4. INSTALLATION

Please read completely before beginning.

WARNING: Installation should only be performed

by an experienced Installer familiar with DC power

distribution systems.

4.1. Unpack and inspect the Newmar Fuse Panel

for possible damage incurred during shipping. If

damage is found, file a claim immediately with the

carrier, and notify Newmar.

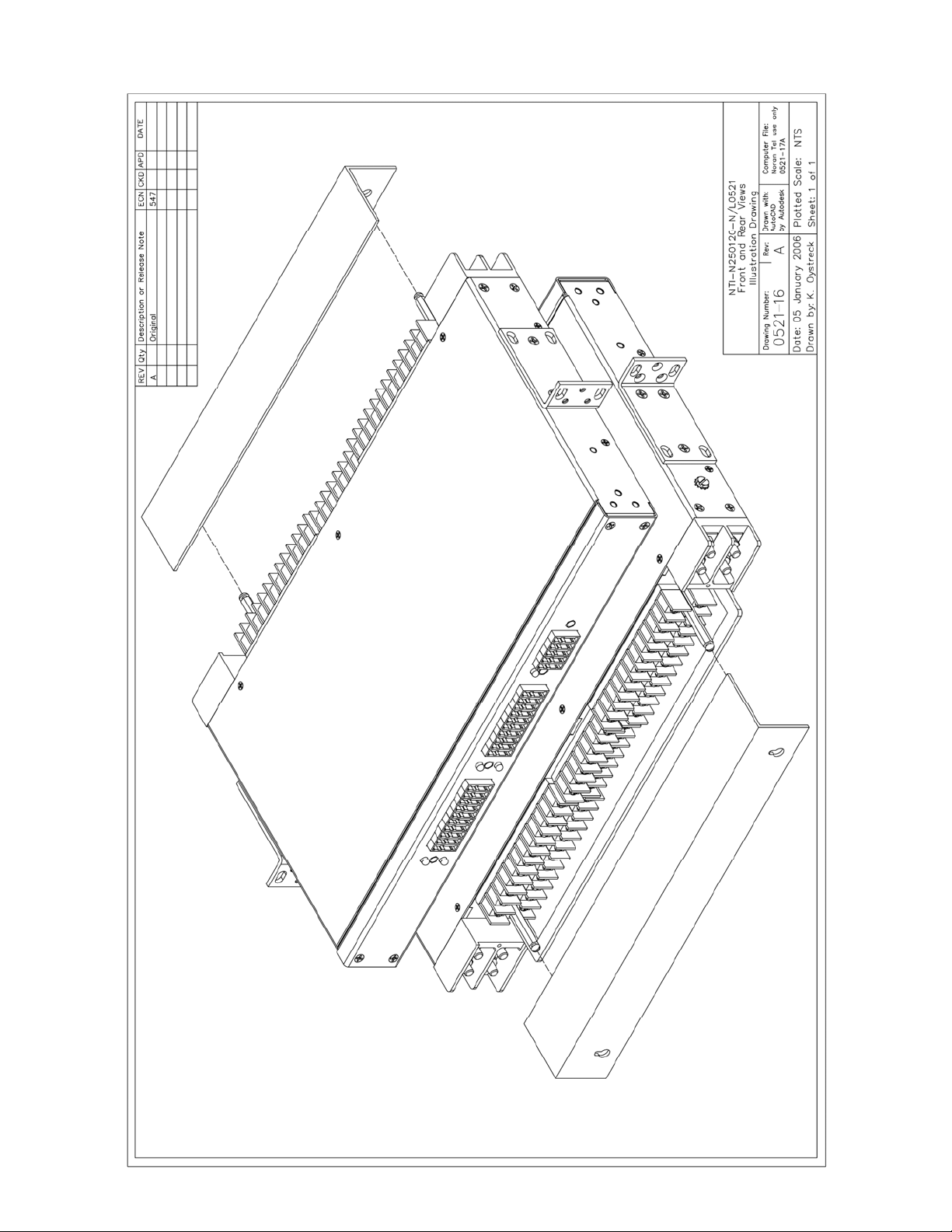

4.2. Once the panel is unpacked, verify that there

are two sets of mounting brackets (1” & 1-3/4”

spacing). Adjust the position and orientation of

the correct mounting brackets on the fuse panel,

such that it will fit the rack you wish to mount the

panel in. Single rack height panels have a

universal bracket that allows the panel to be

mounted on either 19" or 23" wide equipment

racks and can be installed for flush mounting of

the fuse panel, or for a 5" offset mounting.

4.3. Mount the panel on the equipment rack using

the thread forming #12-24 rack mounting screws

and tooth lock washers provided.

WARNING: For safety reasons all wiring should

be done with the power source removed (when

possible).

4.4. Remove the distribution fuse feeding the

input cables that are to be connected to the new

panel. Using input cables specified by the Job

Engineer, hook up the input cables to the input

terminal block on the fuse panel (“BAT” & “RTN”

for each bus). Each high current input terminal

uses a two hole compression lug (1/4” on 5/8”,

torque to 5.5 ft-lbs).

4.5. The battery outputs (“BAT”) are available at

the terminal blocks (#6 screw, up to 10awg fork)

at the rear of the panel. Each fuse position is

numbered and that circuit is available at the

terminal block position with the same number.

4.6. All battery return (“RTN”) connections are

also terminated on barrier strips (#6 screw, up to

10awg fork). Note, these returns are isolated

from the chassis frame.

4.7. This panel has MAJOR Bus A, MAJOR Bus

B and MINOR External alarms. Each alarm has a

common (C), normally open (NO) and normally

closed (NC) alarm contact.

The Minor External Input Alarm is used for alarms

that originate outside the panel (bay alarms). A

ground signal is supplied from another device in

the bay to activate this alarm.

In an alarm the “C” contact will short to the “NO”

contact, and the “NC” will open. Connect the

alarm connections as per your alarm system

requirements. Newmar recommends you fuse the

alarm battery supply (ABS) to 1A or less to protect

the alarm wiring and circuitry.

4.8. CHASSIS GROUND; For safety reasons,

and as recommended by NEBS, the chassis

should be electrically connected to the rack

ground. From step 4.3. the panel should already

be ground to the rack via the #12-24 thread

forming rack screws and outside tooth lock

washers. In addition to grounding via the

mounting brackets, it is recommended you ground

the chassis using a ground cable and the #10 bolt

and locks on side of chassis (#10 screw torque;

2ft-lbs or 2.7Nm).

4.9. Power up the panel by installing the

distribution fuses supplying the panel. The panel

should power up with the Normal Operation LED

illuminated and without any red LEDs illuminated,

and the relays should be in the “Normal” state (“C”

connected to “NC”).

4.10. If you wish to verify the fuse alarm circuit,

you can insert a blown fuse into one of the empty

fuse holders. The red Fuse Alarm LED should

light and the Normal Operation LED should

extinguish and the appropriate “MAJOR” alarm

extension relay should change states to extend

the alarm. If you wish to verify the externally

activated alarm you can connect a GND to the

External Alarm In, the External Alarm LED should

light and the MINOR-external alarm extension

relay should change states to provide the alarm

extension.

4.11. Install panel output distribution fuses as

required. Use the provided designation card to

keep a record of which equipment is connected to

which circuit and what the fuse rating is. Be

careful not to overload the panel bus or BDFB

fuse position rating supplying the panel.

Note: If you have any questions, suggestions, or

problems, please don't hesitate to call Newmar

Technical Support at (714) 751-0488, (email)

us through the Internet at

http//www.newmartelecom.com. Your input helps

us in our ongoing product improvement process

that benefits both of us. Thank You.