L.P.GAS REQUIREMENTS

Connection: 1/2" N.P.T. Minimum 5/8" dia.

flexline. Pressure:11" to 14"WC. A regulator

isrequiredattheL.P.sourceto provideamaxi-

mum of 14"WC. to the rangeregulator.

CONVERTING TO L.P.GAS

ile. If the Back Guard is in place, protect the

Back Guard during removal and installation of

the griddle to prevent scratching.

4. FOR GRILL UNIT

(MODEL RG484(:;L, GG, RG364GL)

To remove the grill assembly,begin by lifting off

the front trim adjacent to the greasegutter.

Beneath the trim, you'll find tWo screws,remove

them. Remove the Briquette Rack with briquettes

(if in place). Remove the (2) screwsholding the

grill igniter in place, then without removing the

wires, gently lay the igniter on the side. Use care

around the grill igniter, it is fragile. Remove the

tie wire securing thl~grill burner then remove the

grill burner. If the Back Guard is in place, pro-

tect the Back Guard during removal and installa-

tion of the grillpar'ts to prevent scratching.

GENERAL

5. OVEN

Empty the oven, remove the tWo oven rack side

supports, the four \:;,racketsand screwsholding the

oven bottom down" and then the oven bottom.

Remove the screwsecuringthe ovenburner, than

remove the burner. Replacethe oven burner ori-

fice with the red color coded orifice supplied

(wired to the tubin!~). Tighten until snug.

5A SMALL OVEN (48" MODELS ONLY)

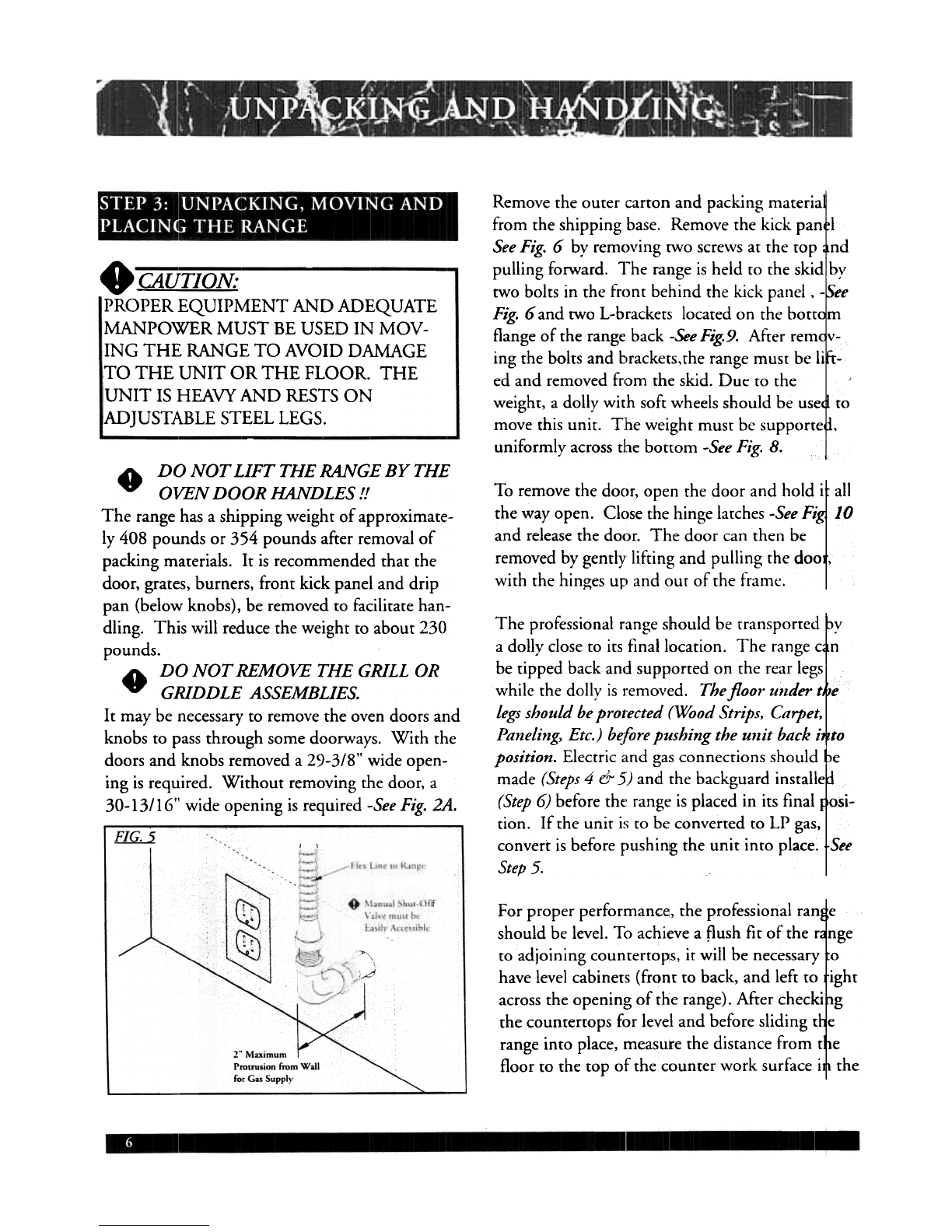

Converting a range from factory setnatural gasto

L.P.is bestdone prior to pushing the range in

placewhile the back of the range is accessible,

prior to installing the back guard. Begin by mak-

ing sure that the range is unplugged. Next

remove the open top burner gratesand the enam-

eled pans beneath the grates. Treat all parts with

careto avoid chipping the porcelain enamel. Lift

and remove all open top burners.

2. REGULATOR

-SeeFig. 16

The convertible regulator on this unit hasa nat-

ural gassetting of5.0" WC. for natural gasand

10" WC. for L.P., and canbe found in the left

rear corner of the burner box. Remove the slot-

ted plug in the regulator and turn it over so that

the side stamped "L.P." facesoutward, then rein-

sert ensuring it is properly locked in place.

3. FOR GRIDDLE UNIT

(MODEL RG484GD,GG, RG364GD) Empty the oven, remove the two side supports,

the four brackets, and screwsholding the oven

bottom down, and then the oyen bottom.

Remove the screw~;ecuringthe oven burner, then

the burner. Tighten the oven orifice hood down

until seatedagainstthe integral predrilled L.P.

pin. A 1/2" deep well socketis ideal for this pur-

pose.Do not over 1:ighten.

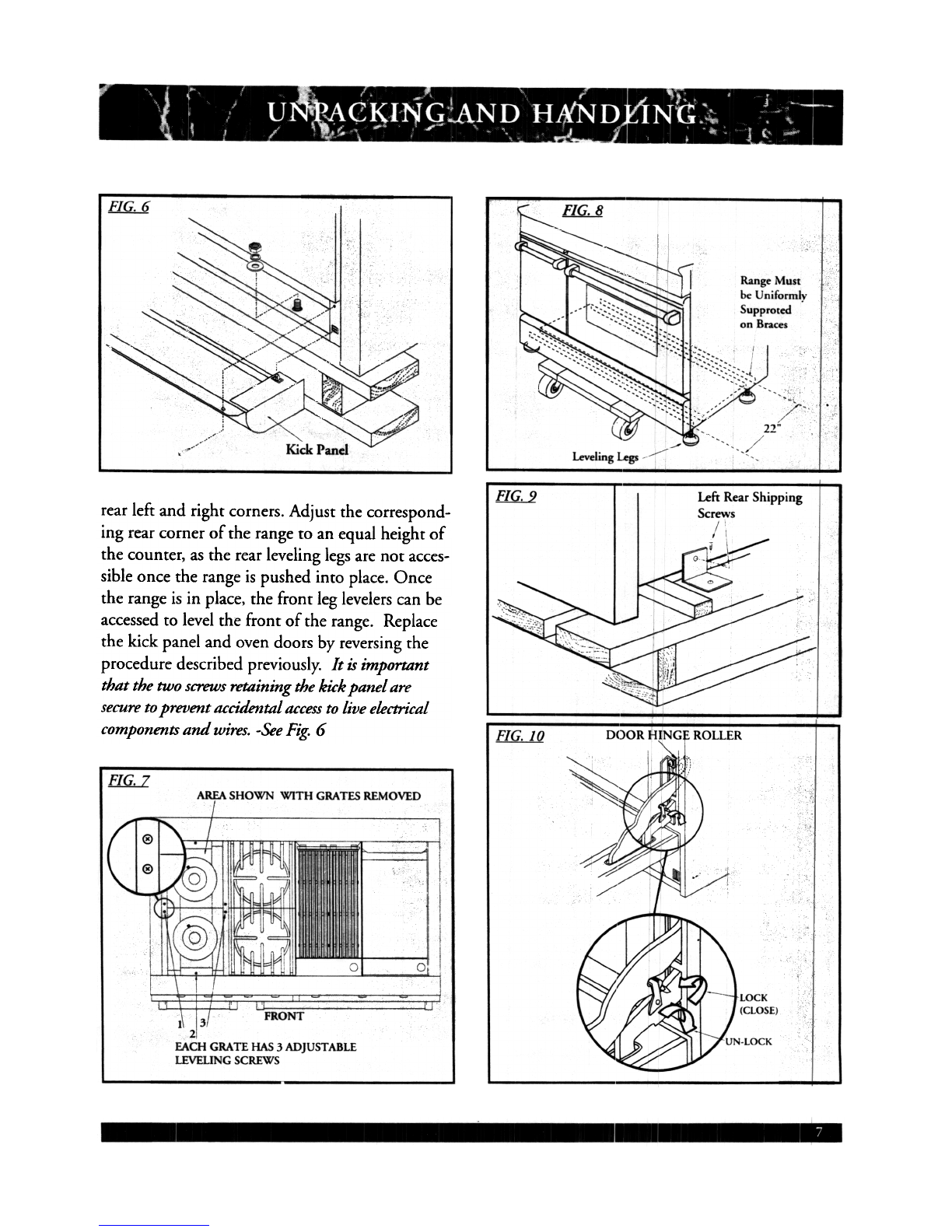

To remove the griddle assembly,first lift off the

front trim adjacent to the greasegutter. Beneath

the trim, you'll find tWo screws,-remove them.

Also remove the rearflue coverand remove the

center shipping screw.With thesescrews

removed, you can now lift off the griddle plate

assembly.Lift vertically and to the rearand

remove the griddle thermostat bulb from beneath

the plate by sliding it out (Do Not Tug Hard at

the Bulb or Capillary). Then remove the screw

securing the griddle burner and remove the burn-

er. Use carearound the griddle igniter, it is frag-

OVEN BROILER6

Remove the servicl~panel in the rear of the