daviteq WSSFC-G4F-NH3 User manual

WSSFC-CAP10-MN-EN-01

FEB-2022

SKU

WSSFC-G4F-NH3

HW Ver.

1.1

FW Ver.

1.0

Item Code

WSSFC-CAP10-8-1500

SIGFOX HIGH PRECISION CAPACITANCE FUEL LEVEL SENSOR FOR DIESEL OIL, VEGETABLE OIL,

LUBRICANT, 1500MM, FIELD CUTTABLE, INTERNAL ANTENNA, TYPE AA BATTERY 1.5VDC, IP67,

RC1 ZONE

WSSFC-CAP10-9-1500

SIGFOX HIGH PRECISION CAPACITANCE FUEL LEVEL SENSOR FOR DIESEL OIL, VEGETABLE OIL,

LUBRICANT, 1500MM, FIELD CUTTABLE, INTERNAL ANTENNA, TYPE AA BATTERY 1.5VDC, IP67,

RC2-RC4 ZONES

CAP10PROEXT0700

CAP10 PROBE EXTENSION LENGTH 700 MM

CAP10PROEXT1000

CAP10 PROBE EXTENSION LENGTH 1000 MM

CAP10PROEXT1500

CAP10 PROBE EXTENSION LENGTH 1500 MM

USER GUIDE FOR SIGFOX-READY

PRECISION FUEL LEVEL SENSOR

WSSFC-CAP10

This document is applied for the following products

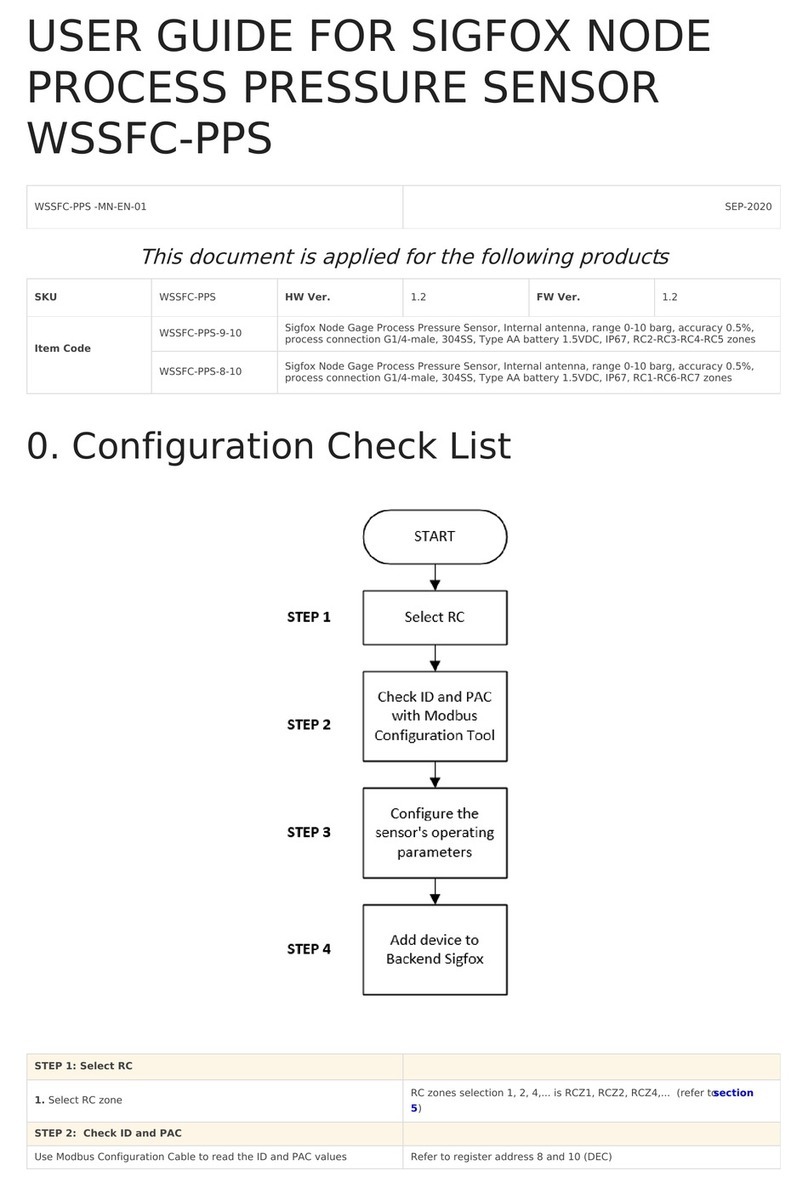

0. Configuration Check List

0.1 Configuration Sigfox Sensor

STEP 1: Select RC

1. Select RC zone

RC zones selection 1, 2, 4,... is RCZ1, RCZ2, RCZ4,... (refer to section

6)

STEP 2: Check ID and PAC

Use Modbus Configuration Cable to read the ID and PAC values

Refer to register address 8 and 10 (DEC)

STEP 3: Configure the sensor's operating parameters

Configure parameters like cycle send data, alarm, a, b,...

Refer to the configuration section 6

STEP 4: Add device to Backend Sigfox

refer to section 6.2 for details

STEP 5: Installation

refer to section 9 for details

HW Ver.

FW Ver.

Release Date

Functions Change

1.1

1.0

DEC-2020

0.2 Setup Fuel Sensor

Default communication of CAP10CNR RS485:

Baudrate : 19200

Data bit : 8

Stop bit : 1

Parity : None

Modbus Slave address : 30

See more how to configure CAP10CNR here

1. Functions Change Log

WSSFC-CAP10 is a Sigfox fuel level sensor that utilizes the 10-year experience of Daviteq in digital capacitance

measuring technique. It delivers high accuracy and stability with 0.1% of span. Ultra-low power design and smart

firmware allow the complete Wireless and Sensor package to run on 2 x AA battery 1.5V for 2-5 years with 15 minutes

updates. It can support the following regions RC1, RC2, & RC4.

Typical Applications: Monitoring fuel level and fuel consumption in fuel tanks of Genset, Boiler, Heavy equipment or

machinery...

SENSORS SPECIFICATION:

Measurement Range (mm)

Standard Range: 700, 1000, 1500, can be extended up to 4000

Accuracy / Resolution / Repeatability

±0.1% of Span / 0.1% / ±0.1% of span

Thermal drift

< +0.03% of span per 10oC

Connector

M12 male, 4-pin, Coding A

Sensor MTBF

More than 10 years

Sensor wetted materials

Aluminum and engineering plastic

Operating Temperature Range

-40 to 85 °C

Operating Humidity Range

0-100% RH

Sensor rating

IP67, outdoor

Certification

CE-Marking per EN61236-1 (with test report)

Standard accessories

Filter footer, flange, gasket, o-ring, self-tapping screws

Sigfox SPECIFICATION:

Sigfox zones

select RC1-RC2-RC4

Antenna

Internal Antenna 2 dbi

Configuration

via Downlink or offline USB cable (PC software is supplied at free)

Battery

02 x AA Type 1.5VDC

RF Module complies to

CE, FCC, ARIB

Working temperature

-40°C..+60°C (using Energizer Lithium Ultimate AA battery)

2. Introduction

3. Specification

After that, Sigfox node will send the first message to Base station.

Then during the operation, there are 03 cases of sending data to base station:

1. When the sensor sampling time interval is reached, the Sigfox node will read the data from Input or sensor

and performing the calculation. After that it will check calculated value with alarm thresholds. If the calculated

was out off the threshold values (Lo or Hi), called alarm, and the number of times of alarm did not pass the limit

of number of alarms, then it will send data to Base station immediately;

2. When the sending time interval is reached, it will send data to Base station immediately, regardless of value;

3. By using the magnet key, the Sigfox node can be triggered to send data to base station immediately. There

will be a beep sound from the buzzer meaning the data has been sent.

6. Operation Principle

Upon power on, the Sigfox node has 60 seconds to wait for off-line configuration (via cable with ModbusRTU

protocol).

NOTE:

Once sending the data to base station by this alarm event, the timer of sending time interval will be reset;

EVENT

PRE-CONDITION

ACTION

LED STATUS

BUZZER STATUS

ACTIVITIES

POST-

CONDITION

FORCE_DATA

Any state

Move Magnet Key

to contact point of

REED SWITCH.

Buzzer beeps 1

time, move

Magnet Key away.

Blink SKY BLUE

Beep 1 time

See FW specs

Back to previous

state

PARAMETERS_UPDATE

Any state

Move Magnet Key

to contact point of

REED SWITCH.

Buzzer beeps 1

time, hold Magnet

Key 5s.

Buzzer beeps 2

times.

Blink PURPLE

Beep 2 times

See FW specs

Back to previous

state

6.1 RC technical details

The RF transmit power will be automatically set as the max value as allowed by the Zone.

Sigfox Radio Configuration (RC) defines the radio parameters in which the device shall operate: Sigfox operating

frequencies, output power, spectrum access mechanism, throughput, coexistence with other radio technologies, etc.

Each radio configuration includes 4 uplink classes: 0u, 1u, 2u, and 3u.

The Sigfox network globally works within the ranges from 862 to 928 MHz. But not all RCs require such a wide range of

operation.

RC1

RC2

RC3

RC4

RC5

RC6

RC7

Uplink center frequency

(MHz)

868.130

902.200

923.200

920.800

923.300

865.200

868.800

Downlink center

frequency (MHz)

869.525

905.200

922.200

922.300

922.300

866.300

869.100

Uplink data rate (bit/s)

100

600

100

600

100

100

100

Downlink data rate (bit/s)

600

600

600

600

600

600

600

NOTE:

Once sending the data to base station by the magnet key, the timer of sending time interval will be reset;

The shortest time interval between the two manual triggers is 15s. if shorter than 15s, there will be no data

sending and you will not hear the beep sound.

the push button can only be used for the first 60 seconds after powering up.

Sigfox recommended

EIRP (dBm)

16

24

16

24

14

16

16

Specifics

Duty cycle

1% *

Frequency

hopping **

Listen Before

Talk ***

Frequency

hopping **

Listen Before

Talk ***

Duty cycle

1% *

* Duty cycle is 1% of the time per hour (36 seconds). For an 8 to 12 bytes payload, this means 6 messages per hour,

140 per day.

** Frequency hopping: The device broadcasts each message 3 times on 3 different frequencies. Maximum On time

400 ms per channel. No new emission before 20 s.

*** Listen Before Talk: Devices must verify that the Sigfox-operated 200 kHz channel is free of any signal stronger

than −80 dBm before transmitting.

Sigfox’s high limit EIRP recommendation is included in each column although regulations sometimes allow for more

radiated power than the Sigfox recommendation.

Sigfox’s recommendation is set to comply with the Sigfox technological approach of:

Low current consumption

Balanced link budget between uplink and downlink communication

Step 1: Log in to the sigfox backend website

Step 2: Click on Device

6.2 Add a device to the Backend Sigfox

the power supply to supply the energy to external sensor to start the measurement. Depends on the type and

characteristic of external sensor, the sensor will take a certain time to finish the measurement.

Once reading the value, it can be scaled to any engineering value by the following formula:

Y = aX + b

Where:

X: the raw value from sensor

Y: the calculated value will be sent to Sigfox base station in the payload data.

a: constant (default value is 1)

b: constant (default value is 0)

So, if there is no user setting for a and b ==> Y = X

The Y value will be compared with Lo and Hi threshold. Please refer below the graph of alarm processing.

Parameter

Description

Possible values

Default value

HIGH_ALARM_SETPOINT

High alarm setpoint for

calculated value

32-bit float

1000000000

LOW_ALARM_SETPOINT_FACTOR

Low alarm setpoint for

calculated value

8-bit unsigned integer

LOW_ALARM_SETPOINT =

HIGH_ALARM_SETPOINT *

LOW_ALARM_SETPOINT_FACTOR /

200

0

ALARM_ENABLE

Enable/Disable ALARM event

0b0 = ALARM event is OFF

0b1 = ALARM event is ON

0b0 = ALARM event is OFF

ALARM_PERIOD

Period of time to send

ALARM event

0b000 = every 10min

0b001 = every 30min

0b010 = every 1h

0b011 = every 2h

0b100 = every 3h

0b101 = every 6h

0b110 = every 12h

0b111 = every 24h

0b000 = every 10min

LED_BUZZER_ENABLE

Enable/Disable LEDs and

Buzzersinteractions for action

not triggered by the reed switch

0b0 = LEDs and Buzzers are OFF

0b1 = LEDs and Buzzers are ON

0b1 = LEDs and Buzzers are ON

HEARTBEAT_PERIOD

Period of time to send

HEARTBEAT event

0b000 = every 1h

0b001 = every 6h

0b010 = every 12h

0b011 = every 24h (1 day)

0b100 = every 48h (2 days)

0b101 = every 72h (3 days)

0b110 = every 120h (5 days)

0b111 = every 240h (10 days)

0b011 = every 24h (1 day)

Here is the information about CAP10CNR

6.4 Configuration Parameters

MEASURE_PERIOD

Period of time to measure

sensor

0b0000 = every 1s

0b0001 = every 2s

0b0010 = every 5s

0b0011 = every 10s

0b0100 = every 20s

0b0101 = every 30s

0b0110 = every 1min

0b0111 = every 2min

0b1000 = every 5min

0b1001 = every 10min

0b1010 = every 20min

0b1011 = every 30min

0b1100 = every 1h

0b1101 = every 2h

0b1110 = every 3h

0b1111 = every 6h

0b1100 = every 1h

TX_REPEAT

Sigfox TX repeat

0b0 = Send RF 1 time

0b1 = Send RF 3 time

0b1 = Send RF 3 time

CYCLIC_DATA_PERIOD

Period of time to send

CYCLIC_DATA event

0b000 = every 10min

0b001 = every 30min

0b010 = every 1h

0b011 = every 2h

0b100 = every 3h

0b101 = every 6h

0b110 = every 12h

0b111 = every 24h

0b010 = every 1h

DEVICE_RESET

Once this parameter is set, the

device shall restart once after

having received the Downlink.

0b1010 = 0xA = force device

reset

others = do nothing

0b0000 = do nothing

DOWNLINK_TYPE

Downlink type

4-bit unsigned integer

See Sigfox Downlink tab

0b0000

Data name

Description

Encoding or Possible values

Length

(in bits)

EVENT_ID

Unique ID identifying the device

event

4-bit unsigned integer

0 = START_UP

1 = HEARTBEAT

2 = PARAMETERS_UPDATE

3 = FORCE_DATA

4 = CYCLIC_DATA

5 = ALARM

4

HW_VERSION

Indicate HW version

4-bit unsigned integer

1..15

4

FW_VERSION

Indicate FW version

8-bit unsigned integer

1..255

8

LATEST_SIGFOX_DOWNLINK

Latest received and valid sigfox

downlink frame

= Current configuration

64-bit encoded field

See Sigfox Downlink tab

64

HW_ERROR

HW error

0b0 = no error

0b1 = error

1

ALARM

Alarm

0b00 = no alarm

0b01 = low alarm

0b10 = high alarm

0b11 = not used

2

BATTERY_LEVEL

Battery level

2-bit unsigned integer

0..3

2

RAW_VALUE

Raw value of CAP10-RS485

16-bit unsigned integer

16

SCALED_VALUE

Scaled value of CAP10-RS485

16-bit signed integer

16

TENTATIVE

Tentative number

8-bit unsigned integer

Formula: (8-bit_Tentative +1)=

real_tentative #

Range: 1 to 256

Accuracy: 1

Example: 0b00000111 =

0x7=7=> 7+1 =>tentative # 8

8

6.5 Payload Fields

6.6 Sigfox Uplink Frame Format

Sigfox Frame software for Sigfox Sensor

Size

START_UP

(led blink WHITE)

Payload

EVENT_ID

HW_VERSION

FW_VERSION

LATEST_SIGFOX_

DOWNLINK

10.0

bits

4

4

8

64

Value

0b0000 = 0

yes

yes

yes

HEARTBEAT

(led blink GREEN)

Payload

EVENT_ID

HW_VERSION

FW_VERSION

LATEST_SIGFOX_

DOWNLINK

10.0

bits

4

4

8

64

Value

0b0001 = 1

yes

yes

yes

PARAMETERS_UPDATE

(led blink PURPLE)

Payload

EVENT_ID

HW_VERSION

FW_VERSION

LATEST_SIGFOX_

DOWNLINK

10.0

bits

4

4

8

64

Value

0b0010 = 2

yes

yes

yes

Size

FORCE_DATA

(led blink

SKY

BLUE)

Payload

EVENT_ID

HW_

ERROR

reserved

ALARM

BATTERY_LEVEL

reserved

RAW_VALUE

SCALED_VALUE

6.0

bits

4

1

3

2

2

4

16

16

Value

0b0011 =

3

yes

zeros

yes

yes

zeros

yes

yes

CYCLIC_DATA

(led blink

SKY

BLUE)

Payload

EVENT_ID

HW_

ERROR

reserved

ALARM

BATTERY_LEVEL

reserved

RAW_VALUE

SCALED_VALUE

TENTATIVE

7.0

bits

4

1

3

2

2

4

16

16

8

Value

0b0100 =

4

yes

zeros

yes

yes

zeros

yes

yes

yes

ALARM

(led blink

RED)

Payload

EVENT_ID

HW_

ERROR

reserved

ALARM

BATTERY_LEVEL

reserved

RAW_VALUE

SCALED_VALUE

TENTATIVE

7.0

bits

4

1

3

2

2

4

16

16

8

Value

0b0101 =

5

yes

zeros

yes

yes

zeros

yes

yes

yes

User can set the down link data in Sigfox back-end system in advance, whenever the Sigfox node connected to base

stations and with downlink waiting is enable at that time (one time in 6 hours), the downlink data will be loaded to

Sigfox node.

The downlink data can be any configuration parameter.

Downlink Frame Format:

Size

DOWNLINK_TYPE = 0

Payload

HIGH_ALARM_SETPOINT

LOW_ALARM_SETPOINT_FACTOR

ALARM_ENABLE

ALARM_PERIOD

LED_BUZZER_ENABLE

8.0

bits

32

8

1

3

1

Value

yes

yes

yes

yes

yes

HEARTBEAT_PERIOD

MEASURE_PERIOD

TX_REPEAT

CYCLIC_DATA_PERIOD

DEVICE_RESET

DOWNLINK_TYPE

3

4

1

3

4

4

yes

yes

yes

yes

yes

0b0000 = 0

Size

DOWNLINK_TYPE = 5

Payload

PRM_ADDRESS

PRM_LENGTH

PRM_VALUE

reserved

DOWNLINK_TYPE

8.0

bits

8

8

16

28

4

Value

yes

0x02 = 2

yes

zeros

0b0101 = 5

6.7 Sigfox Downlink Frame Format

Sigfox Frame software for Sigfox Sensor

The Sigfox node is only able to receive max 04 downlinks a day, each downlink will be waiting in every 06 hours.

Please pay attention when send downlink data. If there was a mistake in sending wrong data, it would

cause the Sigfox node not working properly and user need to configure it by offline cable!!!

Payload

PRM_ADDRESS

PRM_LENGTH

PRM_VALUE

reserved

DOWNLINK_TYPE

8.0

bits

8

8

32

12

4

Value

yes

0x04 = 4

yes

zeros

0b0101 = 5

Modbus

Register

(Decimal)

Modbus

Register

(Hex)

Function

Code

# of

Registers

Description

Range

Default

Format

Property

Comment

2

2

3

4

FW_VERSION

string

Read

6

6

3

2

HW_VERSION

string

Read

8

8

3

2

DEVICE_ID

hex

Read

Product ID

10

A

3

4

DEVICE_PAC

hex

Read

Product PAC

14

E

3

1

SENSOR_TYPE

1-255

uint16

Read

Sensor or

Input Type

Modbus

Register

(Decimal)

Modbus

Register

(Hex)

Function

Code

(Read)

Function

Code

(Write)

# of

Registers

Description

Range

Default

Format

Property

Comment

270

10E

3

16

4

CURRENT_CONFIGURATION

hex

Read/Write

274

112

3

16

1

SERVER_CONFIG

uint16

Read/Write

0: Send to

Sigfox

Network

1: Send to

Dongle

276

114

3

16

1

RADIO_CONFIG

1, 2, 4

4

uint16

Read/Write

RC zones

selection

1, 2 ,4 is

RCZ1,

RCZ2,

RCZ4

277

115

3

16

1

TX_POWER

20

int16

Read/Write

RF Tx

power

278

116

3

16

2

CONSTANT_A

0.06666

float

Read/Write

Constant a

for scaling

measured

value

280

118

3

16

2

CONSTANT_B

-1,113.33

float

Read/Write

Constant b

for scaling

measured

value

282

11A

3

16

2

HIGH_CUT

1E+09

float

Read/Write

High cut

value for

calculated

value

284

11C

3

16

2

LOW_CUT

0

float

Read/Write

Low cut

value for

calculated

value

7. Modbus Memmap

7.1 Data table

7.2 Configuration table

286

11E

3

16

2

SENSOR_BOOT_TIME

800

uint32

Read/Write

Boot time

of

sensor/input,

in ms

306

132

3

16

1

CAP10_BAUD_RATE

0-1

1

uint16

Read/Write

0: 9600,

1:19200

307

133

3

16

1

CAP10_NUM_OF_SAMPLES

1-20

2

uint16

Read/Write

Number of

cap10

sensor

reading

samples

to get

average

Using the configuration cable to connect to the sensor as below picture.

During connection with Modbus configuration tool, the Sigfox node will send all data in realtime: Battery, Battery level,

Vref, Button status, reed switch status, PCB temperature, Measured value, alarm status.

Step to configure & check data:

Step 1: Install the Modbus Configurator Software in the link below

https://filerun.daviteq.com/wl/?id=yDOjE5d6kqFlGNVVlMdFg19Aad6aw0Hs

Step 2: Plug the configuration cable to Computer via USB port;

8. Offline configuration

Serial port configuration on computer: 9600 baud, None parity, 1 stop bit.

Reading data by Function 3.

Writing data by Function 16.

NOTE:

The Modbus configuration can be done in the first 60s after power up the Sigfox node. After 60s, if user can not

finish the configuration, user need to reset the power of Sigfox node again, by removing battery in at least 15s.

How to use the Modbus configuration software

Step 3: Open the housing;

Step 4: Plug the connector to the configuration port;

Step 5: Import the configuration file by importing the csv file: Go to MENU: FILE / Import New / => select the file

with name CONFIGURATION TEMPLATE FILE FOR SIGFOX CAP10 SENSOR FW1.0.csv (

in the link below

). Then click

Connect;

CONFIGURATION TEMPLATE FILE FOR WSSFC-CAP10

To maximize the distance of transmission, the ideal condition is Line-of-sight (LOS) between the Sigfox sensor and

Base station. In real life, there may be no LOS condition. However, the Sigfox sensor still communicate with Base

station, but the distance will be reduced significantly.

9. Installation

9.1 Locate the good place for Radio signal

ATTENTION:

DO NOT install the Sigfox sensor or its antenna inside a completed metallic box or housing, because RF signal

can not pass through metallic wall. The housing is made from Non-metallic materials like plastic, glass, wood,

leather, concrete, cement…is acceptable.

9.2 Mounting

9.2.1 Bracket installation

Sigfox sensor connected to fuel sensor via M12 . connection cable

9.2.2 Site installation

WARNING: The sensor must be securely fixed near the measuring area.

Default communication of CAP10CNR RS485:

Baudrate : 19200

Data bit : 8

Stop bit : 1

Parity : None

Modbus Slave address : 30

Refer here for installation instructions for cap10

This manual suits for next models

3

Table of contents

Other daviteq Measuring Instrument manuals

daviteq

daviteq MBRTU-TBD User manual

daviteq

daviteq WS433-MA-31 User manual

daviteq

daviteq CAP10CNC User manual

daviteq

daviteq MBRTU-SAL User manual

daviteq

daviteq WS433-M12F-ATH User manual

daviteq

daviteq Sigfox WSSFC-PPS User manual

daviteq

daviteq WS433-CO2 User manual

daviteq

daviteq WS433-ULC User manual

Popular Measuring Instrument manuals by other brands

Koeng

Koeng KEG-500 Operation manual

Teledyne

Teledyne HASTINGS 200 Series instruction manual

PDi

PDi DP-110 Operation manual

agratronix

agratronix MT-PRO+ Operator's manual

M-Life

M-Life B.BEAT PRO16 quick start guide

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ECOSCAN CON TDS 5 CONDUCTIVITY PORTABLE... Mode d'emploi