DCA M1Q-FF-85 User manual

Edition 2 July, 2011

Read through carefully and understand these

instructions before use.

GENERAL SAFETY RULES

(ForAll Tools)

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

Work Area

1. Keep work area clean and well lit. Cluttered areas and benches invite

injuries.

2. Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a power

tool. Distractions can cause you to lose control.

Electrical Safety

4. Power tools must be plugged into an outlet properly installed or

grounded in accordance with all codes and ordinances. Never modify

the plug in any way. Do not use any adaptor plugs with grounded

(earthed) power tools. The original plug and proper outlet may reduce the

risk of electric shock.

5. Avoid body contact with grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your

body is grounded.

6. Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

7. Do not abuse the cord. Never use the cord to carry the tools or pull the

plug from an outlet. Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged or entangled

cords increase the risk of electric shock.

8. When operating a power tool outside, use only extension cords intended

for outdoors use. These cords may reduce the risk of electric shock.

Personal Safety

9. Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may

result in serious personal injury.

10.Dress properly. Do not wear loose clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

11.Avoid accidental starting. Be sure switch is off before plugging in. Carrying

tools with your finger on the switch or plugging in tools that have the switch on

invites accidents.

12.Remove adjusting keys or wrenches before turning the tool on. A wrench or a

key that is left attached to a rotating part of the tool may result in personal injury.

13.Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the tool in unexpected situations.

14.Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

Ordinary eye or sun glasses are NOT eye protection.

15.If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

Tool Use and Care

16.Do not force tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it is designed.

17.Do not use tool if switch does not turn it on or off. Any tool that cannot be

controlled with the switch is dangerous and must be repaired.

18.Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

19.Store idle tools out of reach of children and other untrained persons. Tools

are dangerous in the hands of untrained users.

-1- -2-

20. Maintain tools with care. Keep cutting tools sharp and clean. Properly

maintained tools with sharp cutting edges are less likely to bind and are

easier to control.

21. Check for misalignment or binding of moving parts, breakage of parts,

and any other condition that may affect the tools operation. If damaged,

have the tool serviced before using. Many accidents are caused by poorly

maintained tools.

22. Use only accessories that are recommended by the manufacturer for

your model. Accessories that may be suitable for one tool, may become

hazardous when used on another tool.

Ser ice

23. Tool service must be performed only by qualified repair personnel.

Service or maintenance performed by unqualified personnel could result in a

risk of injury.

24. When servicing a tool, use only identical replacement parts. Follow

instructions in the Maintenance section of this manual.

Use of

unauthorized parts or failure to follow Maintenance instructions may create a

risk of electric shock or injury.

VOLTAGE WARNING:

Before connecting the tool to a power source (receptacle, outlet, etc.), be sure the

voltage supplied is the same as that specified on the nameplate of the tool. A

power source with voltage greater than that specified for the tool can result in

SERIOUS INJURY to the user, as well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power source with voltage less than nameplate

rating is harmful to the motor.

SPECIFICATIONS

Rated Power Input 580 W

Strokes per Minute 500-3100 …/min

Bevel Cutting Angle (Right/Left) 0-45 °

Max. Cutting Capacities

Wood 85 mm

Aluminum 20 mm

Steel 10 mm

Net Weight 2.7 Kg

※Due to the continuing program of research and development, the specifications

herein are subject to change without prior notice.

ADDITIONAL SAFETY RULES

1. Always wear safety glasses or goggles. Ordinary eye or sun glasses are NOT

safety glasses.

2. Use only sharp blades in good condition. Replace cracked, dulled or deformed

blade immediately.

3. Hold the tool only by insulated surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

4. Always be sure that the tool is switched OFF before plugging to avoid the risk of

injury caused by accidental starting.

5. Hold the tool firmly. Keep hands away from cutting area and blade.

6. Keep the cord away from the cutting area and position it at the rear of the tool

during the cutting operation.

7. Make sure the blade is not contacting the workpiece before switching on the tool.

8. Avoid cutting nails. Inspect workpiece for any nails and remove them before

operation.

-3- -4-

9. Remove all obstacles both on and under the cutting line of the workpiece

during operation.

10. Check for the proper clearance beyond the workpiece before cutting so that

the blade will not strike the floor, workbench etc.

11. Do not cut oversize workpiece.

12. Rest the base flat on the workpiece in cutting operation, use stable supports

or workbench when cutting small and thin workpieces.

13. Do not leave the tool running. Operate the tool only when hand-held.

14. Always switch off and wait for the blade to come to a complete stop before

removing the blade from the workpiece.

15. Do not stop the blade by lateral pressure on it.

16. Do not touch the blade or the workpiece immediately after operation; they

may be extremely hot and could burn your skin.

17. In order to avoid operational malfunctions, do not saw gypsum board etc.

from below or overhead.

18. Do not work with materials containing asbestos.

19. Be sure to use an earth-leakage circuit breaker, with actuating current not

more than 30mA and actuating time not more than 0.1s, when use this tool

outside, and use only waterproof extension cords intended for outdoors use.

20. Never allow children or untrained person to use the tool.

SAVE THESE INSTRUCTIONS.

WARNING!

MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

GENERAL DESCRIPTION

1.

Screwdriver Inlet Hole 8. Blade Roller Guide

2.

Trigger Switch 9. Saw Blade*

3.

Lock Button 10.

Safety Protector

4.

Hex Wrench 11.

Stroke Rod

5.

Switch for Sawdust Blower 12.

Scale for Bevel Cutting

6.

Base 13.

Hex Socket Head Screw

7.

Blade Orbit Selector Lever 14.

Protractor**

Note: *—Optional Accessory, Sold Separately; **—Commercially Available.

-5- -6-

INSTRUCTIONS FOR OPERATION

Safety Protector

CAUTION:

Always keep the safety protector in

place during operation for your

safety.

The safety protector attached to the

housing prevents unintentional contact

with the saw blade while working and

should not be removed. (Fig. 2)

Switch Action

CAUTION:

Before plugging in the tool, always check to see that the trigger switch actuates

properly and returns to the “OFF” position when released.

Switch can be locked in the “ON” position for ease of operator comfort during

extended use. Apply caution when locking tool in the “On” position and maintain

firm grasp on tool.

To start the tool, simply press the

switch trigger. Release the trigger to

stop.

For continuous operation, pull the

trigger and then push in the lock

button. To stop the tool from the

locked position, pull the trigger fully

and then release it. (Fig. 3)

Speed Control

Speed can be infinitely adjusted between

500 and 3,100 strokes per minute by

turning the adjusting dial. Higher speed is

obtained when the dial is turned clockwise;

lower speed is obtained when it is turned

counterclockwise. (Fig. 4)

Installing or Remo ing the Saw Blade

CAUTION:

Always be sure that the tool is switched OFF and unplugged before installing or

removing the saw blade.

Wear protective gloves when replacing/removing the saw blade.

Always clean out all chips or foreign matter adhering to the blade and/or blade holder.

Failure to do so may cause insufficient tightening of the blade, resulting in a serious

personal injury.

Do not touch the blade or the workpiece immediately after operation; they may be

extremely hot and could burn your skin.

Always secure the blade firmly. Insufficient tightening of the blade may cause blade

breakage or serious personal injury.

To install the saw blade, firstly set the blade orbit selector lever to

level 3.

Then finish the installment as follows:

—Insert the blade into the stroke rod crosswise to the cutting

direction.

-7- -8-

—Turn the saw blade with the teeth facing in the cutting

direction. Slightly lift the saw blade so that the back of the

saw blade comes to rest in the groove of the blade roller

guide. Allow it to engage by pulling slightly.

—Insert the provided screwdriver into

the screwdriver inlet hole and

tighten the locking screw clockwise

to finish the installment. (Fig. 5)

To remove the saw blade, follow the

installing procedure in reverse.

Sawdust Blower

The sawdust blower leads an air jet to the saw blade. The air jet keeps sawdust

from covering the cutting line during operation. The air flow can be switched on or

off with the switch for the sawdust blower.

Sawdust Blowing Level I:

Use low airstream when cutting in metals and when

coolants/ lubricants are used.

Sawdust Blowing Level II:

Use medium airstream when cutting in materials with low

chip removal rate, e. g. hardwood.

Sawdust Blowing Level III:

High airstream, for cuts in materials with high chip removal

rate, e.g. soft wood, plastic, etc.

Selecting Orbital Action

CAUTION:

Select the low orbital action setting (or switch it off) for a finer and cleaner cutting

edge.

Switch the orbital action off for cutting thin materials such as sheet metal.

Select the low orbital action when cutting hard materials such as steel.

Select high orbital action when cutting soft materials and when sawing in the

direction of the grain.

The four orbital action settings of the tool allow optimum adaptation of cutting speed,

cutting capacity and cutting pattern to the material being sawed. The orbital action can

be adjusted in four steps with the blade orbit selector lever, and it also can be adjusted

during operation.

Step 0:

No orbital action.

Step 1:

Low orbital action.

Step 2:

Medium orbital action.

Step 3:

High orbital action.

-9- -10-

Cutting/Sawing Operation

CAUTION:

Always hold the tool with the base flush with the workpiece. Failure to do so may

cause blade breakage, resulting in a serious injury.

Advance the tool very slowly when cutting curves or scrolling. Forcing the tool

may cause a slanted cutting surface and blade breakage.

For tight curves, it is best to use a narrow saw blade.

Switch on the tool without the blade making any contact with the workpiece and

wait until the blade attains full speed. Then rest the base flat on the workpiece and

gently move the tool forward along the previously marked cutting line.

Be el Cutting

CAUTION:

Always be sure that the tool is switched off and unplugged before tilting the

base.

Bevel cuts can be finished at any angle between 0°-45°(left or right) by tilting the

base.

To adjust the cutting angle, loosen the

hex socket head screw and slightly

slide the base towards the saw blade,

then the base can be tilted to a

maximum of 45°to the right or left.

Tilt the base to the desired angle and

retighten the hex socket head screw.

The cutting angle can be pre-adjusted

with the scale for bevel cutting. It is recommended to use a commercial protractor

for precise adjustment. (Fig. 6)

To achieve precise cutting angles, the base can be fitted at 0°and 45°(left and right).

For this, however, the base must be pushed back (towards the motor) to the stop so

that the notch in the base engages in the positioning pin.

For cutting angles out of 0°-45°(left and right), adjust the angle with the scale for bevel

cutting primarily and then use a set square or protractor to finish the adjustment.

When returning the base to the 0°(normal) position, lightly push the base toward the

direction of the motor until it can be felt to engage, then retighten hex socket head

screw.

Repositioning the Base

CAUTION:

With the base set back, it is only possible to work in the 0°(normal) position. The

guide rule as well as the splinter guard cannot be used in this position.

When tightening the screw, the base must be pressed to the rear until it can be felt to

engage.

For flush cuts close to edges, the base can

be moved to the rear for easy operation.

Use a hex wrench to remove the screw,

take off the base and move it to the rear so

that the screw can be screwed into the rear

thread, and then tighten the screw to

secure the base. (Fig. 7)

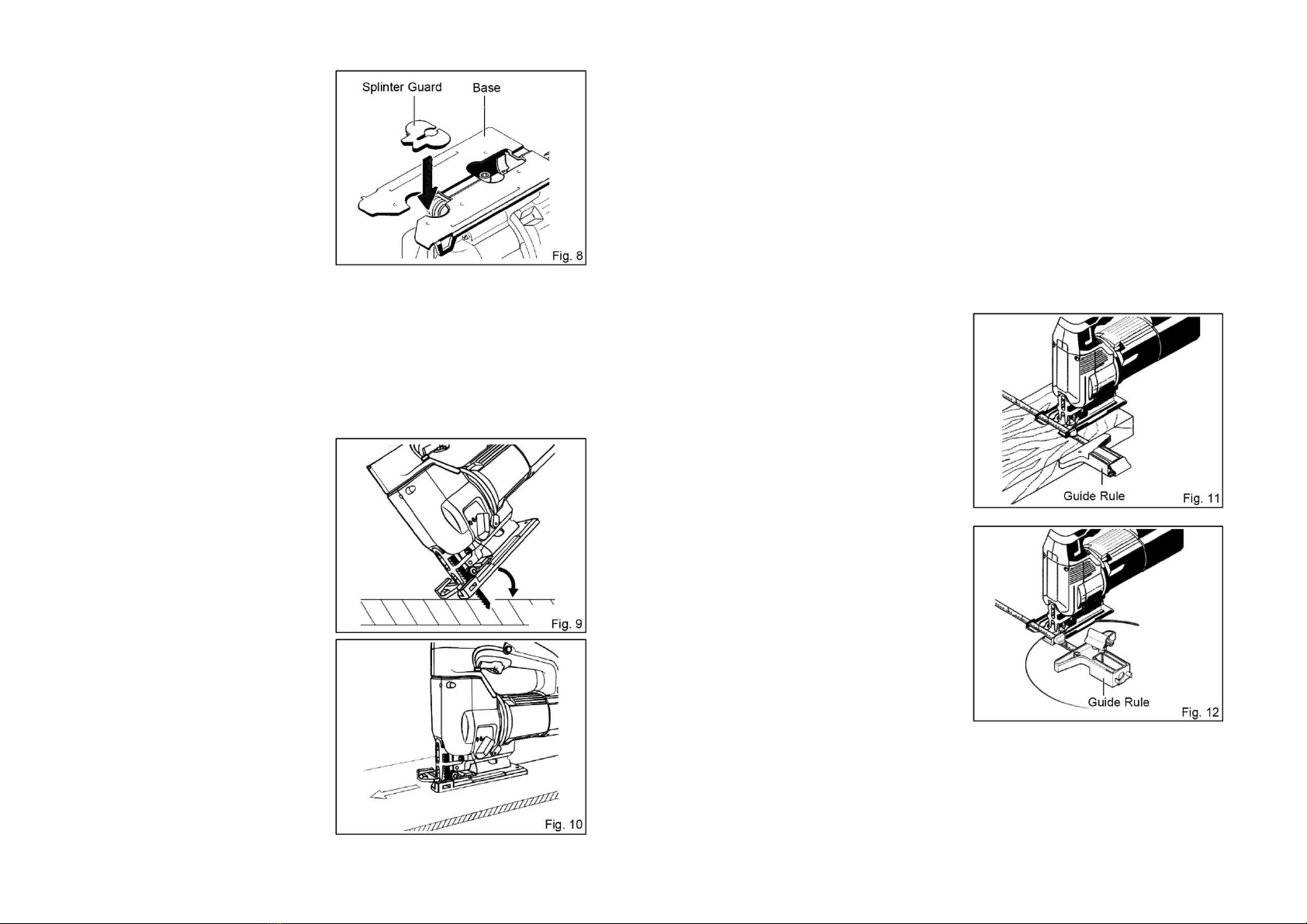

Splinter Guard

CAUTION:

The splinter guard cannot be used for certain types of saw blades (e. g., set saw

blades).

The splinter guard cannot be used when making bevel cuts.

-11- -12-

For splinter-free cuts, the splinter

guard can be used.

To install the splinter guard, simply

press it into the base. (Fig. 8)

Plunge Cutting

CAUTION:

Apply plunge cutting only when working on soft materials, such as wood,

aerated concrete, gypsum plaster boards, etc.!

Use only short saw blade for plunge cutting.

Pull out the saw blade only until it

comes to a complete stop to avoid

kickback when make a plunge cut.

Place the tool with the front edge of

the base onto the workpiece and

switch on. Firmly hold the tool against

the workpiece while tilting the tool and

slowly plunge the saw blade into the

workpiece. (Fig. 9)

When the base fully lays on the

surface, continue sawing along the

cutting line. (Fig. 10)

Metal Cutting

Always use a suitable coolant (cutting oil) when cutting metal or similar materials.

Failure to do so will cause significant blade wear.

Guide Rule (optional accessory)

CAUTION:

Always be sure that the tool is switched off and unplugged before installing or

removing accessories.

The combined circle cutter/parallel guide

rule enables repeatedly cuts in a certain

width conveniently.

To install the guide rule, insert it into the

rectangular hole on the side of the base.

Slide the guide rule to the desired cutting

width position. (Fig. 11)

Certain radius circular cutouts can be

made conveniently and repeatedly by

using the combined circle cutter/parallel

guide rule. (Fig. 12)

With the combined circle cutter/parallel

guide rule parallel cuts or circular cutouts in

materials of up to 30 mm thickness can be

made.

-13- -14-

MAINTENANCE AND INSPECTION

CAUTION:

Always be sure that the tool is switched off and unplugged before attempting to

perform inspection or maintenance.

1.

After Metal Cutting

When cutting metals under extreme working conditions, conductive dust can

accumulate in the interior of the machine and impair its protective insulation.

In such cases, it is recommended to use stationary dust extraction equipment,

to blow out the ventilation slots frequently and to power the tool via a ground

fault circuit interrupter.

2.

Inspecting the Mounting Screws

Regularly inspect all mounting screws and ensure that they are properly

tightened. Should any of the screws be loose, retighten them immediately.

Failure to do so could result in serious hazard.

3.

Maintenance of the Motor

The motor unit winding is the very “heart” of the power tool. Exercise due care

to ensure the winding does not become damaged and /or wet with oil or water.

Always keep the power tool and its ventilation slots clean.

4.

Inspecting of the Blade Roller Guide

The blade roller guide should occasionally be checked for wear and lubricated

with a drop of oil. If it is worn, it must be replaced.

5.

Inspecting and Replacing Carbon Brushes

Remove and check the carbon brushes regularly. Replace when they wear

down to the limit mark. Keep the carbon brushes clean and free to slip in the

holders. Both carbon brushes should be replaced at the same time and use

only identical carbon brushes.

※

※※

※To maintain product SAFETY and RELIABILITY, repairs, any other maintenance

or adjustment should be performed by authorized centers, always using original

replacement parts.

-15- -16-

EXPLAINATION OF GENERAL VIEW

1 Handle Cover 26

Snap Washer

2 Pan Head Tapping Screw

ST4.2×19 27

Washer

3 Nut 28

Pan Head Screw M4×14

4 Pan Head Screw M4×20 (with

Spring and Flat Washers) 29

Needle Bearing HK0608

5 Pan Head Tapping Screw

ST4.2×16 (with Flat Washer)

30

Pin

6 Strain Relief 31

Eccentric Block

7 Cord Guard 32

Sleeve

8 Cord 33

Balance Block

9 Hex Wrench 34

Washer

10

Nameplate 35

Washer

11

Rear Cover 36

Grip Ring

12

Pan Head Tapping Screw

ST4.2×19 37

Washer

13

Capacitor 38

Washer

14

Pan Head Tapping Screw

ST2.9×10 39

Shifter

15

Coil Spring 40

Washer

16

Carbon Brush Holder 41

Eccentric Gear

17

Carbon Brush 42

Needle Bearing TN1

18

Trigger Switch 43

Washer

19

Pan Head Screw M5×25 (with

Spring and Flat Washers) 44

Washer

20

Handle 45

Snap Washer

21

Motor Housing 46

Blower Spigot

22

Pan Head Tapping Screw

ST3.5×9 47

Pan Head Tapping Screw

ST4.2×25

23

Baffle Plate 48

Washer

24

Stator 49

Gear Housing

25

Seal Pad 50

Blade Orbit Selector Lever

EXPLAINATION OF GENERAL VIEW

51

Spring 77

Stroke Rod

52

Retaining Sleeve 78

Slide Support

53

Switch for Sawdust Blower 79

Slide Groove

54

Grip Ring 80

Cross Recessed Countersunk

Head Screw M3.5×10

55

Sleeve 81

Pan Head Screw M4×8 (with

Flat Washer)

56

Felt Washer 82

Positioning Pin

57

Seal Cover 83

Pan Head Screw M4×14

58

Ball Bearing 609SS 84

Guide Plate

59

Circlip for Hole 85

Spring

60

Armature Assembly 86

Pad

61

Ball Bearing 627ZZZC 87

Shim

62

Saddle Washer 88

Pin

63

Washer 89

Gear Housing Cover

64

Bracket 90

Pan Head Screw M4×14

65

Hex Nut 91

Safety Protector

66

Aluminium Base 92

Guide Roller Retainer

67

Inner Base 93

Snap Washer

68

Cross Recessed Countersunk

Head Screw M5×8 94

Shaft

69

Clamp Plate 95

Washer

70

Hex Socket Head Screw M6×16 96

Needle Bearing SCE

71

Lock Screw M6×12 97

Guide Roller

72

Oil-Retaining Bearing 98

Inductance

73

Oil-Retaining Bearing 99

Label

74

Washer 100

Long Wire

75

Shaft Cover 101

Middle Wire

76

Washer 102

Short Wire

-17- -18-

Table of contents