DAYLIFF MJ User manual

WATER METERS

Installation &

Operating Manual

MJ

PD

WP

SPECIFICATIONS

1.

1

2.

SYMBOLS & WARNINGS 3

INDEX

© Davis & Shirtliff Ltd 2020

Contents herein are not warranted

3. INSTALLATION 4

4. OPERATION & MAINTENANCE 7

5. TERMS OF WARRANTY 9

1

1. SPECIFICATIONS

The various Dayliff water meter types are robust and economical designs for

monitoring residential, commercial and agricultural consumption. All meters are

remote monitoring enabled and pulse cables are available on request. Sizes are

available from DN15 to DN100 in three different ranges as follows:-

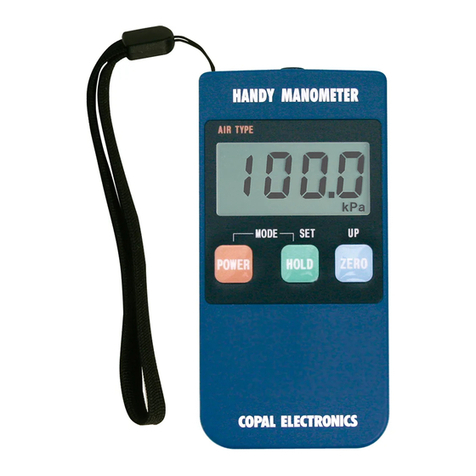

MJ

A high precision and reliable multi jet dry type water meter designed for general

water supply metering applications. It features magnetic drive for lower

transmission resistance, a magnetic shield for external magnetic field protection

and a sealed dry dial to ensure clear and easy reading. The body is made from

composite plastic for DN15 and DN20 sizes and brass for larger sizes. Meters are

supplied with inlet strainers and union connectors.

PD

Rotary piston type meters that provide high accuracy over a wide flow range. The

mechanical transmission movement provides reliability and the liquid sealed

register provides easy and clear reading. Meters are fitted with internal strainers,

non return valves and union connectors and the bodies are made from composite

plastic (15mm size) and corrosion resistant steel for other sizes.

MJ PD WP

Congratulations on selecting a Dayliff Water Meters. They are

manufactured to the highest standards and if installed and operated

correctly will give many years of efcient and trouble free service.

Careful reading of this Installation Manual is therefore important,

though should there be any queries they should be referred to the

equipment supplier.

PERFORMANCE DATA

2

WP

A heavy duty meter with flange connections for bulk flow applications featuring

magnetic drive, a dry dial for clear reading and a removable measuring

mechanism that can be maintained without removing the meter body. The body is

made from cast iron with epoxy coating.

DIMENSIONS AND WEIGHTS

MJ PD WP

3

Rated Flow (m /hr)

3

Max. Flow (m /hr)

Min. Flow (l/hr)

Pressure Rating (bar)

0

Max. Operating Temp ( C)

Max. Pipe Size

Pressure Loss at Rated Flow (bar)

Pressure Loss at Max. Flow (bar)

3

Max. Reading (m )

15

1.5

3

30

16

99999.999 9999.9999 999999

40

0.2

1

15

1.5

3

15

10

40

0.2

1

20

2.5 6 103.5

512 20

7

50 120 200

70

16 16 1616

40 40 4040

0.25 0.24 0.2

0.25

1 1 0.9

1

1

20

2.5

5

25

16

40

0.25

1

50

15

30

7.5

16

50

2”

0.02

0.08

65

25

50

12.5

16

50

2½”

0.015

0.08

80

40

80

20

16

50

3”

0.034

0.015

100

60

120

30

16

50

4”

0.038

0.125

25 32 40

1½”½” ½”¾” ¾”

1¼”

Body thread (D)

Connector thread (d)

Flange size (mm)

Body Length, L (mm)

Overall Length, L1(mm)

Height, H (mm)

Width, W (mm)

Weight with connectors (kgs)

15

½”

-

115

209

96

96

0.6

MJ PD WP

15

½”

-

165

259

106

98

0.7

20

1” 1½” 2”

- - - -

190 260 260 300

1”

294 380 384 431

98 98 98 122

107 118 118 142

0.8 2.9 3.7 6.1

20

1”

-

130

234

96

96

1.48

50

-

-

165

200

-

256

165

12

65

-

-

185

200

-

185

266

13

80

-

-

200

225

-

276

200

16

100

-

-

220

250

-

286

220

18

25 32 40

1½”

¾”

¾”

1

¼”

1

¼”

¾”

Accuracy Class B C B

3

L

H

nxM

DN

D1

D

L

L1

W

D

d

H

15mm

MJ

L

W

D

d

L1

PD WP

2. SYMBOLS & WARNINGS

WARNING

Service lines, valves, connections and meters must be

water tight.

WARNING

Check local codes and regulations before the meter is

removed for service, replacement, or installation.

Settings must be checked for electrical continuity

through the service pipe (provided the pipe is metallic).

CAUTION

Instructions should be carried out by a qualified

professional with parts/ equipment approved by the

local codes and regulations.

WARNING

Meter must not be used as a lever or crowbar to

straighten misaligned piping.

WARNING

Meter shall not be set into a meter opening which is too

long or force the piping into place with the coupling

nuts on the meter setting. This can cause serious

damage to the threaded ends of the meter and to the

meter itself

NOTE

Indoor residential meters may be located in basements,

crawl spaces, utility rooms or in a garage.

4

NOTE

The meter installation should include a valve

downstream from the meter to prevent water loss

during meter servicing or removal from the line.

NOTE

The system should be installed so that the meter can be

read at a convenient outdoor location. For meters that

are located indoors, a remote reading system is

recommended. This eliminates access problems and

avoids customer complaints concerning strangers

entering the home.

WARNING

Before starting any disassembly operation, the water

line must be depressurized. Removing a meter that is

under line pressure can result in serious personal injury

ŸThe meter is a precise measuring device and although robust in design

and construction, should be handled, transported, and installed with

care. The meter should remain within its protective packaging to the point

of installation.

ŸStorage temperatures shall remain within the range of -20°C to +60°C ,

avoiding direct sunlight.

ŸSpecial fittings and accessories are available to provide easier meter

installation and proper alignment.

ŸAll meters should be installed according to local standards or water utility

regulations.

ŸClose the meter's inlet-side valve.

ŸOpen a faucet and wait until water flow stops to depressurize the system.

Do not remove the meter until the flow stops.

ŸCheck valves and make necessary repairs to shut-off valve or inlet side

valve if necessary.

ŸFor proper sealing, use new meter gaskets when changing the meter.

ŸDo not use thread sealant, pipe dope or meter coupling threads, meters

are sealed by the gasket only.

ŸClose the meter's outlet-side valve. Protect the floor below the meter

against potential spills or leaks that could occur. Protect the coupling area

from debris so that the new meter will not be contaminated or damaged.

3. INSTALLATION

45

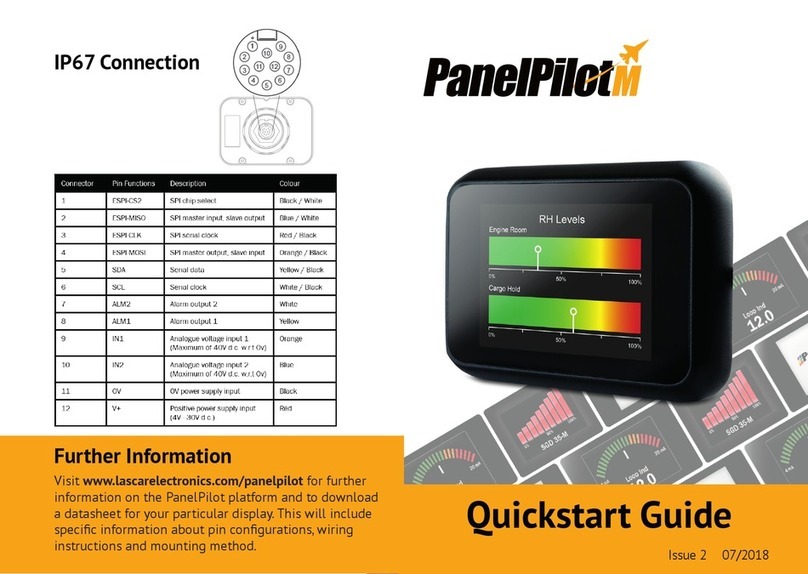

Fig 1

MJ/PD Meter Installation

ŸWhen replacing an existing water meter, loosen meter couplings and

remove the meter and the old gaskets in the coupling nuts.

ŸClean the coupling nuts, removing any dirt from the threads.

ŸVerify the existing setting for proper alignment and spacing. Correct any

misalignment and spacing in the setting.

ŸPlace the connection gaskets inside the connection coupling nuts. Use

rubber gasket hardness of 80-90 Shore A.

ŸSet the meter between the coupling nuts, properly positioned so that the

flow indication/arrow on the meter housing points in the direction of flow.

ŸStart the coupling nuts at the threaded meter ends. Verify that the coupling

nuts are properly aligned to avoid cross threading damage (stripping) to

the meter ends. This is especially important for the engineered

composite/polymer meter.

ŸThe best method for properly starting meter coupling nuts is to position the

nuts squarely against the meter end. Turn the nut counterclockwise (in

reverse) while holding the nut against the meter end. When the first

threads on both the coupling nut and the meter spud end coincide, a

slight click will be heard and the movement of the nut into the starting

position will be felt. At this point, turn the nut clockwise to complete the

connection.

ŸIn a good installation, this can be accomplished by turning the nut by

hand until it is tight. When firmly hand tight, apply an additional ¼ to ½

turn using an open-end wrench with a short handle.

WARNING

DO NOT over tighten.

Coupling Gasket

Coupling Nut

Meter

Tail Piece

PD/MJ Water Meter

46

Fig 2

ŸAfter installation is complete and prior to opening the upstream/inlet

water valve ensure that the valve on the downstream/outlet side of the

meter is shut.

ŸIn case the main/service shut-off valve is closed, open it slowly to

pressurize the service line to the meter setting. Air in the lines may damage

a meter and other equipment. Water hammer from a quick turn-on can

damage plumbing and appliances or cause a water line rupture.

ŸSlowly open the inlet side valve which will fill the meter with water. Once

the water is flowing fully open the meter inlet valve . Partially open valves

can render the meter inaccurate and lead to low water pressure.

ŸCheck for leaks around the meter and connections. Open a

downstream/consumer faucet to allow entrapped air to escape once the

outlet valve is opened. Open the meter outlet side valve slowly to

pressurize the downstream/ consumer side of the system. Turn off the

consumer faucet when normal water flow occurs.

ŸEnsuring that all consumer faucets are shut, observe the low flow detector

in the meter to identify downstream leaks in the consumer's system.

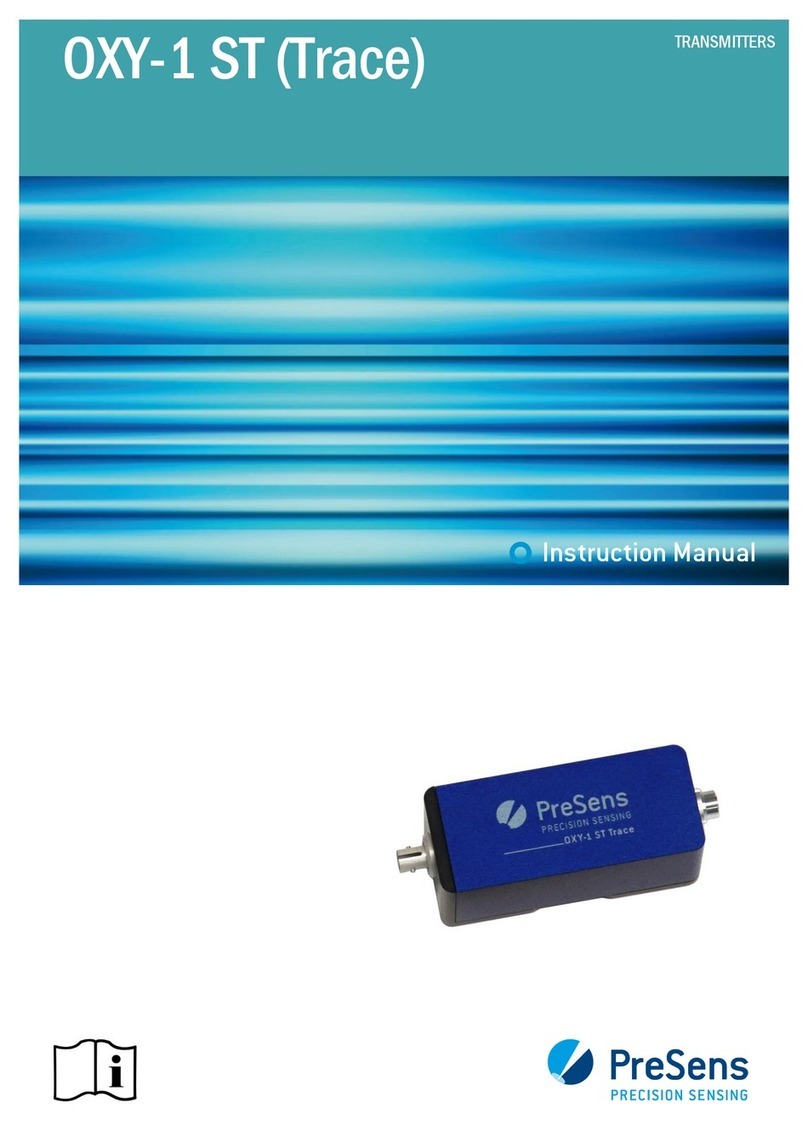

WP Installation

ŸThe meter must be installed with the direction of the flow as indicated by

the arrow cast in the meter body.

ŸIn order to keep the water meter in good working condition, the pipeline

should be cleared before installation.

ŸA horizontal position with the register face upwards is recommended.

ŸThe meter must have 10 diameters straight pipe ahead of the meter and 5

diameters straight pipe after to ensure proper flow through the meter.

ŸThe valves must be installed in the front and the back of the water meter.

ŸAttention should be paid that a cold water meter must not be used for hot

water..

Ÿ It is recommended to install a filter before water meter.

WARNING

The meter can be damaged if subjected to full ow

conditions prior to expelling all the air from the

pipeline.

7

ŸProvide an upstream and downstream shut-off valve of high quality and

with low pressure drop. A valve before the meter will allow local shutoff of

the water if change or repair is later needed. A valve or check valve on the

outlet side of the meter will keep water from draining from the building

when changing or removing the meter.

ŸProvide a drain cock between the meter and the downstream valve.

ŸIn general, install the meter horizontally in the line to obtain optimum

performance as shown in Fig 2. Volumetric meters may also be installed

vertically or at an incline.

ŸEnsure that the installed meter will be easily accessible for reading,

inspection, and service.

ŸProtect the meter and piping against flooding, mechanical damage and

tampering.

ŸThe installed meter must not be an obstacle or a hazard to the customer or

interfere with public safety.

ŸAlways flush the upstream and downstream piping prior to installation.

Ensure that the water in the pipes is completely free of debris.

4. OPERATION AND MAINTENANCE

1257

( Figure one )

6

Inlet

43234

5

67

≥5D ≥10D

1. Water meter

2. Nut

3.Gasket 1

4. Gasket 2

5. Pipeline

6. Gasket 3

7. Screw

WP Bulk Water Meter

Fig 3

8

NOTE

Standard water meters are for cold potable water.

Enquire for hot water (temperatures greater than

50°C).

Correct Wrong

ŸMost meters are rated to 16 bar. If there is a pressure regulator, verify that

the regulator works and is adjusted correctly.

ŸThe service pipe entering and exiting the meter box should be properly

bedded to ensure that it is not axially misaligned. Ensure that pipe

alignment is maintained so that the service pipe or meter will not be

damaged by eventual ground shifts.

Fig 4

9

ii) Standard Warranty

General Terms

If equipment failure occurs in the normal course of service having been

competently installed and when operating within its specified duty limits

warranty will be provided as follows:-

• Up to six months - The item will be replaced or repaired at no

charge.

• Over 6 months, less than one year - The item will be replaced or

repaired at a cost to the customer of 50% of the Davis & Shirtliff

market price.

The warranty on equipment supplied or installed by others is conditional

upon the defective unit being promptly returned free to a Davis &

Shirtliff ofce and collected thereafter when repaired. No element of site

repair is included in the warranty and any site attendance costs will be

payable in full at standard chargeout rates. Also proof of purchase including

the purchase invoice must be provided for a warranty claim to be

considered.

5. TERMS OF WARRANTY

i) General Liability

• In lieu of any warranty, condition or liability implied by law, the liability of

Dayliff in respect of any defect or failure of equipment supplied is limited to

making good by replacement or repair (at the Company's discretion)

defects which under proper use appear therein and arise solely from faulty

design, materials or workmanship within a specified period. This period

commences immediately after the equipment has been delivered to the

customer and at its termination all liability ceases. Also the warranty period

will be assessed on the basis of the date that the Company is informed of

the failure.

ŸThis warranty applies solely to equipment supplied and no claim for

consequential damages, however arising, will be entertained. Also the

warranty specifically excludes defects caused by fair wear and tear, the effects

of careless handling, lack of maintenance, faulty installation, incompetence

on the part of the equipment user, Acts of God or any other cause beyond the

Company's reasonable control. Also, any repair or attempt at repair carried

out by any other party invalidates all warranties.

INS450A-02/20

www.davisandshirtliff.com

This manual suits for next models

2

Table of contents