daviteq MBRTU-TBD User manual

JUL-2021

MBRTU-TBD is an advanced digital turbidity sensor for water quality monitoring, adopt the principle of scattered light,

the design method of using infrared LED light source and optical fiber conduction light path. The filter design is added

inside, which has strong anti-interference ability. Built in temperature sensor, automatic temperature compensation,

suitable for online long-term monitoring of the environment.

1. Digital sensor, direct output RS-485 digital signal, support Modbus / RTU

2. Principle of 90° Angle Scattering Light, the built-in temperature can be compensated automatically;

3. Optical fiber structure, strong resistance to external light interference

4. Infrared LED light source, add filter design, anti light interference, good stability

5. The surface shall be treated with anti-corrosion and passivation

6. Low power consumption and anti-interference design of internal circuit

Item

Specifications

Output

RS-485,MODBUS/RTU

Measuring method

90° scattered light method

USER GUIDE FOR TURBIDITY

SENSOR WITH MODBUS RTU

OUTPUT MBRTU-TBD

This document is applied for the following products

1. Introduction

2. Specification

Features

Technical Data

Range

0 ~ 1000NTU or 0 ~ 100NTU

Accuracy

±5% indication value or ±3NTU, choose the greater (0 ~ 1000NTU)

± 3% indication or ± 2 NTU, choose is greater (0-100 NTU)

±0.5℃

Resolution

0.1NTU, 0.1℃

Working environment

0 ~ 50℃, <0.6MPa

Calibration method

Two-point calibration

Response time

30s T90

Temperature Compensation

Automatic temperature compensation (Pt1000)

Power Supply

12-24VDC±10%, 10mA;

Size

Diameter 30mm; Length 166.5mm;

Protection level

IP68The water depth is 20 meters;

Service life

3 years or above

Cable length

5m

Sensor housing material

PVC

Please wiring as shown below:

Wire color

Description

Brown

Power (12-24VDC)

Black

GND

Blue

RS485A

White

RS485B

Bare line

Shielding Layer

Cable line 4 line AWG-24 or AWG-26 Shielding Wire.

Inductive electrode is basically maintenance free; It is recommended to clean up the sensor probe attachment

4. Wiring

5. Maintenance and Precautions

5.1 Maintenance

every 30 days; Avoid the use of hard objects to cause the damage of the light guide part of the measuring probe

during cleaning; Please wipe with a soft damp cloth.

It is recommended to clean the outer surface of the sensor with water flow. If there is still debris residue, please

wipe it with a wet soft cloth.

Installation measurement: avoid the installation measurement at the place where the water flow is turbulent, and

reduce the influence of water bubbles on the measurement. Keep the measuring probe 2cm away from the

bottom.

The probe of the sensor is fouling or attached with more organisms, so the cleaning force can be increased

appropriately. Slight scratch on the probe surface does not affect the normal use of the sensor. But pay attention

not to penetrate the shell of the probe.

Suggestion: the protective cover of our company should be selected to prevent the influence of microbial

attachment on the measurement results.

Problem

Possible Causes

Solution

The operation interface cannot be connected

or the measurement results are not displayed

Wrong cable connection

Check the wiring mode

Wrong sensor address

Check the address for errors

The measured value is too high, too low or the

value is continuously unstable

The sensor probe is attached by foreign objects

Clean the sensor probe surface

Other

Contact after sales

The default data format for Modbus communication of this sensor is:

MODBUS-RTU

Baud rate

9600 (default)

Device address

1 (default)

Data bits

8 bit

Parity check

None

Stop bit

1bit

Function code 03: Read (R) register value

Function code 06: Write (W) single register value

Register Address

(hex)

Name

R/W

Introductions

Number of registers

(byte)

Data type

5.2 Note

5.3 Other

6. Modbus RTU Protocol

6.1 Information frame format

6.2 Register Address:

0x0100

Temperature value

R

℃ value x10 (for

example: the

temperature of 25.6℃

is displayed as 256,

the default is 1

decimal.)

1 (2 bytes)

unsigned short

0x0101

Turbidity value

R

NTU value x10 (for

example, the turbidity

value of 15.1ntu is

displayed as 151,

with 1 decimal place

by default.)

1 (2 bytes)

unsigned short

0x1000

Temperature

calibration

R/W

Temperature

calibration: the

written data is the

actual temperature

value X10; Read out

data is temperature

calibration offset X10.

1 (2 bytes)

unsigned short

0x1001

Zero point calibration

R/W

Zero point calibration

in air. The data

written during

calibration is 0.

1 (2 bytes)

unsigned short

0x1003

Slope calibration

R/W

Calibrate in the

known standard

solution (50% - 100%

range), and write the

data as the actual

value of the standard

solution × 10.

1 (2 bytes)

unsigned short

0x2000

Sensor address

R/W

The default is 1, and

the data range is 1-

127.

1 (2 bytes)

unsigned short

0x2003

Baud rate setting

R/W

The default is 9600.

Write 0 is 4800; Write

1 is 9600; Write 2 is

19200.

1 (2 bytes)

unsigned short

0x2020

Restore factory

settings

W

The calibration value

is restored to the

default value and the

written data is 0. Note

that the sensor needs

to be calibrated again

after reset.

1 (2 bytes)

unsigned short

unsigned int (unsigned short)

The data consists of two integers.

XXXX XXXX

XXXX XXXX

Byte1

Byte0

Float, According to IEEE 754 (single precision);

The data consists of 1 sign bit, 8-bit exponent, and a 23 bit mantissa .

XXXX XXXX

XXXX XXXX

XXXX XXXX

XXXX XXXX

Byte3

Byte2

Byte1

Byte0

Sign

bit

Exp digit

F decimal

6.3 Data structure type

Integer

Float

6.4 Modbus RTU command:

6.4.1 Function code 03h: read register value

Host send:

1

2

3

4

5

6

7

8

ADR

03H

Start register

high byte

Start register

low byte

Register

number high

byte

Number of

registers low

byte

CRC low byte

CRC high byte

The first byte ADR: slave address code (= 001 ~ 254)

Byte 2 03h: read register value function code

Byte 3 and 4: start address of register to be read

To read the FCC instrument,

Bytes 5 and 6: number of registers to read

Bytes 7 and 8: CRC16 checksums from bytes 1 to 6

Slave return:

1

2

3

4 , 5

6 , 7

M-1 , M

M+1

M+2

ADR

03H

total bytes

Register data

1

Register data

2

……

Register data

M

CRC low byte

CRC high

byte

The first byte ADR: slave address code (= 001 ~ 254)

Byte 2 03h: return to read function code

The third byte: the total number of bytes from 4 to m (including 4 and m)

Bytes 4 to m: register data

Byte m + 1, M + 2: CRC16 check sum from byte 1 to M

When the slave receives an error, the slave returns the error:

1

2

3

4

5

ADR

83H

Information code

CRC low byte

CRC high byte

The first byte ADR: slave address code (= 001 ~ 254)

Byte 2 83h: error reading register value

Byte 3 information code: 01 - function code error

03 - data error

Bytes 4 and 5: CRC16 checksums from bytes 1 to 3

Host send

1

2

3

4

5

6

7

8

ADR

06

Register high

byte address

Register low

byte address

Data high byte

Data low byte

CRC code

Low byte

CRC code

High byte

When the slave receives correctly, the slave sends back:

1

2

3

4

5

6

7

8

ADR

06

Register high

byte address

Register low

byte address

Data high byte

Data low byte

CRC code

Low byte

CRC code

High byte

When the slave receives an error, the slave returns:

1

2

3

4

5

ADR

86H

Error code information

code

CRC code

Low byte

CRC code

High byte

6.4.2 Function code 06h: write single register value

The first byte ADR: slave address code (= 001 ~ 254)

The second byte 86h: write register value error function code

Byte 3 error code information code: 01 - function code error

03 - data error

Byte 4 and 5: CRC check sum from byte 1 to 3

a) Change slave address:

Address:0x2000 (42001)

Number of registers: 1

Function code: 0x06

Default sensor address: 01

Change the Modbus device address of the sensor, and change the device address from 01 to 06. The example is as

follows:

Send command: 01 06 20 00 00 06 02 08

Respond: 01 06 20 00 00 06 02 08; Note: the address is changed to 06 and stored after power failure.

b) Baud rate:

Address: 0x2003 (42004)

Number of registers: 1

Function code: 0x06

Default value: 1 (9600bps)

Supported values: 0-2 (4800-19200bps)

The baud rate can be changed by the upper computer setting, and it can work without restart after the change. The

baud rate saves the upper computer setting after power failure. Baud rate support 4800960019200. The baud rate of

integer value allocation is as follows:

Integer

Baud rate

0

4800 bps

1

9600 bps

2

19200 bps

Send command: 01 06 20 03 00 02 F3 CB

Respond: 01 06 20 03 00 02 F3 CB Note: the baud rate is changed to 19200bps and saved after power failure.

a) Measuring temperature command:

Address: 0x0100 (40101)

Number of registers: 1

Function code: 0x03

Read sample values: 19.2℃

Send command: 01 03 01 00 00 01 85 F6

Respond: 01 03 02 00 C0 B8 14

6.5 Command example

6.5.1 Default register

6.5.2 Function register

Returns hexadecimal unsigned integer data, temperature value = integer / 10, 1 bit decimal place is reserved.

b) Turbidity measurement instruction:

Address: 0x0101 (0x40102)

Number of registers: 1

Function code: 0x03

Read sample values: 9.1 NTU

Send command: 01 03 01 01 00 01 D4 36

Respond: 01 03 02 00 5B F9 BF

Register returns hexadecimal unsigned integer data, turbidity value = integer / 10, 1 decimal place reserved.

c) Continuous reading of temperature and turbidity instructions:

Address: 0x0100 (40101)

Number of registers: 2

Function code: 0x03

Read sample values: Temperature 19.2 ℃ and turbidity 9.1 NTU

Send command: 01 03 01 00 00 02 C5 F7

Respond: 01 03 04 00 C0 00 5B BB F4

Register returns hexadecimal unsigned integer data, temperature value = integer / 10, 1 decimal place reserved

Register returns hexadecimal unsigned integer data, turbidity value = integer / 10, 1 decimal place reserved.

d) Humidity measurement command:

Address: 0x0107 (40108)

Number of registers: 1

Function code: 0x03

Read sample values: relative humidity 40%

Send command: 01 03 01 07 00 01 34 37

Respond: 01 03 02 01 90 B9 B8

Register returns hexadecimal unsigned integer data, humidity value = integer / 10, 1 decimal place reserved.

a) Temperature calibration

Address: 0x1000 (41001)

Number of registers: 1

Function code: 0x06

Calibration example: calibration at 25.8 ° C

Send command: 01 06 10 00 01 02 0D 5B

Respond: 01 06 10 00 01 02 0D 5B

The sensor needs to be calibrated in a constant temperature environment after the temperature indication no longer

fluctuates.

b) Turbidity zero calibration

Address: 0x1001 (41002)

6.5.3 Calibration instruction

Number of registers: 1

Function code: 0x06

Calibration example: calibration in air

Send command: 01 06 10 01 00 00 DC CA

Respond: 01 06 10 01 00 00 DC CA

c) Turbidity slope calibration

Address: 0x1003 (41004)

Number of registers: 1

Function code: 0x06

Calibration example: calibration in 50NTU turbidity solution

Send command: 01 06 10 03 01 F4 7D 1D

Respond: 01 06 10 03 01 F4 7D 1D

7. Dimensions

Manufacturer

Daviteq Technologies Inc

No.11 Street 2G, Nam Hung Vuong Res., An Lac Ward, Binh Tan Dist., Ho Chi Minh City, Vietnam.

Tel: +84-28-6268.2523/4 (ext.122)

Email: info@daviteq.com | www.daviteq.com

Revision #31

Created Tue, Jul 20, 2021 3:06 AM by Tien Nguyen

Updated Fri, Jul 23, 2021 3:07 AM by Tien Nguyen

8. Contact

Table of contents

Other daviteq Measuring Instrument manuals

daviteq

daviteq WS433-ULC User manual

daviteq

daviteq WS433-CO2 User manual

daviteq

daviteq MBRTU-SAL User manual

daviteq

daviteq WS433-M12F-ATH User manual

daviteq

daviteq WS433-MA-31 User manual

daviteq

daviteq CAP10CNC User manual

daviteq

daviteq WSSFC-G4F-NH3 User manual

daviteq

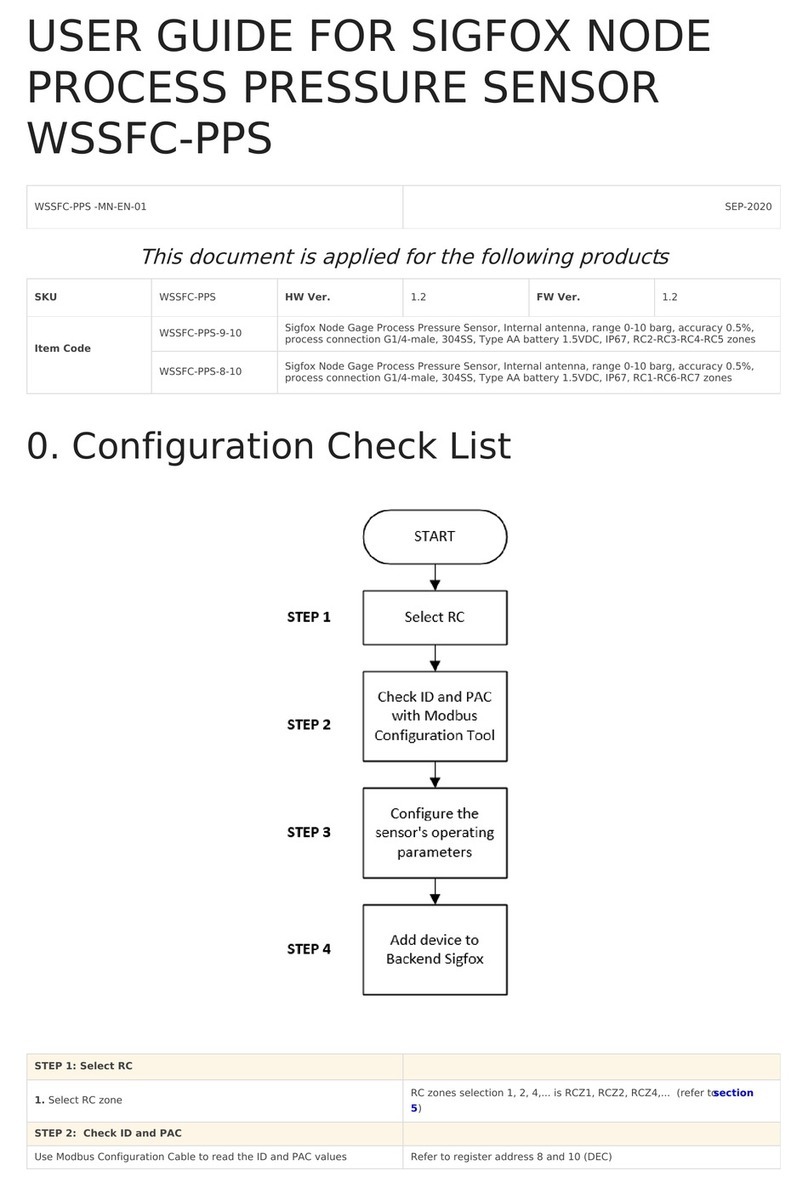

daviteq Sigfox WSSFC-PPS User manual

Popular Measuring Instrument manuals by other brands

Bushnell

Bushnell Pro 1m 205107 instruction manual

Jeulin

Jeulin Initio 2 manual

Amphenol

Amphenol THE MODAL SHOP 831 quick start guide

Acrel

Acrel APM Series Installation and operation instruction

Halma

Halma Ocean Optics DH-mini UV-Vis-NIR Installation and operation manual

ATAGO

ATAGO PAL-89S instruction manual