Form I-OH, PN 120390 R4, Page 7

part of a burner, connect a pressure relief valve into the discharge line between the

pump and the shutoff valve and arrange to return surplus oil to the supply tank or to

bypass it around the pump, unless the pump includes an internal bypass.

Any fuel oil line incorporating a heater shall be provided with a relief valve arranged

to discharge to the return line when any valve, pump, or other device may prevent the

release of excessive pressure because of the expansion of the oil when heated.

Where oil is supplied to a burner requiring uniform ow by gravity feed and a constant

level valve is not incorporated in the burner assembly or the oil is not supplied by an

automatic pump, install a constant level valve in the supply line at the gravity tank or as

close as practical, to ensure uniform delivery of oil to the burner. The vent opening of

the constant level valve should be connected by piping or tubing to the outside of the

building, unless the constant level valve is provided with an anti-ooding device. Do

not connect the vent piping or tubing of constant level valves to tanks or tank vents.

Prior to entering enclosures, such as vaults or pits, where pumps and accessories are

installed, provide for adequate ventilation.

6.1.1 Standard Single Stage Burner Pump with Single Supply Pipe

The standard burner is equipped with a single-stage, 3450 RPM pump with the lift

capacity shown in FIGURE 4. Maximum lift is 8 ft (2.4M). Fittings, valves and lters

will reduce total line length allowed. Check component manufacturer's information for

equivalent length reduction required to compensate for pressure loss. A one-pipe sup-

ply system must be absolutely airtight, or leaks and/or loss of prime may result. Follow

instructions in Paragraph 8.2, Check-Test-Start (Operating Procedure) to bleed the

line. Bleed for 15 seconds after last air is seen from easy ow bleed valve to be certain

lines are air free.

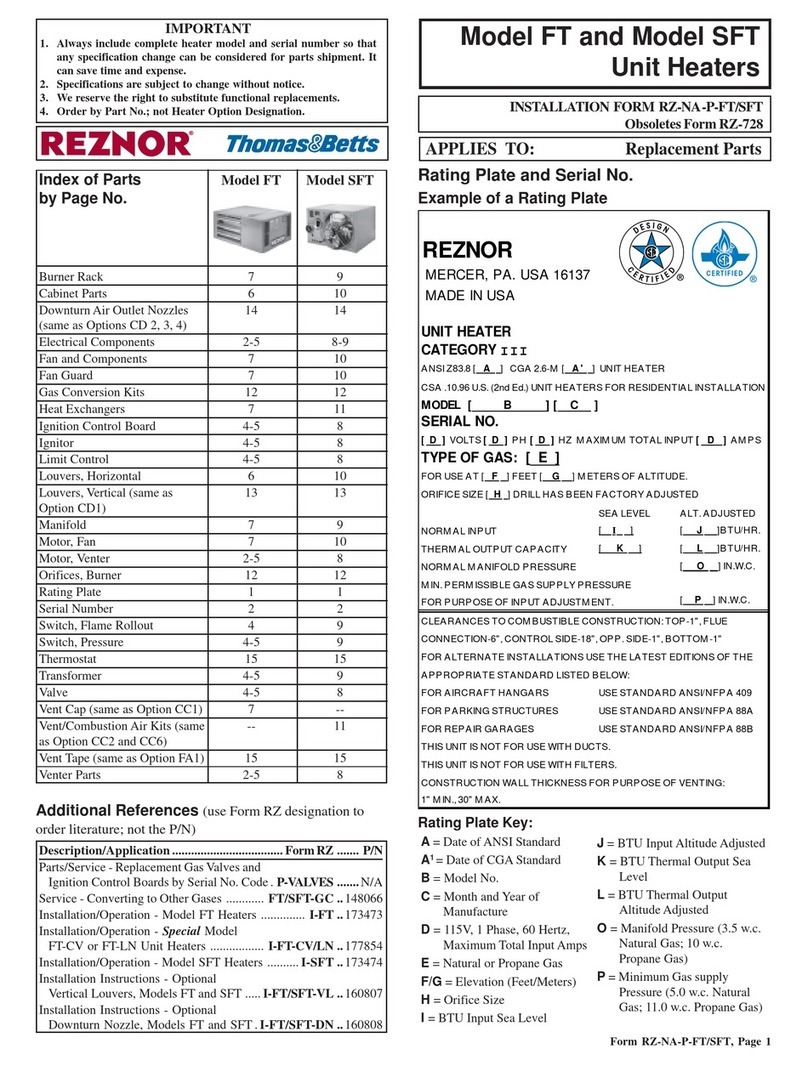

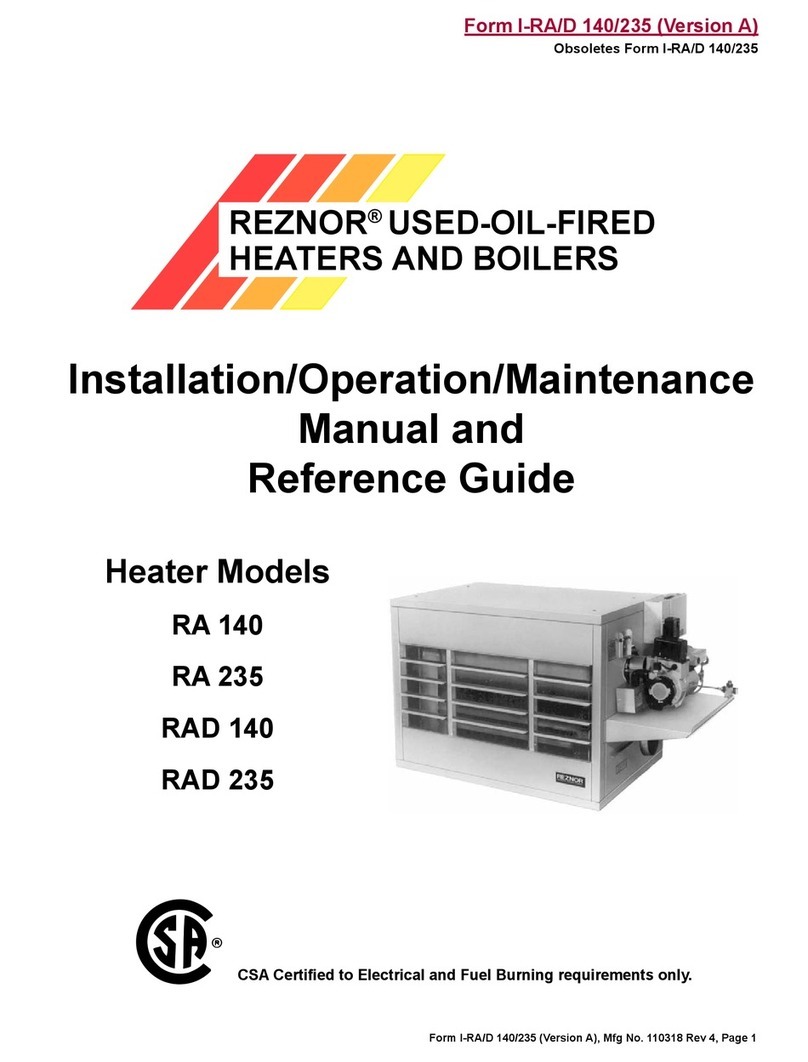

FIGURE 4 - Single Pipe Supply System (single-stage burner pump)

Maximum Horizontal Line Length (ft) by

Heater Size and Size of Tubing

Maximum Horizontal Line Length (M) by

Heater Size and Size of Tubing

Lift 95 140 190 Lift 95 140 190

(ft) 3/8" 1/2" 3/8" 1/2" 3/8" 1/2" (M) 3/8" 1/2" 3/8" 1/2" 3/8" 1/2"

0 822 3158 556 2222 423 1667 0.0 251 963 169 677 129 508

1 719 2763 486 1944 370 1458 0.3 219 842 148 593 113 444

2 616 2368 417 1667 317 1250 0.6 188 722 127 508 97 381

3 514 1974 347 1389 264 1042 0.9 157 902 106 423 80 318

4 411 1579 278 1111 211 833 1.2 125 481 85 339 64 254

5 308 1184 208 833 158 625 1.5 94 361 63 254 48 191

6 205 789 139 556 106 417 1.8 62 240 42 169 32 127

7 103 395 69 278 53 208 2.1 31 120 21 85 16 63

8 0 0 0 0 0 0 2.4 0 0 0 0 0 0

Length =

6 ft - (.75 X Lift)

(.0086 for 3/8" tubing or

.00218 for 1/2" tubing) X(Firing Rate in GPH - OH95, .085;

OH140, 1.25; OH190, 1.35)

Formula for determining gures (ft) in TABLE 5 above.

TABLE 5 - Maximum Horizontal Line Length

(ft/M) with a Single Pipe Supply System

6.1.2 Two-Pipe Supply System with Standard Single-Stage Pump

or Optional Two-Stage Pump

A two-pipe supply system may be used with the standard burner pump or with a two-

stage pump if Option BZ1 was ordered. The two-stage pump provides dual pumping

gears. To install the two-pipe supply system, remove the 1/4" plug from the return line

port and insert the 1/16" bypass plug (Shipped with the burner pump; see FIGURE

17, page 17.). Attach the inlet and return lines. Always terminate the return line 3 to 4

inches (76 to 102mm) above the supply line inlet. See FIGURE 5.