Daystrom Heathkit IP-22 User manual

Page

4

1--3

CONSTRUCTION NOTES

This manual is supplied to assist you in every

way to complete your kit with the least possible

chance for error. The arrangement shown

is

the result of extensive experimentation and

trial.

If

followed carefully, the result will be a

stable instrument, operating at a high degree

of dependability. We suggest that you retain the

manual in your files for future reference, both

in the use of the instrument and for its main-

tenance.

UNPACK THE KIT CAREFULLY

AND

CHECK

EACH PART AGAINST THE PARTS LIST. In so

doing, you will become acquaintedwiththeparts.

Refer to the charts and other information onthe

inside covers of the manual to help you identify

the components.

If

some shortage or parts

damage is found in checking the Parts List,

please read the REPLACEMENT section and

supply the information calledfortherein. Include

all inspection slips in your letter

to

us.

Resistors generally have a tolerance rating of

10%unless otherwise stated in the Parts List.

Tolerances on capacitors are generally even

greater. Limits of

+

1000/0and -20

O/o

are common

for electrolytic capacitors.

We suggestthat you do the following before work

is started:

1.

Lay out all parts so that they are readily

available.

2.

Provide yourself with good quality tools.

Basictool requirements consist of a screw-

driver with a

1/4"

blade; a small screw-

driver with a

1/8"

blade; long-nose pliers;

wire cutters, preferably separate diagonal

cutters; a pen knife or a tool for stripping

insulation from wires; a soldering iron (or

gun) and rosin core solder. A set of nut

drivers and a nut starter, while not neces-

sary, willaid extensively in construction of

the kit.

Most kit builders find it helpful to separate the

various parts into convenient categories. Muffin

tins or molded egg cartons make convenient

trays for small parts. Resistors and capaci-

tors may be placed with their lead ends in-

serted in the edge of

a

piece of corrugated

cardboard until they are needed. Values can

be written on the cardboard next to each

component. The illustration shows one method

that may be used.

L-J

.

,

Page 5

PARTS

LIST

Refer to the Parts Pictorial which folds out

PART PARTS DESCRIPTION

No. PerKit

Resistors-Capacitor

1-22

1

22

KS2

1/2 watt resistor

(red-red-orange)

1B-23

1

5.6

KC2

2 watt resistor

(green-blue-red)

1B-3 2 10

KS2

2 watt resistor

(brown-black-orange)

25-57

1

100 pfd 200 V electrolytic

capacitor

Controls-Switches

1

10-52

1

2

KS2

linear control

(tab mounting)

10-57

1

10

KS2

linear control

(tab mounting)

60-3

1

Slide switch, spring return,

DPDT

61

-

1 1

Toggle switch, SPST

63-234 2 Rotary switch, 8-position,

10 ampere contacts.

Transformer-Diode

54-99

1

Transformer

57-27 2 Silicon diode

Hardware

250-49 2

250-83 2

250-89 17

250-128 6

250-137 4

252-

1

2

252- 3 9

252-4 4

252-5 4

252-7 2

252-22 8

252-54 6

253-10 2

254-

1 11

254-2 4

254-3 4

254-4 2

254-7 2

'

259-1 2

3-48

x

1/4" screw

#10

x

1/2" sheetmetalscrew

6-32

x

3/8" screw

#10

x

7/8" sheetmetalscrew

8-32

x

3/8" screw

3-48 nut

6-32 nut

8-32 nut

10-32 nut

3/8" control nut

#6 speednut

#10 speednut

3/8" control flat washer

#6 lockwasher

#8 lockwasher

#10 lockwasher

3/8" control lockwasher

#3 lockwasher

#6

solder lug

#6

spade lug

PART PARTS DESCRIPTION

No. PerKit

Terminal Strips-Sockets

431-1

1

Dual-lug terminal strip

431-2

1

2-lug terminal strip

-

431-27

1

3-lug terminal strip

431-12

1

4-lug terminal strip

434-15

1

7-pin tube socket

434-23

1

Lamp socket

434-109 2 3-prong AC receptacle

Metal Parts

90-237

1

Cabinet

200-M275

1

Transformer chassis

200-M276

1

Subchassis

203-212F800, 801, 802

1

Front panel

204-M345 2 Vertical support bracket

204-M346 2 Horizontal support

bracket

205-M253

1

Reinforcing plate

Wire

89-15

1

3-wire line cordwith 3-prong

plug

344-6

1

Length #18 hookup wire

346-

1 1

Length sleeving

Miscellaneous

75-17 4 Bushing, binding post

Strain relief, line cord

Binding post cap, black

Handle

Rubber feet

Meter, 0-1 ma

OC2 tube

Lamp, 3 watt, 120 volt

Pilot light assembly

8 ampere fuse

Fuse holder

Binding post base

Adapter, 3-prong to 2-prong

Knob

Solder

Manual

Page

6

k-3

PROPER SOLDERING TECHNIQUES

Only a small percentage of HEATHKIT equip-

ment purchasers find it necessary to return

an

instrument for factory service.

Of

theseinstru-

ments, by far the largest portion

malfunction

due to poor or improper soldering.

If

terminals are brightandclean andfreeof wax,

frayed insulation and other foreign substances,

no difficulty will be experienced in soldering.

Correctly soldered connections are essential

if

the performance engineered intc;

a

kit is to be

fully realized.

If

you are a beginner with no

experience in soldering, a half hour's practice

with some odd lengths of wire may be a worth-

while investment.

For most wiring, a 30 to 100 watt iron or its

equivalent in asoldering

gun

isvery satisfactory.

A lower wattage iron than this may not heat the

connection enough to flow the solder smoothly

over the joint. Keep the iron tipclean and bright

by wiping it from time to time with a cloth.

Wherever there isapossibilityof bare leads

shorting to other parts orto the chassis,the

leads should be covered with insulating

sleeving. Where the use of sleeving is spe-

cifically intended, thephrase "use sleeving"

is included in the associated construction

step.

In

any case where there is the pos-

sibility of an unintentional short circuit,

sleeving should be used, Extra sleeving is

provided for this purpose.

4.

Crimp or bend the lead (orleads)aroundthe

terminal to form a good joint without re-

lying on solder for physical strength.

If

the wire is too large to allow bending or

if

the step states that the wire is not to be

crimped, position the wire so that a good

solder connection can still be made.

5.

Position the work, if possible, sothat gravity

will help to keep the solder where you want

it.

CHASSIS WIRING AND SOLDERING

6.

Place a flat side of the soldering iron tip

1.

All wire used is the type with colored against the joint to be soldered until it is

insulation (hookup wire).

In

preparing a heated sufficiently to melt the solder.

length of hookup wire, remove

11'4"

of

insulation from each end unless directed

otherwise in the construction step.

7.

Then place the solder against the heated

terminal and it will immediately flow over

the joint; use only enough solder to thor-

2.

Leads on resistors, capacitors and similar oughly wet the junction. It is usually not

components are generally much longer than necessary to fill the entire hole in the

they need to be to make the required con- terminal with solder.

nections.

In

these cases, the leadsshouldbe

cut to proper length before the part isadded

to the chassis.

In

general, the leads should

8.

Remove the solder and then the iron from

be just long enough to reach their termin- the completed junction. Use carenottomove

ating points. the leads until the solder is solidified.

c-1

..

Page

7

A poor or cold solder joint will usually look heated until the solder flows smoothly over the

crystalline and have a grainy texture, or the entire junction.

In

some cases, it may be neces-

solder will stand up in a blob and will not have sary to add a little more solder to achieve a

adhered to the joint. Such joints should be re- smooth bright appearance.

CRIMP WIRES HEAT CONNECTION APPLY SOLDER ALLOW SOLDER PROPER SOLDER

TO FLOW CONNECTION

NOTE: ALL GUARANTEES ARE VOIDED AND WE WILL NOT REPAIR OR SERVICE

INSTRUMENTS IN WHICH ACID CORE SOLDER OR PASTE FLUXES HAVE BEEN

USED. WHEN IN DOUBT ABOUT SOLDER, IT IS RECOMMENDED THAT A NEW

ROLL PLAINLY MARKED "ROSIN CORE RADIO SOLDER" BE PURCHASED.

STEP-BY-STEP PROCEDURE

The following instructions are presented in a kit; however, in some instances the illustra-

logical step-by-step sequence to enable you to tions may be slightly distorted to facilitate

complete your kit with the least possible con- clearly showing all of the parts.

fusion.

Be

sure to read each step all the way

through before beginningthe specifiedoperation. The abbreviation "NS" indicates that a con-

Also read several steps ahead of the actualstep nection should not be soldered yet as other

being performed. This will familiarize you with wires will be added. When the last wire

is

the relationship of the subsequent operations. installed, the terminal should be soldered and

When the step

is

completed, check it off in the the abbreviation "S" isusedtoindicatethis. Note

space provided. This isparticularly important that a number will appear after each solder

as it may prevent errors or omissions, espe- instruction. This number indicatesthenumber of

cially if your work is interrupted. Some kit leads that are supposed to be connected to the

builders have also found it helpful to mark each terminal in point before it is soldered. For

lead in colored pencil on the Pictorial as it

is

example, if the instruction reads, "Connect a

added. lead to lug

1

(S-2)," it will be understood that

there will be two leads connectedtotheterminal

The fold-out diagrams in this manual may be at the time it

is

soldered.

removed and attached to the wall above your

working area; but, because they are an integral The steps directing the installation of resistors

part of the instructions, they should be returned include color codes to help identify the parts.

to the manual after the kit

is

completed. Also,

if

a part is identified by a letter-number

designation on the Schematic, its designation

In

general, the illustrations in this manual will appear inthe construction stepwhich directs

correspond to the actual configuration of the its installation.

c-1

Page

9

. .

STEP-BY-STEP ASSEMBLY

FRONT

PANEL

Before tightening the nut, position the

Refer to Pictorial

1

for the following steps. space between lugs

7

and

8

toward pilot

light

H.

NOTE: It would be well to place a soft cloth on

your work surface to prevent scratching the

front panel when assembling the front panel in

the following steps.

(

)

Position the front panel as shown

in

Pic-

torial

1

and mount AC receptacle A. Note

that the 2-screw side of the receptacle is

toward locations C and D. The receptacle

<:

7

CIWAWER

is mounted by pushing it into its hole from

the front of the panel until the two tabs

snap out to hold

it

in place,

9

CONTROL

FLAT

WASHER

(

)

Similarly, mount AC receptacle

B.

The

2-screw side of receptacle B should be

away from locations C and D.

INSULATOR BVSHlNtS.

ASSEMBLE SO PINS

IMTEWMESH AS

SHOWN

Detail 1A

(

)

Mount binding post base

C

as

shown in

Detail

lk

Use two binding post bushings,

a

#6

solder lug, and

a

6-32 nut. Orlent

the solder lug

as

shown.

(

)

Similarly, mount binding post base D.

(

)

Mount slide switch E with two

6-32

x

3/8"

screws. This switch should be oriented so

that

it

is

in its OUTPUT position

as

indi-

cated by the front panel markings.

(

)

Mount pilot light

H.

After inserting the

pilot light through the front panel, bend

four of

its

small tabs down against the

panel to secure it in place.

i

(

)

Mount rotary switch

F

as shown in Detail

1B. Use a

3/8"

control lockwasher, a

3/8"

control flatwasher, and a

3/8"

control nut.

Detail 1B

(

)

Similarly, mount rotary switch

G.

The

space between lugs

1

and 2 should be to-

ward the pilot light.

(

)

Referring to Detail lC, mount fuse holder

J

and one of the horizontal support brack-

ets.

BRACKET

Detail 1C

(

?

Similarly, mount toggle switch

K

and the

other horizontal support bracket. The two

nuts used to mount this switch should be

positioned on the switch bushing sothat the

end of the bushing

is

flush with the outside

nut after the nut

is

tightened.

( )

Mount the meter movementtothefrontpanel

usii:g

r?he

i'uts and lockwashers furnished

with the meter. Be carefulnotto overtighten

the meter mounting nuts as this could

crack the plastic meter base. Now remove

the shorting wire

(if

present) from between

the mete; terminals, but do not loosen the

nuts on the meter terminal studs.

PARTS PICTORIAL

*

w

:"

SCREW

W

RESISTOR

*lo

x

3"

SHEET

METAL SCREW

#431-

1

I-LUG

TERM1

NAL

2

WATT

6-32

x

3"

BHMS STRI

P

CDUALI

RESISTOR

#

25-57

ELECTROLYTIC CAPACITOR

3-48

NUT

#

10-57

MOUNT CONTROL

DPDT

SLIDE SWITCH

10-32

NUT

#\OX

gtt

SHEET

METAL SCREW

8-32

X

2''

BHMS

-

"

CONTROL.

NUT

86

SPEEDNUT

2-L.UG

TERMINAL

STRIP

7-PIN

WAFER

SOCKET

-

CONTROL FLAT

#

6

*

10

WASHER LOCKWASHER LOCKWASHER

f3

*

8

LOCKWASHER LOCKWASHER

$"

CONTROL. #75-29

L.OCKWASHER LINE CORD

STRAIN RELIEF

*

6

SOLDER

*6

SPADE LUG

LUG

--

\,/

#204

-

M

346

#

63-234 HORIZONTAL SUPPORT BRACKE

ROTARY SWITCH

#75-17

;r'

5'

-

27

#412-10 BlNDlNG POST

*

427-2

BINDING POST BASE

Z

2DE

PILOT

Ll

GHT ASSEMBLY BUSHING #IOO-Ml6B BINDING POST CAP

Page 10

Refer to Pictorial 2 for the following steps.

(

)

Temporarily hold the transformer chassis

against thefrontpanel sothatitsfour mount-

ing holeslineup withthoseinthefront panel,

(See Detail 4A on Page 13.) Now draw an

outline of the transformer chassismounting

area on the front panel. This areashouldbe

kept clear of wiring in the following steps.

NOTE: Use the #18 hookup wire to make the

following connections. When preparing a length

of hookup wire, strip

1/4" of insulationfromeach

end.

(

)

Connect an 8" wire fromlug Zof fuse holder

J

(S-1) to lug

1

of toggle switch

K

(S-1).

(

)

Connect one end of a 16" wire to lug 2 of

toggle switch

K

(S-1). Dress this wire be-

tween switch

G

and the edge of the front

panel as shown. Leave the end free.

(

)

Connect one end of a 16" wire to lug

1

of

fuse holder

J

(S-1). Dress as shown and

leave the end free.

NOTE: When connecting wires to lugs 2, 3,

4,

and 5 of slide switch E, wrap the firstwire

around the lug and connect the second wire to

the hole in the lug.

(

)

Connect a 4-1/4" wire from lug 4 of slide

switch E (NS) to lug C of switch

F

(S-1).

(

)

Connect a 3" wire from lug2of slide switch

E

(NS) to lug C of switch

G

(S-1).

(

)

Connect one end of a 10-1/2" wire to lug 2

of slide switch

E

(S-2). Dress in the direc-

tion shown and leave the end free tempo-

rarily.

(

)

Connect one end of an 11-1/2" wire tolug 4

of slide switch

E

(S-2). Dress in the

direction shown and leave the end free

temporarily.

(

)

Connect one end of a 16" wire to lug 5 of

slide switch E (NS). Dress as shown and

leave the end free.

(

)

Connect one end of a 16" wire to lug 3 of

slide switch E (NS). Dress as shown and

leave the end free.

(

)

Connect one end of a 6" wire to lug 6

of slide switch E (S-1). Dress this wire

perpendicular to the front panel and leave

the other end free.

(

)

Connect one end of a 7" wire to lug

1

of

slide switch E (S-1). Dress this wire per-

pendicular to the front panel and leave the

other end free.

(

)

Cut both pilot light leads to 2" long, strip

1/4" of insulation from the end of each

lead, and tin the ends. ("Tin" means to

melt a small amount of solder over the

exposed wire ends.)

(

)

Connect either pilot light lead to lug5 of

slide switch

E

(S-2).

(

)

Connect the other pilot light lead to lug 3 of

slide switch E (S-2).

(

)

Connect one end of a 4-1/2" wire to lug

1

of the meter (S-1). Leave the other end

free.

(

)

Connect one end of a 5-1/4" wire to lug 2

of the meter (S-1). Leavetheotherendfree.

(

)

Connect one end of a 10-1/2" wire to the

solder lug of binding post C (S-1). Leave

the other end free.

J

Detail 2A

&

(

)

Prepare a 3-3/4" hookup wire and solder a

spade lug to one end as shown in Detail 2A.

(

)

Place the spade lug under screw 3 of AC

receptacle

B

and tighten. Connect the other

end of this wire to the solder lug of binding

post

D

(NS).

(

)

Prepare a 2- 1/2" hookup wire and solder a

spade lug to one end.

(

)

Place the spade lug under screw 3 of AC

I

receptacle A and tighten. Connect the other

end of this wire to the solder lug of binding

post D (S-2).

(

)

Prepare a 4" hookupwire andsolderaspade

lug to one end. Now solder a spade lug to

both the other end of this wire and to the

free end of the wire coming from lug 2 of

slide switch E.

c-JJ

Page

11

( )

Placethe solderlug withtwo wires attached

under screw

1

of A

C

receptacle A andtight-

en. Place the solder lug with one wire at-

tached under screw

1

of

AC

receptacle

B

and tighten.

(

)

Prepare a 4" hookup wireandsoldera spade

lug to one end. Now solder a spade lug to

both the other end of this wire and to the

free end of the wire coming from lug

4

of

slide switch

E.

8-32

NUT

&

(

)

Place the spade lug with two wires attached

( )

4-1ug with

a

6-32

under screw 2 of AC receptacle Aandtight-

x

3/8" screw, two #6 lockwashers, and a

en. Place the spade lug with one wire at- 6-32 nut as shown in Detail 3A.

tached under screw 2 of AC receptacle

B

( )

Place four #10 speednuts over the holes

and tighten. in the bottom flanges of the transformer

chassis. The flat sides of the speednuts

This completes preparation of the front panel. should face outward.

Compare the wiring to Pictorial 2 toseethat all

connections and lead dress are correct. All

(

)

Similarly, place four #6 speednuts over the

terminals should be soldered except lugs

1

holes in the front flange of the transformer

through 8 of switches F and

G,

which will be chassis.

wired later.

(

)

Fasten a vertical support bracket to the

TRANSFORMER CHASSIS

left side of the transformer chassis as

shown in Pictorial 3. Use 8-32

x

3/8"

screws, #8 lockwashers, and 8-32 nuts.

Refer to Pictorial 3 for the following steps.

(

)

Similarly, fasten the remaining vertical

( )

Position thetransformeronthetransformer support bracket to the right side of the

chassis as shown in Pictorial 3. Thesideof transformer chassis.

the transformer with the two short black

leads should be away from the open side of

(

)

Dress all of the leads (except the two black

leads) coming from the transformer near

the chassis. Secure the transformer to the terminal strip L, aroundtotheright, andout

chassis with four #10 lockwashers and four of the open side of the chassis.

10-32 nuts.

( )

Dress all of the leadscomingfromthe other

side of the transformer to the left, and

out of the open side of the chassis.

6

SPEEDNUT

0

LOCKWASHER

310

SPEEDNUT

LEFT

Pictorial 3

Page 12

L53333

Pictorial

4

I

Refer to Pictorial

4

for the following steps. front panel.

I

( )

Place the transformer chassis against the

(

)

Secure the transformer chassis to thefront

front panel as shown in Pictorial

4.

The panel with four 6-32

x

3/8" screwsasshown

I

vertical support brackets should fit inside

in

Detail

4A,

of the horizontal support brackets which

are mounted on the front panel. Make sure

(

)

Fasten thehorizontalsupportbracketstothe

that the transformer leadsandhookupwires vertical support brackets with 6-32

x

3/8"

are not pinched between the chassis and screws, #6 lockwashers, and 6-32 nuts.

e-b&!lJ3

.

,

Page 13

( )

Place a #10 speednut over the hole in the Connect transformer leads to switch

F

asfol-

I

end flange of each vertical su2portbracket. lows:

The flat sides of the speednuts should face

I

outward. Lead Color to lug

NOTE: The transformer leads are precut and

(

Red

tinned. DO NOT cut these leads forthe following

( )

~~,-~-~~ll~~

steps.

Connect transformer leads to switch G asfol-

(

)

Black-orange

lows

:

(

)

Yellow

Lead Color

( )

Brown-yellow

(

)

Green-red

(

)

Blue-yellow

( )

Gray

(

Orange

(

)

Green-yellow

(

)

Black-yellow

(

)

Black-green

to lug

( )

Brown 3 (S-1)

1

(S-1)

(

)

Blue

2

(S-1)

2

(S-1)

(

)

White

1

(S-1)

3 (S-1) NOTE: The two black transformer leads will

4

(S-1) be connected later.

5

(S-1)

(

)

For neater appearance, the transformer

leads running along each edge of the front

6

(S-1) panel beside the transformer may be taped

together with electrical or household ad-

7

(S-1) hesive tape. Any excess lead length should

be pulled into the space under the trans-

8

(S-1) former chassis.

-

4

3

"

6

-

32

X

g

SCREWS

(USE

43

-

-

-.

-

-

-

4

Detail

4A

Page 14

&%+

-:-9

Pictorial 5

Refer to Pictorial 5 for the following steps.

NOTE: Each of the wires mentioned in the

next five steps are already connected at oneend

to a component on the front panel.

In

each step,

carefully trace the wire back to its front panel

origin before connecting

it

to terminal strip

L.

Pictorial

2

(fold-out on Page 10) shows front

panel component designations.

(

)

Connect the wire coming from lug

1

of fuse

holder

J

to lug

2

of terminal strip

L

(NS).

( )

Connect the wire comingfromlug

2

of toggle

switch

K

to lug

4

of terminal strip

L

(NS).

(

)

Connect the wire coming from lug 5of slide

switch E to lug 4 of terminal strip

L

(NS).

(

)

Connect the wire coming from lug 3of slide

switch E to lug 1 of terminal strip

L

(NS).

(

)

Connect the wire coming from binding post

C

to

lug 3 of terminal strip

L

(NS).

(

)

Connect either black transformer lead to

lug

1

of terminal strip

L

(NS).

(

)

Connect the other black transformer lead

to lug 4 of terminal strip

L

(S-3).

(

)

Referring to Detail 5A, install the line cord

and line cord strain relief in the hole in the

rear of the transformer chassis. About

1"

of the outer line cord insulation should

extend beyond the strain relief, inside of

the chassis.

&%J=?Y-=*~wJ

Page

15

Detail

5A

NOTE: When connecting the line cord leads

(

)

Install the two knobs on the shafts of

in the following steps, cut each lead to the rotary switches

F

and G. The setscrew

length required to reach the lug called out in

in

each knob should be tightened against

the step; then strip

1/4"

of insulation from the the flat side of the switch shaft.

lead and tin ("tin" means melt a small amount

of solder over the exposed wire end).

(

)

Screw the two binding post caps on the

Connect the line cord leads to terminal strip L binding posts at C and D.

asfollows:

Lead Color

(

)

White

(

)

Black

to lug Carefully check all connections made thus far

against Pictorials 2,

4,

and

5.

When satisfied

1

(S-3) that all wiring

is

correct, set the front panel-

transformer chassis assembly aside while as-

2 (S-2) sembling the subchassis.

(

)

Green 3 (S-2)

Page 16

s-J

Refer to Pictorial 6 for the following steps.

TWIST

TABS

Detail 6A

(

)

R5. Mount 2

KQ

control M (#lo-52) on the

subchassis. Refer to Detail 6A.

(

)

R7, Similarly, mount 10

KO

control

N

(#lo-57).

(

)

Mount the 7-pin tube socket at V1. Use

3-48 screws, #3 lockwashers, and 3-48

nuts as shown in Detail

63.

Make sure

that the tube socket blallk space

is

placed

asshown in Pictorial

6.

3-48

SCREWS

&

iC

3

LOCKWASHERS

I

6

3-48

NUTS

I

Detail 6B

(

)

Mount dual-lug terminal strip

P.

Use a 6-32

x

3/8" screw, two #6 lockwashers, and a

6- 32 nut. ReferbacktoDetail 3A on Page

11.

(

)

Mount 3-lug terminal strip

Q

and 2-lug

terminal strip R with a 6-32

x

3/8" screw,

three #6 lockwashers, and a 6-32 nut.

Place the lockwashers as shown in Detail

6C.

6

LOCKWASHER

@

6-32

NUT

I

Detail 6C

( )

Mount lamp socket S with 6-32

x

3/8"

screws, #6 lockwashers, and 6-32 nuts.

(

)

Place two #6 speednuts over the holes in

each end flange of the subchassis. The flat

sides of the speednuts should face out-

ward.

( )

Connect a 4-1/4" wire from lug 2 of termi-

nal strip

P

(NS) to lug

1

of terminal strip

R

(NS).

( )

Connect

a

3-3/4" wire from lug 3 of con-

trol

M

(S-1)

to lug 5of tube socket V1 (S-1).

( )

Connect a 2- 1/2" wirefrom

lug

1of terminal

strip R (NS) to lug 4of tube socket V1 (S-1).

(

)

Connect a 3-3/4" wire from lug

1

of

terminal strip

Q

(NS) to lug

1

of lamp

socket S (NS).

Page 17

~35-J='-~=~3

Pictorial

6

(

)

Connect a 2-1/4" wire from lug 1 of tube

(

)

D2. Connect a silicon diode from lug

1

socket V1 (S-1) to lug

2

of lamp socket (5-3) to lug 3 (NS) of terminal strip

Q.

S (S-1). The positive

(+)

lead goes to lug

1.

Avoid

overheating the diode lead when soldering.

(

)

C1. Connect the 100 pfd electrolytic ca-

pacitor from lug 1 of terminal strip P

(S-1) to lug

1

of terminal strip

Q

(NS). The

( )

Dl. Connect a silicon diode from lug 2 (NS)

positive

(+)

lead goes to terminal strip

Q.

to lug 3 (S-2) of terminal strip

Q.

The

positive

(+)

lead goes to lug 3.

(

)

R4. Connect a

5.6

KS2

(green-blue-red)

2 watt resistor fromlug 2 of terminalstrip

(

)

R2. Connect a 10 (brown-black-orange)

P

(S-2) to lug

1

of control

M

(S-1). 2 watt resistor from lug

1

(NS)tolug 2 (NS)

of terminal strip

R.

(

)

R6. Connect a 22

KC2

(red-red-orange)

1/2 watt resistor from lug 2 of control

M

( )

R1. Connect a 10

KSt

(brown-black-orange)

(S-1) to lug

1

of control N (S-1). Use 2 watt resistor from lug 2 of terminalstrip

sleeving on the lead to control

N.

R (NS) to lug

1

of lamp socket S (S-2).

Table of contents

Popular Transformer manuals by other brands

Tube Amp Doctor

Tube Amp Doctor VT100ESG-S operating instructions

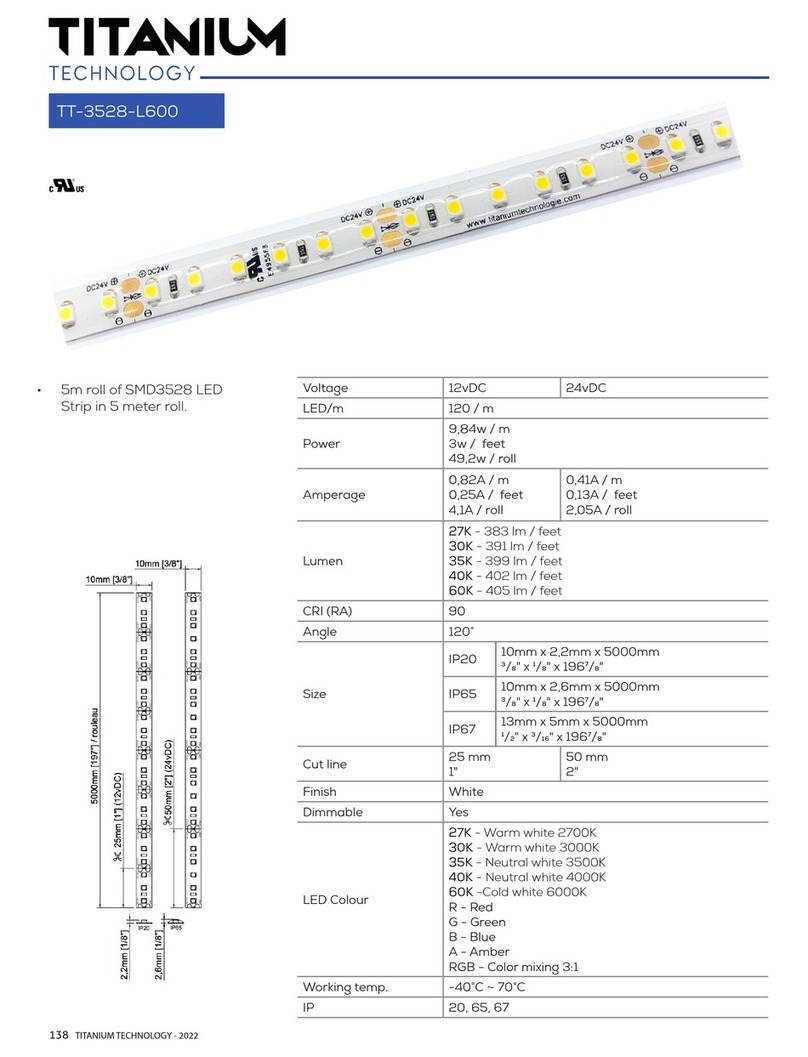

Titanium

Titanium TT-3528-L600 Connection instructions

Hobart

Hobart 6T28-600CL Operation and maintenance manual

METREL

METREL MA 4804 instruction manual

Velatia

Velatia Ormazabal cgm.3 Operation instructions

Mercury

Mercury HOLLY TERROR Assembly manual