3

ÍndexOperation instructions

cgm.3 ENA type

IG-235-EN version 02

ÍNDEX

1 Description and main characteristics 4

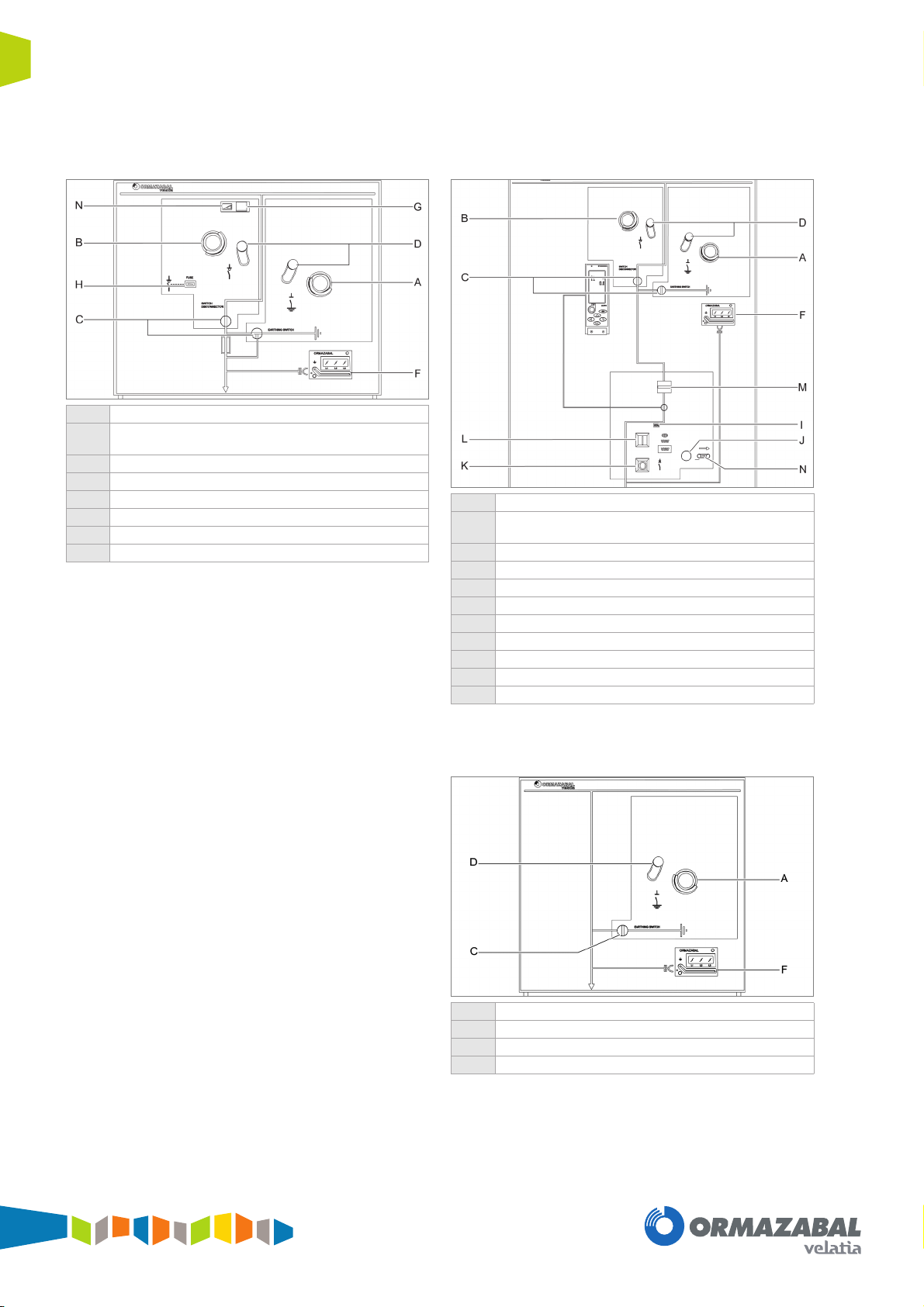

1.1 Switchgear elements . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Voltage presence indicator . . . . . . . . . . . . . . . 7

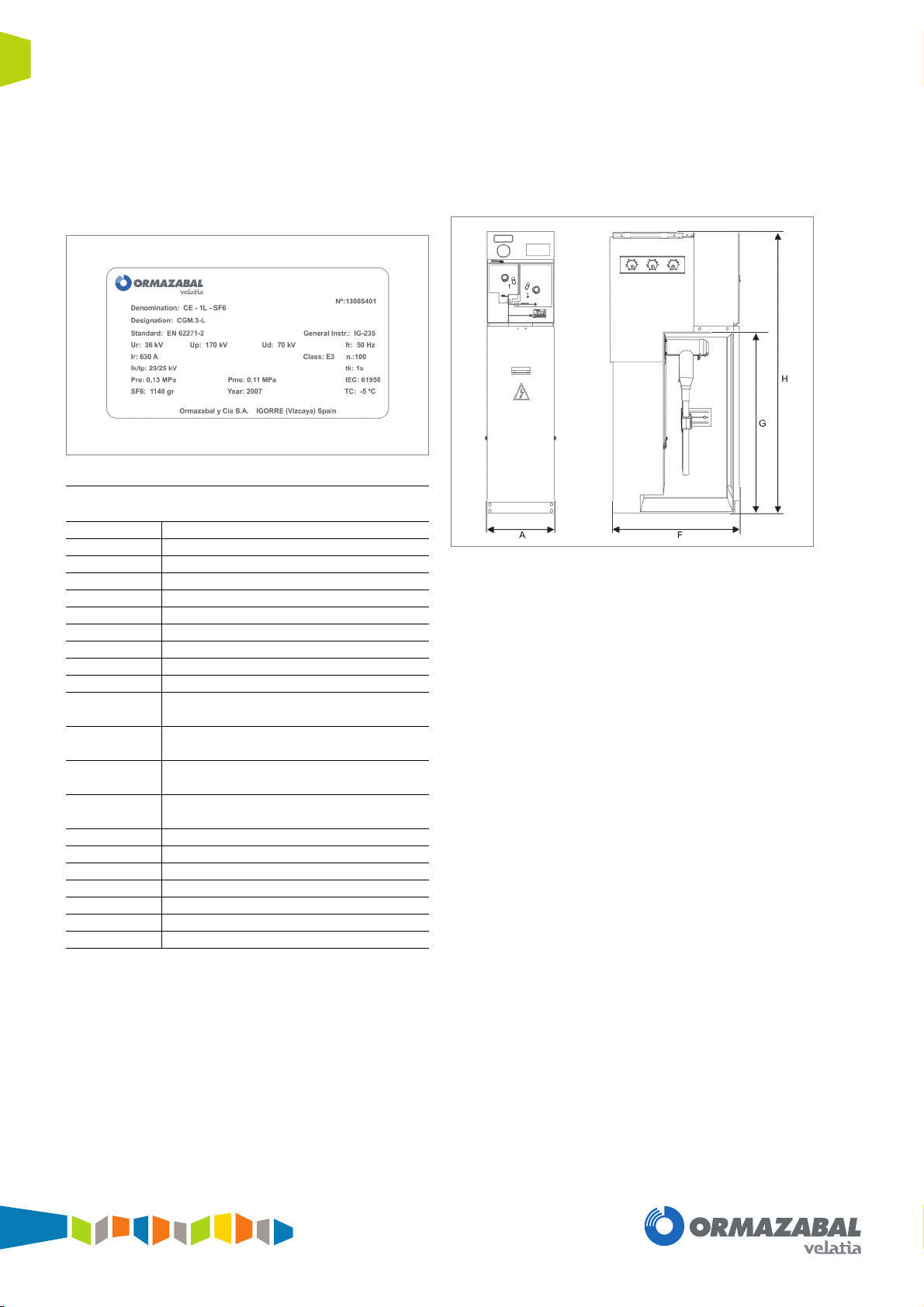

1.1.2 Name plate . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Mechanical characteristics . . . . . . . . . . . . . . . 8

2 Recommended sequence of operations 10

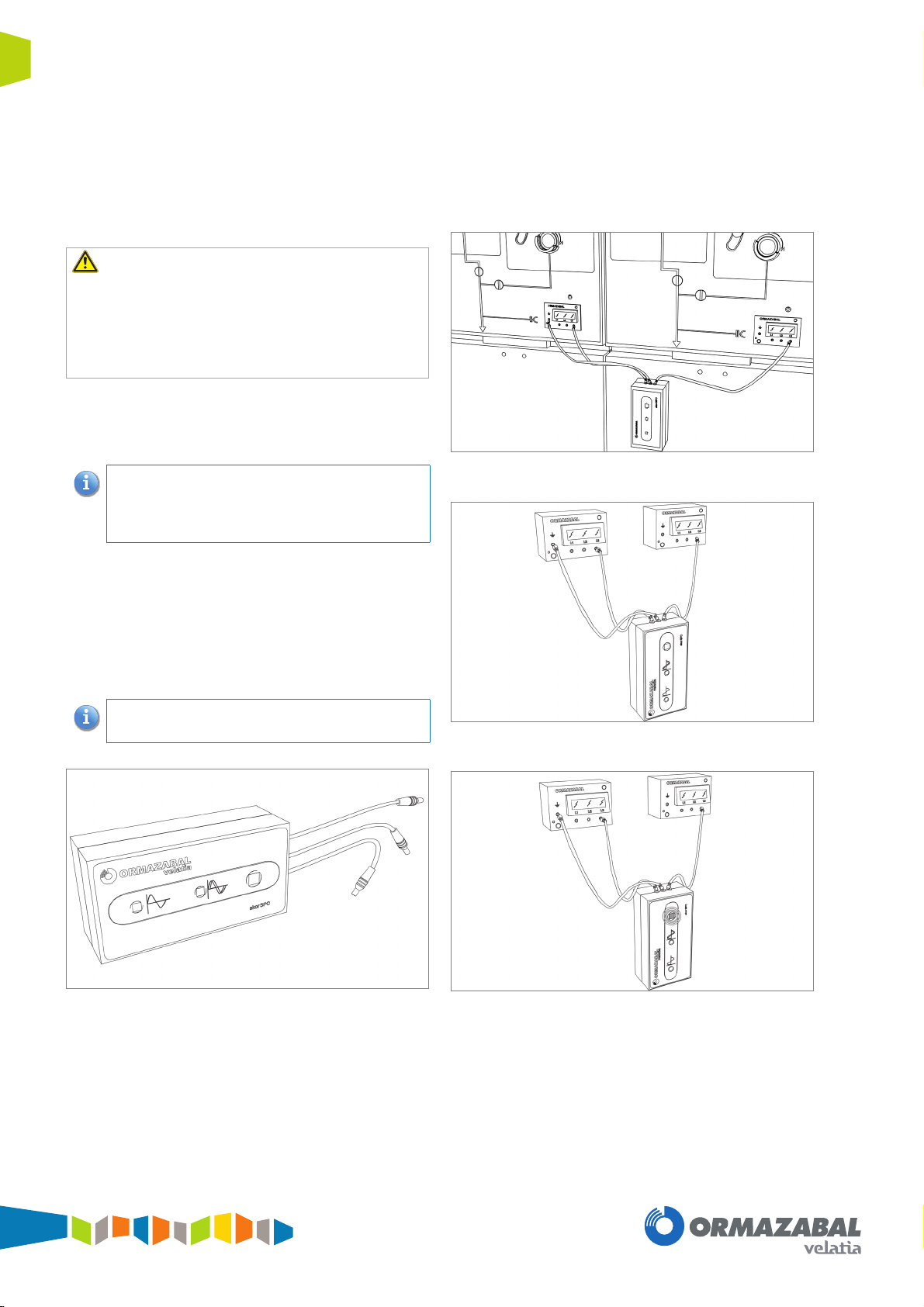

2.1 Checking voltage presence and

phase balance . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1.1 ekor.spc phase comparator . . . . . . . . . . . . . . 10

2.2 Mechanism operating handles . . . . . . . . . . . 11

2.2.1 Switch - disconnector driving

mechanism handle (B) . . . . . . . . . . . . . . . . . 11

2.2.2 Spring charging handle for circuit

breaker driving mechanisms . . . . . . . . . . . . . 11

2.3 cgm.3-l switchgear . . . . . . . . . . . . . . . . . . . . 12

2.3.1 Opening operation from

the earthing position . . . . . . . . . . . . . . . . . . . 12

2.3.2 Switch closing operation from

the open position . . . . . . . . . . . . . . . . . . . . . . 12

2.3.3 Opening operation from the switch -

disconnector closed position . . . . . . . . . . . . . 12

2.3.4 Earthing operation from the open position . . 12

2.3.5 Cable test . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 cgm.3-p switchgear . . . . . . . . . . . . . . . . . . . . 13

2.4.1 Opening operation from

the earthing position . . . . . . . . . . . . . . . . . . . 13

2.4.2 Switch - disconnector closing operation

from the open position (using the BR-A

driving mechanism) . . . . . . . . . . . . . . . . . . . . 13

2.4.3 Opening operation from the switch -

disconnector closed position . . . . . . . . . . . . . 13

2.4.4 Earthing operation from the open position . . 13

2.4.5 Selection of recommended fuses . . . . . . . . . 14

2.4.6 Fuse replacement sequence . . . . . . . . . . . . . 15

2.5 cgm.3-rb switchgear with earthing . . . . . . . . . 17

2.5.1 Opening operation from

the earthing position . . . . . . . . . . . . . . . . . . . 17

2.5.2 Earthing operation from

the open position . . . . . . . . . . . . . . . . . . . . . . 17

2.6 cgm.3-v switchgear with driving mechanism

A(M)V-EF and RA(M)V-EF (3G) . . . . . . . . . . 17

2.6.1 Opening operation from

the earthing position . . . . . . . . . . . . . . . . . . . 17

2.6.2 Closing operation from the open position . . . 18

2.6.3 Opening operation from

the closed position . . . . . . . . . . . . . . . . . . . . 19

2.6.4 Earthing operation from the open position . . 20

2.7 cgm.3-v switchgear with driving

mechanism A(M)V and RA(M)V (3G) . . . . . . 21

2.7.1 Opening operation from

the earthing position . . . . . . . . . . . . . . . . . . . 21

2.7.2 Closing operation from the open position . . . 22

2.7.3 Opening operation from

the closed position . . . . . . . . . . . . . . . . . . . . 23

2.7.4 Earthing operation from the open position . . 24

3 Safety locking facilities and

interlocking 26

3.1 Mechanical interlocking . . . . . . . . . . . . . . . . . 26

3.2 Safety locking facilities . . . . . . . . . . . . . . . . .26

3.2.1 Locking with a padlock . . . . . . . . . . . . . . . . .26

3.2.2 Locking with a key lock (optional) . . . . . . . . . 26

4 Maintenance 27

4.1 Voltage presence indicator test . . . . . . . . . . . 27

4.2 Specific maintenance for the

cgm.3-v switchgear . . . . . . . . . . . . . . . . . . . .27

5 Additional information 28

5.1 Current transformers arrangements . . . . . . . 28

5.2 Spares and accessories . . . . . . . . . . . . . . . . 28

5.3 Environmental information . . . . . . . . . . . . . . . 29

The instructions for the transport, storage and

installation of the cgm.3 ENA type switchgears are

included in the Ormazabal's MO-091 document.