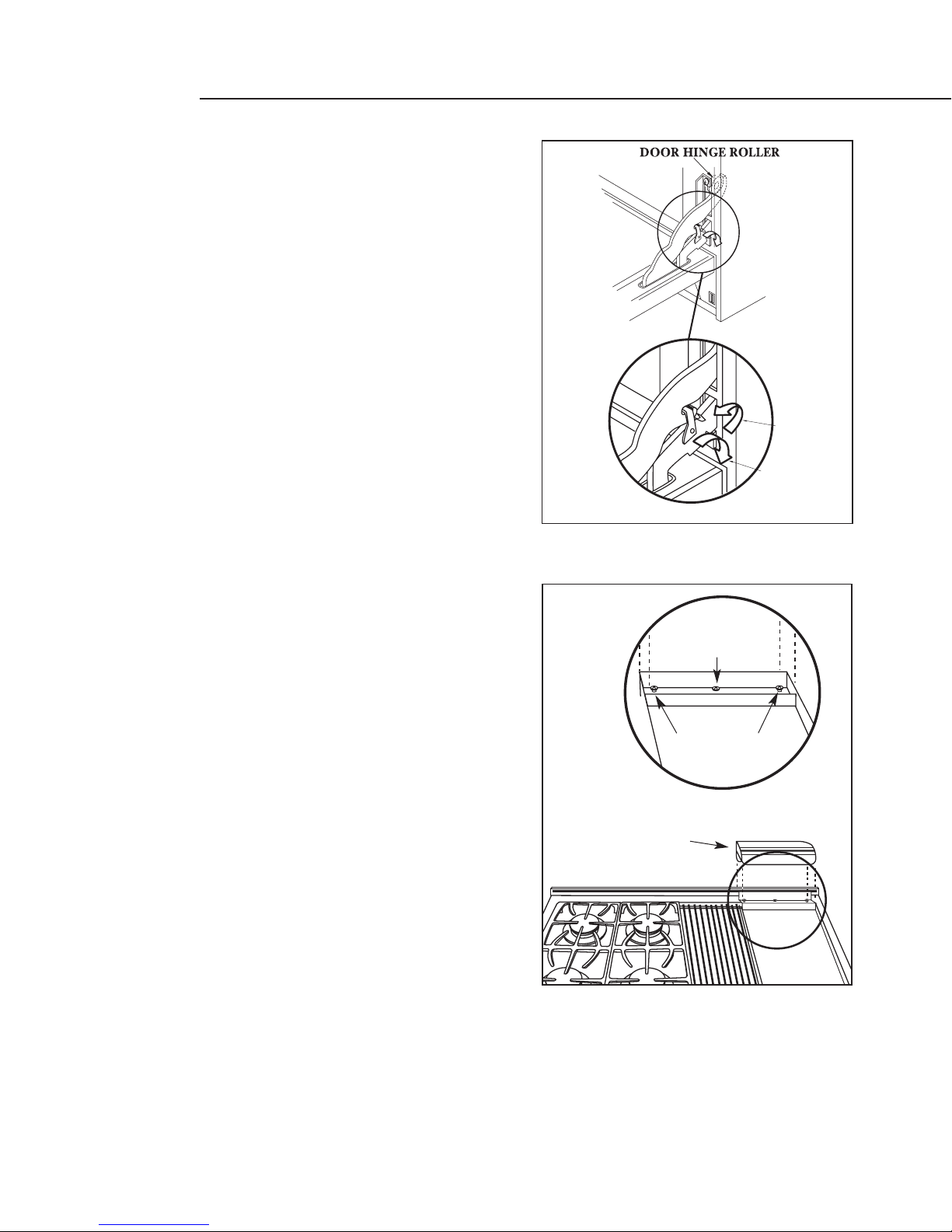

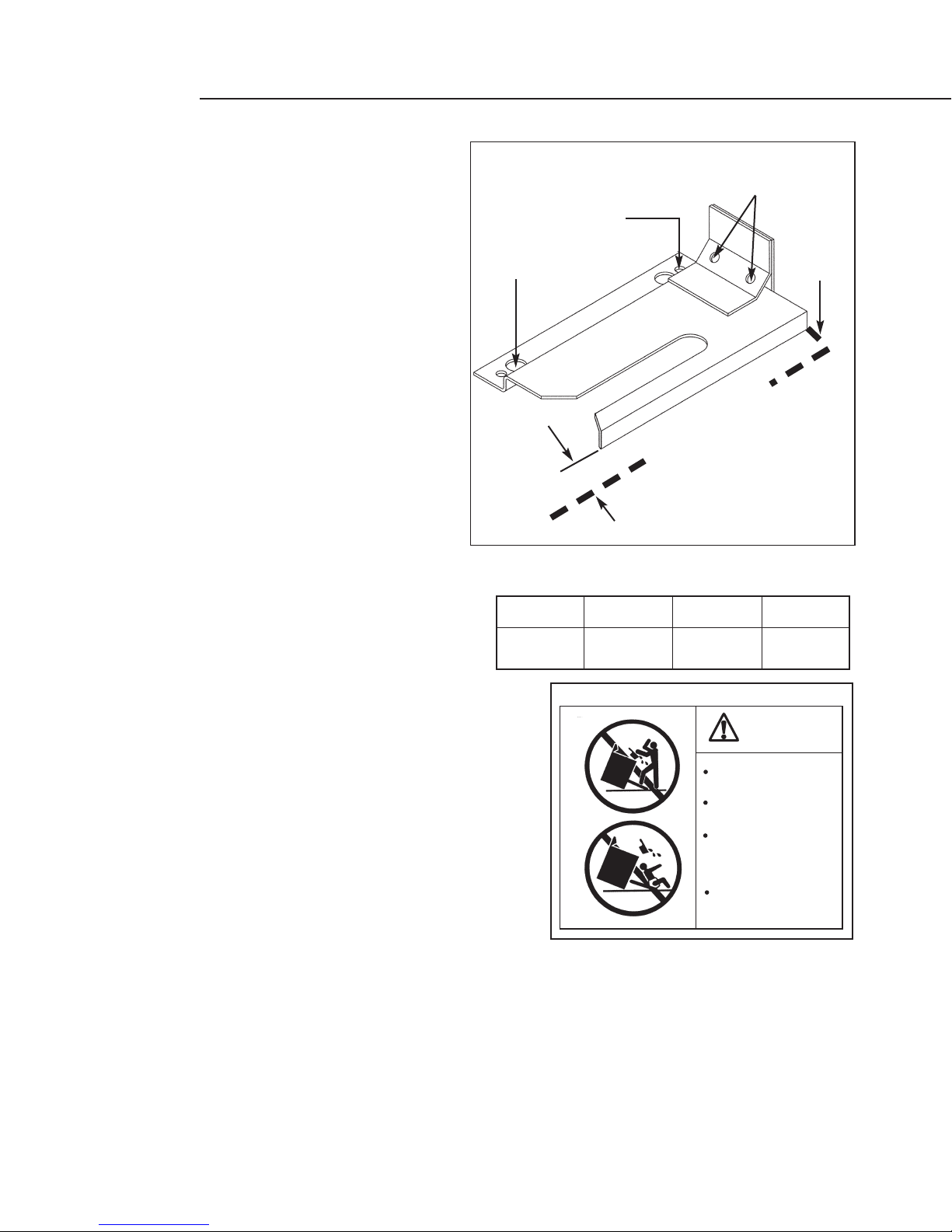

INSTALLING ANTI - TIP DEVICE

9

All ranges must have an anti-tip device

correctly installed as per the following

instructions. If you pull the range out

from the wall for any reason, make sure

that the device is properly engaged

when you push the range back against

the wall. If it is not, there is a possible

risk of the range tipping over and

causing injury if you or a child stand, sit

or lean on an open oven door.

INCLUDED PARTS:

Included with this kit are:

(4) #10 x 2”wood screws,

(1) Anti-tip bracket, and (1) Installation

Instructions.

INSTALLING THE KIT:

Instructions are provided for wood and

cement floors. Any other type of

construction may require special instal-

lation techniques as deemed necessary

to provide adequate fastening of the Anti-

tip bracket to the floor and wall. The use of

this bracket does not preclude tipping of

the range when not properly installed.

WOOD CONSTRUCTION:

Place the bracket against the back wall,into the right

rear corner where the range is to be located. Leave a

gap between the wall (or side of range) and the

bracket (see fig. 6). Drill (2) 1/8”diameter pilot holes

in the center of the small holes. A nail or awl may be

used if a drill is not available. Fasten the bracket

securely to the floor and wall.

CONCRETE OR CEMENT CONSTRUCTION:

Hardware Required:

(2) sleeve anchors, lag bolts, and washers (not

provided). Locate the bracket as described above.

Drill the recommended size holes for the hardware.

Install the sleeve anchors into the holes and then install the lag bolts through the bracket. The bolts

must be properly tightened as recommended for the hardware. Fasten the bracket securely to the

floor and wall.

ONCE INSTALLED:

Complete the range installation per the instructions provided with the product. Check for proper

installation of the range and Anti-tip device by grasping the back of the unit and carefully attempt to

tilt the range forward.

A= 1/4”

Model

Series RDS-305

1/2”

RDS-48

5/8”

RDS-36