dB AM Series Guide

Series AM Fan Convectors

Installation, Operation & Maintenance Instructions

Dunham-Bush Ltd, Downley Road, Havant, Hants PO9 2JD

Document Ref:

023 9247 7700

info@dunham-bush.co.uk

121-000-001-D

UK:www.dunham-bush.co.uk

Global:www.dunham-bush.com

July 2021

1

INSTALLER: Please leave these instructions, heater wiring diagram & access panel keys with the user.

INTRODUCTION

This booklet provides guidance to identify, handle,

install, commission, operate and maintain

Dunham-Bush Series AM fan convectors. The

instructions apply to the standard range of 22

models shown on page 2. Please study the

instructions carefully before commencing any

installation work.

IDENTIFICATION

The fan convector serial number, model description,

figure number (size) are displayed on a label found

on the inside of the heater access panel. If specified,

a stencil reference may also be marked on the

heater on-site identification.

DESCRIPTION

Each Series AM fan convector comprises a sheet

steel casing with a lockable access panel, fan/motor

assemblies, air filter and hot water heating coil.

Single phase electric elements can be fitted instead

of a hot water coil. Heaters can be supplied for one

or two speed fan operation ; single speed units are

pre-set to low, medium or high speed, and two

speed units are pre-set to low/medium, low/high or

medium/high speeds, as ordered.

Fan control is by means of switches and/or

thermostats, listed in Accessories.

Diagram 1: Series AM Model 13 Figure 04 with left hand coil connections - *items are optional accessories

2

Diagram 2: Range of standard models and accessories

3

RANGE

The standard range comprises 22 standard models,

in 4 categories - floor standing, ducted floor

standing, wall mounted and ceiling mounted. Refer

to Diagram 2 on page 2 for model identification.

All models are available in seven sizes (figure

numbers), with the nominal output indicated by the

figure number.

Size

Nominal output

(kW)

Casing width

(mm)

Fig 03

2.6

695

Fig 04

4.7

895

Fig 06

6.0

895

Fig 08

8.2

1195

Fig 10

9.4

1195

Fig 12

11.4

1495

Fig 15

12.7

1495

Table 1: Nominal outputs and sizes

CONTROLS

Fan motors

Conventional synchronous AC motors or energy

efficient EC motors can be provided. EC motors are

available as one of two options:-

ECS - speed control by an external 2-10VDC signal

ECM - speed control by fitted speed interface

Air thermostats

Air thermostats can be provided to automatically

switch the heater on/off and to change the fan

speed/heat output, in response to a fall or rise in

ambient air temperature. Thermostats can be fitted or

remote as follows :-

Fitted air thermostats - Models 13, 15, 17, 20, 21, 23

and 25 only.

Capillary thermostats, or room thermostats with an

accelerator heater, can be fitted for on/off and speed

change.

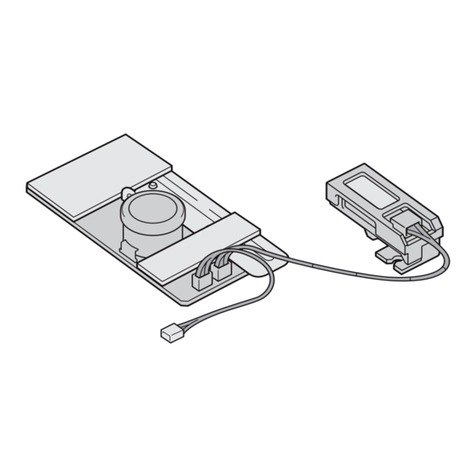

Diagram 3: Fitted on/off & high/low thermostats

Remote thermostats - All models

Standard or tamper resistant room thermostats with

an accelerator heater, can be provided for on/off and

speed change.

Low temperature cut-out (LTC) thermostat

A low temperature cut-out thermostat may be

provided to operate the heater when hot water is

supplied to the coil. This will automatically stop the

heater at the end of a normal operating period e.g.

when the boiler plant shuts down:-

Type 1 (fixed) make circuit at 50°C±3K

break circuit 38°C±3K

Type 2 (adjustable) range 30 - 90°C

Switches

Fitted switches (external, or internal) or remote

switches (flush or surface wall mounting) can be

provided to switch the heater on/off, change fan

speed and/or override any thermostats.

Diagram 4: Fitted man/off/auto & high/low switches

The man/off/auto switch allows the fans to circulate

room air when the boiler plant is shutdown during the

summer.

A FAI/recirc switch can also be provided to open or

close fresh air inlet (FAI) dampers (models 19, 22,

53 and 88 with optional motorised damper).

Switch types are:

1 on/off

2 high/off/low

3 manual/off/auto

4 manual/off/auto and high/low

5 FAI/recirc

6 FAI/recirculation and high/off/low

7 FAI/recirculation and manual/off/auto

8 FAI/recirculation, manual/off/auto and

high/low

Special controls

If specified, the heater may incorporate special

controls such as relays, thermal controls etc.

These will be shown on the wiring diagram supplied

with each heater.

4

ACCESSORIES

Electric heating (single stage up to 6kW) on sizes

Fig 03, Fig 04 and Fig 06 on all models. Heaters are

single speed and may be supplied with

programmable thermostat/timeclock.

Manual damper for fresh air inlet or recirculating air

on models 19, 22, 53 and 88.

Motorised damper with 230V actuator for fresh air

inlet or recirculating air on models 19, 22, 53 and 88.

(Use with FAI /recirc. switch)

100mm, 150mm or 200mm high plinth on floor

mounted models

Remote pencil proof grille and fixing frame available

on models 15, 16, 17, 41, 21, 23 and 92.

Isolating valves fitted on flow and return coil

connections on most heaters as space permits, or

supplied loose for fitting to pipework.

PREPARATION

Handling

The purchaser is responsible for off-loading. Heaters

are individually packed and two/three persons can

usually handle the heaviest heater. If a significant

quantity is delivered, they may be palletised and

shrink-wrapped, so a fork-lift or similar will be

required for lifting. Heater must not be dropped or

suffer impact in any circumstances.

Storage

Heaters should be stored in clean, dry conditions.

Any packaging should not be removed until the

heater is required for installation and should only be

removed if damage is suspected at delivery

.

Fixing & Connections

Make proper provision for fixings. The structure to

which heaters are to be fixed must be fit for purpose

and capable of accepting plugs and screws, anchor

bolts or drop rods. Floor models require a level base.

Floor and wall models require a sound flat wall

surface. Heater casings are supplied with knockouts

for pipework and conduit entry.

Piping and electrical conduit should, as far as

possible, have been completed and any wall

apertures for loose grilles and ductwork should be

fully prepared.

WARNING:

Some internal components may have sharp edges. Protective gloves should be worn.

INSTALLATION

General

1.

Check the identity of the heater marked on

the outside of the carton. The carton can be

saved to protect the heater from damage by

other trades after installation.

2. Unlock and remove the access panel with the

key provided with the heater. On ceiling

models, safety screws retain the access panel

in a hinged position.

3. Re-check the identity of the heater, from the

serial number on the nameplate.

Diagram 5 : Mains inlet plug and fuse holder

4. The inner cover, fans/motors pipework cover

plate, filter and grilles can all be removed to

provide better access when making pipework

connections and to allow easier lifting of wall

and ceiling models. (See Diagram 6)

5. Disengage the line connector to disconnect

the wiring harness to the fan platform. On

ceiling models, remove the platform retaining

brackets before removing the platform.

6. Remove the casing knockouts,to suit pipework

and conduit entry

Diagram 6 : Fan and inner side plate removed

5

Floor models 13, 15, 16, 17, 19, 25, 37, 41 and 88

1. Models 15 & 41 - see Diagram 12 on page 9.

Model 17 - see Diagram 13 on page 10.

Models 19 & 88 - see Diagram 14 on page 11.

2. Note the position of the Ø5 fixing holes in the

heater backplate; mark-out, drill and plug.

3. Position and fix the heater ; ensure that the

foam strip around inlet and outlet apertures

on models 15, 16, 17, 19, 41 and 88 provides

an adequate seal.

4. If specified, fit loose grilles and fixing frames

into wall apertures, models 15, 16, 17 and 41,

as detailed on page 14. (If applicable, fit

external weatherproof louvres for models 19

and 88).

5. Pipe up as detail in

Pipework Connections

on

page 6.

6. Wire up as detailed in

Electrical Connections

and Controls

on page 7.

7. If supplied, fit the adjustable (type 2) low

temperature cut-out thermostat to the

LTHW flow pipe.

8. After filling the system, check for leaks (see

Commissioning

on page 7).

9. Replace all components previously removed.

10. Where appropriate, cut the back out of the

carton and tape into position over the heater.

11. When ordered with the heater, a plinth will be

fitted at our works ; pipework can enter the

plinth through knockouts provided

(see Diagram 18 on page 14).

Fixed duct models 20, 21, 22 and 60

1. Model 21 - see Diagram 15 on page 12.

Model 22 - see Diagram 14 on page 11.

2

.

In addition to the main access panel, unlock

the duct access panel, lift and remove.

3. Note the positions of the Ø5 fixing holes in the

heater backplate; mark-out, drill and plug.

4. Position and fix the heater ; ensure that

the foam strip around apertures on models 21

and 22 provides an adequate seal.

5. If specified, fit loose grilles and fixing frames

into wall apertures, model 21, as detailed on

page 14. (If applicable, fit external

weatherproof louvres for model 22).

6. Connect pipework to the coil as described in

Pipework Connections

on page 6.

7. Wire up as detailed in

Electrical Connections

and Controls

on page 7.

8. If supplied, fit the adjustable (type 2) low

temperature cut-out thermostat to the LTHW

flow pipe.

9. After filling the system, check for leaks (see

Commissioning

on page 7).

10. Replace all components previously removed.

11. Where appropriate, cut the back out of the

carton and tape into position over the heater.

12. When ordered with the heater, a plinth will be

fitted at our works ; pipework can enter the

plinth through knockouts provided

(see Diagram 18 on page 14).

Adjustable duct models 23 and 92

1. Models 23 & 92 - see Diagram 16 on page 13.

2. In addition to the main access panel, the

adjustable top duct and duct access panel can

be removed.

3. Remove the main access panel and note the

positions of the Ø5 fixing holes in the heater

backplate; mark-out, drill and plug.

4. Position and fix the heater into position ;

ensure that the foam strip around apertures

provides an adequate seal, before securing

the heater in position with suitable fixings,

through the holes in the backplate.

5. Raise the adjustable duct to suit the position

of the wall aperture, previously prepared.

6. Fix the adjustable duct into position, through

the holes in the duct side flanges, ensuring

there is a good seal between the heater and

wall.

7. If specified, fit loose grilles and fixing frames

into wall apertures, as detailed on page 11.

8. Connect pipework to the coil as described in

Pipework Connections

on page 6.

9. Wire up as detailed in

Electrical Connections

and Controls

on page 7.

10. If supplied, fit the adjustable (type 2) low

temperature cut-out thermostat to the LTHW

flow pipe.

11. After filling the system, check for leaks (see

Commissioning

on page 7).

12. Replace all components previously removed.

13. Where appropriate, cut the back out of the

carton and tape into position over the heater.

14. When ordered with the heater, a plinth will be

fitted at our works ; pipework can enter the

plinth through knockouts provided.

(see Diagram 18 on page 12).

6

Ceiling/wall models 28, 30, 31, 34, 38, 52 and 53

1. Loosen the M8 screws which attach the

suspension brackets to the heater casing and

remove the brackets.

2. Position and fix the suspension brackets to

the ceiling or wall; see Diagram 19 on page

15.

3. Lift the heater into position and secure the

heater to the suspension brackets by the four

M8 screws. (If applicable, fit external

weatherproof louvres for model 53).

4. Connect pipework to the coil as described in

Pipework Connections

below.

5. Wire up as detailed in

Electrical Connections

and Controls

on page 7.

6. If supplied, fit the adjustable (type 2) low

temperature cut-out thermostat to the LTHW

flow pipe.

7. After filling the system, check for leaks (see

Commissioning

on page 7).

8. Replace all components previously removed.

9. Where appropriate, cut the back out of the

carton and tape into position over the heater.

Pipework connections

WA1, WA2 & WA3 coils

- DN20 (3/4”BSP) female parallel

WA4 coils

- 22mm plain copper tails

Local isolating and regulating valves are

recommended. Observe the correct flow and return

positions, to ensure the rated heat output, see

Diagram 7. Fill the system and check for leaks.

Coils fitted

with :-

Cold test

pressure (bar g)

Working pressure

(bar g)

Type M air

vent

10.5

7.0

Type A air

vent

9.0

7.0

Table 2: Site test and working pressures

Diagram 7: Hot water coil connections, as viewed on the header/connection end of the coil.

NOTE: For correct operation, the back face of the Type 2 adjustable low temperature cut-off

thermostat needs to be in contact with a straight length of pipe approx. 100mm.

Avant Garde & LST Heaters

Avant –Garde and LST heaters are supplied

with controls valves which automatically shut

off the water flow when the fan is not

running.

Depending on the model and coil

arrangement supplied, the valves may be

supplied loose with special pipework for

fitting on site (see Diagram 8).

Flow and return connections must be

connected as shown in Diagram 8. The

diagram shows 4 port valve arrangement (2

port valve similar), with the LTC position

indicated.

Diagram 8: Control valve and LTC fitting locations

7

Electrical Connections and Controls

1. Connect a 230v/1ph/50Hz supply to the IEC

mains inlet connector. (see Diagram 5 on

page 4).

2. Fix any remote accessories-switches or

thermostats in the appropriate locations and

connected to the 12 way terminal block, as

shown on the wiring diagram supplied with the

unit (N.B. the 12 way terminal block is fitted

only when remote accessories are ordered

and shown on our wiring diagram).When

supplied the terminal block is located behind

the plate on which the mains inlet connector is

fitted.

Loose Grille and Fixing frame

1. Check dimensions and position of the grille

and frame in relation to the heater.

2. Prepare an opening to accept the frame.

3. Fit spire captive nuts into the slots in each

corner of the frame, and fix to the opening with

appropriate fixings (not supplied).

4. Fit the grille to the frame, aligning the holes in

the grille with the spire nuts in the frame and

fix using the black self-tapping screws

provided.

5. An alternative fixing can be to omit the fixing

frame and screw through the grille flanges

directly onto a suitable surround.

COMMISSIONING

General

1. Purge air from the coil using the manual or

automatic air vent, or through the mains

above the coil if applicable. Balance the

water flow rate through the system to

accepted practice.

2. If LTC thermostat fitted, the fans will run

when water in the flow pipe reaches the

required temperature. For a type 1 (fixed

setting) 54°C ± 3K or for type 2 (adjustable

setting) 30-90°C. A setting of 20K less than

the mean water temperature is

recommended). In the absence of hot

water, a temporary link can be used.

3. If fitted, adjust air thermostats to the

specified temperatures. If no settings are

specified, typical settings are:

a) on/off thermostat - set to 20°C

b) high/low thermostat - set to 16°C.

4. Check the operation of all thermostats by

varying their settings to achieve the desired

effect on the fan.

5. If switches are fitted check for satisfactory

operation.

6. A manual/off/auto switch will bypass all

thermostats when in the manual position.

This allows the fan to circulate room air

when no hot water is present.

7. If a manual damper is fitted, check the

operation of the damper lever.

8. If a motorised damper is fitted, check for

satisfactory operation. Damper control is

provided by a FAI/recirc. switch, if fitted.

9. Leave this document and all wiring

diagrams with the end user.

8

Fan Speed Adjustment (EC Motors)

1. Heaters fitted with EC motors are available

as one of two standard options:-

ECS - variable fan speed with speed control

by an external 2-10VDC signal (e.g.

from BMS)

ECM - single or dual fan speed with speed

control using switches or thermostats

via a fitted speed interface.

2. In the unlikely event that fan speeds require

adjustment, refer to the wiring diagram

supplied with the heater. Contact Dunham-

Bush for guidance on adjusting fan speeds

and selecting appropriate DC signal voltages.

3. The ECM speed controller is located

underneath the fan/motor platform and

comprises electronic controls with inputs

from thermostats and/or switches and a

single analogue 2-12VDC output signal to

the motor(s).

4. Refer to Diagram 9; three fan speeds are

available. Single speed heaters will use one

speed and dual speed heaters will use two

speeds, which can be varied by adjusting the

appropriate potentiometers; signal voltage can

be measured across 0V and CTRL terminals.

5. Avoid setting fan speeds too low:-

a) low fan speeds can cause stratification of

heated air within the room, reducing

effective comfort

b) low fan speeds with electric heating can

cause false tripping of high-temperature

safety cut-outs in the heater.

6. All connections to the EC fan controller shown

in Diagram 9 are safe low voltage of 10VDC

or less.

Diagram 9: Fan speed interface with 3 speeds

(ECM fan motor option only)

Size

Low speed

Medium speed

High speed

Fan

voltage

(VDC)

Airflow

(l/s)

Running

current

(A)

SFP

(W/l/s)

Fan

voltage

(VDC)

Airflow

(l/s)

Running

current

(A)

SFP

(W/l/s)

Fan

voltage

(VDC)

Airflow

(l/s)

Running

current

(A)

SFP

(W/l/s)

Fig 3

3.4

50

0.08

0.16

4.6

75

0.14

0.19

6.2

110

0.26

0.26

Fig 4

3.5

75

0.10

0.13

5.5

110

0.20

0.20

7.5

150

0.40

0.30

Fig 6

5.2

105

0.18

0.19

7.5

150

0.40

0.30

8.8

175

0.54

0.38

Fig 8

3.4

130

0.16

0.12

5.8

220

0.40

0.21

7.1

275

0.64

0.27

Fig 10

5.4

205

0.35

0.19

7.0

270

0.64

0.27

7.7

290

0.77

0.31

Fig 12

4.4

210

0.30

0.16

5.8

280

0.54

0.22

7.0

350

0.82

0.27

Fig 15

5.8

280

0.54

0.22

6.7

330

0.60

0.21

7.0

350

0.82

0.27

Table 3: Electrical data for EC motors (ECM motor options only; data for ECS motor option will vary)

Optional Panel Lock Indicators

Colour indicators show whether an access panel is

locked or unlocked. The lock position is shown

through the 10mm viewing window next to the lock;

green indicates the panel is safely locked and

cannot be removed or fall out; red indicates that the

access panel is unlocked.

Lock indicators can be retro-fitted to all Series AM

models by replacing the standard access panel with

a new one which includes the lock indicators. For

panel lock indicators, refer to Dunham-Bush, stating

part numbers reference 21-253-208. Price and

delivery upon application.

Diagram 10: Lock indicator green –panel locked Diagram 11: Lock indicator red –panel unlocked

9

Diagram 12: Typical installation detail for Models 15 and 41

10

Diagram 13: Typical installation detail for model 17

11

Diagram 14: Typical installation detail for models 19, 22, 53 and 88.

12

Diagram 15: Typical installation detail for model 21

13

Diagram 16: Typical installation detail for models 23 and 92

14

Diagram 17: Fixing detail for loose grille and fixing frame

Diagram 18: Fixing detail for plinth

15

Diagram 19: Fixing detail for suspension brackets (wall and ceiling mounted units)

16

CLEANING AND MAINTENANCE

WARNING:

Prior to undertaking any cleaning or maintenance, ensure that all electrical supplies are disconnected from

the heater via local isolators. Some internal components may have sharp edges. Protective gloves should be

worn.

Inspection

Frequency of cleaning and inspection depend

upon the operating conditions. Initially, it is

suggested that the air filter is inspected after 6-8

weeks and cleaned as required at regular

intervals. Cleaning the air filter ensures that the

heater delivers the required air flow rate and heat

output. The heater should not be operated without

a filter, since the heater coil fins will become

clogged with fluff and dust particles, resulting in

reduced performance.

Filter access and removal

To gain access to the air filter, unlock and remove

the access panel with the special key provided.

Floor, wall and duct models, pull the access panel

at the top and lift clear. Ceiling models, hinge the

access panel down and allow it to hang from the

safety screws (note: access panel can be

removed by removing the safety screws).

Cleaning

1. Air filters can be cleaned by tapping out

excess dust and washing in warm water

(up to 40°C), using detergent if necessary.

The filter must be rinsed and allow to dry

naturally before replacing. Do not use a

vacuum cleaner, as it can damage the filter

media. Filters should be replaced after

approximately 20 washes.

2. Because the air filter retains most of the

dusty particles, it will only be necessary to

clean the fan/motor assemblies and heater

coil annually. An industrial vacuum cleaner

can used to clean the inside of the heater,

in particular the heater coil(or electric

element) and fans, with the air being

sucked through the heater coil in the

opposite direction to normal air flow. All

accessible surfaces can be wiped with a

dry cloth.

Maintenance

1.

Coil

- Purge any air from the coil using the

manual air vent (using a suitable key) or by

turning the knurled thumbwheel on the

automatic air vent if fitted. Automatic air

vents have a built-in check valve which

allows the head to be removed without

draining the system.

2.

Motors

- The fan motor has ‘sealed for life’

bearings which do not require any

maintenance, other than visual inspection.

3.

Fuse

- The mains inlet connector on the

electrical connections box incorporates a

2A anti-surge fuse. A spare fuse is

supplied in a slide out fuse holder next to

the socket.

4.

Controls

- see accessories . A wiring

diagram is supplied with each heater.

Further copies are available on request,

please quote the serial number from the

nameplate, located inside the heater.

Please note :

1. If fitted, the LTC thermostat will switch

power to the fan only when the thermostat

reaches the required temperature. For a

type 1 (fixed setting) approx. 50°C ± 3K or

for type 2 (adjustable setting) 30-90°C (the

recommended setting is 20K less than the

mean water temperature)

2. If air thermostats are fitted (either to the

heater or remote mounted on a wall),

adjust to the specified temperatures.

Typical settings are:

a) on/off thermostat - set to 20°C

b) high/low thermostat - set to 16°C.

3. If fitted or remote switches are being used,

check that they operate correctly. Note : if

manual/off/auto switch is provided, all

thermostats are by-passed in the manual

position, which allows the fans to circulate

room air when the boiler plant is shutdown.

SPARES/SERVICE

PLEASE WRITE THE DETAILS OF THE UNIT HERE.

These details will be required when ordering spares for you Dunham-Bush Series AM Fan Convector.

UNIT TYPE AND MODEL INFORMATION

SERIAL NUMBER

DATE OF INSTALLATION

Spare parts/service –Please contact our office, contact information shown below.

Manufacturer reserves the right to change any product specification without notice.

Table of contents

Popular Heater manuals by other brands

Brant Radiant Heaters

Brant Radiant Heaters BAH Series Installation operation & maintenance

Mi-T-M

Mi-T-M MH-0400-0M10 Operator's manual

Dru

Dru ALTO Instructions for installation and operation

Reznor

Reznor OH Installation & operation manual

Volvo

Volvo 30756864 installation instructions

Aktobis

Aktobis WDH-IFH22 manual

YMGI

YMGI WMMS-09EU-V2B Installer's instruction & user's manual

Rointe

Rointe Symga instruction manual

Ancona

Ancona Prima Dual User's manual & installation instructions

Detroit Radiant Products

Detroit Radiant Products AG2 series Insert manual

Klarstein

Klarstein Taal Smart manual

Stelpro

Stelpro ACWS1000 Series user guide