Dazon Raider Max 175D User manual

File No.:SF-E175-WX-B01-D

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

2

FOREWORD

This service manual has been specially prepared to provide all the necessary information for the

proper maintenance and repair of the RAIDER Max 175 (EEC-approved for on-road use).

The Buggy fits the needs of a wide variety of buggy users above 16 years old. Those who will service

this Buggy should carefully review this manual before performing any repair or service.

All information, illustrations, photographs and specifications contained in this manual are based on

the latest product information available at the time of publication. Due to the improvements or other

changes, there may be some discrepancies in this manual. Therefore, if the newest information is

requested in future, please contact the local distributor.

Distributors reverse the right to make production changes at any time, without prior notice or

incurring any obligation to make the same or similar changes for the vehicles previously built or sold.

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

3

CONTENTS

1.

General Information ------------------------------------------------------------------------4

2. Periodic Maintenance and Tune-Up Procedures --------------------------------------7

3. Engine ----------------------------------------------------------------------------------------14

3.1 Lubrication System--------------------------------------------------------------------14

3.2 Cylinder Head & Valve---------------------------------------------------------------16

3.3 Drive Pulley, Clutch & Driven Pulley---------------------------------------------21

3.4 Final Transmission Box--------------------------------------------------------------22

3.5 Ac Generator & Starting Clutch---------------------------------------------------24

3.6 Crankcase & Crankshaft------------------------------------------------------------26

3.7 Cooling System-------------------------------------------------------------------------28

3.8 Carburetor------------------------------------------------------------------------------31

4Reverse Gearbox--------------------------------------------------------------------------- 41

5Wiring Diagram ---------------------------------------------------------------------------- 43

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

4

1. General Information

1.1 Model Identification

1.1.1 Frame Number

The frame number or VIN is stamped under the seat on the frame and stuck behind the seat.

1.1.2 Engine Number

The engine number is located on the upper rear right engine case.

1.2 Fuel and Oil Recommendations

Be sure to use the specified fuel and oil

1.2.1 Fuel

Please use the gasoline of SAE 90# or above.

Also we recommend you to use the unleaded gasoline.

1.2.2 Engine Oil

Please use the high-quality engine oil of SAE 10w/30SF.

1.3 Break-in Procedure

For your first 2 hours of riding, don’t exceed 2/3 throttles.

Vary the engine speed for the first 5 hours.

Never hold the engine at full throttle for long periods of time.

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

5

1.4 Specifications

DIMENSIONS SINGLE-SEAT/DOUBLE-SEAT

Overall Length 2330mm / 2300mm

Overall Width 1310mm / 1460mm

Overall Height 1425mm / 1425mm

Wheelbase 1475mm / 1520mm

GroundClearance 200mm / 250mm

VIN AccordwithGMVRA01-01

Statutory Plate& Safety Labels Accord with GB 7258-1997

ENGINE

Model PMI162MK

Type Forced water-cooled, single cylinder, 4-stroke

Engine Capacity 175cc

Displacement 174.5ml

Bore×Stroke 62mm×57.8mm

Max. Power 7.4kw or 7500r/m

Max. Torque 12.5N.m or 6500 r/m

Idle Speed 1500±100 r/m

CO Emission 7.0g/km

HC Emission 1.0 g/km

Fuel Type SAE 90# or above (unleaded)

Min. Fuel Consumption 354g/KW.h

Lubricate Oil Type SAE 15W / 40SF

Lubrication Pressure & splash

Cooling Fluid SHELL (Antifreeze)

Antifreeze Temperature of Cooling Fluid - 450C

Mixing Ratio (Cooling Fluid : Water ) 1:1

Cooling Water-cooled

Ignition C.D.I.

Starting Electric

SparkPlug D7

Spark Plug Gap 0.6~0.7mm

Transmission Chaintransmission

Transmission Ratio F 1:1, B 1:1.758

Primary Transmission Ratio 2.2-0.9

Compression Ratio 10±0.1:1

Reduction Ratio 2.8

Clutch Automatic, centrifugal, dry, shoe type

Generator Outer rotor, flywheel

Carburetor Vacuumfilmtype

Absorber Normal(in10

5 times of experiments)

Air Cleaner Paper element, filtration type

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

6

Gear-Shifting Automatic, centrifugal

CAPACITIES

Front/RearTireLoadCoefficient 36

Front/RearTireSpeedLevel L

Fuel Tank 7.0L, 130kpa (no leakage in experiments)

Starting Time ≤15s

Climbing ≥20%

Top speed 63km/h

Tachometer 33-40km/h(meterscale:40km/h)

Turning Radius 3m / 3.5m

AccelerationNoiseLevel ≤80dB (A)

Horn DL80-90 12V 3A 105dB, 93<dB (A) <112

Headlight 12V35W/35W

Headlight High Beam Intensity Accord with laws ®ulations

Taillight 12V 5W /21W

TurningLight 12V10W

LicenseLight 12V5W

Battery 12V8Ah

Anti-theftLock ≥200N.m

RearviewMirror Accordwithlaws®ulations

CHASSIS

Front/RearBrake Hydraulicdisc,footcontrol

Front Wheel Brake Force 760N / 1140N

Rear Wheel Brake Force 832N / 1038N

BrakingDistance ≤7 m@30km/h

ParkingBrake Hydraulicdisc,handcontrol

Front Tire 20.5 × 8.0–10

Rear Tire 20.5 × 8.0–10

TIRE PRESSURE

Front 175kpa

Rear 200kpa

WEIGHT

NetWeight 235kg / 255kg

zThe specifications are subject to change without notice.

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

7

2. Periodic Maintenance and Tune –up Procedures

2.1 Location of Parts

Double-seat

Headlight

Rearview Mirror

Roll Bar

Seat Belt

Seat

Steering

Wheel

Front

Wheel

Turning

Light

Front

Mudguard

Front Shock

Absorber

Awning

Control Panel

Brake

Handle

Reverse

Handle

Fan

Rear

Reflector

Rear

Wheel

Taillight

Rear Rack

Turning

light

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

8

Single-seat

zPlease demand for a copy of the Parts Book from your dealer and locate each component location.

Roll Bar

Headlight

Turning Light

Front Wheel

Seat

Rear Rack

Seat Belt

Rear Wheel

Front

Shock

Absorber

Throttle Pedal

Rear Shock Absorber

Control Panel

Rearview Mirror

Steering Wheel

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

9

2.2 Periodical Checks and Services

The maintenance intervals in the following table are based upon average riding conditions.

Riding in unusually dusty areas requires more frequent services.

Items 1st Service of 1st week Daily Monthly Quarterly Yearly

Tire Press /Wear X X X X R

Handle Brake Cable A A A A

Brake Performance X X X X X

Brake Pad X X R R

Brake Fluid X X X X R

Nuts /Bolts X X X X X

Air Filter X X C R R

Carburetor A A A C

Spark Plug X CA CA R

Drive Chain CAL CAL CAL CAL CAL

Gear Box Oil X X X R

Engine Oil X X R R R

Chassis X X X X

Valve Clearance A A A A

Reverse Cable A A A A

Reverse Assy. X

Battery X X X R

Cooling Water X X X X X

Throttle Cable X X R

Drive Belt X R R

Driven Plate Sub Assy. X X R

Fuel Filter X C C R

Note: X: inspect, clean or replace if necessary; C: clean; A: adjust; L: lubricate; R: replace.

Attention: In order to keep the 6-month warranty valid, please

a) find an approved DAZON dealer to carry out the 1st service and quarterly service;

b) keep the proof of any service carried out. As in the unlikely event of a warranty claim being necessary, the

service history needs to be available.

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

10

2.3 Maintenance and Tune-up Procedures

This section describes the servicing procedures of every item in the Periodic Maintenance

Intervals Table above.

2.3.1 Spark Plug

Clear up the carbon around the spark plug to prevent it from dripping into the cylinder when

removing the spark plug.

Remove the spark plug:

a) In general, it should be carried on after the engine has cooled down;

b) If the spark plug is too tight to remove, spray some rust inhibiter on

the spark plug washer and the thread part; after the inhibiter has

soaked the washer and thread part, rotate the spark plug;

c) Clear up the filth and carbon accumulation on the spark plug with

a steel brush or a blade;

d) Inspect the spark plug gap (in general, it should be about 0.6 - 0.7 mm.);

e) When the carbon accumulation and wear of the spark plug are too serious, replace the spark

plug with a new one of the same specification.

2.3.2 Tire Pressure / Wear

Check the tire pressure before each of your driving.

The tire pressure is very important for the riding stability.

Specifications: Front Tire: 175kpa

Rear Tire: 200kpa

2.3.3 Brake Performance

a) Always check if there is plenty of brake fluid in the brake fluid

reservoir;

b) Check if the front/rear brake pad is in good condition;

c) Check the brake rotor for abnormal wear.

2.3.4 Air Cleaner

Clean the air cleaner quarterly, or more often when driving in dusty

conditions.

If the air cleaner is clogged with dust, its performance will be severely

decreased, even the engine damages will probably be caused.

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

11

Inspection and Cleaning of Filters

zPaperFilter

a) Remove the filter from its housing;

b) Lightly tap the filter on an object to knock out the dust;

c) Replace the filter element if it is wrinkled or torn.

zFoam Filter

a) Remove the filter out of its steel cage;

b) Wash the filter in non-flammable cleaning solvent;

c) Submerge the filter in oil and squeeze it to remove excess oil;

d) Install the filter element back into the air box.

2.3.5 Nuts and Bolts in Chassis

Inspect the nuts and bolts in the chassis during the first week and every month thereafter.

The nuts and bolts become loose normally after use, please check for the looseness regularly.

2.3.6 Tightening Torque Table

Conventional Marked Bolt 8.8 Marked BoltBolt Diameter

(mm) N•m Kg•m lb-ft N•m Kg•m lb-ft

4 1-2 0.1-0.2 0.7-1.5 1.5-3 0.15-0.3 1.0-2.0

5 1-4 0.2-0.4 1.5-3.0 3-6 0.3-0.6 2.0-4.5

6 4-7 0.4-0.7 3.0-5.0 8-12 0.8-1.2 6.0-8.5

8 10-16 1.0-1.6 7.0-11.5 18-28 1.8-2.8 13.0-20.0

10 22-35 2.2-3.5 16.0-25.5 40-60 4.0-6.0 29.0-43.5

12 35-55 3.5-5.5 25.5-40.0 70-100 7.0-10.0 50.5-72.5

14 50-80 5.0-8.0 36.5-58.0 110-160 11.0-16.0 79.5-115.5

16 80-130 8.0-13.0 58.0-94.0 170-250 17.0-25.0 123.0-181.0

18 130-190 13.0-19.0 94.0-137.5 200-280 20.0-28.0 144.5-202.5

2.3.7 Fuel Switch Inspection

a) Stop the engine, remove the gasoline tube from the carburetor, and check if the gasoline is

flowing;

zBefore and during the cleaning, inspect the element for tears; replace it if it’s torn.

zMake sure that the element is seated properly and no foreign material can pass by it

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

12

b) After expelling the gasoline remnant (about 5-10 ml) from the negative pressure switch and

negative pressure tube, if the gasoline doesn’t flow, the switch is in good condition; otherwise,

the negative pressure tube needs cleaning;

c) Remove the negative pressure tube from the gasoline supply tube, and suck it with mouth or

apply pressure on it with a vacuum pump, and then release the pressure;

If the gasoline flows out of the gasoline tube when under pressure, and stops flowing when

released from pressure, the switch is in good condition.

Note: a) Smoking and lighting fires are strictly forbidden.

b) Before the operation, blow enough air from the supply side of the negative pressure switch,

so as to eliminate the stuff sticking on the diaphragm.

2.3.8 Final Gear Oil

Inspect the final gear oil monthly and replace it quarterly.

a. Check the oil level: remove the oil level screw on the left rear

engine case;

b. Drain out the oil: remove the drain plug at the rear bottom of

the engine case;

Recommendation: before draining the final gear oil, please

warm the engine for at least 10 minutes.

Notes: We recommend the Mobile 85w/90 gear oil for the final drive case. However, in extreme

cold weather conditions, the vehicle may become hard to start, so we advise some lighter viscous

oil, such as 75 wt or the equivalent motorcycle transmission fluid.

2.3.9 Engine Oil

Inspect the engine oil before every riding and replace it monthly.

a) Remove the drain plug from the left side bottom of the engine,

and drain out the left oil into an oil pan for disposal;

b) Remove the large cap on the left bottom of the engine ,and

remove the screen;

c) Wash the screen with some cleaning solvent and reassemble it;

make sure that the O-ring is still in good conditions;

d) Refill the engine with the SAE10W/30SF engine oil and run the

engine for 5 minutes;

e) Check the oil level on the filler cap stick to assure that it’s proper;

Gear Oil Capacity 0.2L 85w/90

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

13

f) Screw in the large cap.

2.3.10 Chassis

Inspect, clean or replace it monthly if necessary and lubricate it quarterly.

a) Grease the chassis bushings and bearings with some grease quarterly to make sure that they can

operate smoothly and enjoy an extended life;

b) If it’s used in extremely wet, muddy or dusty conditions, we recommend you to service it more

often.

2.3.11 ReverserAdjustment

a) Press down the reverse lever to the "FW" position so that the

units can move forward;

Pull back the lever to "BW" so that the units can move backward.

b) Adjusting Nut #1 on the top of the reverse cable can adjust the

mesh status inside the reverse gear box. In the forward position

there should be about 1/4 inch play in the cable for the correct

adjustment.

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

14

3. Engine

3.1 Lubrication System

3.1.1 Lubrication diagram

3.1.2 Trouble shooting

zThe engine oil level is too low.

a) The engine oil is consumed naturally;

b) The engine oil leaks;

c) The piston rings are worn.

zThe engine oil is dirty.

a) The engine oil isn’t replaced in time;

b) The cylinder head gasket is damaged.

zThe lubrication isn’t good.

a) The engine oil level is too low;

b) The oil filter is clogged, or the oil pipes are clogged;

c) The oil pump is damaged

3.1.3 Specifications

Engine Oil Capacity 1.0L (Disassembling) 0.8L (Replacing)

Engine Oil 10W/30SF

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

15

3.1.4 Engine Oil

zInspection

a) Stop the engine;

b) Stay the vehicle on the flat ground for 2-3 minutes;

c) Inspect the oil level.

Note: The oil level gauge shouldn’t be screwed in.

zReplacement

a) Remove the oil filler cover, and drain out the oil remnant

when the engine is warm;

b) Reassemble the cover;

Torque: 18-20 N.m.

c) Check if the O-rings are damaged; replace if necessary;

d) Fill in the same type of engine oil;

Engine oil capacity: 1.0 L (Disassembling)

0.8L (Replacing)

Engine oil type: 10W/30SF

e) Start the engine to check if there is any oil leakage;

f) Stop the engine and check the oil level again.

zEngine Oil Screen

a) Drain out the oil;

b) Take out the spring filter;

c) Assemble the screen, spring and filter cap;

d) Add enough oil into the engine.

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

16

3.2 Cylinder Head & Valve

3.2.1 Disassembly Diagram

1. TimingSprocket 2.TimingChain

3.TensionBar 4.AirCleanerBracket

5.RockerArm,AirExhaust 6.RockerArm,AirIntake

7.RockerArm,Valve 8.CamShaftComp.

9. Spark Plug 10. Exhaust Valve

11.Tensioner 12. Gasket, Tensioner

13. Cylinder 14. Gasket, Cylinder

15.Rubber Pipe, Water Inlet 16.Intake Valve

17.Intake Pipe Comp. 18.Thermostat Comp.

19. Temperature Sensor 20.Rubber Pipe, Water Return

21.Guide Bar 22.Valve Comp.

123

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

13

14

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

17

3.2.2 Trouble Shooting

zThe compression is too low or not stable.

a) Valve

The lifter isn’t adjusted well;

The valve is burnt or deformed;

The valve spring is damaged;

The valve timing is faulty;

The valve seat seal is faulty.

b) Cylinder Head

The cylinder head gasket leaks air;

The cylinder head is deformed or cracked.

c) Cylinder piston is faulty.

zThe compression is too high.

There is carbon accumulation on the piston or in the combustion chamber.

zNoise

The lifter isn’t adjusted well.

The valve is burnt, or the valve spring is damaged or worn.

The rocker or the rocker shaft is damaged or worn.

3.2.3 Assemble Valve Rocker Arms & Shafts

a) Check if the seals on the valve rocker arm shafts are in good

condition; if damaged, replace them;

Put some engine oil on the surface of the rocker arm shafts and

the seals.

b) Assemble the two valve rocker arms (exchangeable) in the

place as shown in the picture;

Valve Rocker Arm

Seal

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

18

c) Insert the rocker arm shaft with the mark “IN” into the hole on

the left side of the cylinder head cover and the hole of the rocker

arm;

At the same time, insert the rocker arm shaft with the mark “EX”

into the holes on the right side of the cylinder in the same way;

d) Turn the dials of the two rocker arms to the position as shown

in the picture;

Fasten the two dials.

3.2.4. Adjust Valve Clearance

a) Open the engine peephole cap;

Adjust the flywheel “ T ” to the maximum reading, while

the engine piston reaches the top dead point;

b) Loosen the lock bolts at the intake / exhaust valve dials;

;

Hole on Left Side

of Cylinder

Hole on Right Side

of Cylinder

RockerArm of

Ex. Valve

RockerArm of

In. Valve

En

g

ine

Fl

y

wheel

In. Valve Dial

Ex. Valve Dial Lock Bolt

Lock Bolt

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

19

c) Turn fully outward the intake / exhaust valve dials until the

dials can’t be turned any more;

d) Turn inward the intake / exhaust valve dials for

1.5~ 2.0 scales (at this moment, the valve clearance

should be 0.08mm~0.1mm);

e) Fasten the lock bolts at the intake / exhaust valve dials.

Inward

Ex.

Valve

Dial

Outwar

d

In.

Valve

Dial

Outward

RaiderMax175(single-seat,double-seat):ServiceManual EECVersion:2.0 April 2005

20

3.3 Drive Pulley, Clutch & Driven Pulley

3.3.1 Disassembly Diagram

1.Crankecase,Right 2.DrivenPulleyComp.

3.Belt 4.DrivePulleyComp.

5.Gasket,LeftCrankcase 6.Crankcase,Left

7.SpecialScrewSet 8.Shroud(LeftCrankcaseCover)

5

1

2

34

Table of contents

Other Dazon Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Taylor-Dunn

Taylor-Dunn BG-015-00 Operation, t roubleshooting and replacement parts manual

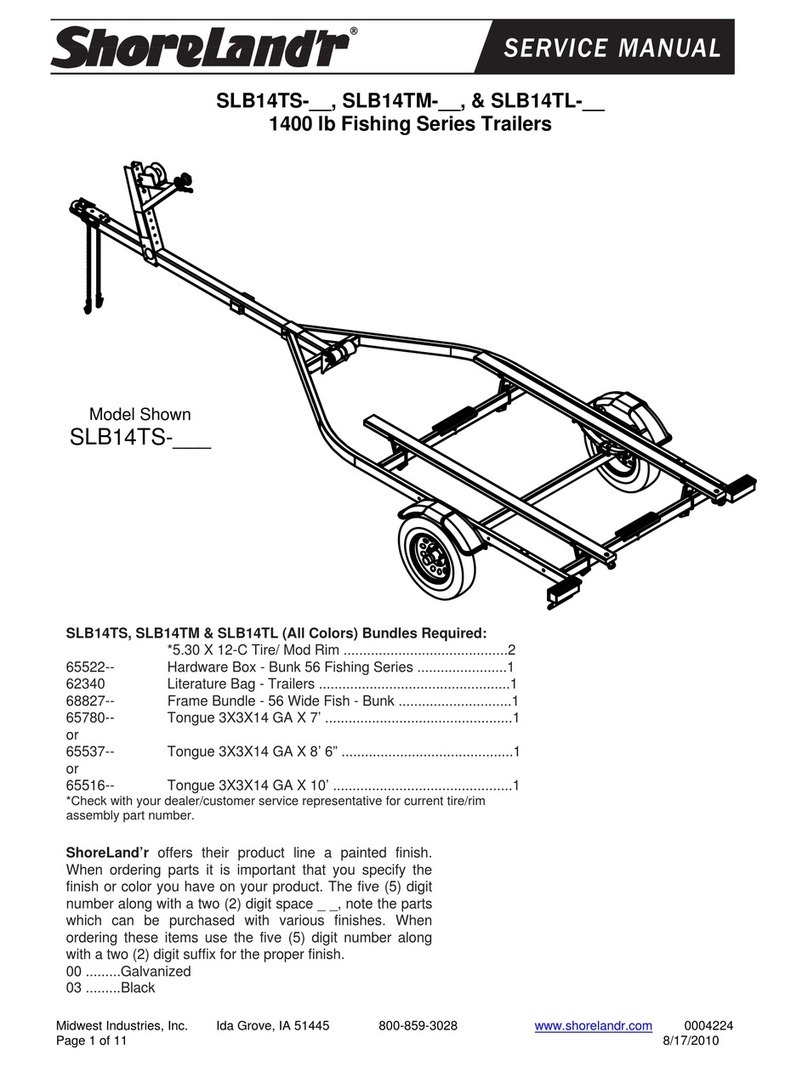

ShoreLand'r

ShoreLand'r SLB14TS Series Service manual

Equipter

Equipter RB4000 Operator's manual

Polaris

Polaris Ranger 6x6 700 EFI 2009 owner's manual

Crown

Crown CU-48 OFF-ROAD SERIES owner's manual

Landoll

Landoll LT10A Series Operator's manual

Taylor-Dunn

Taylor-Dunn RE-380-36 Service and Replacement Parts Manual

Pongratz

Pongratz L-AT G-K Additional Operating Manual

Toro

Toro Groundsmaster 7210 Operator's manual

Baja motorsports

Baja motorsports SD65 Sand Dog Setup instructions

Kellfri

Kellfri 23-TV06PRO manual

Linhai

Linhai LH50DU Owner's/operator's manual