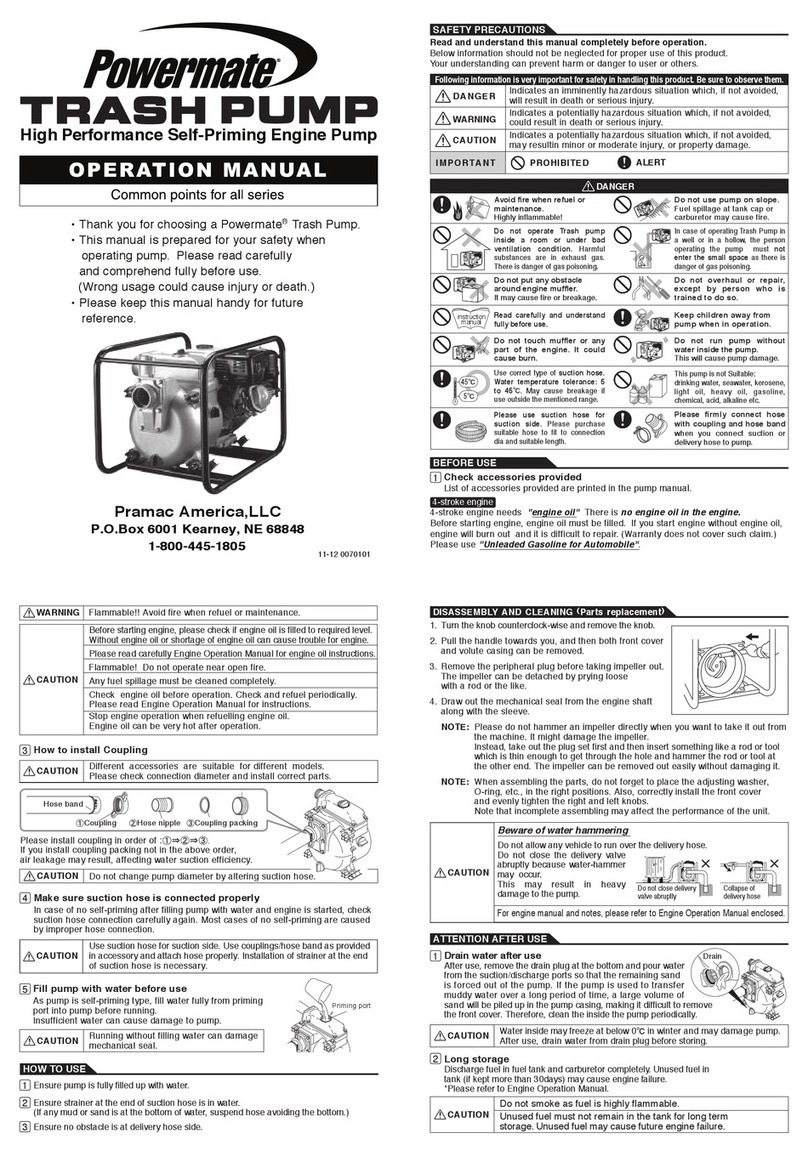

Priming and Operation

Thepumpbodyandsuctionlineshouldbelledbypouringwaterintothepriming

plugholeadjacenttotheoutlet.Screwontheprimingplug,closethedischarge

valvetwothirdsandswitchpumpon.Graduallyopenthedischargevalveandthe

pipelinells.

Inhighsuctionliftconditions,thepumpmaymakeanoisesimilartoitpumpingsand

orgravel;thiswillusuallybecavitationoccurring.Reduceowuntilthecavitation

noisestops.Oncethedischargepipelinellsyoucanopenthevalve.Ifthe

cavitationnoisereturns,closethedischargevalveslightlyuntilitstops.

Inthecaseofinstallationswherethereisapositivesuctionpressure(ooded

suction)removethepump’sprimingplugandslowlyopenthegatevalveinthe

suctionpipingtoallowwatertoenterthepumpfromthesuctionlineuntilallairis

expelled.Replacetheprimingplugandfullyopenthegatevalveinthesuctionline

andswitchthepumpon.

Primeshouldbeestablishedalmostimmediately,however,itmaybenecessaryto

re-primeseveraltimesonsomeinstallationsbeforefullyestablishedoptimumpump

performanceisobtained.

Ifpumprunsbutwillnotpumpwater,checkforthefollowing:

1. Suctionlineandpumpbodynotlledwithwater.

2. Leakingfootvalve.

3. Airleaksinsuctionlines.

4. Airtrappedinsuctionline(evenonoodedsuction)possiblywhenthereisan

unevenriseinthepipingfromwatertopump(eliminate“humpsandhollows”)

8 5

Threephasemodelswithoutputpowerof1.4kWandoverhavebeendesignedto

allowforconnectioneithersideoftheCapacitorCover(marked“A”ingureone)

onthemotor.(NOTE:Threephasemotorsdonothavecapacitorsttedinthe

CapacitorCover).

Thisisachievedbywayofeitherofthetwo19mmaccessholes(marked“B”

ingureone).Theaccessholesaredesignedtoacceptmoststandardcable

grommets.Theunusedholecanbesealedbyinsertingtheplugenclosedwiththe

pump.ToconnectathreephasePressurePumpstartbyremovingtheTerminal

Cover(“C”)

InaccordancewithAS3350.2.41weareobligedtoinformyouthatthispumpisnot

tobeusedbychildrenorinrmpersonsandmustnotbeusedasatoybychildren.

Ashortfourcoreex(“D”)isttedfromthemotorterminals(“E”).Thisleadis

insertedthroughtheblankinggrommet(“F”).

Pressureswitchorothercontrolleads(“G”)canbettedaswell.Incomingpower

(“H”)canbettedthroughthepreferredaccesshole,andterminatedasshownin

FigureThree.Aterminationkitisavailableifrequired.

Inserttheblankinggrommet(“F”)intothecapacitor

cover(“A”).Fixtheshortlead(“D”)intothepath

providedinthenon-driveendshieldandreplacethe

terminalcover(“C”).

IMPORTANT NOTE: THREE PHASE MODELS ONLY

Whentheunitisconnectedandoperatingthephasebalanceshouldbechecked.

Thisshouldbewithin5%variation.“Rolling”theleadsmayhelptoimproveasmall

unbalance,butmajorphaseunbalancewillusuallybeattributedtoaninputpower

unbalance.Thismustbeaddressedbeforethepumpisused.

IP55 Compliant Connection

Forsomeinstallations,suchaswetareasindairies,thepumpisrequiredtobeIP55

compliant.TheHMpumpisIP55compliant(modelsover1.05kWareIP56).

3. Switchon.

4. Primeshouldestablishalmost

immediatelywithastrong

owofwater,however,in

someinstallationsitmay

benecessarytorepeat

theaboveoperationto

removeallairfromthe

system.

1. Ensureoutletnearestto

pumpisopen.

2. Fillpumpbodyandsuctionline

throughprimingplugholelocated

abovesuctioninletandreplaceplug.

Before nalising wiring connections, check that motor rotates in direction of

arrow (clockwise when shaft is viewed from wiring connection end except

HM270 models which rotate anti-clockwise). To alter rotation, change any

two power leads at motor terminals.

Power connections and wiring must be carried out by an Authorised

Electrician.

WARNING: Some insects, such as small ants, nd electrical devices

attractive for various reasons. If your pump enclosure is susceptible to

insect infestation you should implement a suitable pest control plan.

Note: Minimum three phase voltage supply at the motor must not fall below

374 volts, otherwise motor damage may result which is not claimable under

Guarantee.

Do not run pump dry or allow to run continuously in a loss of prime

condition. If this pump is allowed to pump water containing sand or other

abrasive material, the effective life of the pump will be shortened.