings must not be

blocked or covered. The openings should never be blocked by placing the product on the bed, sofa, rug, or other similar surface. This product

should never be placed near or over a radiator or heat register. This product should not be placed in a built-in installation unless proper ventilation

is provided.

7. This product should be operated only from the type of power source indicated on the marking label. If you are not sure of the type of power

supply to your home, consult your dealer or local power company.

8. This product is equipped with a three wire grounding type plug, a plug having a third (grounding) pin. This plug will only fit into a grounding type

power outlet. This is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to replace your obsolete outlet.

Do not defeat the safety purpose of the grounding type plug. Do not use a 3-to-2 prong adapter at the receptacle; use of this type adapter may

result in risk of electrical shock and/or damage to this product.

9. Do not allow anything to rest on the power cord. Do not locate this product where the cord will be abused by persons walking on it.

10. Do not overload wall outlets and extension cords as this can result in the risk of fire or electric shock.

11. Never push objects of any kind into this product through slots as they may touch dangerous voltage points or short out parts that could result

in a risk of fire or electrical shock. Never spill liquid of any kind on the product.

12. To reduce the risk of electrical shock, do not disassemble this product, but take it to a qualified serviceman when some service or repair work

is required. Opening or removing covers may expose you to dangerous voltages or other risks. Incorrect re-assembly can cause electric shock

when the appliance is subsequently used.

13. Unplug this product from the wall outlet and refer servicing to qualified service personnel under the following conditions:

a) When the power supply cord or plug is damaged or frayed.

b) If liquid has been spilled into the product.

c) If the product has been exposed to rain or water.

d) If the product does not operate normally by following the operating instructions. Adjust only those controls, that are covered by the operating

instructions because improper adjustment of other controls may result in damage and will often require extensive work by a qualified technician to

restore the product to normal operation.

e) If the product has been dropped or has been damaged.

f) If the product exhibitsa distinct change in performance.

14. Avoid using a telephone (other than a cordless type) during an electrical storm. There may be a remote risk of electric shock from lightning.

15. Do not use the telephone to report a gas leak in the vicinity of the leak.

16. Do not exceed the maximum output rating of the auxiliary power receptacle.

SerialBootBar v.090212d Page 5

Quick Start

Front Panel

Rear Panel –NEMA Versions

Rear Panel –IEC Versions

Quick Start Defaults

Serial Parameters 115,200 bps, 8 Data Bits, No Stop Bits, One Parity Bit (115200, 8, N, 1)

Command Line Quick Start:

Username: admin

Password admin

To view outlet status iBootBar> get outlets

To turn on off outlet 1 iBootBar> set outlet 1 off

To reboot outlet 2 iBootBar> set outlet 2 cycle

Outlet Status

Indicators

Reset Pushbutton

(Recessed)

Mains (Inlet) Power

Indicators

Linecord for

NEMA Models

Circuit Breaker

2nd Linecord and

Circuit Breaker

on

-

2N Models

8 NEMA 5-15

Outlets

Serial

(DCE)

Control Inputs

Expansion for Future

Applications

8 IEC C13 Outlets

IEC C-14 (10 Amp) or

IEC C

-

20 (20 Amp) Inlets

2nd Inlet and

Circuit Breaker

on

-

2

C

Models

Page 6Serial iBootBar v090212d

General Overview

8 Independently controllable outlets

The Serial iBootBar (sBB) series is designed to provide power distribution

and remote power control. Each sBB allows eight outlets to be

independently switched on and off for reboot, energy management and

security. The sBB has many features to make the management of power

distribution simple and cost effective:

Serial RS-232 Control RS-232 serial control allows for direct control of the sBB outlets, and

complete setup of all parameters. Serial parameters are completely

configurable.

Contact Closure Control Each outlet is associated with a discrete input that can be connected to

a physical switch or relay. Changing the state of the input will operate

the outlet. Outlets are individually configurable for On and Off state

relative to contact closed or open.

Dual power inputs for redundant

power feeds (some models)

Models with dual inputs (sBB-2N-or sBB-2C-) have two inlets (mains).

Each main feeds four outlets Inlet A supports outlets 1-4 and Inlet B

feeds 5-8. Dual power inlet models can be used to support higher current

devices, as each inlet can carry its rated load, doubling the amperage of

a single inlet device. Dual Inlet models can also be used to source power

from two redundant sources, with each source feeding a power supply of

a single device.

Support for dual redundant powered

devices In addition to two power sources, pairs of outlets can be linked together

to allow simultaneous control. This allows a single command to power

down devices with dual redundant power supplies.

Multiple users with assigned rights

and simultaneous control Up to 16 users can be assigned administrator or user only rights, plus

access to specific outlets and groups. Users only see the outlets and

groups they are assigned to.

Grouping of outlets for simultaneous

management Multiple outlets can be linked together in named groups and managed

together. Example: power cycling all devices of a certain type together.

SerialBootBar v.090212d Page 7

Installation

Rack Mounting

The iBootBar is designed for mounting in a standard 19” equipment cabinet.

1. There are two L-shape brackets marked as “L”and “R”, install the “L”bracket on the left side of the sBB chassis then

the “R”bracket on its right side.

2. Install the sBB to the standard 19-inch rack.

Serial Port

The iBootBar has a 9 pin D subminiature connector for RS-232 serial control. The connector is configured as DCE for

direct connection to a laptop or other terminal device. Default serial parameters are 115,200 bps, 8 data, no parity, 1 stop

bit (115200,8,n,1).

Serial Port pinout:

Control Inputs

Serial Boot Bars have 16 terminal block connections for control of individual

outlets using contact closure / contact open connections. Each connection

marked 1 through 8 controls the outlet of the same number. The remaining

8 connections are ground, and are interchangeable. Using a small flat-

blade screwdriver, depress the wire release mechanism for one of the

terminals on the terminal block and insert the bare wire into the terminal.

Remove the screwdriver to secure the wire. Gently tug on the wire to verify

that it is secure in the terminal block.

The default setting for the sBB is:

Contact Open = Power On

Contact Closed = Power Off

This setting is changeable through the serial port.

Caution: Use only dry switch or relay closures, or open

collector relay drivers to connect to the sBB inputs. If you

have any doubts about proper connections, consult Dataprobe

Technical support.

Pin No Description

2Receive Data

3Transmit Data

5Signal Ground

Depress release to insert or remove wire

Page 8Serial iBootBar v090212d

Expansion

Future Expansion. No function in the current Serial iBootBar.

SerialBootBar v.090212d Page 9

Power Source

The sBB-N15 provides a linecord for connection to a 15 Amp 115VAC

service. The total maximum current load for all outlets on the sBB-N15

cannot exceed 12 Amps.

The sBB-2N15providestwo linecords for connection to 15 Amp 115VAC

services. The total maximum current load for outlets on any linecord

cannot exceed 12 Amps. Each linecord distributes power to four outlets.

The sBB-N20 provides a linecord for connection to a 20 Amp 115VAC

service. The total maximum current load for all outlets on the sBB-N20

cannot exceed 16 Amps.

The sBB-2N20 provides two linecords for connection to 20 Amp 115VAC

services. The total maximum current load for outlets on any linecord

cannot exceed 16 Amps. Each linecord distributes power to four outlets.

The sBB-C10 is for international applications and can be used on 100V to

240VAC. The sBB-C10 provides an IEC 320 style universal inlet for

connecting a detachable power cord. A standard IEC to CEE7 European

cord set is supplied with the unit for use on 10 Amp 240VAC service*.

The total maximum current load for all outlets cannot exceed 12 Amps at

115VAC or 10 Amps when used at 240VAC.

The sBB-2C10 is for international applications and can be used on 100V

to 240VAC. The sBB-2C10 provides two IEC 320 style universal inlets for

connecting a detachable power cord. Two standard IEC to CEE7

European cord sets are supplied with the unit for use on 10 Amp

240VAC service*. The total maximum current load for outlets on any

linecord cannot exceed 12 Amps at 115VAC or 10 Amps when used at

240VAC. Each linecord distributes power to four outlets.

The sBB-C20 is for international applications and can be used on 100V to

240VAC. The sBB-C20 provides an IEC 320 style universal inlet for

connecting a detachable power cord. A standard IEC to CEE7 European

cord set is supplied with the unit for use on 20 Amp 240VAC service*.

The total maximum current load for all outlets cannot exceed 16 Amps.

The sBB-2C20 is for international applications and can be used on 100V

to 240VAC. The sBB-2C20 provides two IEC 320 style universal inlets for

connecting a detachable power cord. Two standard IEC to CEE7

European cord sets are supplied with the unit for use on 16 Amp

240VAC service*. The total maximum current load for outlets on any

linecord cannot exceed 16 Amps. Each linecord distributes power to

four outlets.

* Power cords for other countries are available from your local source. If a power cord with a different terminating plug is

required, be sure it is properly rated and meets all the required local electrical standards.

Page 10 Serial iBootBar v090212d

Serial Operation

Command Line Interface

The Command Line Interface provides complete setup of all function of the iBootBar. Some commands of the CLI require administrative rights. These are

indicated in the table below.

To access the sBB, connect to the serial port and type Enter, the user will be prompted for Username and Password. The default for both is admin

Outlet Commands

Command Description Access Fact Def

get outlets Returns the status of ALL the outlets the user has rights to. User

get outlet <1-8> Returns the status of the designated outlet. The user must have

rights to the selected outlet. User

set outlet <1-8> <on/off/cycle> Sets the selected outlet to the selected state. The user musthave

rights to the selected outlet. User

set outlet <1-8> name <name> Setsthe name of the selected outlet of the selected iBootBar. 20

characters max. Admin Outlet <#>

get outlet <n> control.on

set outlet <n> control.on <open/closed>

Gets or sets the state that the control input causes the

corresponding outlet to turn On. Admin Open

get outlet <1-8> initial.state

set outlet <1-8> initial.state <on/off/last>

Get or set the initial state of the selected outlet of the currently

selected iBootBar. Initial state is the condition of the outlet when the

iBootBar is powered up. This command will be ignored if external

control is enabled withset external control enable

Admin Last

SerialiBootBar v090212d Page 11

User Commands

Command Description Access Fact Def

get users Return a list of all current users Admin

get user <username> Returns the selected user’s details Admin

add user <username> Added a user to the root iBootBar’s user table. 16 users maximum.

20 Characters max.

Note: the new user’s password will default to the same as the

username.

Users default to no rights to any outlets. Add user rights to outlets

and groups.

Admin

del user <username> Deletes the selected user from the root iBootBar’s user table Admin

ren user <username> <newname> Renames the selected user in the root iBootBar’s user table. 20

character max. Admin

set user <username> outlet <1-8/all> <yes/no> Sets the users right to the selected outlet Admin No Rights

set user <username> group <name> <yes/no> Sets the user’s rights to the selected group Admin No Rights

set user <username> role <admin/user> Sets the user’s roll. Admin User

set user <username> password <password> <confirm> Sets the user’s password. 20 characters max. Admin User’s Name

Page 12 Serial iBootBar v090212d

Device Commands

Command Description Access Fact Default

get outlets This command displays a list of connected devices, and their current

status. User

set name <name> Set the name of the selected iBootBar. 20 characters max. User

get current Gets the measured current of the iBootBar Admin

get external control

set external control <enable/disable>

Get or set external control capability. Enabling this will allow the

external inputs to control its corresponding outlet. Admin enable

get cycle

set cycle <1-99>

Get or set the cycle time in seconds. Cycle time is the time that the

outlet will be off during a reboot (on–off –on) or on during a cycle (off

–on–off)

User 10

get delay

set delay <0-99>

Get or set the delay time in seconds. When multiple outlets are

turned On by a single command, this delay controls the interval

between powering up of the outlets. This delay is used to limit power

up inrush.

User 1

get current alarm

set main <a/b> highalarm <nn.n>

set main <a/b> lowalarm <nn.n>

High and Low alarms are used to monitor current conditions and

send an alert via the serial port when the high or low thresholds are

exceeded.

From 0.0 to10.0/15.0/20.0 (depending on max current for device) in

0.1amp increments. For devices with two Mains, Main A and Main B

are set separately, but displayed together with the get command.

Admin Highalarm:

10.0 for 10 Amp

Models

15.0 for 15 Amp

Models

20.0 for 20 Amp

Models

Lowalarm:

0.0 Amp

SerialiBootBar v090212d Page 13

Command Description Access Fact Def

set logging <yes/no> Turns on or off event logging

get logging Gets the current logging setting

set alarms <yes/no> Turns on ofoff current alarm reporting

get alarms Gets current alarm reporting status

get console Displays the current console configuration, Timeout and Baud Rate Admin

set console timeout <30-3600/disable> Console can be set to automatically logout with no activity for 30

seconds to 1 hr in seconds, or disabled. Admin 120

set console baudrate <2400/4800/9600/19200/38400/

57600/115200>

The baud rate of the serial port. 400,4800,9600,19200

,38400,57600,115200 bps Admin 115200

set factory defaults Resets all parameters to their factory settings Confirmation is

required. Note: This command can take up to 30 seconds to execute.

Admin

logout Ends the session User

reboot Reboots the selected iBootBar. This will not change the status of the

outlets. Admin

Group Commands

Command Description Access Fact Def

get groups Returns a list of the groups that the current user has rights to. User

get group <groupname> Returns the details of the selected group User

set group <groupname> <on/off/cycle> Controls the selected group User

Page 14 Serial iBootBar v090212d

Command Description Access Fact Def

add group <groupname> Adds a new group. 20 characters max. Up to 8 groups maximum Admin

set group <groupname> outlet <1-8/all> <yes/no> Adds or deletes a specific outlet on a specific device from the

selected group. Admin

ren group <groupname> <newname> Renames the selected group. 20 characters max. Admin

del group <groupname> Deletes the selected group.Admin

Firmware Upload Commands

Command Description Access Fact Def

get upload enable Admin

set upload enable Get or set the ability for the root iBootBar to accept a firmware upload. Admin No

SerialiBootBar v090212d

Control Input Operation

The eight control inputs can be used to operate the outlets. Shorting any of the inputs to ground will change the state of the

outlet with the same number as the input. (Input 1 controls Outlet 1, Input 2 controls Outlet 2, etc.)

Caution: Use only dry switch or relay closures, or open collector relay drivers to connect to the sBB inputs. If you have any

doubts about proper connections, consult Dataprobe Technical support.

The default control is Input Open = Outlet On, Input Grounded = Outlet Off.

This can be changed using the set outlet <n> control.on <open/closed> command.

Example:

set outlet 3control.on closed Causes Outlet three to be Input Closed (to Ground) = Outlet On, Input Open = Outlet Off

get outlet 3 control.on will check the current setting.

Page 16 Serial iBootBar v090212d

Advanced Operation

Loggingand Alarm

Logging and Alarm capabilities allow messages to be sent via the serial port when state changes occur. Logging

messages indicate a change in outlet state. Alarm messages occur when current draw measurements go in our out of

alarm. Both these message types occur only when an administrator or user is not logged into the Serial iBootBar.

Use the following commands to turn On or Off the logging and alarm capabilities.

set logging <yes/no>

set alarm <yes/no>

Logging Message Format

The messages will be formatted as follows:

<cr><lf><device name> -<outlet #> <outlet name> -<control type> -<source><cr><lf>

Where:

<cr> =ASCII carriage return

<lf> = ASCII line feed character

<device name> = User programmed name of the sBB

<outlet #> =The number of the outlet; 1-8

<outlet name> = the user programmed name of the outlet that has changed

<source> = “CLI ”, “Expansion Port ”, or “Control Port ”

Example: ServerRoom –ServerA –Off –Expansion Port.

Alarm Message Format

The messages will be formatted as follows:

<cr><lf><device name> -<main> -<alarm message> -<current><cr><lf>

Where:

<cr> =ASCII carriage return

<lf> = ASCII line feed character

<device name> = User programmed name of the sBB

<main> =“Main A” or “Main B”

<message> =“High Alarm”, “Low Alarm”, or “Alarm Clear”

<current> =actual current measurement

Example: ServerRoom –Main A –High Alarm –8.7

SerialiBootBar v090212d Page 17

Firmware Upgrades

The iBootBar can be upgradedvia the network if the upload feature has been enabledusing the set upload enable yes

command on the console interface. To upgrade the iBootBar download the latest version of the firmware and upgrade utility

from the Dataprobe website.

Password Recovery

Holding the reset button on the front panel of the iBootBar for 5 seconds or longer will initiate a password recovery mode.

Once the reset button is released, the user has 30 seconds to log in to the CLI using the username admin and password

admin. Upon accessing the CLI, change the username and password for User 1 as desired.

Page 18 Serial iBootBar v090212d

Specifications

Physical:

Height: 1U 1.75 in (4.5 cm)

Width: 19.0 in (48.25 cm)

Depth: 6.00 in (15.25 cm)

Weight: 7 lbs (3.25 Kg)

Environmental:

Temperature

Operating: 0 to 40oC

Storage: -10 to 85oC

Relative

Humidity 0 to 95%

Non-

Condensing

Input Required Model Input Output Control

sBB-N15 N15 8 x N15 I, S,

sBB-N15-MN15 8 x N15 I, S, M

sBB-2N15 2 x N15 8 x N15 I, S, L

sBB-2N15-M2 x N15 8 x N15 I, S, M

sBB-N20 N20 8 x N15 I, S

sBB-N20-MN20 8 x N15 I, S, M

sBB-2N20 2 x N20 8 x N15 I, S

sBB-2N20-M2 x N20 8 x N15 I, S, M

sBB-C10 C14 8 x C13 I, S

sBB-C10-MC14 8 x C13 I, S, M

sBB-2C10 2 x C14 8 x C13 I, S

sBB-2C10-M2 x C14 8 x C13 I, S, M

sBB-C20 C20 8 x C13 I, S

sBB-C20-MC20 8 x C13 I, S, M

sBB-2C20 2 x C20 8 x C13 I, S

sBB-2C20-M2x C20 8 x C13 I, S, M

Key:

Input: N15 NEMA 5-15 Linecord 115VAC 15 Amps combined total switched

N20 NEMA 5-20 Linecord 115VAC 20 Amps combined total switched

C14 IEC320 C14 Receptacle 100-240VAC 10 Amps total at 240VAC Max

C20 IEC320 C20 Receptacle 100-240VAC 20 Amps total at 240VAC Max

Outlet: N15 NEMA 5-15 Receptacle 115VAC 12 Amps Max

C13 IEC 320 C13 Receptacle 100-240VAC 10 Amps Max

SerialiBootBar v090212d Page 19

Compliance Statements

FCC Part 15 Regulation

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy, and if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Plug the equipment into an outlet on a circuit that is different from the one used by the receiver.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC rules. Operation of this device is subject to the

following conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference that may cause undesired operation.

WARNING: Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user’s authority to operate the

equipment

EMC, Safety, and R&TTE Directive Compliance

The CE mark is affixed to this product to confirm compliance with the following European

Community Directives:

• Council Directive 89/336/EEC of 3 May 1989 on the approximation of the laws of Member

States relating to electromagnetic compatibility;

And

• Council Directive 73/23/EEC of 19 February 1973 on the harmonization of the laws of

Member States relating to electrical equipment designed for use within certain voltage

limits;

and

• Council Directive 1999/5/EC of 9 March on radio equipment and telecommunications

terminal equipment and the mutual recognition of their conformity.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la classe AB respecte toutes les exigences du Reglement Canadien sur

le matériel brouilleur.

This product meets the applicable Industry Canada technical specifications

Page 20 Serial iBootBar v090212d

Technical Support, Returns and Warranty

Dataprobe Technical Support is available 8:30AM to 5:30PM ET to assist you in the installation and operation of this

product. To obtain Technical Support call 201-934-5111, or Email us at [email protected]. Please have the following

information available when you call:

•Model of Product

•Lot and Version Numbers

•Data of Purchase

•Name of Seller (if other than Dataprobe)

If you purchased this product through an Authorized Dataprobe Reseller, you should contact them first, as they may have

information about the application that can more quickly answer your questions.

WARRANTY

Seller warrants this product, if used in accordance with all applicable instructions, to be free from original defects in

material and workmanship for a period of One Year from the date of initial purchase. If the product should prove defective

within that period, Seller will repair or replace the product, at its sole discretion.

Service under this Warranty is obtained by shipping the product (with all charges prepaid) to an authorized service center.

Seller will pay return shipping charges. Call Dataprobe Technical Service at (201) 934-5111 to receive a Return Materials

Authorization (RMA) Number prior to sending any equipment back for repair. Include all cables, power supplies and proof

of purchase with shipment.

THIS WARRANTY DOES NOT APPLY TO NORMAL WEAR OR TO DAMAGE RESULTING FROM ACCIDENT, MISUSE,

ABUSE OR NEGLECT. SELLER MAKES NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY EXPRESSLY

SET FORTH HEREIN. EXCEPT TO THE EXTENT PROHIBITED BY LAW, ALL IMPLIED WARRANTIES, INCLUDING ALL

WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR ANY PURPOSE ARE LIMITED TO THE WARRANTY

PERIOD SET FORTH ABOVE; AND THIS WARRANTY EXPRESSLY EXCLUDES ALL INCIDENTAL AND

CONSEQUENTIAL DAMAGES.

Some states do not allow limitations on how long an implied warranty lasts, and some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights, and you may have other rights which vary from jurisdictions to jurisdiction.

WARNING: The individual user should take care to determine prior to use whether this device is suitable, adequate or safe

for the use intended. Since individual applications are subject to great variation, the manufacturer makes no representation

or warranty as to the suitability of fitness for any specific application.

Dataprobe Inc.

This manual suits for next models

7

Table of contents

Other Dataprobe Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

Microsemi

Microsemi 9001GO-ET User's installation guide

Ingrasys

Ingrasys iPoMan II-1200 user manual

philippi

philippi STV 200 Series instruction manual

PSC

PSC POWER STAR LiFE Operation manual

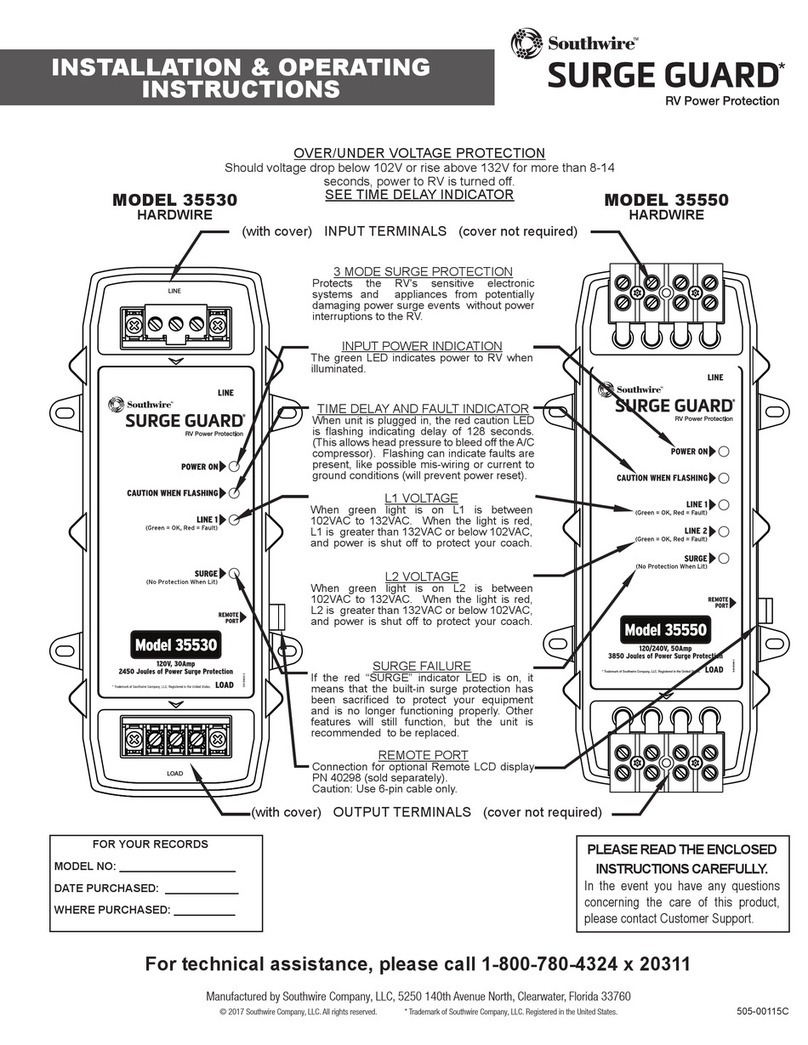

Southwire

Southwire Surge Guard 35530 Installation & operating instructions

ETA Systems

ETA Systems PD11SP owner's manual