Datex-Ohmeda Tec 5 User manual

Tec 5 Continuous

Flow Vaporizer

Operation and Maintenance Manual

User Responsibility

This Product will perform in conformity with the description thereof contained in this

operating manual and accompanying labels and/or inserts, when assembled, operated,

maintained and repaired in accordance with the instructions provided. This Product

must be checked periodically. A defective Product should not be used. Parts that are

broken, missing, plainly worn, distorted or contaminated should be replaced

immediately. Should such repair or replacement become necessary, Datex-Ohmeda

recommends that a telephonic or written request for service advice be made to the

nearest Datex-Ohmeda Field Service Support Center. This Product or any of its parts

should not be repaired other than in accordance with written instructions provided by

Datex-Ohmeda and by Datex-Ohmeda trained personnel. The Product must not be

altered without the prior written approval of Datex-Ohmeda’s Quality Assurance

Department. The user of this Product shall have the sole responsibility for any

malfunction which results from improper use, faulty maintenance, improper repair,

damage, or alteration by anyone other than Datex-Ohmeda.

CAUTION wU. S. Federal and Canadian law restrict this device to sale by or on the order of

a licensed medical practitioner. Outside the U. S. A. and Canada, check local

laws for any restrictions that may apply.

Datex-Ohmeda products have unit serial numbers with coded logic which indicates a

product group code, the year of manufacture and a sequential unit number for

identification.

AAA A 12345

This alpha character indicates the year of product manufacture

and when the serial number was assigned; “Y” = 1995, “Z” = 1996,

“A” = 1997, etc. “I” and “O” are not used.

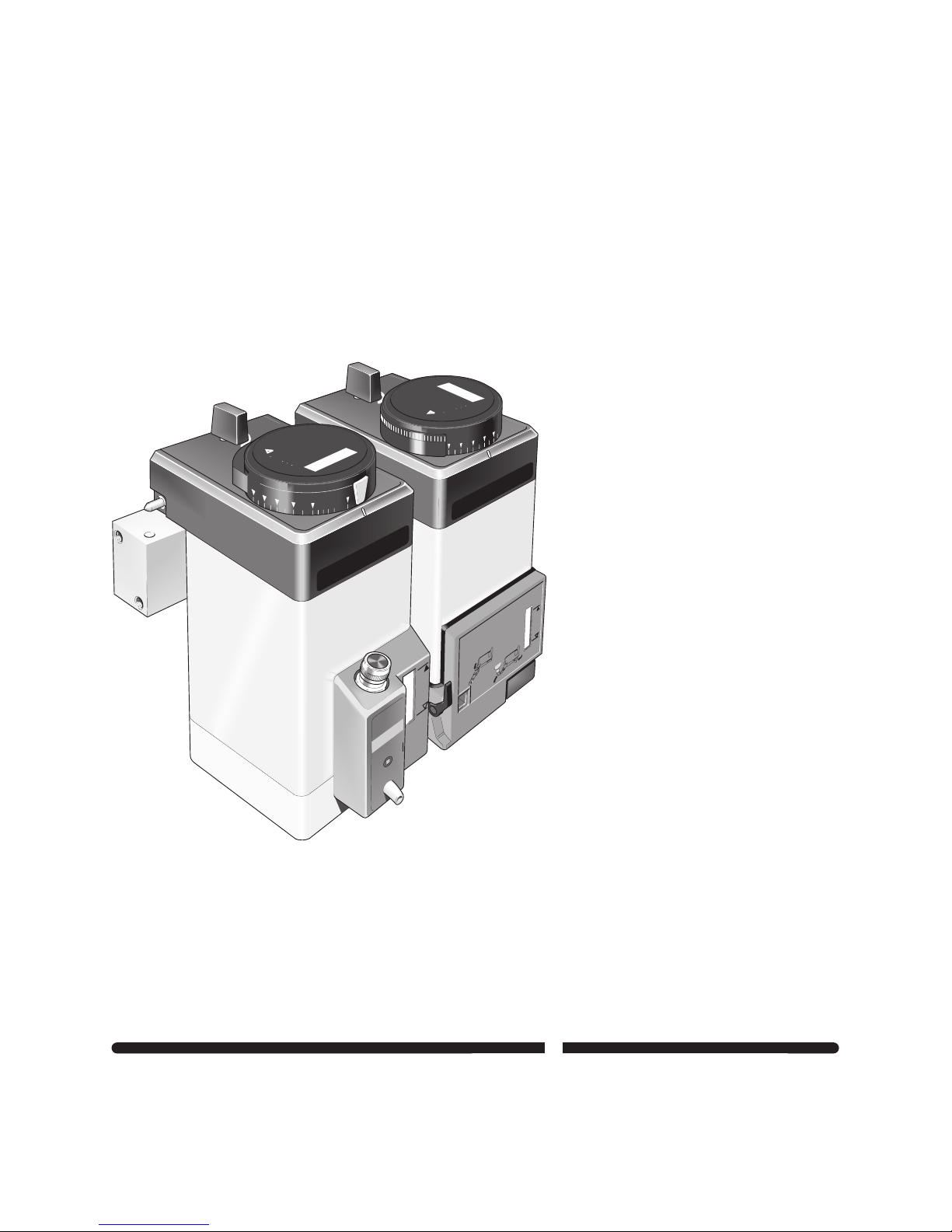

Tec 5 Continuous

Flow Vaporizer

Lock

before

use

2

Warning

Keep upright at all times

See manual for

Operational Instructions.

Factors affecting performance.

Service and maintenance

recommendations

Next service date

!

Use Only Isoflurane

3

4

5

1

.8

Lock

before

use

Use Only

Enflurane

1

2

3

4

5

0%

.8

.6

.4

.2

Warning

Keep upright at all times

See manual for

Operational Instructions.

Factors affecting performance.

Service and maintenance

recommendations

Next service date

!

Of

Contents

Page

1.0 Introduction .................................................... 1

1.1 Operation And Maintenance Manual......................................................1

1.2 Precautions.............................................................................................1

1.3 Symbols..................................................................................................1

2.0 Servicing Policy ............................................... 2

3.0 Description ..................................................... 3

3.1 General....................................................................................................3

3.2 Control Dial.............................................................................................3

3.3 Safety Interlocks.....................................................................................3

3.4 Vaporizer Identification Label................................................................4

4.0 Operating Instructions ........................................ 4

4.1 General....................................................................................................4

4.2 Vaporizer Mounting Procedure..............................................................5

4.3 Checking For Correct Mounting Of The Vaporizer................................6

4.4 Turning ON The Vaporizer......................................................................6

4.5 Vaporizer Removal.................................................................................6

4.6 Filling And Draining................................................................................7

4.6.1 General....................................................................................................7

4.6.2 Filling A Vaporizer Which Incorporates A Screw Cap Filler..................7

4.6.3 Draining A Vaporizer Which Incorporates A Screw Cap Filler..............8

4.6.4 Filling A Vaporizer Which Incorporates A Keyed Filler..........................9

4.6.5 Draining A Vaporizer Which Incorporates A Keyed Filler...................10

4.6.6 Filling A Vaporizer Which Incorporates A Quik-Fil™ Filler.................11

4.6.7 Draining A Vaporizer Which Incorporates A Quik-Fil™ Filler..............12

5.0 Maintenance ..................................................13

5.1 Schedule...............................................................................................13

5.1.1 Every Two Weeks.................................................................................13

5.1.2 Every Three Years................................................................................13

5.2 Cleaning................................................................................................13

5.3 Contamination......................................................................................14

5.4 Repairs..................................................................................................14

6.0 Principle Of Operation .......................................15

6.1 Interlock Mechanism............................................................................15

6.2 Selectatec Series Mounted Manifold Gas Circuit................................17

6.3 Vaporizer Valve And Sump Assembly.................................................18

6.4 Gas Flow Through The Vaporizer.........................................................19

6.4.1 General..................................................................................................19

6.4.2 By-pass Circuit.....................................................................................19

6.4.3 Vaporizing Chamber Circuit.................................................................19

7.0 Performance ..................................................21

7.1 Performance Curves.............................................................................21

7.1.1 Isotec 5%..............................................................................................21

7.1.2 Fluotec 5%............................................................................................22

7.1.3 Enfluratec 5%.......................................................................................23

7.1.4 Sevotec 5%...........................................................................................24

7.1.5 Sevotec 8%...........................................................................................25

7.2 Effects Of Variables..............................................................................26

7.2.1 Anaesthetic Agent Consumption.........................................................26

7.2.2 Temperature.........................................................................................26

Tec 5 Vaporizer Contents 1

O & M Manual Part No. 1105-0100-000 August 1999

Contents 2 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

Contents

Page

7.2.3 Barometric Pressure............................................................................26

7.2.4 Back Pressure (Steady)........................................................................27

7.2.4.1 Low And Moderate Pressures27

7.2.4.2 High Pressures 27

7.2.5 Back Pressure (Fluctuating).................................................................27

7.2.6 Carrier Gas Composition......................................................................27

7.2.7 Time Out Of Service.............................................................................27

7.2.8 Other Variables.....................................................................................28

8.0 Checking The Calibration ...................................28

9.0 Analytical Techniques .......................................29

10.0 Specification ..................................................30

10.1 Calibration.............................................................................................30

10.2 Resistance To Gas Flow With Vaporizer Out Of Circuit......................30

10.3 Liquid Capacity.....................................................................................30

10.4 Weight And Dimensions......................................................................30

10.5 Environmental Conditions....................................................................30

10.6 Performance.........................................................................................30

11.0 Warranty .......................................................31

Illustrations

Fig. 1 Vaporizer Identification Label................................................................4

Fig. 2 Vaporizer Mounting Procedure..............................................................5

Fig. 3 Locking The Vaporizer On To A Manifold..............................................5

Fig. 4 Turning ON The Vaporizer......................................................................6

Fig. 5 Unlocking The Vaporizer From A Manifold............................................6

Fig. 6 Filling A Vaporizer Which Incorporates A Screw Cap Filler..................7

Fig. 7 Draining A Vaporizer Which Incorporates A Screw Cap Filler..............8

Fig. 8 Filling A Vaporizer Which Incorporates A Keyed Filler..........................9

Fig. 9 Draining A Vaporizer Which Incorporates A Keyed Filler...................10

Fig.10 Filling A Vaporizer Which Incorporates A Quik-Fil™ Filler.................11

Fig.11 Draining A Vaporizer Which Incorporates A Quik-Fil™ Filler.............12

Fig.12 Vaporizer Interlock Mechanism...........................................................15

Fig.13 Two Vaporizers Locked On To The Manifold -

Both Turned OFF...................................................................................16

Fig.14 Two Vaporizers Locked On To The Manifold -

Vaporizer A Turned ON........................................................................16

Fig.15 Manifold By-pass Circuit......................................................................17

Fig.16 Vaporizers Flow - Schematic Diagram................................................19

Fig.17 Tec 5 Vaporizer Gas Flow.....................................................................20

Tec 5 Vaporizer Page 1

O & M Manual Part No. 1105-0100-000 August 1999

1.0 Introduction

1.1 Operation And Maintenance Manual

This Operation And Maintenance (O&M) Manual contains the information required in order to install,

operate and maintain the Tec 5 Continuous Flow Vaporizer.

Requests for servicing facilities, advice or assistance must be addressed either to a local Datex-Ohmeda

Field Operations Unit or to an Datex-Ohmeda Authorised Distributor.

Additional copies of this manual, quoting Tec 5 Continuous Flow Vaporizer O & M Manual Part No.

1105-0100-000, can be requested from a local Datex-Ohmeda Field Operations Unit or from an Datex-

Ohmeda Authorised Distributor.

It is recommended that all relevant documentation, including the O & M Manual and accompanying

labels and/or inserts, is immediately available to all prospective operators.

1.2 Precautions

A number of Warnings and Cautions are used throughout this manual to draw attention to the possible

hazards and/or adverse conditions which may occur if the information and instructions provided are not

strictly observed.

Cautions and Warnings are preceded by awsymbol and are used to draw attention to a condition

which can endanger either the patient or the operator and can result in damage to the equipment.

Special attention must be paid to each Warning and Caution as it appears in the manual.

1.3 Symbols

Systems with this mark agree with the European Council Directive (93/42/EEC) for

Medical Devices when they are used as specified in their operation and maintenance

manuals. The xxxx is the certification number of the Notified Body used by

Datex-Ohmeda's Quality Systems.

European Union Representative

Page 2 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

2.0 Servicing Policy

During initial installation of a Tec 5 vaporizer, the Next Service Date label located on the vaporizer dial

must be completed by the Technician/Engineer/Customer responsible for the installation.

Datex-Ohmeda recommends that all Tec 5 Vaporizers are serviced every three years, irrespective of

conditions of use.

Servicing procedures for this Product must be performed by Datex-Ohmeda trained personnel in

accordance with written instructions provided by Datex-Ohmeda.

wWarning: Only Technicians/Engineers trained and certificated by Datex-Ohmeda to repair and/or

service the Tec 5 Vaporizer should attempt to repair and/or service it and it must be repaired and/or

serviced at an Datex-Ohmeda Authorised Service Centre in accordance with written instructions

provided by Datex-Ohmeda. Detailed information for more extensive repairs is included in the Tec 5

Vaporizer Service Centre Manual which is available only to Authorised Service Centres.

Warranty repair and service procedures must be performed at an Datex-Ohmeda Authorised Service

Centre. A Datex-Ohmeda Service Representative can be contacted at the nearest Datex-Ohmeda Field

Operations Unit or Datex-Ohmeda Authorised Distributor.

Do not use malfunctioning equipment. If any assistance is required, contact the nearest Datex-Ohmeda

Field Operations Unit or Datex-Ohmeda Authorised Distributor.

If the equipment is to be transported to the nearest Datex-Ohmeda Field Operations Unit, drain the

vaporizer, package it securely for protection in its original packaging and ship it prepaid. Enclose the

following items as applicable:

1. A letter describing in detail any difficulties experienced with the equipment.

2. Warranty information, such as a copy of the invoice or other applicable documentation.

3. Purchase order number to cover repair of equipment not under warranty.

4. Ship to and bill to information.

5. The name and telephone number of the person to contact.

Tec 5 Vaporizer Page 3

O & M Manual Part No. 1105-0100-000 August 1999

3.0 Description

3.1 General

wWarning: This manual and all its associated documentation must be studied thoroughly before any

attempt is made to install, operate or maintain any part of the Tec 5 Vaporizer.

The Tec 5 Vaporizer is designed for out of circuit use in continuous flow techniques of inhalation

anaesthesia.

The vaporizer is temperature, flow and pressure compensated so that its output remains relatively

constant despite cooling due to evaporation, variations in inlet flow and fluctuating pressures as

described in Section 7.2 Effect of Variables.

Each vaporizer is agent specific and is clearly labelled with the name of the anaesthetic agent for which

it is designed.

The vaporizer is designed to be used on Selectatec Series Mounted Manifolds. The vaporizer can be

installed on other Selectatec Manifolds but the interlock system is designed to function on Selectatec

Series Mounted Manifolds only.

Mounting a Tec 5 vaporizer on a Selectatec 7 Compatibility Block is not recommended.

"It is a requirement of European Standard prEN 740 - Anaesthetic Workstations And Their Modules, that

an appropriate gas monitor is used to monitor the concentration of anaesthetic agent vapour in the

inspiratory gas when the vaporizer is in operation, in order to provide protection against hazardous

output in the event of a device malfunction".

wWarning: If the vaporizer has been inverted, connect it to a gas scavenging system, set the dial to

5% and purge the vaporizer with the carrier gas at 5 litres/minute for 5 minutes.

wCaution: Although the vaporizer incorporates an integral non-spill system, the vaporizer is intended

to be operated in its upright position.

wCaution: Turn the Vaporizer OFF when it is not in use.

3.2 Control Dial

A single control dial with a concentration scale calibrated in percentage of anaesthetic agent vapour per

total volume (% v/v) is employed to set the desired concentration of the anaesthetic agent.

A dial release is incorporated in the dial assembly to prevent accidental displacement of the control dial

from the OFF position. To select an ON setting it is necessary to pull in the dial release and

simultaneously rotate the dial counter-clockwise.

The dial and dial release are designed to enable an ON setting to be selected using only one hand.

3.3 Safety Interlocks

The vaporizer incorporates an interlock mechanism. This mechanism also interfaces with the Selectatec

Series Mounted Manifold to comprise an interlock system which is designed to help ensure that the

following criteria are satisfied:

1. The vaporizer must be locked on to the manifold before it can be turned ON.

2. Only one vaporizer at a time can be turned ON when two or more Tec 4, Tec 5 or Tec 6 vaporizers

are fitted on a Selectatec Series Mounted Manifold.

3. The gas flow enters only the vaporizer which is turned ON.

4. Any unwanted anaesthetic trace vapour is minimised after a vaporizer is turned OFF.

Page 4 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

TEC5

SEVOFLURANE

wWarning: Earlier versions of the Selectatec Series Mounted Manifold which provide mounting

positions for three vaporizers require that if only two vaporizers are fitted then the centre position

must be occupied. If the centre position is not occupied the interlock which helps to ensure that only

one vaporizer at a time can be turned ON is ineffective.

Later versions of the Selectatec Series Mounted Manifold which provide mounting positions for three

vaporizers incorporate an additional interlock which helps to ensure that only one vaporizer at a time

can be turned ON even if the centre position is not occupied.

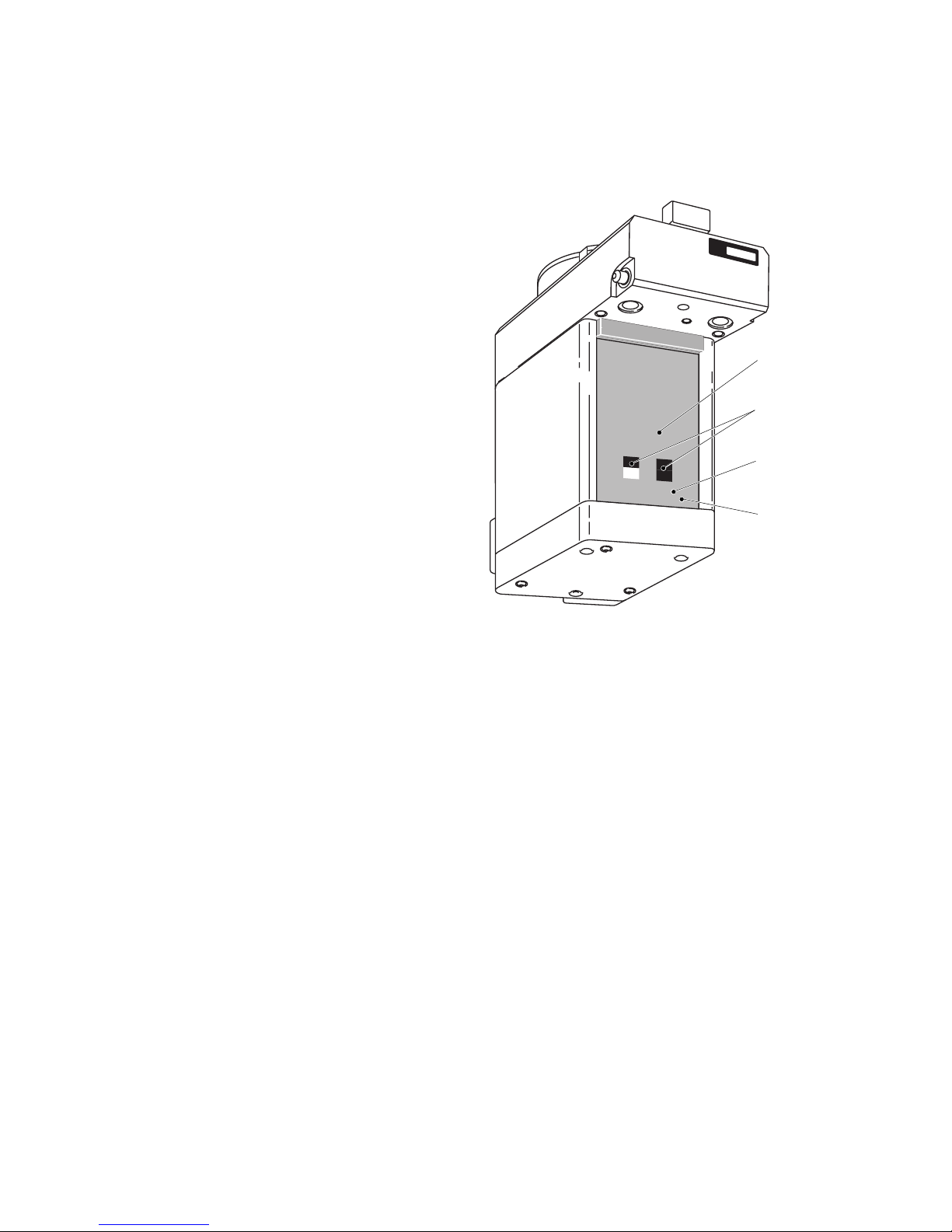

3.4 Vaporizer Identification Label

A vaporizer identification label is affixed

to the back panel of the vaporizer as

illustrated on Fig. 1.

An anaesthesia system fitted with a

vaporizer identification unit uses this label

to identify the vaporizer type.

Do not affix any additional labels or

markings to the back panel, they may

adversely affect the operation of the

vaporizer identification unit.

Fig. 1 Vaporizer Identification Label

4.0 Operating Instructions

4.1 General

The vaporizer is designed to be used on Selectatec Series Mounted Manifolds. The vaporizer can be

installed on other Selectatec Manifolds but the interlock system is designed to function on Selectatec

Series Mounted Manifolds only.

Mounting a Tec 5 vaporizer on a Selectatec 7 Compatibility Block is not recommended.

wWarning: It is a requirement of European Standard prEN 740 - Anaesthetic Workstations And Their

Modules, that the gas monitoring device referred to at 3.1 of this manual is in operating condition,

by being enabled and functioning , prior to use of the vaporizer.

wWarning: Handle the vaporizer with care at all times. Do not lift or support the vaporizer by holding

the control dial.

wWarning: Before mounting a vaporizer on to the manifold ensure that only one 'O' ring is fitted to

each manifold port valve. Ensure that each 'O' ring is intact and that there is no foreign matter

around the mating surfaces. A damaged 'O' ring and/or foreign matter around the mating surfaces

can cause leaks.

wWarning: Do not use a vaporizer if the liquid level decreases to below the minimum level.

wWarning: Before using a vaporizer allow it to attain the ambient temperature of the location in

which it is to be used.

IDENTIFICATION

CODE

AGENT NAME

VAPORIZER

NAME TEC 5

VAPORIZER

IDENTIFICATION

LABEL

AA.13.051

Tec 5 Vaporizer Page 5

O & M Manual Part No. 1105-0100-000 August 1999

123

PUSH DOWN

TO FULL EXTENT

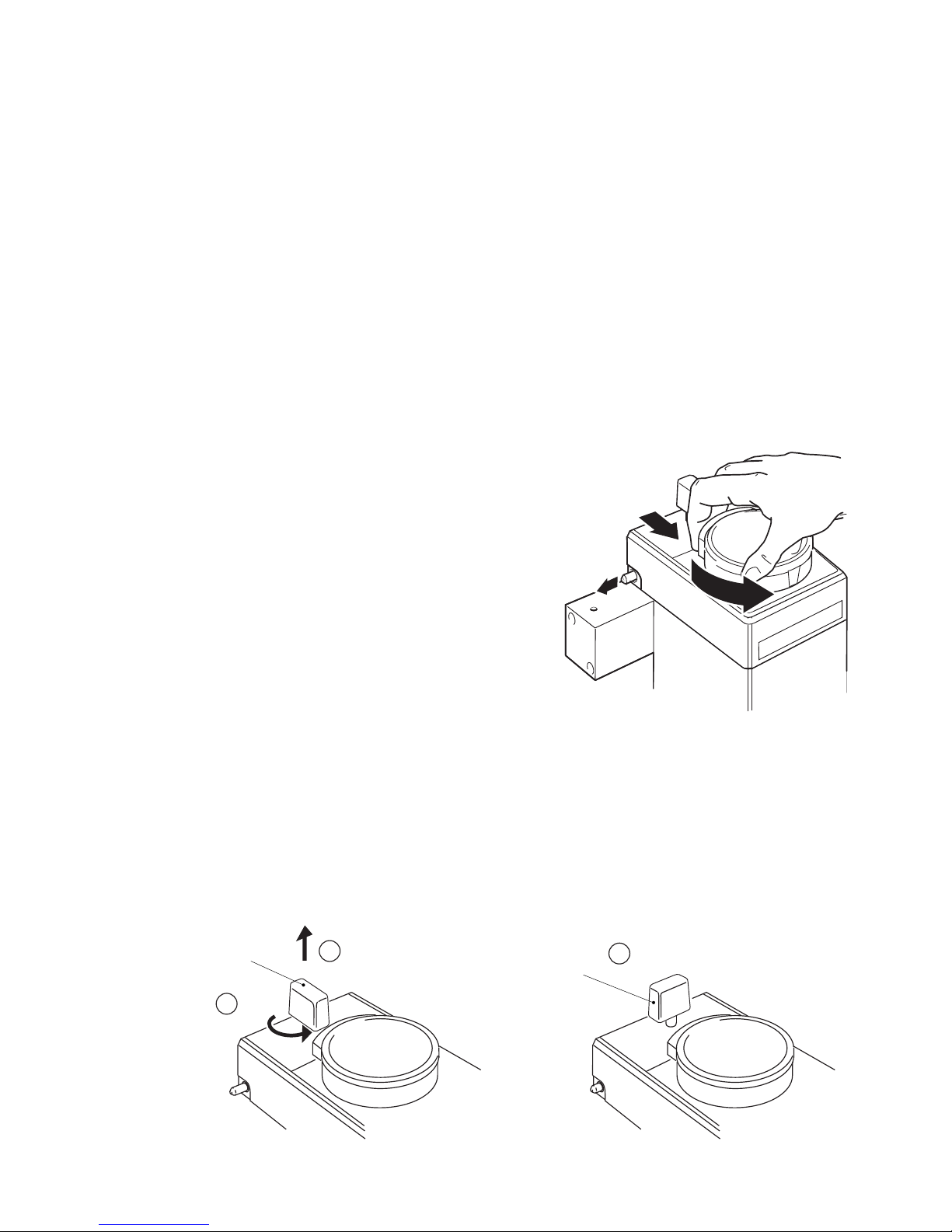

4.2 Vaporizer Mounting Procedure

1. Remove the red coloured dust caps fitted to the vaporizer interlock block ports, illustrated on Fig. 2.

2. Check that each port valve 'O' ring is intact and not damaged. Renew each 'O' ring if necessary.

3. Make sure that the vaporizer control dial is in the OFF position.

4. Make sure that the vaporizer locking lever is at the unlocked position, that is, in the up position.

Fig. 2 Vaporizer Mounting Procedure

5. Carefully lower the vaporizer on to the manifold so that the vaporizer interlock block covers the two

manifold port valves with the interlock block ports correctly engaged with the manifold port valves.

wCaution: Push the locking lever down to the full extent of its travel before attempting to turn it. The

mechanism may be damaged if an attempt is made to turn the lever before it is at the full extent of

its vertical travel.

6. Press down the locking lever

1to the full extent of its travel and then turn it clockwise

2to the

locked position

3to lock the vaporizer on to the manifold as illustrated on Fig. 3.

REMOVE DUST CAPS

FROM INTERLOCK BLOCK

PORTS

CHECK INTERLOCK BLOCK

PORTS ENGAGE CORRECTLY

WITH MANIFOLD PORT VALVES

CHECK LOCKING LEVER

IS UNLOCKED (UP)

LOCKING

LEVER

DIAL

RELEASE

LOCKED

TURN

LOCKING

LEVER

DIAL

RELEASE

CHECK DIAL IS AT OFF

CHECK EACH MANIFOLD

PORT VALVE 'O' RING. FIT

NEW 'O' RING(S) IF

NECESSARY

Fig. 3 Locking The Vaporizer On To A Manifold

AA.13.052

AA.13.053

Page 6 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

4.3 Checking For Correct Mounting Of The Vaporizer

wWarning: To help to ensure correct operation, do not use a vaporizer which is visibly out of line on the

manifold or which can be lifted off the manifold when the locking lever is in the locked position.

1. If more than one vaporizer is fitted, visually check to make sure that the tops of vaporizers are square

to the manifold. If a vaporizer is visibly out of line, remove it from the manifold and attempt to mount it

correctly. Do not use a vaporizer which cannot be mounted correctly.

2. When the vaporizers appear to be level and their locking levers are in the locked position, attempt to lift

each vaporizer from the manifold.

3. If a vaporizer can be lifted OFF the manifold, remove it from the manifold and attempt to mount it

correctly. Do not use a vaporizer which cannot be mounted correctly.

4. Make sure only one vaporizer at a time can be turned ON, thus checking that the interlock rods are in

alignment.

5. Check the anaesthesia system for leaks in accordance with the relevant O&M Manual with the vaporizer

dial turned to 0% and then repeat the check with the vaporizer dial turned OFF.

4.4 Turning ON The Vaporizer

Note: Do not attempt to turn the dial if the vaporizer is

not properly locked on to the manifold.

1. Pull in the dial release illustrated on Fig. 4 and

rotate the dial counter-clockwise. Note that it is

not possible to turn ON the vaporizer if an

adjacent Tec 4, Tec 5 or Tec 6 vaporizer is turned

ON.

2. The vaporizer should not be used between OFF

and the first graduation mark. To avoid inadvertent

delivery of small concentrations the control dial

should be turned OFF when the vaporizer is not in

use. Fig. 4 Turning ON The Vaporizer

4.5 Vaporizer Removal

1. Rotate the dial clockwise to turn OFF the vaporizer. If it is not completely turned to the OFF position it

cannot be released from the manifold.

2. Referring to Fig. 5, unlock the vaporizer from the manifold by turning the locking lever

1counter-

clockwise to the unlocked position. Release the locking lever

2, check that the locking lever springs

up to the unlocked condition

3and then carefully lift the vaporizer straight up and off the manifold.

LOCKING

LEVER

UNLOCKED

LOCKING

LEVER

TURN

RELEASE

1

23

Fig. 5 Unlocking The Vaporizer From A Manifold

AA.13.053

AA.13.054

Tec 5 Vaporizer Page 7

O & M Manual Part No. 1105-0100-000 August 1999

4.6 Filling And Draining

4.6.1 General

wWarning: Do not fill the vaporizer with any agent other than the agent specified on the front label.

The vaporizer is designed for that agent only. Filling the vaporizer with any agent other than that

specified can prove to be dangerous to a patient.

wWarning: Do not fill the vaporizer unless the control dial is in the OFF position.

wWarning: Do not turn the dial ON during filling or attempt to fill beyond the ¥mark.

wWarning: Do not drain the agent into any container other than a properly marked drug container.

wWarning: Ensure that the filler cap is tightened prior to use.

Periodically check the agent level. The vaporizer should be refilled at appropriate intervals. The

vaporizer is designed to function according to specification as long as there is agent visible above

the mark.

The vaporizer must be filled and used in an upright position. Small deviations from the upright position

do not affect either the output or the safety of the vaporizer, but because the agent depth is shallow in

relation to the diameter of the vaporizing chamber, more frequent checks of the agent level should be

performed to avoid a misleading impression of the amount of agent in the vaporizer when small

deviations from the upright position occur.

At intervals, ideally not exceeding two weeks, the vaporizer should be drained into the correct drug

bottle when the agent is low. This helps to preserve the drug purity by removing oxidized impurities,

accumulated contaminants and stabilisers. Discard the agent in a manner consistent with local policies

and guidelines. Less frequent intervals may be used when the anaesthetic agent does not contain

additives or stabilising agents.

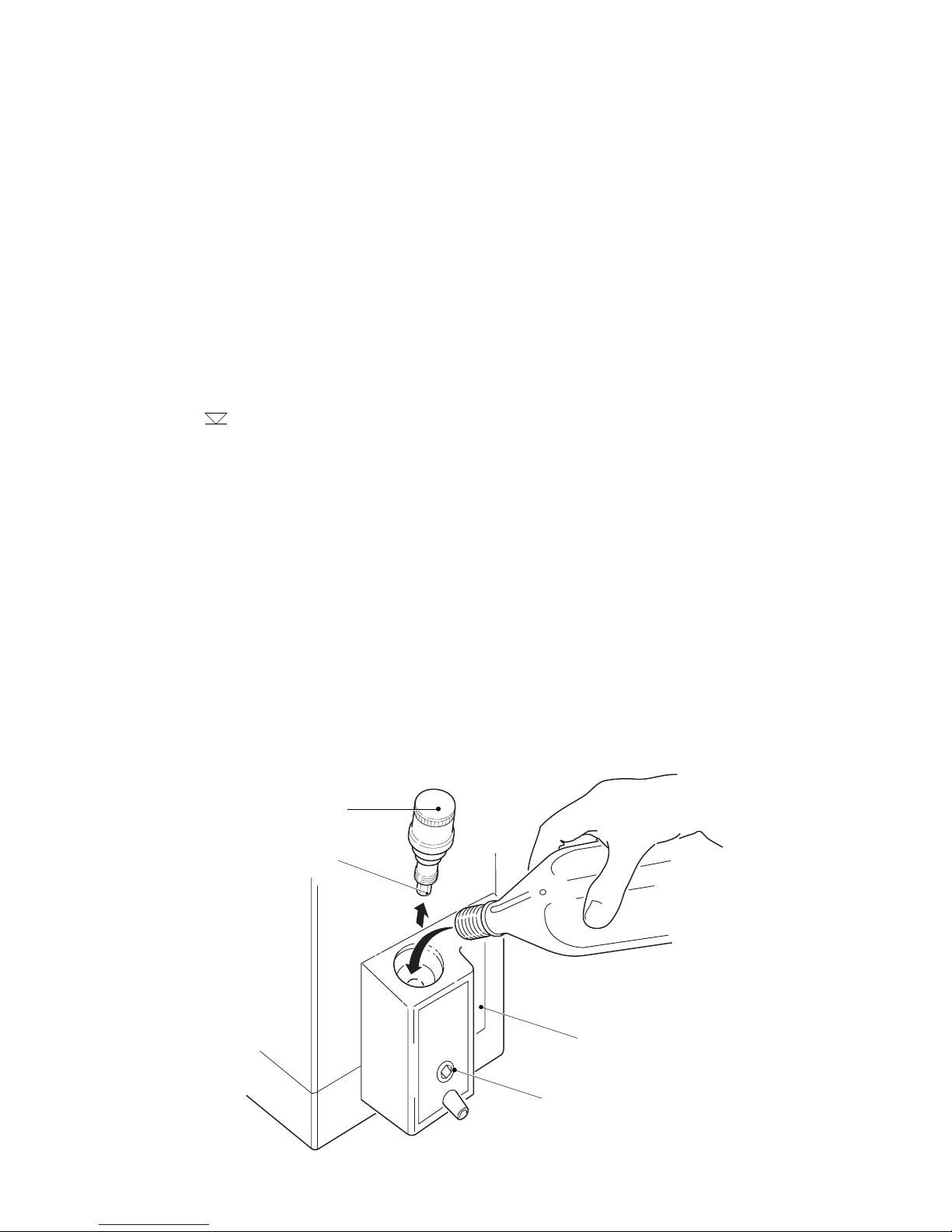

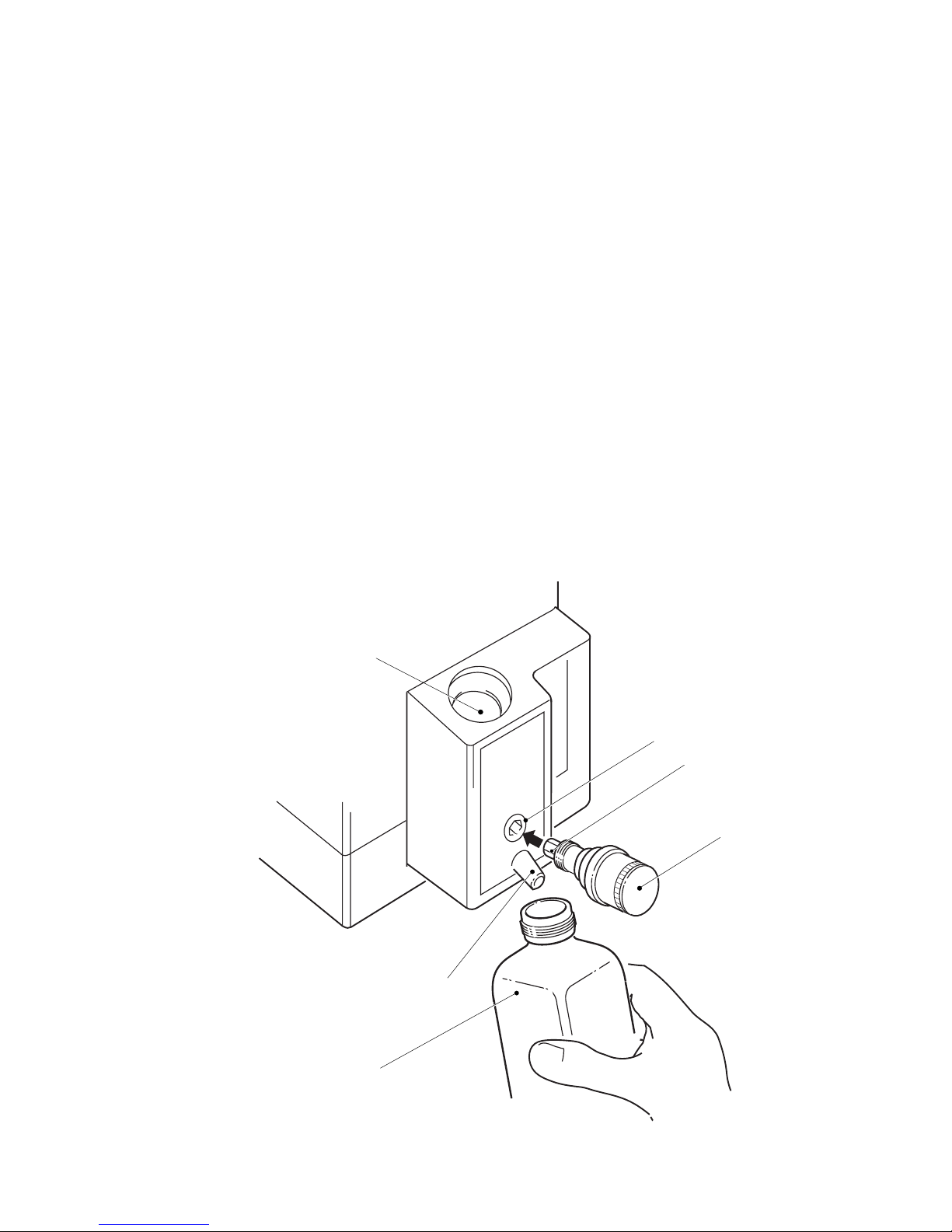

4.6.2 Filling A Vaporizer Which Incorporates A Screw Cap Filler

wWarning: Before filling a vaporizer fitted with a screw cap filler, turn the cap slowly to allow any

pressure to vent slowly.

1. Turn the vaporizer dial clockwise to the OFF position.

Fig. 6 Filling A Vaporizer Which Incorporates A Screw Cap Filler

FILLER CAP

HEXAGON

SIGHT GLASS

DRAIN PLUG

AA.13.024

Page 8 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

2. Remove the filler cap by turning it counter-clockwise. Ensure that the drain plug is closed by

tightening it with the hexagonal end of the filler cap.

3. Verify that the anaesthetic agent is the same as that specified on the vaporizer front label. Observe

the agent level through the sight glass indicator on the side of the filler body and pour the agent

slowly into the filling port, as illustrated on Fig. 6, until the level reaches the¥mark. The level may

decrease slightly as the wicks absorb the agent.

4. Replace the filler cap and tighten it to minimise any possibility of leaks.

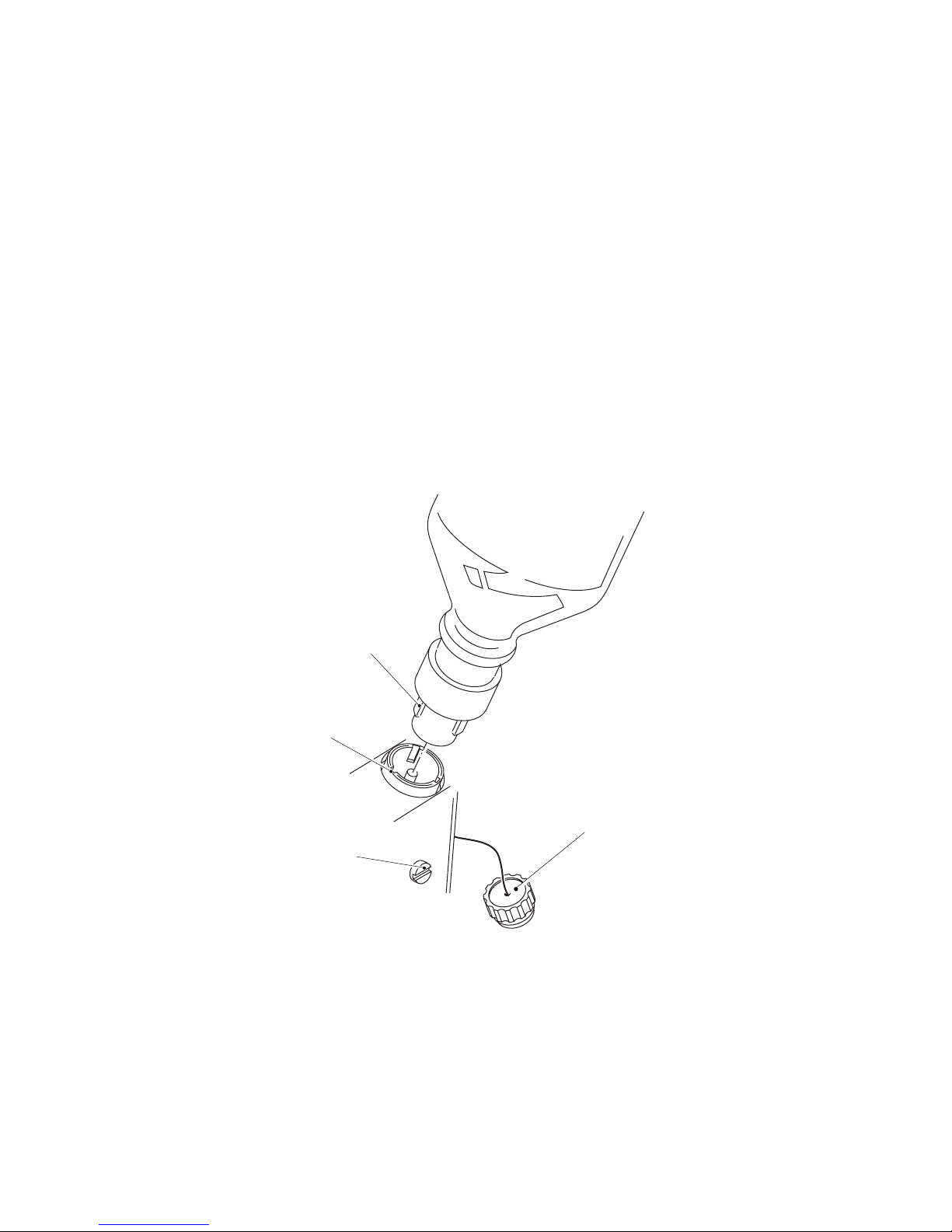

4.6.3 Draining A Vaporizer Which Incorporates A Screw Cap Filler

wCaution: Do not allow a bottle to become completely full during draining procedures.

The vaporizer must only be drained into a properly marked container, as follows:

1. Remove the filler cap and insert the hexagonal end of the cap into the drain plug situated below the

filling port on the filler body as illustrated on Fig. 7.

2. Position a properly marked container under the drain spout.

3. Unscrew but do not remove the drain plug to allow the vaporizer contents to pour from the drain

spout into the container.

4. After draining is complete, tighten the drain plug to minimise any possibility of leaks.

5. Replace the filler cap and tighten it to minimise any possibility of leaks.

FILLING PORT

DRAIN SPOUT

CONTAINER

FILLER CAP

DRAIN PLUG

HEXAGONAL

END

Fig. 7 Draining A Vaporizer Which Incorporates A Screw Cap Filler

AA.13.028

Tec 5 Vaporizer Page 9

O & M Manual Part No. 1105-0100-000 August 1999

4.6.4 Filling A Vaporizer Which Incorporates A Keyed Filler

wCaution: Always hold the bottle below the level of the end of the bottle adaptor and also below the

level of the filler port until the adaptor is clamped into position.

wCaution: If it is suspected that there is liquid in the adaptor air tube, remove the bottle adaptor from

the bottle and carefully shake the adaptor two or three times to clear the tube.

The filling system consists of three elements, the bottle collar, the bottle adaptor and the filling and

draining unit fitted to the vaporizer. The vaporizer must only be filled using the correct agent specific

filling system, as follows:

1. Screw the agent specific bottle adaptor firmly on to the bottle.

2. Ensuring that the bottle (1) is held below the level of the end of the bottle adaptor and below the

level of the filler port, insert the end of the bottle adaptor into the filler port (2) as illustrated on

Fig. 8.

3. Tighten the locking clamp by pulling the locking clamp lever forward and downward (3) until the

bottle adaptor is clamped.

wCaution: When it is set correctly, the clamp secures the bottle adaptor without using the full travel

of the locking lever. The lever must not be forced to its lowest limit of travel.

4. Raise the bottle above the level of the filler port (4) and then open the filler port valve by pulling the

port valve lever forward (5) to its full extent.

3

2

6

4

5

1

021AT5 OM

Fig. 8 Filling A Vaporizer Which Incorporates A Keyed Filler

AGENT SPECIFIC

BOTTLE COLLAR

BOTTLE

LOCKING

CLAMP

LEVER

PORT

VALVE

LEVER

AGENT SPECIFIC

BOTTLE COLLAR

LOCKING

CLAMP

LEVER

AGENT SPECIFIC

BOTTLE ADAPTOR

AA.13.046

AA.13.045

Page 10 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

Note: The vaporizer normally fills in less than one minute. If the vaporizer is dry the level decreases

slightly as the wick absorbs the agent.

5. When the vaporizer is full, return the port valve lever (5) to the closed condition to close the valve.

6. Lower the bottle to below the level of the filler port (6) and allow any agent in the tube to drain

back into the bottle.

7. Release the locking clamp lever, return it to the up position and then remove the bottle adaptor

from the filler port.

4.6.5 Draining Vaporizer Which Incorporates A Keyed Filler

wCaution: Do not allow a bottle to become completely full during draining procedures.

The vaporizer must only be drained into a properly marked container, as follows:

1. Position the bottle below the level of the filler port and insert the end of the bottle adaptor into the

filler port (1) as illustrated on Fig. 9.

2. Tighten the locking clamp by pulling the lever forward and downward (2) until the adaptor is

clamped.

3. Open the filler port valve by pulling the lever forward to its full extent (3).

4. Hold the bottle below the level of the filler port to allow the vaporizer contents to flow into the

bottle (4).

5. When the vaporizer is drained, close the port valve.

6. Release the locking clamp and return it to the up position.

7. Remove the bottle adaptor from the port.

2

1

4

3

022AT5 OM

Fig. 9 Draining A Vaporizer Which Incorporates A Keyed Filler

LOCKING

CLAMP

LEVER

AGENT SPECIFIC

BOTTLE COLLAR

FILLER

PORT

VALVE

LEVER

AGENT SPECIFIC

BOTTLE ADAPTOR

LOCKING

CLAMP

LEVER

AA.13.027

AA.13.026

Tec 5 Vaporizer Page 11

O & M Manual Part No. 1105-0100-000 August 1999

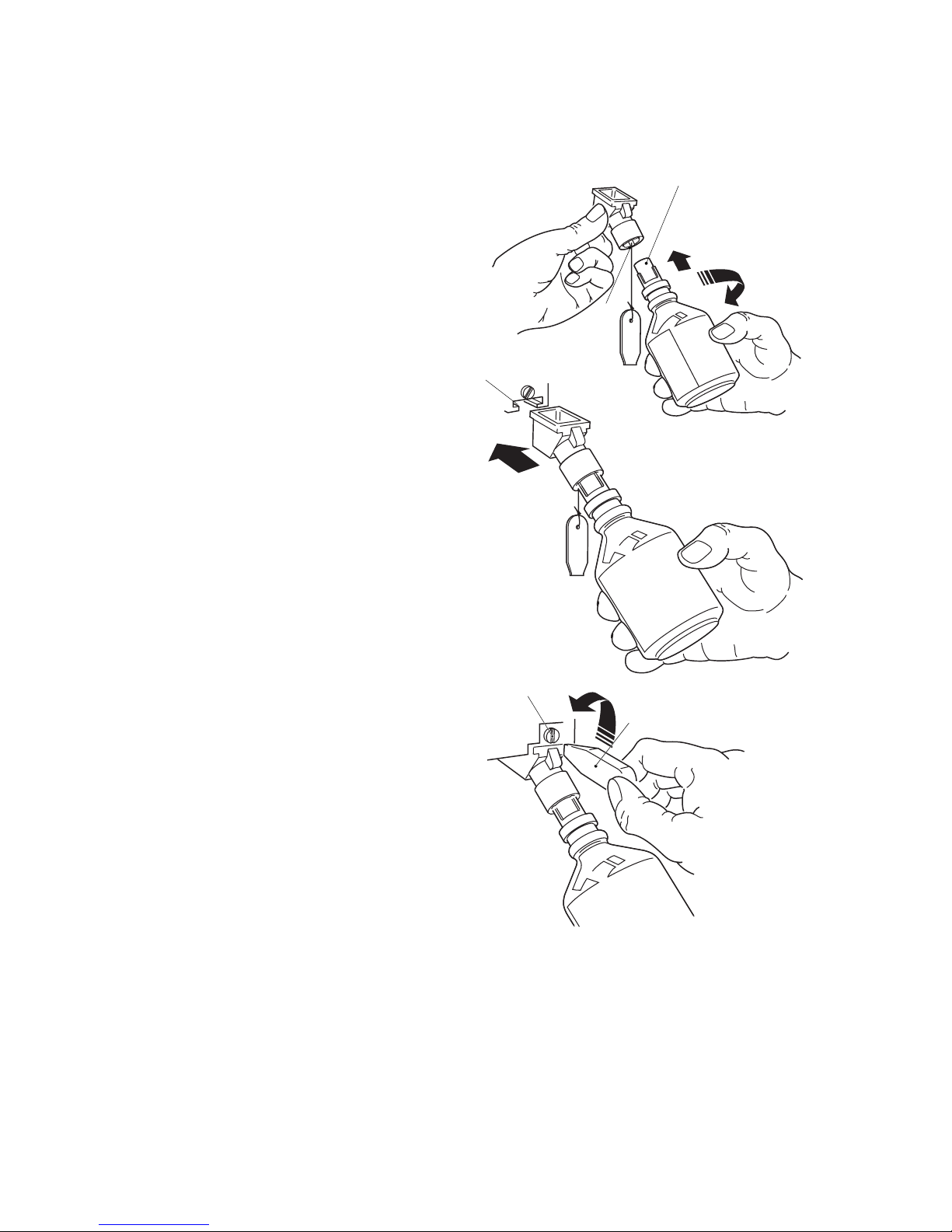

4.6.6 Filling A Vaporizer Which Incorporates A Quik-Fil™ Filler

wWarning: Ensure that the drain plug screw (1), located on the lower front of the vaporizer, is

correctly tightened to prevent loss of liquid agent.

1. Remove the protective cap from the anaesthetic agent bottle filler, checking that the bottle and filler

mechanism are not damaged.

2. Remove the filler cap (2) and insert the bottle nozzle into the filler block. Rotate the bottle to align

the bottle filler nozzle keys (3) with the index slots (4) in the filler block as illustrated on Fig. 10.

3. Press the agent bottle fully into the vaporizer filler block. Allow the liquid to flow into the vaporizer

until the maximum level mark¥is reached, paying particular attention to the level in the sight

glass and the air return bubbles flowing into the bottle.

4. Release the bottle when the vaporizer is full and the continuous stream of bubbles ceases.

5. Withdraw the bottle from the vaporizer filler and replace the filler cap (2) and the cap on the agent

bottle. Ensure that the filler cap is tightened to minimise any possibility of leaks.

2

3

1

4

Fig. 10 Filling A Vaporizer Which Incorporates A Quik-Fil™ Filler

AA.13.056

Page 12 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

2

1

3

5

4

Fig. 11 Draining A Vaporizer Which Incorporates A Quik-Fil™ Filler

4.6.7 Draining A Vaporizer Which Incorporates A Quik-Fil™ Filler

wCaution: Do not allow a bottle to become completely full during draining procedures.

The vaporizer must only be drained into a properly marked container, as follows:

1. Remove the cap from the vaporizer

filler.

2. Remove the protective cap from an

empty bottle. Insert the bottle nozzle

into the drain funnel. Rotate the

bottle to align the index slots in the

drain funnel (1) with the bottle filler

nozzle keys (2) and screw the drain

funnel onto the empty bottle as

illustrated on Fig. 11.

3. Fully insert the drain funnel into the

keyed drain slot (3) in the bottom of

the vaporizer filler block.

4. Unscrew the drain plug (4) with the

key (5). Continue to drain the

vaporizer until empty.

5. After draining is complete, tighten

the drain plug to minimise the

possibility of leaks and withdraw

the drain funnel.

6. Replace the filler cap and tighten it

to minimise the possibility of leaks.

7. Unscrew the drain funnel from the

bottle and refit the protective cap.

Note: If further drain funnels are required

they should be obtained from the local

Abbott Laboratories representative.

AA.13.058 AA.13.057

AA.13.059

Tec 5 Vaporizer Page 13

O & M Manual Part No. 1105-0100-000 August 1999

5.0 Maintenance

wWarning: Do not modify, tamper with or disassemble the vaporizer because of the dangers of

damaging the unit and altering the accuracy of graduation.

Observation of the instructions previously provided, regular servicing and normal professional vigilance

is normally all that is required to maintain the vaporizer in a safe working condition.

5.1 Schedule

5.1.1 Every Two Weeks

When the agent level is low, drain the contents of the vaporizer into an appropriately marked container

and discard the agent. Less frequent intervals may be used when the anaesthetic agent does not

contain additives or stabilising agents, but the procedure must be performed at least once every year.

5.1.2 Every Three Years

Datex-Ohmeda recommends that all Tec 5 Vaporizers are serviced every three years, irrespective of

conditions of use.

The vaporizer should be serviced at an Datex-Ohmeda authorised Service Centre.

This service includes the following:

1. Complete disassembly of components.

2. Thorough cleaning.

3. Inspection for damage and wear.

4. Renewal of wicks, seals and damaged or worn components.

5. Where appropriate, replacement of discontinued parts with more up-to-date parts.

6. Lubrication where necessary.

7. Checks of delivered vapour concentrations under closely defined conditions at different

temperatures and flows with regraduation or adjustment where necessary.

5.2 Cleaning

wWarning: Do not put water or any other solvent into a vaporizer. A vaporizer should be filled with the

specified anaesthetic agent only.

wWarning: Do not immerse the vaporizer in any liquid, including water.

wWarning: Do not autoclave the vaporizer.

Clean the exterior of the vaporizer with a damp cloth.

Never allow cleaning agents to accumulate either in the filler, the gas inlet and outlet ports or around

the control dial.

Page 14 Tec 5 Vaporizer

August 1999 O & M Manual Part No. 1105-0100-000

5.3 Contamination

If the vaporizer is either filled or partly filled with an incorrect agent or any other contaminant, water for

example, proceed as follows:

1. Drain the vaporizer and discard all liquid.

2. Return the vaporizer to a Service Centre stating, if possible, the type of contaminant used.

5.4 Repairs

Repairs must only be performed by the Manufacturer's Service Representatives.

Tec 5 Vaporizer Page 15

O & M Manual Part No. 1105-0100-000 August 1999

6.0 Principle Of Operation

6.1 Interlock Mechanism

The vaporizer locking lever, illustrated on Fig. 12, is interlocked with the vaporizer percentage control dial in

such a way that the control dial release, located at the rear of the dial, cannot be actuated until the vaporizer

locking lever is in the locked position.

With the vaporizer locking lever in the locked position the dial release can be pressed in towards the dial to

operate the interlock mechanism which simultaneously actuates the following:

1. The interlock extension rods, which extend to minimise the possibility of adjacent vaporizers being

turned ON.

2. The two port valve actuating spindles, which actuate the Selectatec Manifold port valves to allow fresh

gas to flow through to the vaporizer.

3. The vaporizer percentage control dial release, which allows the dial to be turned to select the required

percentage.

Turning the control dial to OFF automatically reverses the operating sequence, which allows the dial release

to move out to lock the dial in the OFF position, closes the manifold port valves and vents the vaporizer gas

connecting ports and retracts the extension rods to allow an adjacent vaporizer to be turned ON.

Turning the locking lever to the unlocked position releases the vaporizer allowing it to be removed from the

manifold.

PERCENTAGE

CONTROL DIAL

PORT VALVE

ACTUATING

SPINDLE

SELECTATEC

SERIES

MOUNTED

MANIFOLD

CONTROL DIAL

RELEASE

VAPORIZER

LOCKING LEVER

PORT

VALVES PORT

VALVES

EXTENSION

ROD

Fig. 12 Vaporizer Interlock Mechanism

AA.13.020

Table of contents

Other Datex-Ohmeda Vaporizer manuals