DCSENG S LT Series User manual

PIPE(TUBE) CUTTER Of Best Technology SAFETY PRECAUTIONS

Thanks for choosing the S-Cutter. Make sure that you carefully read and fully understand the Manual to use the device correctly and keep yourself and your properties safe.

Manual

( -100LT / -150LT / -200LT)

PIPE(TUBE) CUTTER Of Best Technology

CONTENTS

1. SAFETY PRECAUTIONS032. Must-Follow Rules063. Instruction Before Use084. How to Use S-LT Series105. Quality Warranty28

S-Cutter 301Keep workplace clean and well-lit at all times.An untidy or dark workplace may cause accidents.02Consider your work environment.Do not let it wet.Do not use in humid place.Install bright lighting in the work place.Do not use the machine near the flammable liquids or gases.03Keep yourself safe from electric shock.Do not touch the grounded parts(i.e. Water pipes, heaters, ranges, refrigerators).Ensure the grounding wire is properly connected to the ground and use it.04Keep out any unauthorized persons.Do not let the outsiders contact with tool or extension cord.Do not let visitors access to the work area.05Keep the product safe.Cut off the power when the tool is not in use, and keep it where it is notaccessible to outsiders.06Do NOT operate at overload.More efficient and safe operations are enabled within a permitted power range. 07Always use the proper tools.Use the standard parts and components provided by the head office. Do not use the tool for purposes other than their intended use or in

places

away from the working range. 08Dress properly.Do not wear loose clothing or jewelry. You may be hurt by the moving parts of the tool.It is recommended to wear non-slip footwear for outdoor work.09Be sure to wear safety glasses and protective gloves.Wearing safety gear such as goggles and gloves can reduce the risk of bodily injury.Scattering chips can do serious damage to the eyes or cause a burn.SAFETY PRECAUTIONS

PIPE(TUBE) CUTTER Of Best Technology 4 www.s-cutter.co.kr10Do NOT abuse the cord.Do not drag the product by pulling the electric cord.Do not unplug the cable by pulling the cord itself. Keep the cord safe from heat, oil and sharp edges.11Secure the workpiece.Secure the workpiece by using a lock.12Pay attention to your work.Please note the fall and cut piping pinch.13Manage the product carefully.Keep the product clean and efficient for safe operation.Manage with the proper lubricant, apply a corrosion inhibitor to prevent corrosion when not in use for a long time.When replacing the management regulations and tools, comply with the instructions.Check plugs and wires regularly and contact experts to repair the damage.Check connection cables regularly and replace damaged parts.Keep the control board dry and avoid getting oil or grease.14Remove from power source.When not in use, checked or replaced, turn off the switch.15Please check before operation.Make sure that the tool(blade) has been tightened, blade direction and

the

direction of rotation.Make sure that the piping is tightened.Make sure the piping direction of rotation(Check reverse rotation switch Forward(CW)).Make sure that the cutting, chamfered speed and rotational speed.16Be careful of operating the machine accidently.Do not carry when the power is connected.When turning on, make sure that the operation switch is off.17Electrical cable for connection outdoors.Use the authorized extension poser cord with a qualifying mark.Do not connect the currently used cable to other equipment. Have a separate circuit breaker.

S-Cutter 518Be cautious all the time.Observe work process and process accordingly.Do not use this product if the concentration is blurred,Do not operate by force the cutting speed and rotational speed.19Make sure that there is no damage on the product.Check the safety device and examine thoroughly that the mildly

damaged

parts now function normally before resuming the use of the tool. Check if the Product got stuck, or the parts are damaged. The complete operation of the tool is not guaranteed unless all parts

are

normally assembled, and all requirements are met. Unless otherwise stated in the Manual, the damaged safety device or

parts

are repaired or replaced at the customer service center. 20Caution!For your safety, use the parts and tools indicated on the manual or recommended by the manufacturer.Use of other parts or additional tools that are not recommended on

the

manual and catalog may occur accidents.21Repair request to the expertsFor your safety, use the tools and accessories specified in the Manual

or

recommended by the distributor. The use of other tools and accessories

not

mentioned in the Manual or catalogue may result in bodily injury.

PIPE(TUBE) CUTTER Of Best Technology 6 www.s-cutter.co.krThe instructions in this user manual contains information that is important to the safe use of this product.Not following these instructions can cause death, serious injury, and massive property damage.For safety, the instructions are divided into ‘WARNING’ and ‘CAUTION’ depending on degree of risk, and the details are as follows:Symbol

Description

WARNING※ There is a high possibility of serious injury or death when the instructions are violated.CAUTION※ There is a possibility of serious injury or death when the instructions are violated.※ There is a possibility of device failure or degradation when the instructions are violated.Precautions were recorded to prevent an accident that might easily occur while

using

or handling the Product and execute operations safely. The safety warnings and cautions cannot cover all conditions or situations that

can

take place during operation. Therefore, remain focused during operation or

storing.

Read and fully understand the Manual to prevent an accident. Special safety precautions‘WARNING’ or ‘CAUTION’ mark makes a user stay alert because there is a possibility of hazards under particular conditions. Must-Follow Rules

S-Cutter 7● Make sure the power is connected to the ground. Leakage current due to electric shock may occur if the product is not connected to the grounding.● Do NOT pour water or cutting fluid. Due to water or other liquids on the electric motor, electric shock, or death may occur. Use cutting fluid until tools are slightly wet.● Do NOT use tools in wet conditions or rain. Serious injury or death may occur by electric shock.● Avoid fingers, hands or clothes to touch the blade while operating. When fingers, hands, or other body parts stuck in the machine, it may occur serious injury. ● Avoid fingers, hands or other body parts to touch where pipe and roller meet while operating. When fingers, hands, or other body parts stuck in the machine, it may occur serious injury.● Before supplying power to the product, be sure to turn off the operation switch. Plugging in with the switch on may cause sudden rotation and occur serious injury.● Do NOT let any part of body to touch the compression device of product. Serious injury may result.● Make sure to wear safety equipment. Chips generated during the operation may scatter and cause serious eye injury.● Be sure to apply our supplied product and cutting blades only for their intended uses. Use only products certified for their quality (state-certified or higher-quality) in the event there is difficulty in procuring our products and accessories. If violated, performance degradation and serious injury may occur.● Do NOT leave the product rotated. workers may result in bodily injury.● Place cutting chips safely. When cutting chips meet flammable substances, it may cause fire and burns.● Wear gloves and long-sleeved clothes to wear. Scattering chips can cause burns.● Use Extension cord as short as possible. If too long or too thin, it may cause overload.● Operation before commissioning. Check the machine before use for safety.WARNINGCAUTION

PIPE(TUBE) CUTTER Of Best Technology 8 www.s-cutter.co.kr1.Check the electric leakage breakerMake sure the system is powered on the circuit breaker is installed.Check if an electric leakage breaker(ELB) with rated capacity is installed in all electric units.Make sure that the ground wire is connected to the powered system.2.Extension power cordIf an electrical outlet is not nearby, use an extension power cord. Choose a proper one in terms of length and thickness, considering the flow of electricity. If it is too long or thin, voltage increases, causing overload. Use a short power cord as much as possible. ※ Specification of the extension cord has to be at least ×

(250V-10A).3.Check the powerCheck the power supply stated on the nameplate and use the proper power source. 4.Check the switch is offIf an electric power cord is damaged, it must be repaired or replaced with a new one immediately. Unaware that the switch is turned on, the number of accidents due to a sudden rotation of the plug is inserted in the power being.Instruction Before Use

S-Cutter 9

100LT / 150LT / 200LT

The most cost-effective orbital cutting machine!The world best convenience and work speed!Equipment capacity : 1/4 – 8inch (Pipe O.D 6mm - 220mm)

PIPE(TUBE) CUTTER Of Best Technology 10 www.s-cutter.co.krHow to Use S-LT Series How to use S-LT Series Instructions before use Please read about how to use manual provided by the headquarter or suppliers.Users must be educated before use.Make sure to remove the power when changing the cutting or beveling blade.Be sure to use consumables(such as cutting and beveling blades) for this equipment that are provided by us.Make sure to connect the grounding, and confirm the voltage.Make sure to wear protective equipment such as protective glasses before work.Beware of burns when using beveling tools which is extremely hot after operation.Beware of burns by gearbox in case of prolonged use.

INDEX 01.Name of the parts and controls 02.Mounting of the cutting and beveling blade 03.Pipe setting04.How to cut the pipe05.How to bevel the pipe06.How to use the handle clutch07.Adjustment of the cutting and rotating speed08.Emergency STOP / RESET switch09.Maintenance and inspection10.Product specifications

S-Cutter 11

1.

Name of the parts and controls● Name of the partsNONameDescription1MachinePipe cutting and beveling machine2S-LT Series_MTMachine table3S-LT Series_RSPipe transfer device4S-LT Series_VS Long-pipe support and transfer device(adjustable)5Fixing leverPositioning bolt according to the diameter6ToolboxBox for storing tools

PIPE(TUBE) CUTTER Of Best Technology 12 www.s-cutter.co.kr● Name of the function partsNONameNOName1Vise jaw9Cutting handle gear box2Vise handle10Cutting head fixing nut3Cutting head11Folding bracket4Cutting motor12Rotating handle lock5Motor control part13Beveling stopper6Cutting handling14Rotating handle7Cutting handle fixing hole15Rotating oil nipple8Clutch16Vise oil nipple ● Name of the controls NONameFunction1On/Off switchON/OFF2Run/Stop switchRun / Stop / Reset3Speed adjusting switchCutting speed adjustment4Power cablePower supply cable5Fuse5Ø-20mm, 250V-8A

S-Cutter 132.Mounting of the cutting and beveling blade① To push the cutting head aside, loosen the cutting head fixing nut (A), move it in the arrow direction, hold the head with hand, and turn it in the folding bracket

direction

(B).② Turn it until the head moves to about 90°, when a clicking sound is heard, so as

to

make sure that the cutting handle gear box remains firmly fixed.③ Check the arrow sign on the cutting blade and then put into the cutting shaft; Then, mount the fixing pin of the washer with the hole of the cutting shaft and tighten with the nut(firmly with a 22mm spanner).④ Hold the cutting head and return it to its original position; Then, tighten the cutting head fixing nut (A) using the 22mm spanner(for S-100LT, T-wrench(6mm) is used).Right-side nutWasherLeft-side nutCutting bladeWasher

PIPE(TUBE) CUTTER Of Best Technology 14 www.s-cutter.co.kr● When beveling, mount the beveling blade on the shaft and tighten with the

nut(firmly

with a 22mm spanner). - Do not use cutting washer2-1.Fixing the brush1) Fix the stainless brush to be close to the cutting blade and then firmly fixed with

a

wing bolt (ⓐ) on the outside and a knurled bolt (ⓑ) on the inside as shown in

the

figure below. It is recommended to be used for improvement of the cutting quality and for extension of the saw blade’s lifespan. For outer sideFor inner sideFor outer sideFor inner side

S-Cutter 153.Pipe setting3-1.S-LT Series_VS : Height adjustment of the Pipe1) If the pipe is long, extend a vise support device(S-LT Series_VS) mounted at the back of the table with aligning to pipe length as shown in the figure. 2) A standard table(S-LT Series_MT) is applicable to a maximum pipe length of 4m; If the pipe length is 6m, use one or more auxiliary supports as indicated in the figure. 3) A standard table(S-LT Series_MT) is designed for lightweight load; Therefore, one or more auxiliary supports fabricated on the site should be used

when

it is applied to heavy pipes. 4) Adjust the scale on the pole of the S-LT Series_VS to the top part of the

machine

table, as shown in the figure, according to the size of a pipe to be processed.

Auxiliary

support

PIPE(TUBE) CUTTER Of Best Technology 16 www.s-cutter.co.kr3-2.S-LT Series_RS : Pipe transfer device1) S-LT Series_RS, a pipe feeder, is designed to fix a pipe to the machine and

then

adjust its height(up and down) to bring the urethane into close contact with

the

bottom of the pipe and turn the handle to feed the pipe forward or backward

to

situate it to a desired cutting position.2) The S-LT Series_RS can be adjusted depending on the outside diameter of a pipe; However, no additional manipulation is required when it is applied repeatedly to pipes of the same diameter.

4.How to cut the pipe4-1.How to use the stopper for cutting1) Rotate the stopper bolt left or right until the stopper is aligned with the

cutting

position of the cutting blade, as shown in the figure(Memory programmable).ForwardBackwardDescentAscentFixing nutstopperBeveling bladeCutting blade stopper stopper bolt

S-Cutter 172) Align the side of the preset stopper with the line that is marked on a pipe for its cutting position(memory function), as shown in the figure below; and, it must

be

restored to its original position so it is not interrupted by pipe when it is unused.4-2.Decision of the blade position1) Turn the rotating handle lock slightly left or right to tighten the inner gear(in place), as shown in the figure, and fix a pipe temporarily until its section to be cut comes into contact with the blade. Default position of the stopperCutting bladeWhen it approaches

PIPE(TUBE) CUTTER Of Best Technology 18 www.s-cutter.co.kr2) Turn and place the cutting handle in the cutting handle fixing hole, as shown in

the

left figure, and hold and move the cutting head(motor) up and down while pulling the cutting handle clutch, as shown in the right figure.

3) Move the cutting head(electric motor) up and down, as shown in the figure on the left, and adjust it to have the cutting blade maintain an appropriate depth value before the cutting handle clutch is released, as shown in the right-side figure(when the head returns automatically).Cutting handledownup(pull clutch forward in order to move cutting headWhen clutch is pulled

S-Cutter 194-3.How to cut the pipe1) Separate the cutting handle from the fixing hole making sure that the cutting

blade

should have an adequate distance from the pipe.2) Adjust the cutting position of the pipe(refer to Section 4.2) and turn the vise handle to fix it firmly.3) Turn on the power switch mounted on the cutting head(motor) and rotate the cutting handle slowly into the cutting handle fixing hole(downward) so as for the cutting

blade

to penetrate the pipe, as shown in the right figure(Placing the cutting handle in its fixing hole allows the cutting blade to come to the cutting position, as indicated in Section 4.2). Cutting handleCutting headCutting handle

PIPE(TUBE) CUTTER Of Best Technology 20 www.s-cutter.co.kr4) Move the rotating handle lock upward to release it, as shown in the figure below,

and

then turn the rotating handle in the direction as shown in the figure on the right

to

begin with the cutting work(be noted that the rotating handle turns only to one direction).5) Pay much attention not to let the cut portion of the pipe fall down when the cutting is over.6) Separate the cutting handle from the fixing hole after the work is finished so that

the

cutting blade keeps distance adequately from the cut section of the pipe. *Note) When the cutting handle enters(at the beginning of cutting work/subsequent penetrating work), repeat the penetration cycle several times(repeated cycles of “enter-retract-enter”).Rotating handledesigned to rotate in one direction

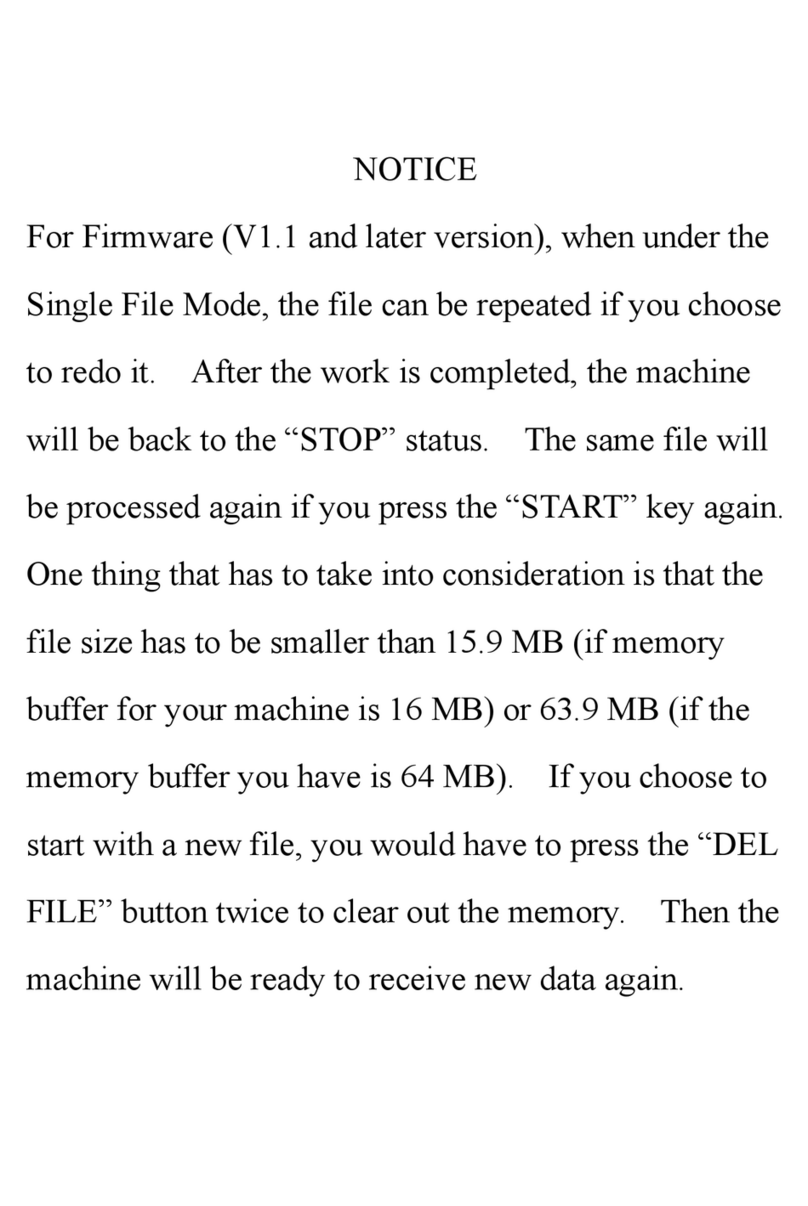

This manual suits for next models

3

Table of contents

Other DCSENG Cutter manuals