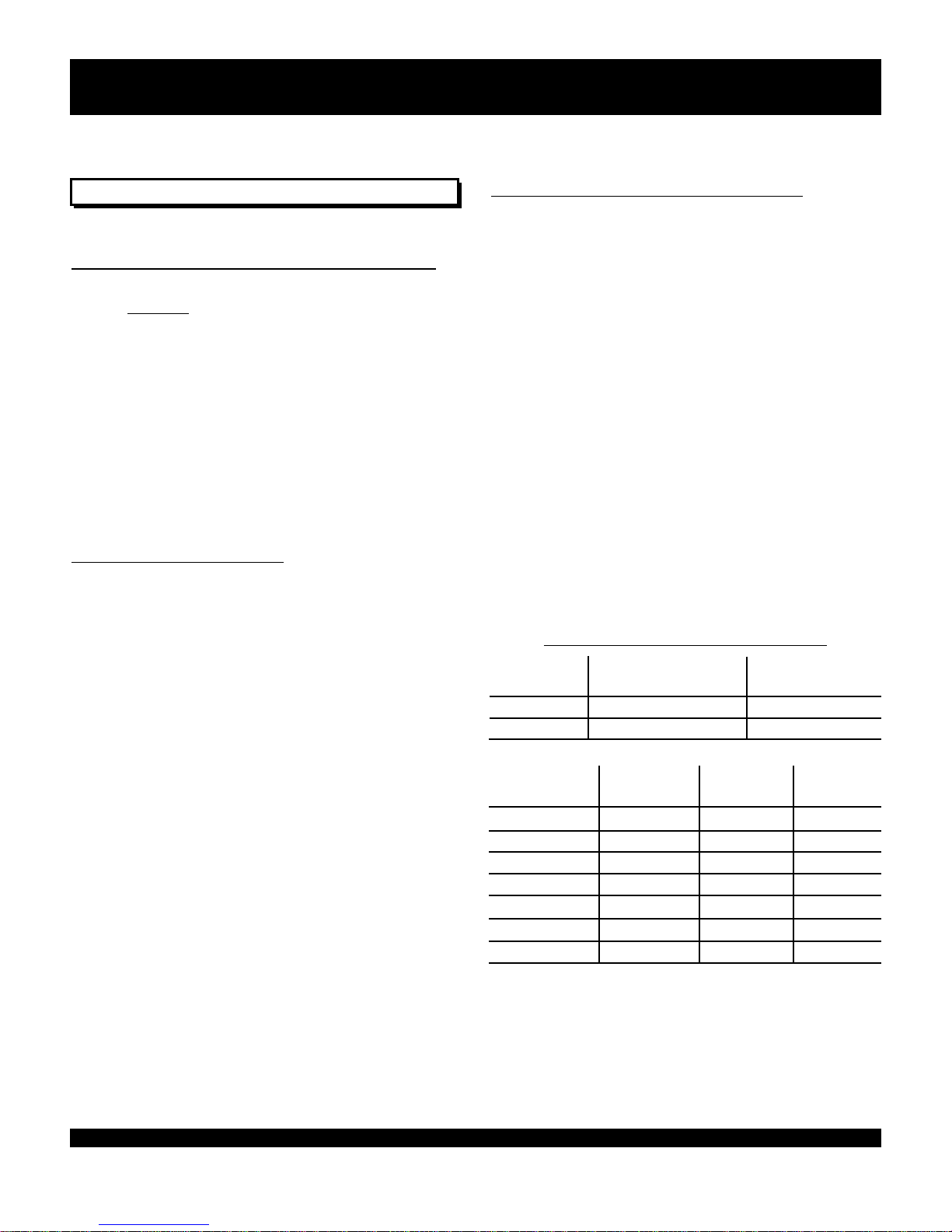

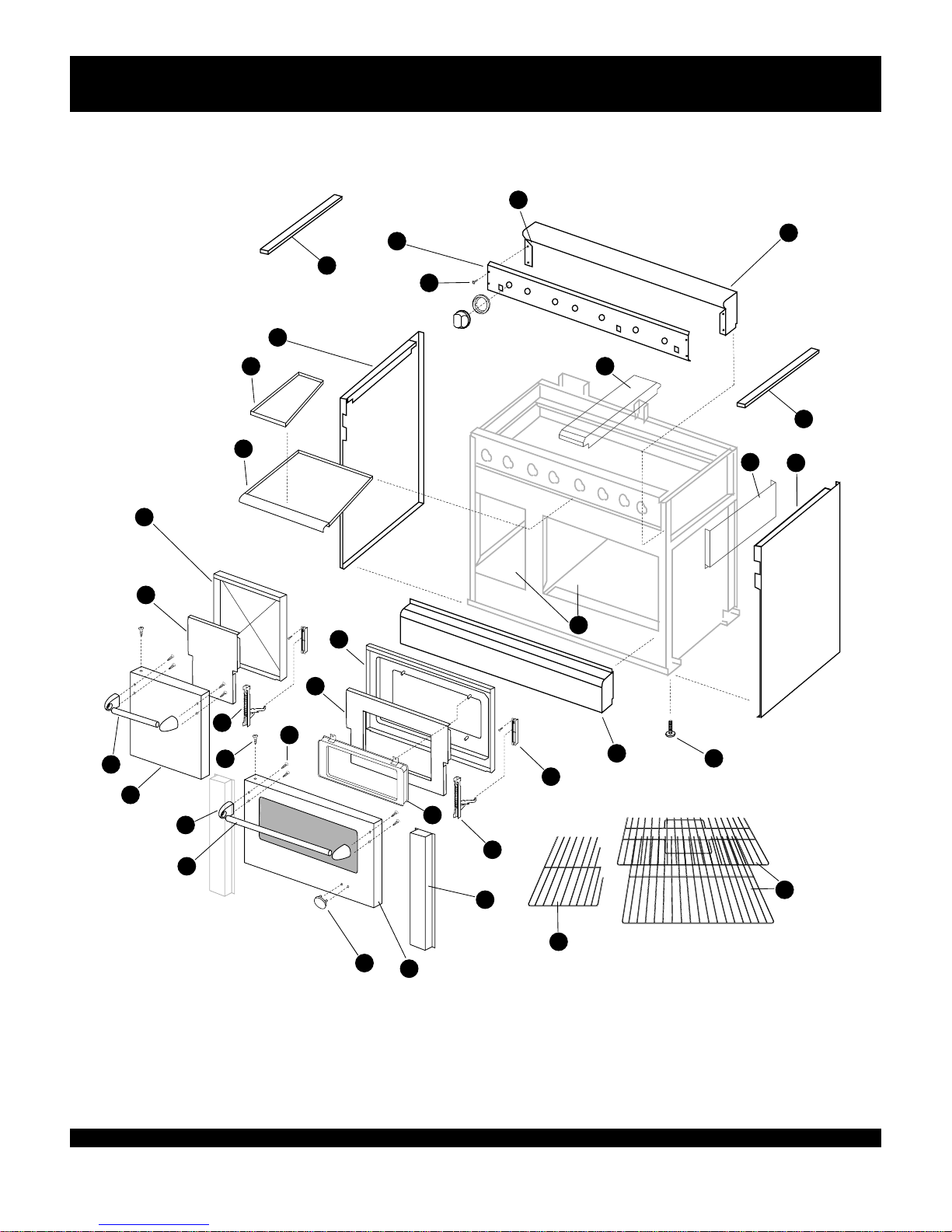

PARTS LIST:

ITEM # PART # DESCRIPTION

1 90104-01 RG 48 LANDING LEDGE

90104-02 RG 36 LANDING LEDGE

90104-03 RG 304 LANDING LEDGE

2 90100-PA RG 484GG VALVE PANEL

90100-01 RG 486GD VALVE PANEL

90100-02-PA RG 486GL VALVE PANEL

90102-PA RG 366 VALVE PANEL

90102-01-PA RG 364GD VALVE PANEL

90102-02-PA RG 364GL VALVE PANEL

90099-PA RG 304 VALVE PANEL

90101-PA C 484GG VALVE PANEL

90101-01-PA C 486GD VALVE PANEL

90101-02-PA C 486GL VALVE PANEL

90103-PA C 364GL VALVE PANEL

90103-01-PA C 364GD VALVE PANEL

90347 RGA 304 (SS) VALVE PANEL

90347-01 RGA 304 (WHITE) VALVE PANEL

90103-02-PA C 366 VALVE PANEL

3 90090-01 RG 48 RIGHT BODY PANEL

90217-01 RG 36 RIGHT BODY PANEL

90114-01 RG 304 RIGHT BODY PANEL

4 90090-02 RG 48 LEFT BODY PANEL

90217-02 RG 36 LEFT BODY PANEL

90114-02 RG 304 LEFT BODY PANEL

5 18052-02 LEVELING LEG

6 90164 RG 48 KICK PANEL ASSEMBLY

90219 RG 36 KICK PANEL ASSEMBLY

90228 RG 304 KICK PANEL ASSEMBLY

7 150034-3 HINGE RECEPTACLE

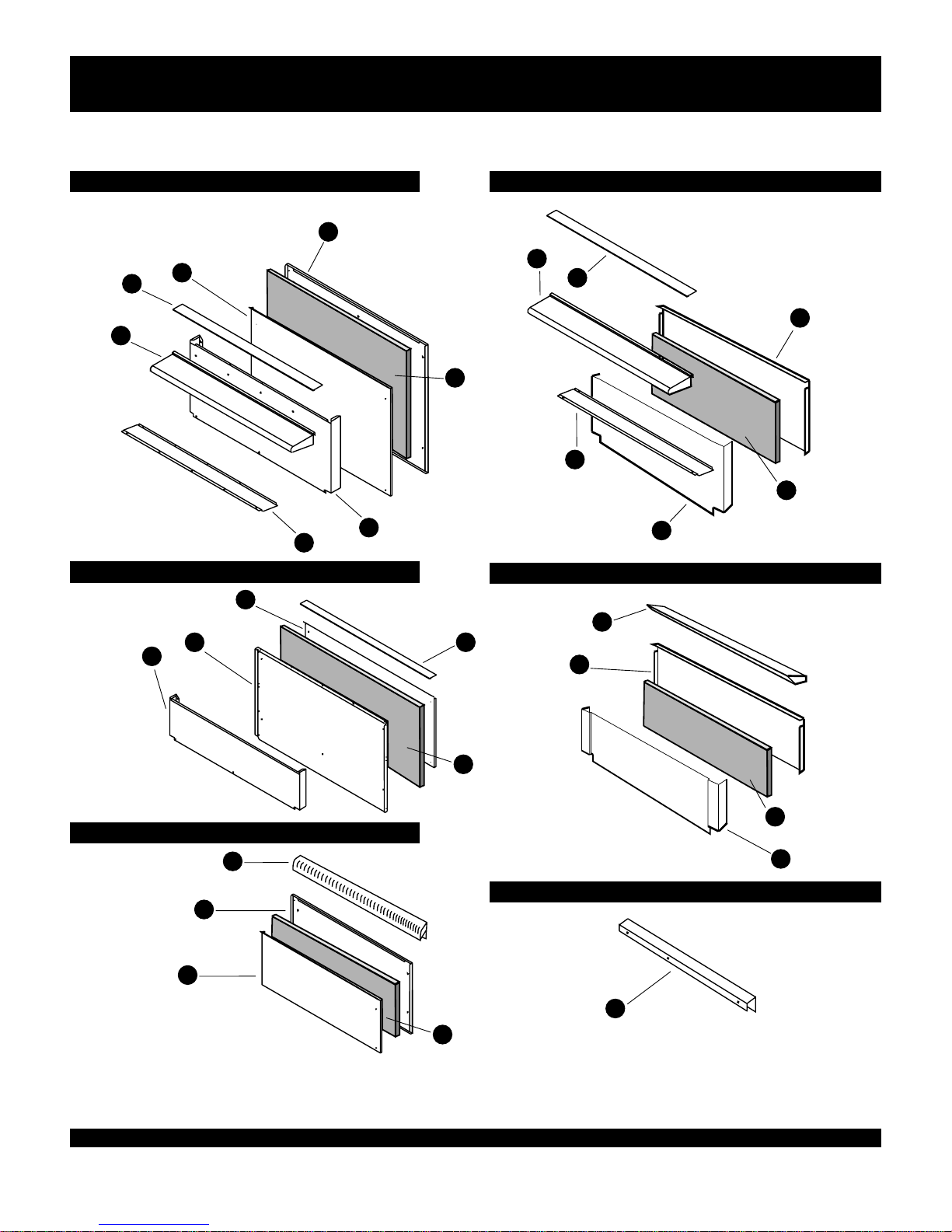

8 90186-PC 27" DOOR INSIDE LINER (RG 48/36)

90200-PC (RG 304) DOOR INSIDE LINER

9 150034-1 27" OVEN DOOR HINGE (RG 48/36)

15097 (RG 304) OVEN DOOR HINGE

10 14131 WINDOW PACK

11 90106 27" OVEN OUTSIDE DOOR PANEL (RG 48/36)

90094-02 (RG 304) OVEN OUTSIDE DOOR PANEL

11A 90184-02(27”), 90184-01(12”) OVEN DOOR ASSEMBLY

90184-03 RG 304 DOOR ASSEMBLY

12 17001 DCS LOGO -SM. (COOKTOPS)

17001-03 DCS LOGO -LG. (RANGES)

13 90187-02 27" OVEN DOOR HANDLE (RG 48/36)

90187-03 (RG 304) OVEN DOOR HANDLE

14 18164 DOOR HANDLE ENDCAP

15 90112 12" DOOR OUTSIDE PANEL

16 90187-01 12" DOOR HANDLE

17 90107 27" DOOR INSULATION RETAINER (RG 48/36)

90097 (RG 304) DOOR INSULATION RETAINER

18 90113 12" DOOR INSULATION RETAINER

19 90111-PC 12" DOOR INSIDE PANEL

20 15001-34 BOLT - DOOR HANDLE

21 15001-09 SCREW - DOOR TOP

22 90068-01-L/H, 90068-02-R/H DRIP PAN - 48"

90212-36" , 90234-30" DRIP PAN

22A 90202-02-L/H, 90202-01-R/H DRIP PAN HANDLE - 48"

90213-36" , 90208-30" DRIP PAN HANDLE

23 30313-3 DRIP PAN LINER (UNDER GRILL / GRIDDLE ONLY)

24 150034-2 12" OVEN DOOR HINGE

25 90054-01 (R), 90054-02 (L) COOKTOP 48 SIDE TRIM

90053-02 (R), 90053-01 (L) COOKTOP 36 SIDE TRIM

26 90259-01(R), 90259-02(L) RG 366 FRONT PANEL

27 90196-01-PC 27” OVEN BOTTOM

90196-02-PC 12” OVEN BOTTOM

90273-PC RG 304 OVEN BOTTOM

28 90055-01(R), 90055-02(L) C 48”, 366 only SIDE INSULATION RETAINER

90050-01(L),90050-02(R) C 364 SIDE INSULATION RETAINER

29 90163 RG / RGA CENTER SPACER- GRATE

30 19003-1(BAKE), 19003-3(BROIL) 27” OVEN RACK

19044-01(BAKE), 19044-02(BROIL) RG / RGA 304 OVEN RACK

31 19003-02 12” OVEN RACK

7

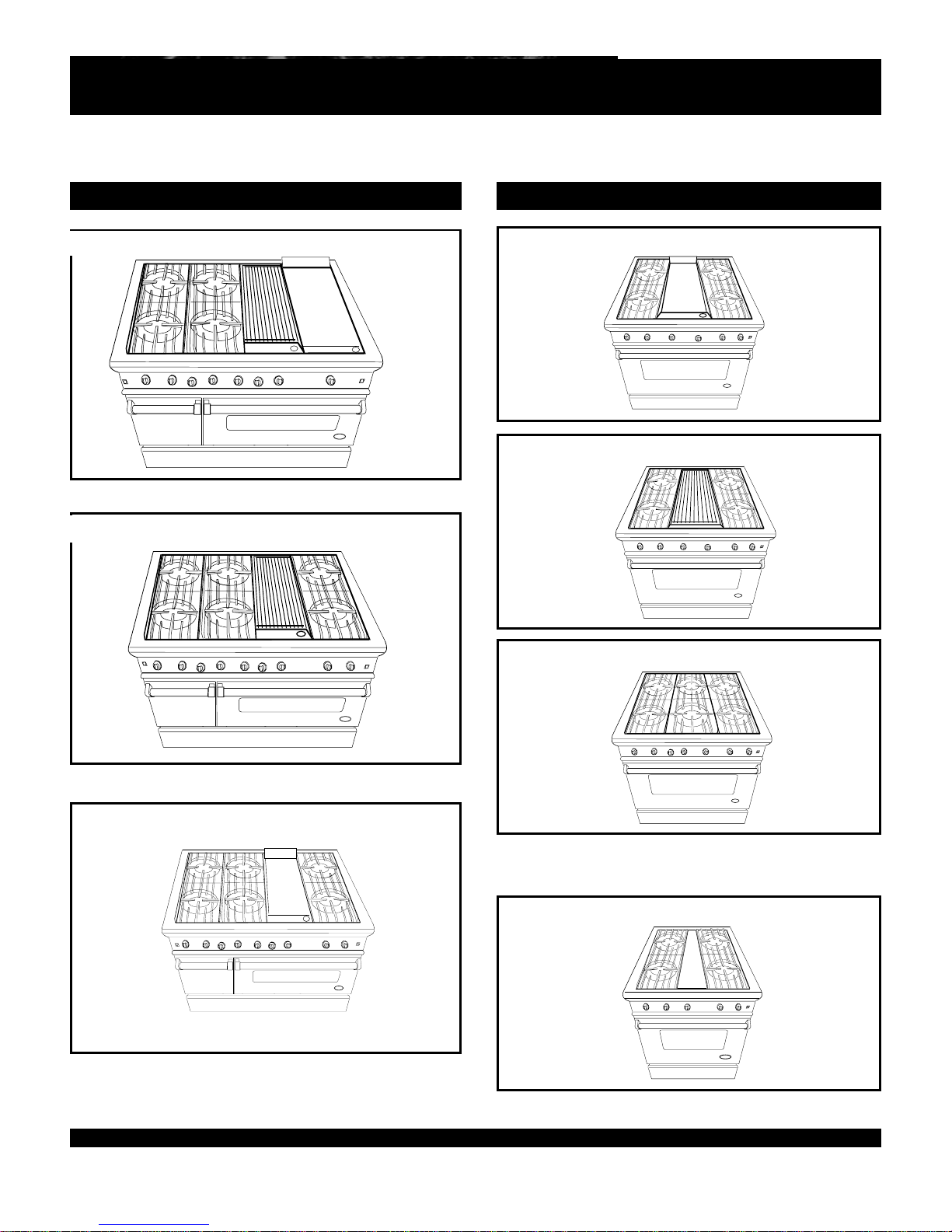

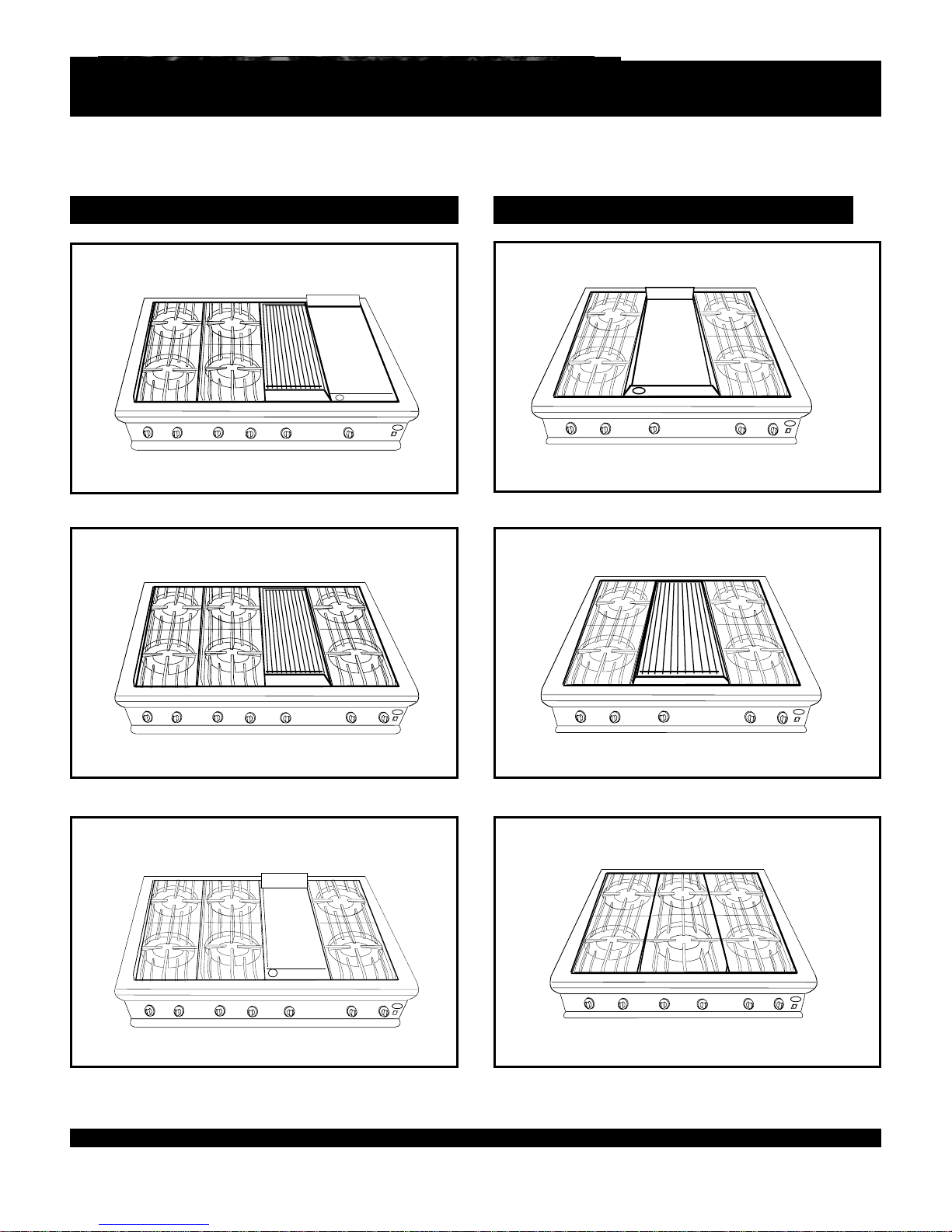

BODY PARTS ASSEMBLY