DD Compound Vac Checker User manual

Vac Checkerâ

Digital Vacuum Gauge

Instruction manual

Content

Content

1Safety and waste disposal .......................................................................... 3

1.1 About this document .............................................................................. 3

1.2 Safety .................................................................................................... 3

1.3 Waste disposal ...................................................................................... 4

2Technical data.............................................................................................. 5

3Description of the instrument..................................................................... 7

3.1 Use ........................................................................................................ 7

3.2 Instrument overview............................................................................... 7

3.3 Displays overview .................................................................................. 8

3.4 Control keys overview............................................................................ 9

4Operation.................................................................................................... 10

4.1 Connecting........................................................................................... 10

4.2 Switching instrument on and off........................................................... 10

4.3 Switching background illumination on and off ...................................... 10

4.4 Setting units and AutoOff..................................................................... 11

4.5 Displaying temperature values............................................................. 14

4.6 Field calibration.................................................................................... 14

4.7 Calibration with reference vacuum gauge............................................ 15

5Maintenance............................................................................................... 16

5.1 Changing batteries............................................................................... 16

5.2 Cleaning the instrument....................................................................... 16

6Tips and assistance .................................................................................. 18

6.1 Questions and answers ....................................................................... 18

1Safety and waste disposal

3

1 Safety and waste disposal

1.1 About this document

·The instruction manual is an integral part of the instrument.

·Keep this document throughout the entire operating life of the instrument.

·Always use the complete original instruction manual.

·Please read this instruction manual through carefully and familiarise yourself

with the product before putting it to use.

·Pay particular attention to the safety instructions and warning advice in order

to prevent injury and damage to the product.

1.2 Safety

General safety instructions

·Only operate this instrument in the proper manner, for its intended purpose

and within the parameters specified in the technical data.

·Do not apply any force to open the instrument.

·Do not operate the instrument if there are signs of damage at the housing,

mains unit or connected cables.

·Always comply with the locally valid safety regulations when carrying out

measurements. Dangers may also arise from objects to be measured or the

measuring environment.

·Do not store the product together with solvents.

·Do not use any desiccants.

·Only perform maintenance and repair work on this instrument that is

described in this documentation. Follow the prescribed steps exactly.

·Use only original spare parts from Testo.

1Safety and waste disposal

4

Batteries

·Improper use of batteries may cause the batteries to be destroyed, or lead to

injury due to current surges, fire or escaping chemicals.

·Only use the batteries supplied in accordance with the instructions in the

instruction manual.

·Do not short-circuit the batteries.

·Do not take the batteries apart and do not modify them.

·Do not expose the batteries to heavy impacts, water, fire or temperatures in

excess of 60 °C.

·Do not store the batteries in the proximity of metal objects.

·Do not use any leaky or damaged batteries.

·In the event of contact with battery acid: rinse affected areas thoroughly with

water, and if necessary consult a doctor.

·Take batteries out of the instrument immediately if they are not functioning

properly or if they show signs of overheating.

·Remove all batteries from the instrument if it is to remain unused for a longer

period.

Warnings

Always pay attention to any information denoted by the following warnings.

Implement the precautionary measures specified!

Display

Explanation

WARNING

Indicates possible serious injury.

CAUTION

Indicates possible minor injury.

ATTENTION

Indicates possible damage to equipment.

1.3 Waste disposal

·Dispose of faulty rechargeable batteries and spent batteries in accordance

with the valid legal specifications.

·At the end of its useful life, dispose of the instrument via separate collection

for electro- and electronic devices. Please observe local regulations

concerning waste disposal. Or alternatively return the product to

DD-Compound for disposal.

2Technical data

5

2 Technical data

Feature

Values

Absolute pressure sensor

(absolute)

max. 6 bar (87 psi)

ATTENTION

Pressure exceeded.

Destruction of the absolute pressure

sensor!

-

Do not exceed the maximum value.

Vacuum measuring range

1100 - 0 mbar / 825080 - 0 micron

Sensor overload (relative)

5 bar / 72 psi

Vacuum resolution

0.01 hPa / 10 micron

Vacuum accuracy

(at 22

°C, after field calibration,

confidence level

95%)

- 0 to 1.33 hPa / 0 to 1000 micron: up to

±10 micron

-

0 to 200 hPa / 0 to 150000 micron:

±0.3% FS = ±0.6 hPa

-

200 to 1100 hPa / 150000 to 825080

micron:

±0.3% FS = ±3.3 hPa

Operating temperature

-20 to 50 °C / -4 to 122 °F

Storage temperature

-20 to 50 °C / -4 to 122 °F

Temperature measuring range

-20 to 50 °C / -4 to 122 °F

Temperature resolution

0.1 °C / 0.1 °F

Battery life

2400 h (2x AA) (approx. 130 h with background

illumination activated)

Protection class

IP 42

Parameter

mmHG, Torr, mbar, hPa, micron, inH2O, inHg.

Pa

Measuring cycle

0.5 sec

Sensor

1× absolute pressure sensor

Connections

- 2× 7/16" UNF

- 1x MiniDIN

Warranty

2 years

2Technical data

6

Setting values alarm treshold

Unit

Setting range

Resolution

mbar / hPa

0 - 7,5

0,05

micron

0 - 7500

50

3Description of the instrument

7

3 Description of the instrument

3.1 Use

The Vac Checkerâis a digital vacuum gauge for the precise measurement of

extremely small pressures in the vacuum range. This allows you to monitor the

evacuation (usually during commissioning) of refrigeration systems and heat

pumps.

With the Vac Checkerâ, you can therefore measure the current pressure in a

refrigeration system, and thus gather information about the degree of

dehumidification and the removal of foreign matter (oils, foreign gases, etc.).

A vacuum gauge is always used in conjunction with a vacuum pump (generates

the vacuum). A manifold (analogue or digital) is also often used in order to

obtain controlled access to the refrigeration system.

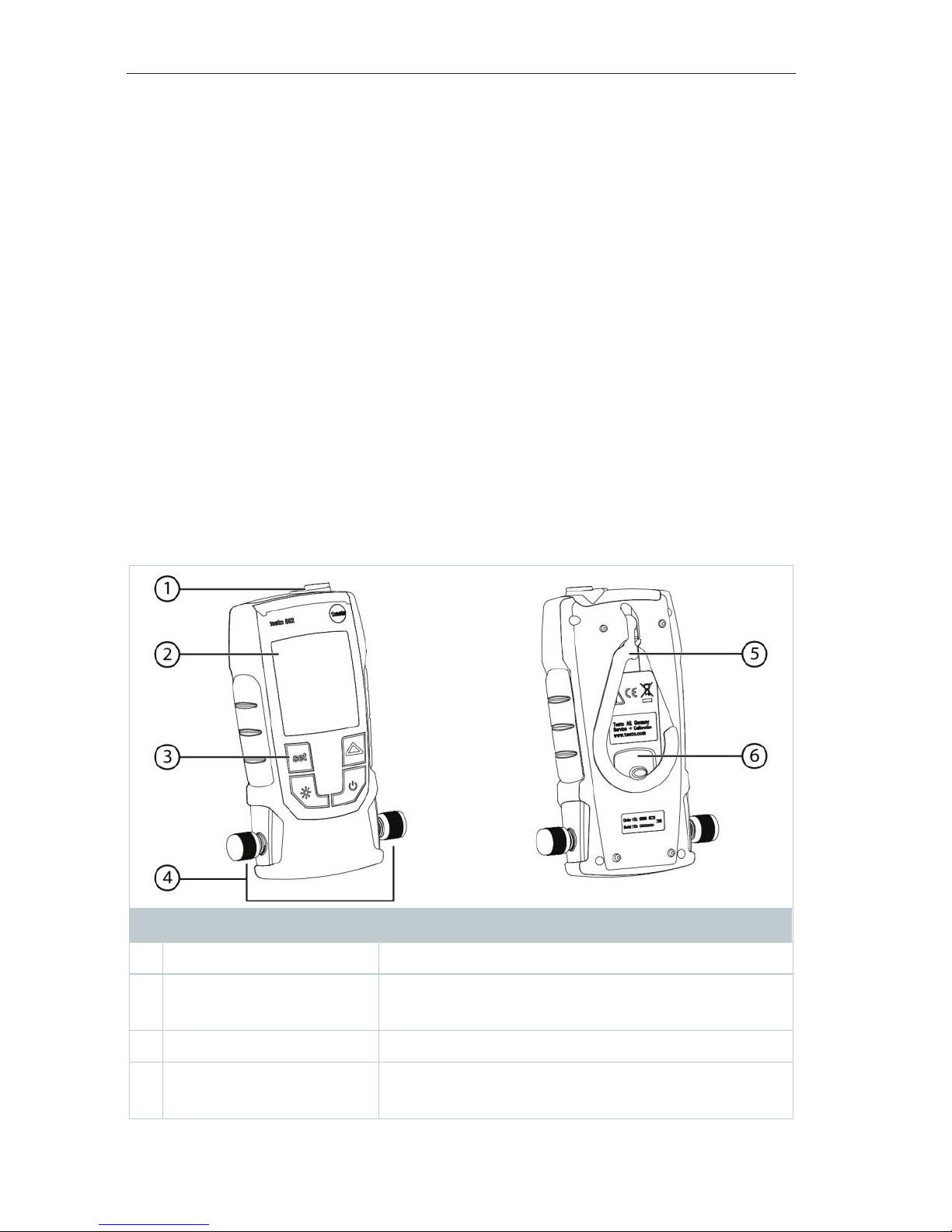

3.2 Instrument overview

Element

Function

1

MiniDIN probe socket

Cable connection for connecting to the testo 570.

2

Display

Displays instrument status icons, measuring units

and measuring values.

3

Control keys

Instrument operation.

4

Connections 7/16" UNF,

brass

Connection of refrigerant hoses, vacuum pump,

manifold

s, etc.

3Description of the instrument

8

5

Hook

Suspension device

6

Battery compartment

Contains two AA batteries.

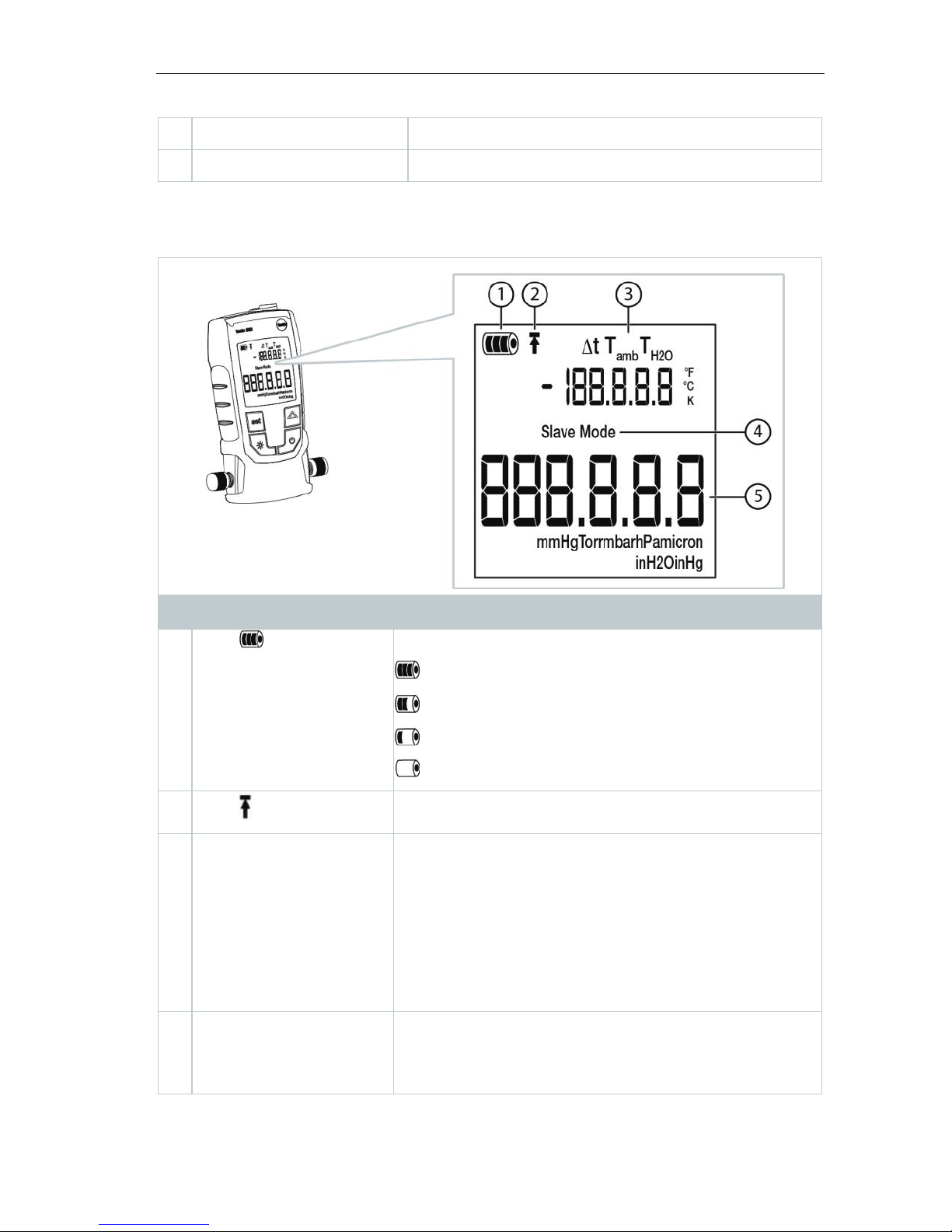

3.3 Displays overview

Element

Function

1

Icon [ ]

Displays the remaining battery capacity.

>75%

>50%

>25%

<10%

2

Icon [

]

An alarm threshold is set.

3

Temperature display

- selected, currently measured temperature

-

Measurement parameter:

TH2O = evaporation temperature of water

Tamb = ambient temperature

Dt = temperature difference between

evaporation temperature of water and ambient

temperature

- unit set (°C, °F)

4

Slave Mode

Appears when the Vac Checkerâ, is connected to

a testo 570 via a connecting cable and the

testo

570 is in Evacuation mode.

3Description of the instrument

9

5

Pressure display

Displays the currently measured pressure, the

measurement parameter and the unit set (mmHG,

Torr, mbar, hPa, micron, inH2O, inHg

).

3.4 Control keys overview

Element

Function

1

- Switches to the settings.

- Switches between the set-up options.

2

Switches the display illumination on or off.

3

Switches the instrument on or off.

4

- Switches between the temperature displays.

- Navigates in the Set menu.

4Operation

10

4 Operation

4.1 Connecting

Always use refrigerant hoses that are specifically intended for

evacuations.

1

- Remove sealing caps.

- Connect the

Vac Checkerâ,

to the

circuit.

4.2 Switching instrument on and off

1

- Press

.

ê

The instrument switches on or off.

4.3 Switching background illumination on

and off

1

- Switch the instrument on.

- Press

.

ê

The background illumination switches

on or off.

4Operation

11

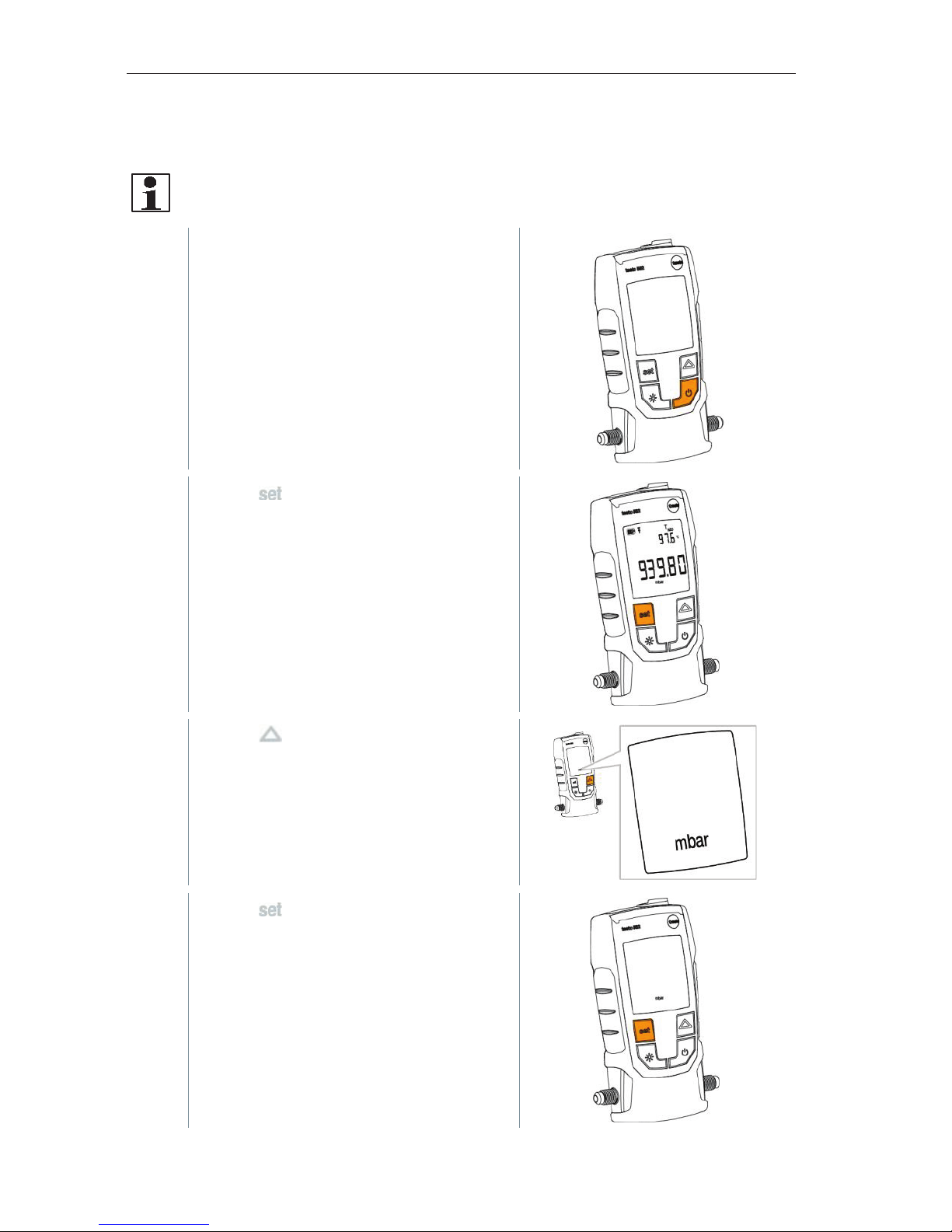

4.4 Setting units and AutoOff

The set-up menu must always be completely navigated through, even if

only one parameter needs to be changed.

1

- Switch the instrument on.

2

- Press to change settings.

3

- Press to set the pressure unit

required.

4

- Press .

ê

The unit is set.

ê

The display shows the temperature

unit.

4Operation

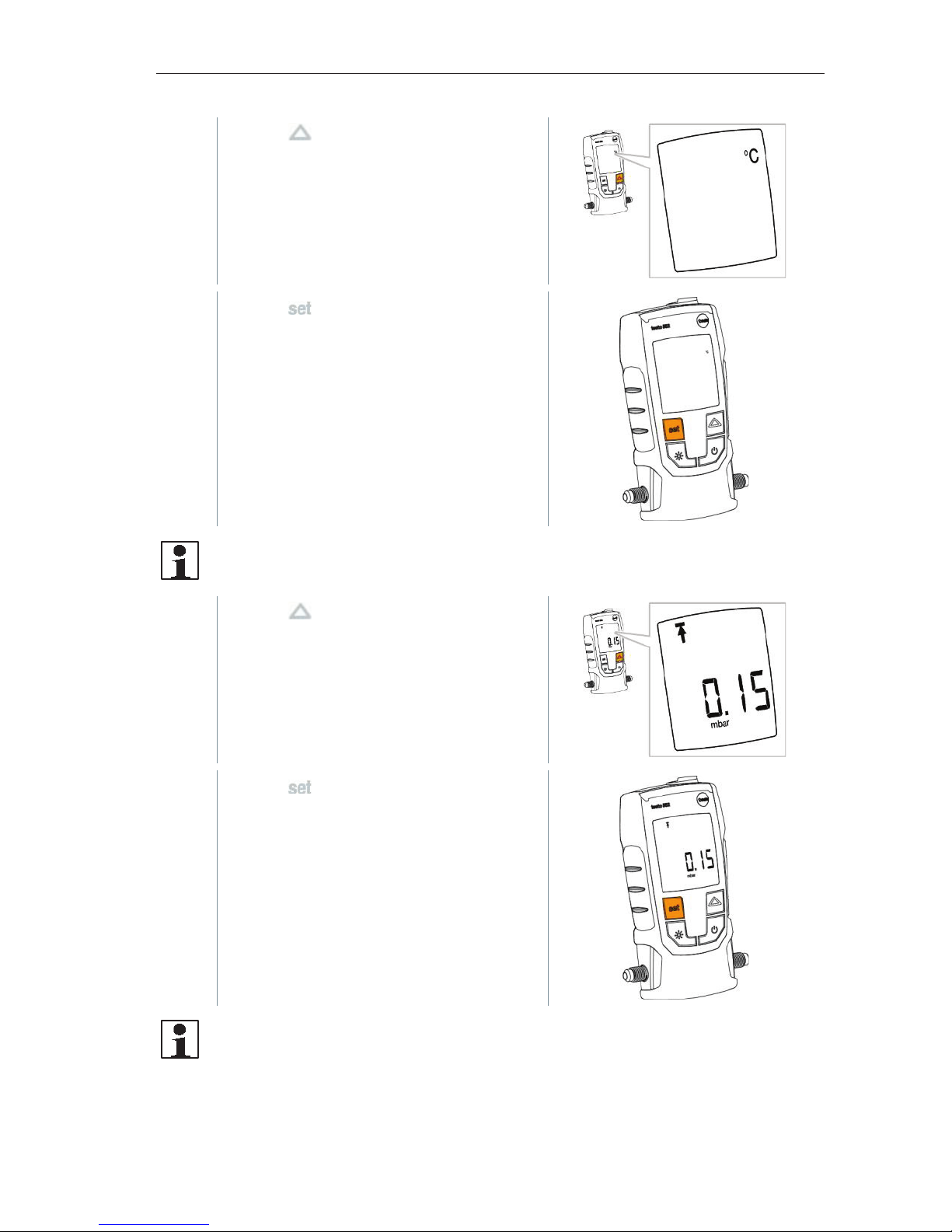

12

5

- Press to set the temperature unit

required.

6

- Press .

ê

The temperature unit is set.

ê

The display shows the setting for the

alarm threshold.

Adjusting the alarm threshold causes an alarm to be triggered when the

set value is exceeded.

7

- Press to set the alarm threshold.

8

- Press .

ê

The alarm threshold is set.

ê

The display shows the AutoOff setting.

If AutoOff is activated, the instrument switches off after 2 hours in which

no buttons are pressed.

4Operation

13

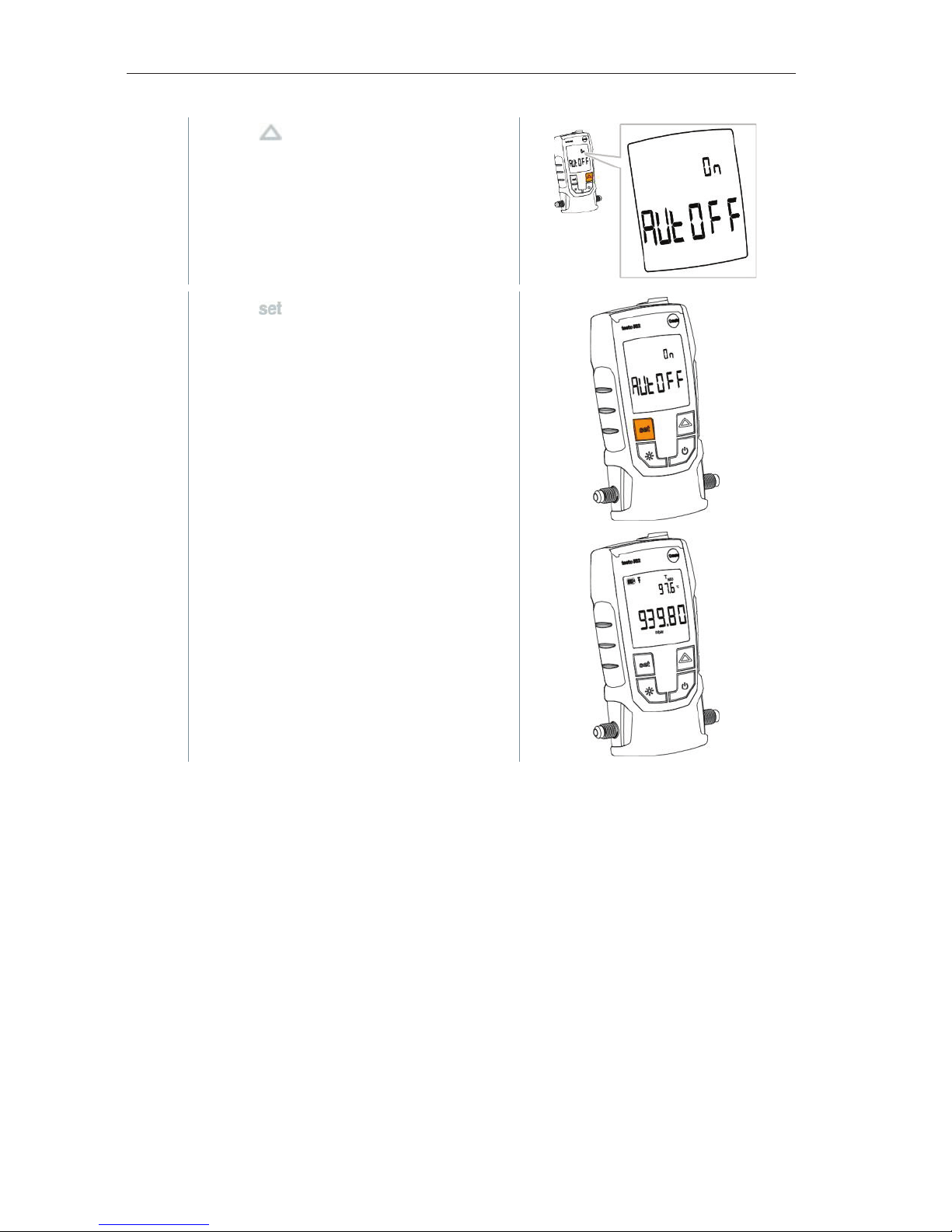

9

- Press to switch AutoOff on or off.

10

- Press .

ê

All settings are stored.

ê

The display changes to the measuring

mode.

ê

The instrument can now be used.

4Operation

14

4.5 Displaying temperature values

1

- Press to change the temperature

measurement parameter.

ê

The temperature measurement

parameter switches between TH2O,

in °F for °F.

4.6 Field calibration

- Field calibration should be carried out at <15 hPa, field calibration is

not possible at ambient pressure.

-

The connected vacuum pump should ideally be able to create a

minimum trace pressure of <0.1hPa.

- Field calibration tunes the Vac Checkerâto your vacuum pump.

1

- Connect the vacuum pump to a port of the Vac Checkerâ.

- Close the second port with the sealing cap

.

- Start the vacuum pump.

2

- Wait until minimum pressure is reached.

- Press

and at the same time for at least 3 seconds.

ê

The

Vac Checkerâis zeroed and field calibration is completed.

4Operation

15

4.7 Calibration with reference vacuum

gauge

- Calibration should be carried out at <15 hPa (<11250 microns),

calibration is not possible at ambient pressure.

- You need a reference vacuum gauge.

1

- Connect the vacuum pump to a port of the reference vacuum gauge

- Connect the

Vac Checkerâin parallel.

- Start the vacuum pump.

2

- Wait until minimum pressure is reached. (Duration approx. 2 min)

- Press

and at the same time for at least 3 seconds.

- Using the

key, input the reading from the reference vacuum gauge

(e.g. 150 microns/0.2 hPa).

- On the

Vac Checkerâpress and at the same ti

me for at least

3

seconds.

ê

The

Vac Checkerâis calibrated and calibration is completed.

5Maintenance

16

5 Maintenance

5.1 Changing batteries

1

- Switch the instrument off.

2

- Flip hook up.

3

- Open the battery compartment.

4

- Remove batteries.

5

- Insert new batteries, observing the

indications inside the battery

compartment.

6

- Close the battery compartment.

7

- Fold hook down.

5.2 Cleaning the instrument

ATTENTION

Agg

ressive cleaning agents or solvents.

Sensor may be damaged!

-

The sensor should not be cleaned.

ATTENTION

Aggressive cleaning agents or solvents.

The instrument may be damaged!

-

Only clean the instrument housing.

-

Use mild household cleaning agents or soapy water.

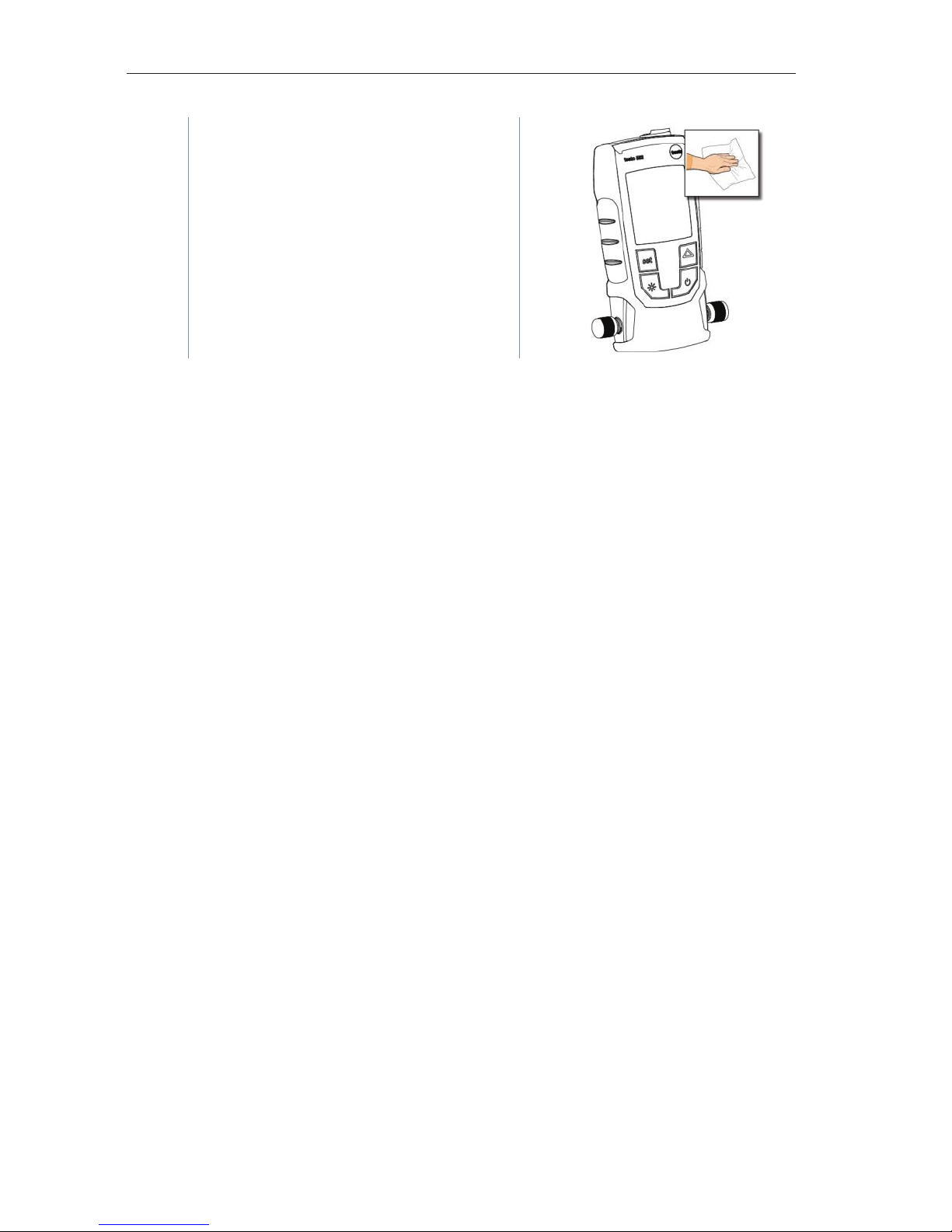

ü

- Close the connections using the sealing caps.

- Close the battery compartment lid.

5Maintenance

17

1

- Wipe the instrument housing with a

damp cloth. Use mild household

cleaning agents or soapy water for

this.

6Tips and assistance

18

6 Tips and assistance

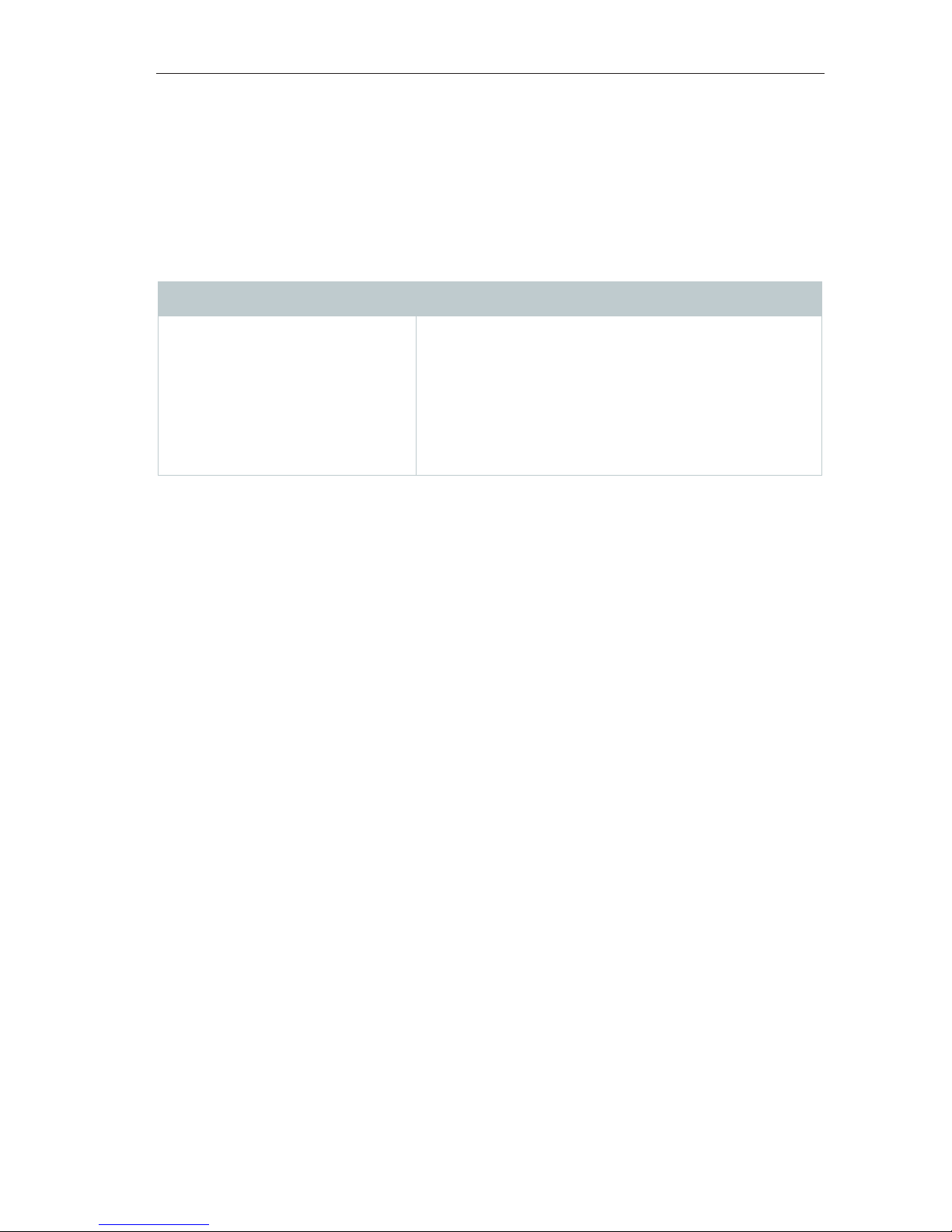

6.1 Questions and answers

Question

Possible cause / solution

Readings are incorrect.

- Check that the Vac Checkerâis connected

properly.

-

Connect the Vac Checkerâ

directly to the

vacuum pump in order to check the values.

-

Check that all hoses are leak-tight.

-

Carry out the field calibration of Vac

Checkerâ.

If we have not been able to answer your question, please contact your dealer or

DD-Compound at www.dd-compound.de

Table of contents